Method for recycling lithium iron phosphate in waste lithium ion batteries

A lithium-ion battery and lithium iron phosphate technology, which is applied in the field of waste power lithium-ion battery recycling and recycling, can solve problems such as increased costs and secondary pollution, and achieve the effects of reducing overall production costs, low cost, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 50 g of dried waste lithium iron phosphate power battery positive electrode material to 1.0 L of mixed acid solution of citric acid and oxalic acid (concentration 1.1 mol / L), then add 10.0 mL of 30 wt % hydrogen peroxide aqueous solution, and put it in a water bath Heat to near boiling, then cool down to 85°C and maintain the reaction for 150 minutes.

[0029] (2) After cooling down to room temperature, measure the ratio of lithium, iron and phosphorus in the solution, and add an appropriate amount of lithium dihydrogen phosphate to make the molar ratio of Li, Fe and P in the solution reach 1.05:1:1.05.

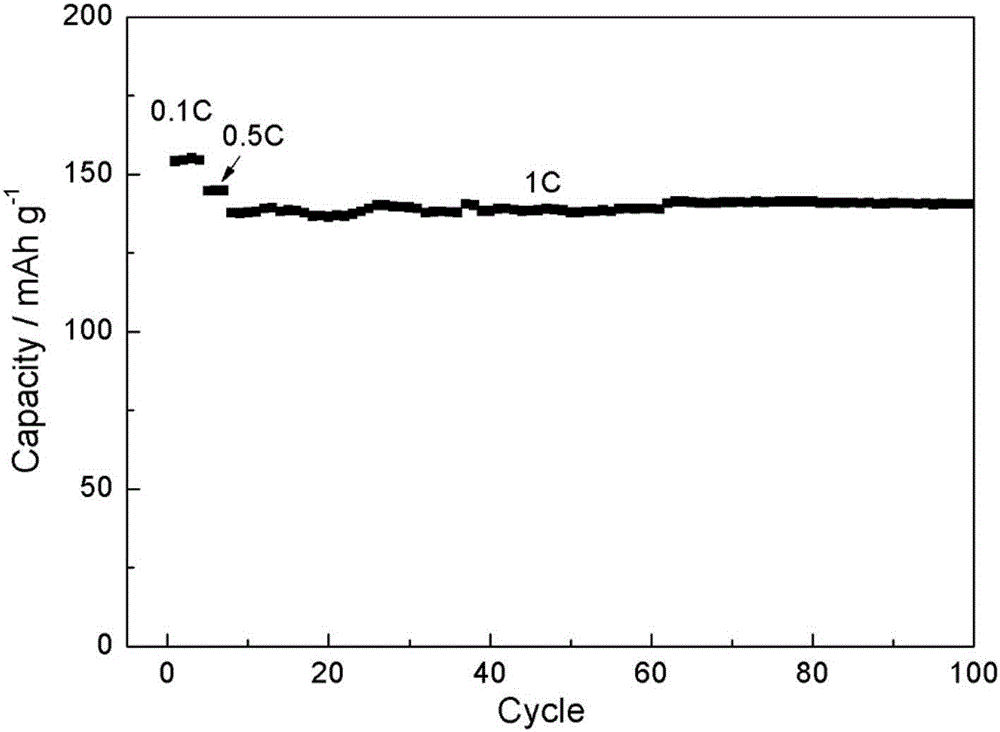

[0030] (3) A mixed solvent of ethanol and propanol (volume ratio to the mother liquor is 3:2) was added to the mother liquor to obtain a coarse precipitate of the lithium iron phosphate precursor. Disperse the coarse precipitate of lithium iron phosphate together with sucrose in ethanol (the amount of sucrose added is 7.5wt%, the solid-to-liquid ratio is 1:2), ...

