Recovery method of positive active material in lithium ion battery waste material

A positive electrode active material and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of unsatisfactory capacity and low charge-discharge efficiency of lithium-ion secondary batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

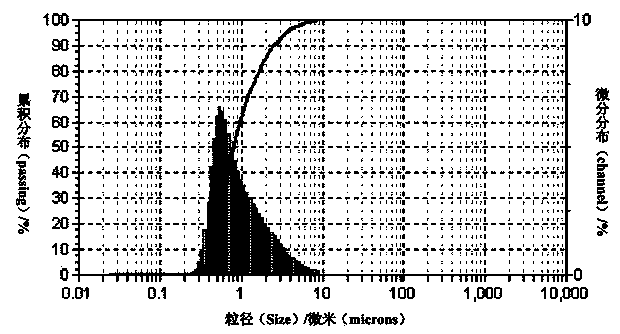

[0030] Take 200g of waste lithium iron phosphate positive electrode, put it into a material tray, put it into a high-temperature resistance furnace under an Ar gas atmosphere, heat-treat it at a furnace temperature of 450°C for 2 hours, then cool with the furnace, and sieve to obtain the detached active powder material, and then put the detached active powder material into the material tray, put it into a high-temperature resistance furnace under the protection of Ar gas atmosphere, and sinter at a high temperature of 725 °C for 4 hours, and then cool with the furnace at a cooling rate of 2.0 °C / min, the lithium iron phosphate cathode active material sample S1 was obtained after jet milling.

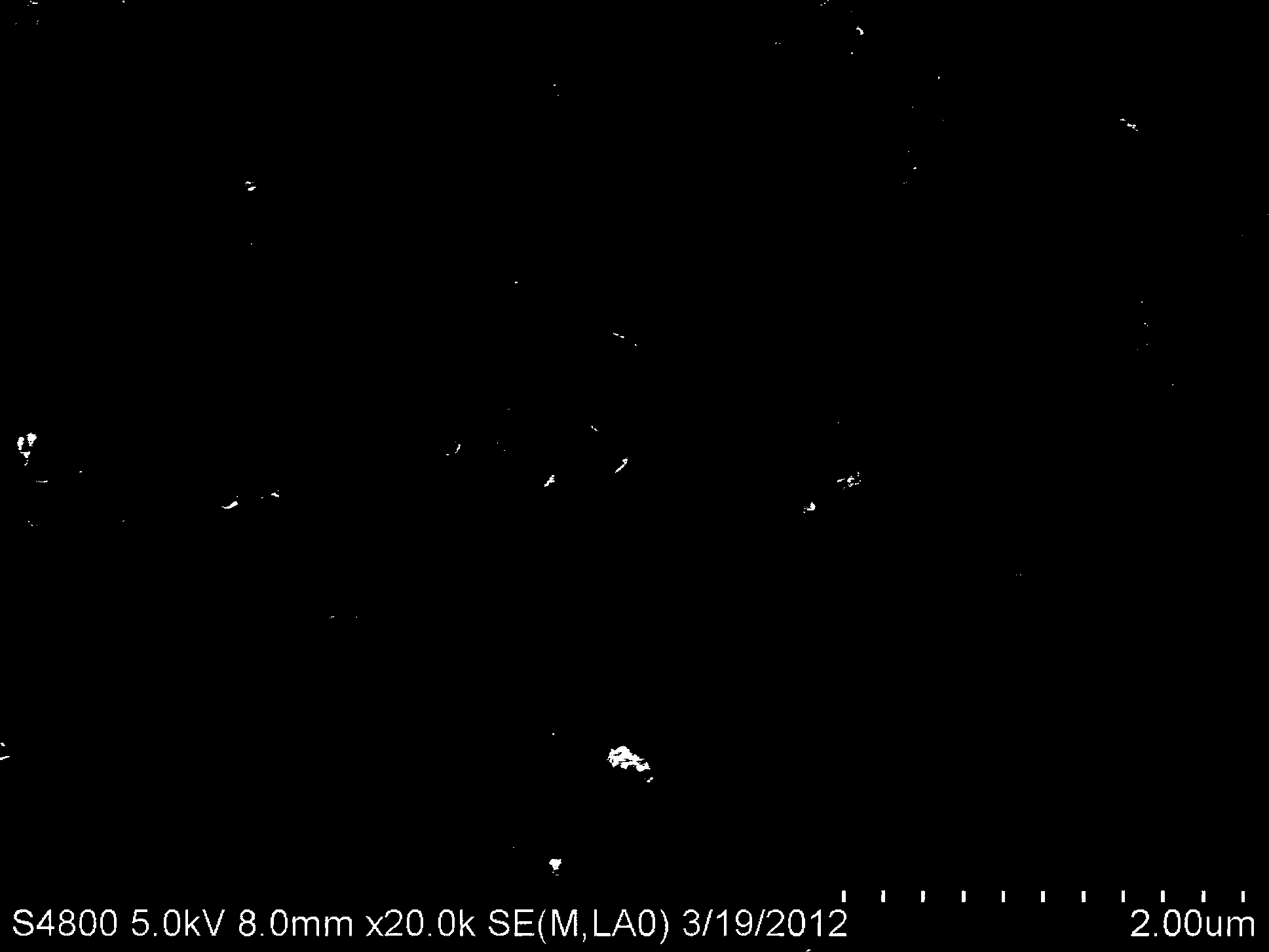

[0031] The sample S1 was tested by an X-ray diffractometer of the Rigaku D / MAX2200PC type in Japan, and the obtained diffraction pattern was as follows image 3 As shown, it can be seen from the figure that the diffraction peak is sharp, its peak intensity is 13750CPS, and its half-peak...

