Method for preparing magnesium-aluminum-zinc hydrotalcite from aluminum-air battery electrolytic waste liquid, and application thereof

An aluminum-air battery, electrolytic waste liquid technology, applied in chemical instruments and methods, aluminum compounds, alkali metal compounds, etc., can solve the problems of difficult separation and recycling of alkaline substances, improve initial coloring, reduce production costs, Simple device operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

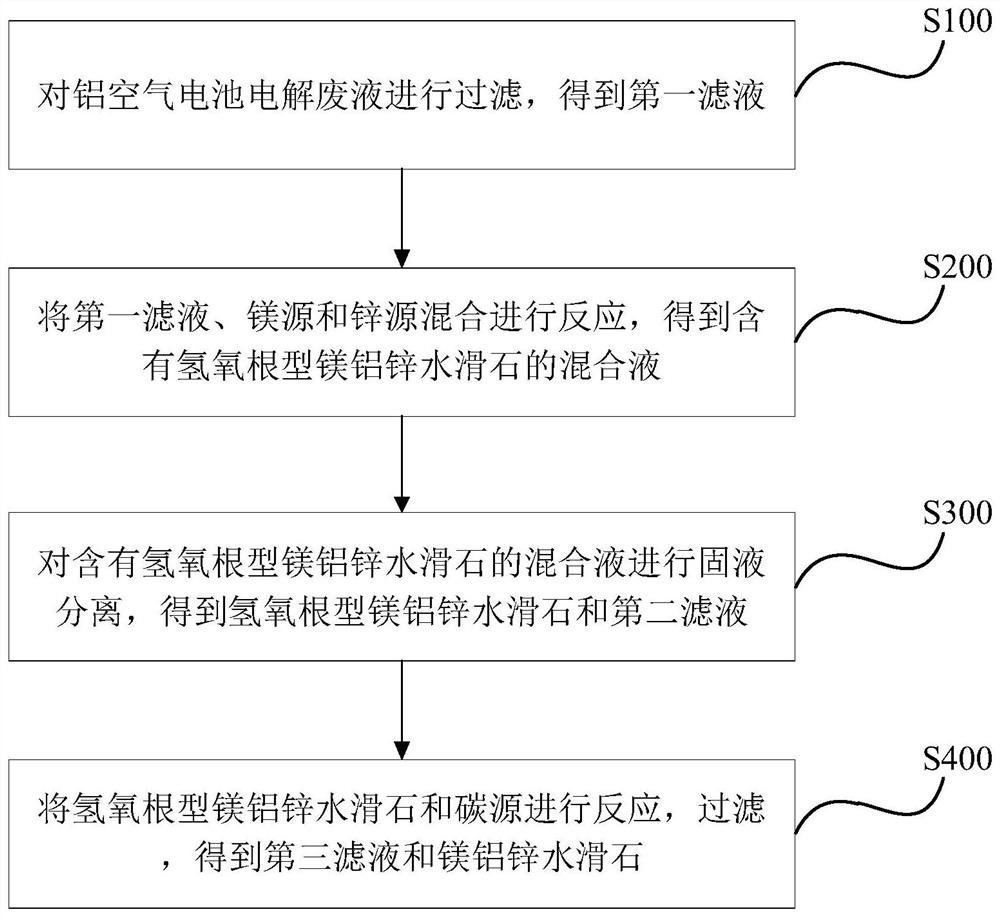

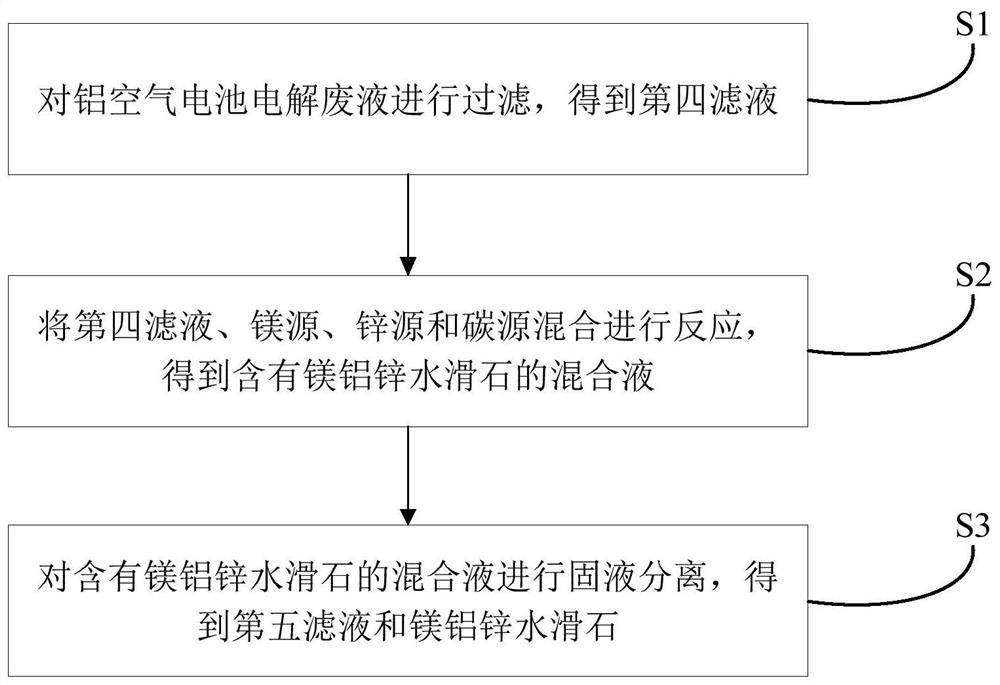

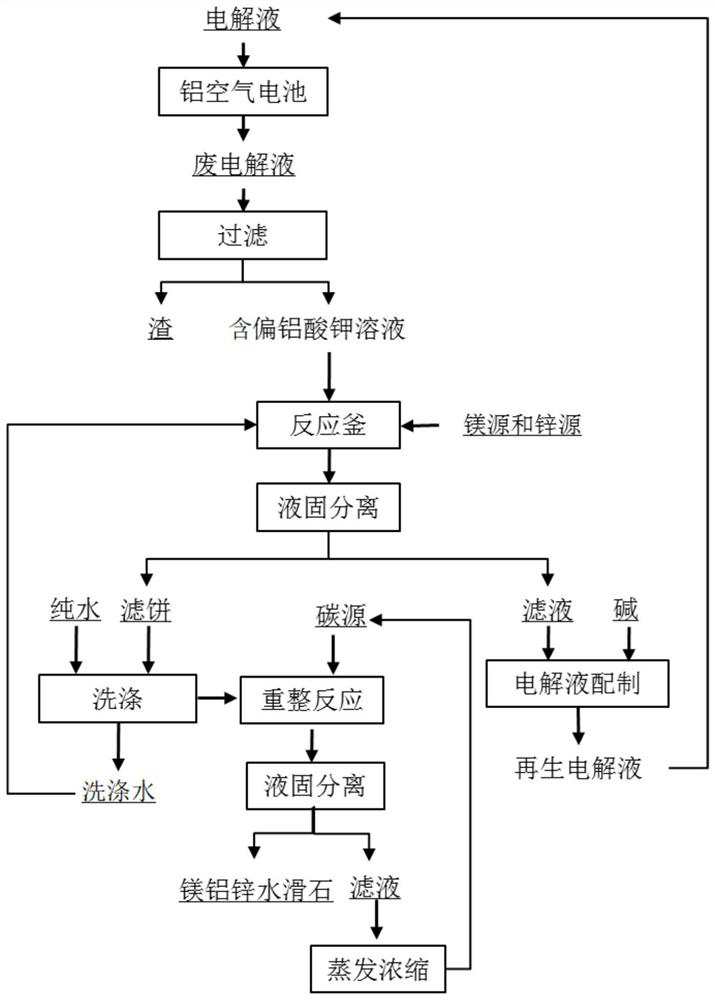

Method used

Image

Examples

Embodiment 1

[0068] Take the filtered filtrate of the waste electrolyte of the 100L aluminum-air battery after discharge and put it in a 300L reactor, in which the aluminum content is 102.5g / L, heat and stir, and when the solution temperature reaches 60°C, the molar ratio of aluminum, magnesium and zinc is 1:2.8: 0.2 Weigh 42.8kg of magnesium oxide and 6.2kg of zinc oxide respectively into the reaction kettle, heat and stir to make the reaction temperature reach 120°C, and after constant temperature hydrothermal reaction for 6 hours; use plate and frame filter press to filter the reactant under pressure, and the filtrate is regenerated alkali The concentration of the lye is 3.1mol / L, and then