Embodiment 2

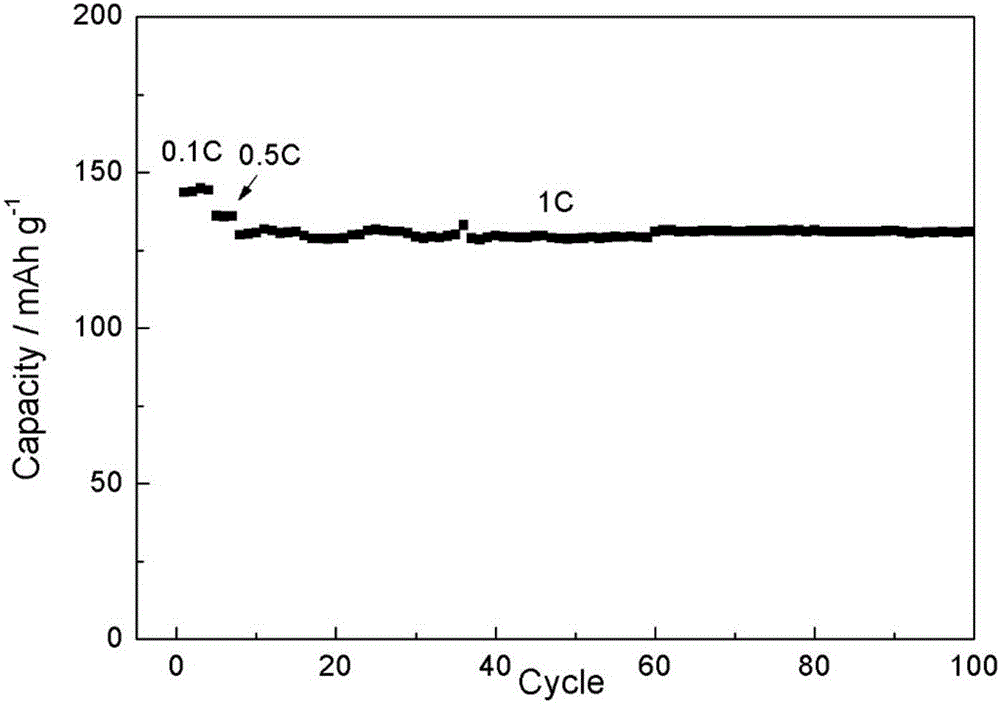

[0034] (1) Add 50 g of dry waste lithium iron phosphate power battery positive electrode material to 500 mL of mixed acid solution of citric acid and oxalic acid (concentration 1.1 mol / L), then add 5.0 mL of 30 wt % hydrogen peroxide aqueous solution, and heat in a water bath After boiling, the temperature was lowered to 85°C and the reaction was maintained for 15 minutes.

[0035] (2) Add ethanol to the mother liquor (the volume ratio of the mother liquor is 4:1) to obtain a coarse precipitate of the lithium iron phosphate precursor.

[0036] (3) Disperse the coarse precipitate of lithium iron phosphate together with sucrose in ethanol (5wt% sucrose addition, solid-to-liquid ratio 1:2), high-energy ball milling for 6 hours according to our company's electrode material production process, and the obtained slurry After filtering and drying to remove the solvent, it was calcined at 800° C. for 10 hours in a nitrogen:hydrogen (95:5) mixed atmosphere to obtain a regenerated lithiu...

Embodiment 3

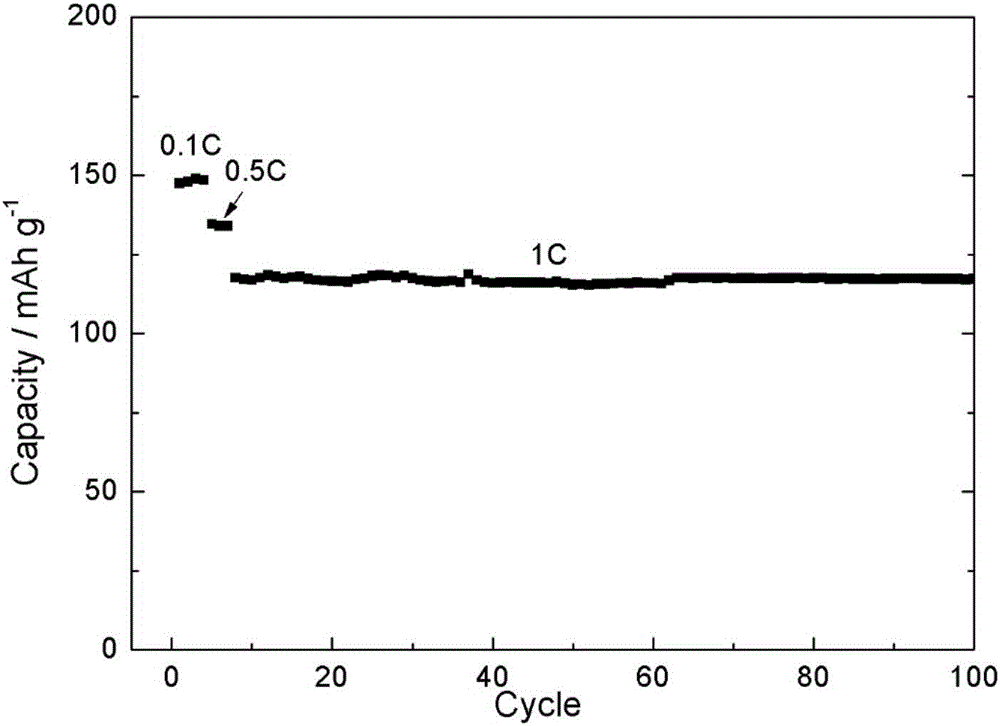

[0040] (1) Add 50 g of dry waste lithium iron phosphate power battery positive electrode material to 800 mL of mixed acid solution of citric acid and oxalic acid (concentration 1.2 mol / L), then add 5.0 mL of 30 wt % hydrogen peroxide aqueous solution, and heat in a water bath The reaction was maintained for 120 minutes until near boiling.

[0041] (2) After cooling down to room temperature, measure the ratio of lithium, iron and phosphorus in the solution, and add an appropriate amount of lithium dihydrogen phosphate to make the molar ratio of Li, Fe, and P in the solution reach 1.1:1:1. Ethanol was added to the mother liquor (the volume ratio to the mother liquor was 2:1) to obtain a rough precipitate of the lithium iron phosphate precursor.

[0042] (3) Disperse the coarse precipitate of lithium iron phosphate together with sucrose in ethanol (the addition of sucrose is 2 wt%, and the solid-to-liquid ratio is 1:2). The difference from Example 1 is that according to our comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com