Embodiment 2

[0033] Get 200g of dried waste lithium iron phosphate positive slurry, put it into a tray, put it into N 2 In the high-temperature resistance furnace under the gas atmosphere, heat treatment at the furnace temperature of 400 ° C for 6 hours, then cool with the furnace, and then put it in the N 2 In a high-temperature resistance furnace under the protection of an air atmosphere, sinter at a furnace temperature of 700°C for 2 hours, then cool with the furnace at a cooling rate of 5°C / min, and ball mill to obtain a lithium iron phosphate cathode active material sample S2.

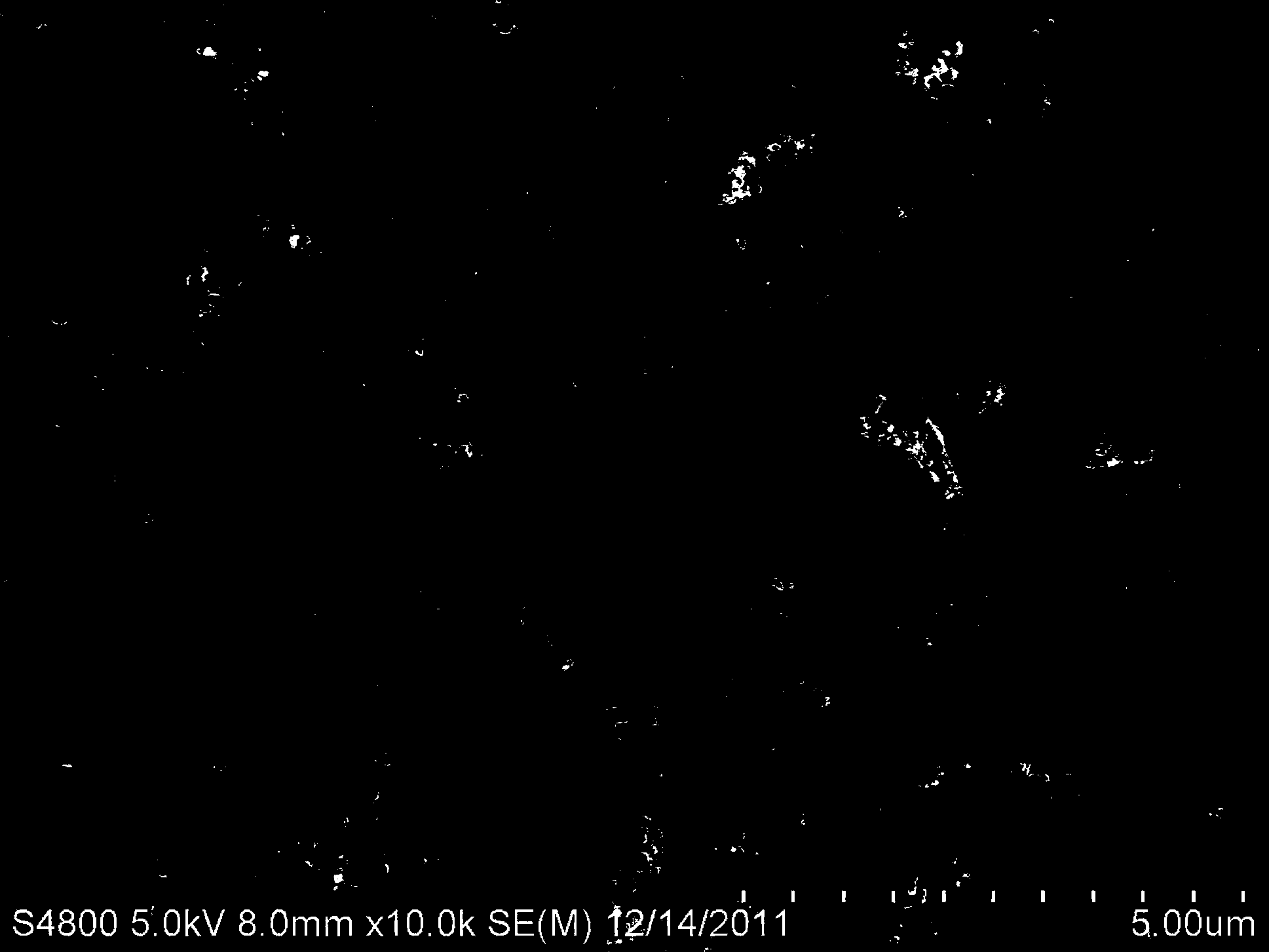

[0034] The obtained sample S2 is tested using the same X-ray diffractometer and scanning electron microscope used in Example 1 respectively, and the obtained XRD diffraction pattern is the same as image 3 Basically similar, the obtained scanning electron microscope picture is as figure 1 Basically similar. The diffraction peaks of the tested XRD diffraction pattern are all lithium iron phosphate diffraction...

Embodiment 3

[0036] Take 200g waste lithium iron phosphate positive electrode, put it into the material tray, put it into H 2 and N 2 Mixed gas (by volume ratio H 2 / N 2 =5:95) in the high-temperature resistance furnace under the atmosphere, heat treatment at the furnace temperature of 425°C for 4 hours, then cool with the furnace, sieve the detached active powder material, and then put the detached active powder material into the tray , and then placed in a high-temperature resistance furnace under the protection of Ar gas atmosphere, sintered at a furnace temperature of 750°C for 6 hours, and then cooled with the furnace at a cooling rate of 0.5°C / min. S3.

[0037] The obtained sample S3 is tested using the same X-ray diffractometer and scanning electron microscope used in Example 1 respectively, and the obtained XRD diffraction pattern is the same as image 3 Basically similar, the obtained scanning electron microscope picture is as figure 1 Basically similar. The diffraction peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com