potassium hydroxide or sodium hydroxide is added to the regenerated lye to make the concentration of the lye reach 6mol / L. At an electrolyte temperature of 60°C, the anode is aluminum alloy, the cathode is an air electrode, and the current density is 160mA / cm 2 The discharge performance test of the al...

Embodiment 2

[0070] Take 100L aluminum-air battery discharge and the filtered aluminum content of the waste electrolyte is 102.5g / L filtrate, get 42.8kg magnesium nitrate and 6.2kg zinc nitrate and dissolve them in 300L deionized water, and dissolve 157.2kg potassium carbonate in deionized water. While stirring the three mixed solutions, drop them into the 500L reaction kettle. After the dropwise addition is completed, conduct hydrothermal reaction at a constant temperature of 90°C for 8 hours; filter with mechanical pressure, wash to pH=7, and dry at 80°C to obtain magnesium aluminum hydrotalcite.

[0071] Figure 5 The SEM spectrum of the magnesium-aluminum-zinc hydrotalcite was prepared for Example 1. It can be seen from the figure that the prepared magnesium-aluminum-zinc hydrotalcite has a uniform particle size and a good overall appearance; Figure 6 For the TG-DSC curve of the magnesium aluminum zinc hydrotalcite prepared in embodiment 1, from Figure 6 It can be seen from the TG ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com