Novel molecular sieve PVC composite stabilizing agent and its preparation method

A composite stabilizer and molecular sieve technology, applied in the field of new molecular sieve PVC composite stabilizer and its preparation, can solve the problems of poor coloring ability of composite lead salt stabilizer, poor compatibility of PVC base materials, and white spots in finished products, and achieve excellent results. Thermal stability, reducing dosage, improving thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Roast kaolin at 550-650°C for 2-3 hours;

[0028] (2) mixed with soda ash, so that the molar ratio of the components in the solution is controlled at n(H 2 O) / n(Na 2 O) / n(SiO 2 )=1:1.5:2.5, then aged at 60°C for 2h;

[0029] (3) Crystallization under hydrothermal conditions at 90°C for 4 hours;

[0030] (4) Finally, it is separated by filtration, washed with deionized water until neutral, and then dried to obtain the synthetic product.

[0031] The prepared calcium stearate, zinc stearate, lubricant, surface modifier and auxiliary heat stabilizer are mixed, and then compounded with molecular sieves. The specific mixing method is as follows:

[0032] First add 30 parts of calcium stearate and 25 parts of zinc stearate into the reaction kettle and mix well. Take the mixed material, add it into a kneader, heat and stir, add 15 parts of pentaerythritol ester, knead at 100-110°C for 20 minutes, then add 10 parts of polyethylene wax and 15 parts of epoxidized soybean...

Embodiment 2、3

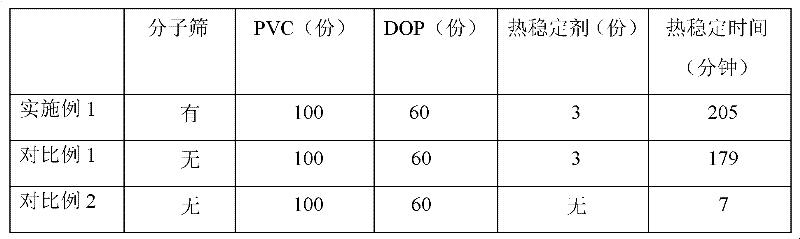

[0037] Add the above-mentioned molecular sieve stabilizer to 100 parts of PVC in the same amount, and then add 60 parts of diisooctyl phthalate (DOP), and then according to the national standard GB2113-82 "Plastic whiteness test method", the prepared three PVC plastics were tested for heat-resistant whiteness. It can be found from Table 3 that the prepared new molecular sieve PVC composite stabilizer has better thermal stability than the traditional stabilizer.

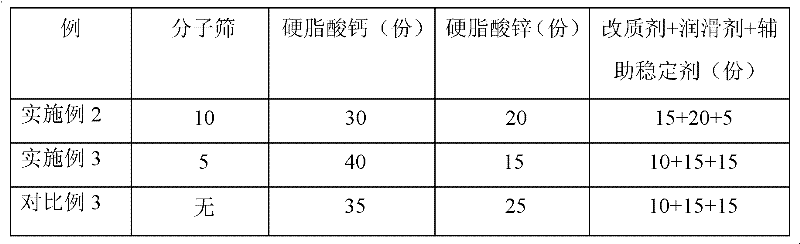

[0038] Table 2: Composite heat stabilizer composition formula

[0039]

[0040] Wherein: the lubricant is selected from polyethylene wax, monoglyceride or stearic acid; the surface modifier is selected from pentaerythritol ester or triphenyl phosphite; the auxiliary heat stabilizer is selected from epoxy soybean oil or dibenzoylmethane.

[0041] Table 3: The relative whiteness value (%) of the test piece tested in a whiteness meter tested with a standard whiteness board with a whiteness of 85%

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com