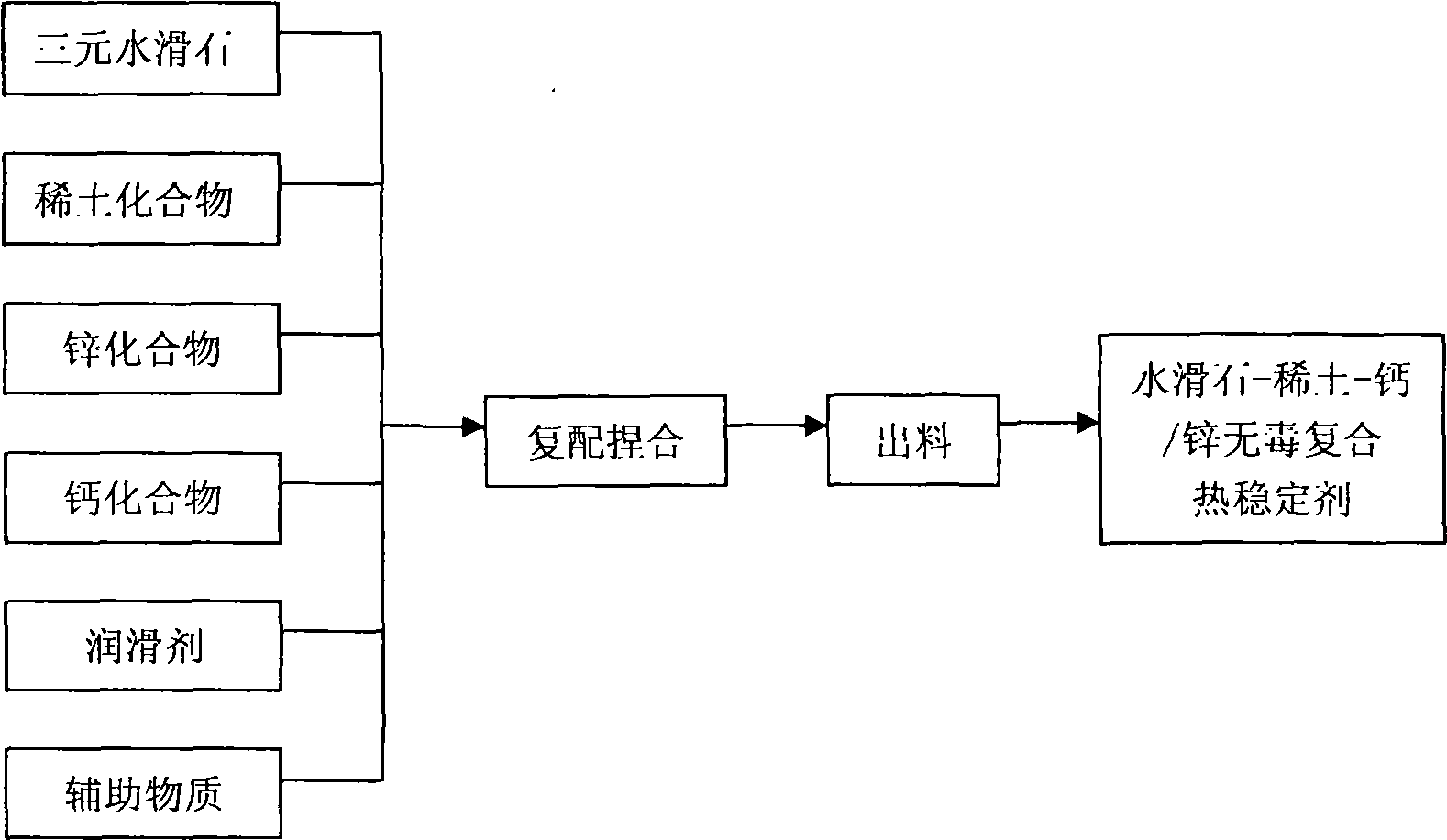

Ternary hydrotalcite-rare earth-calcium/zinc nontoxic composite heat stabilizer and preparation thereof

A composite heat stabilizer and hydrotalcite technology, which is applied in the field of plastic processing aids to achieve the effects of no vulcanization pollution, smooth appearance, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 38g MgCl respectively 2 (0.4mol), 13.36g (0.1mol) AlCl 3 and 17.74 g of ReCl 3 , after mixing, add deionized water to 500ml to prepare Mg 2+ / Al 3+ Mixed salt solution with a molar ratio of 3; weigh 42.4g Na 2 CO 3Add (0.4mol) 38.4gNaOH (0.96mol) to 500ml of deionized water, prepare a mixed lye and add it to the reaction kettle, add the prepared magnesium aluminum rare earth salt solution and stir quickly, control the temperature between 90°C and 100°C, and strongly Stir to keep the pH value at 9-11, continue to stir for 30 minutes after the addition is complete, then add stearic acid with a mass fraction of 3%, continue to stir and react for 1 hour, crystallize at 50°C for 8-12 hours, and dry to obtain Intercalation modified rare earth magnesium aluminum ternary hydrotalcite.

[0038] 25.6g of ternary hydrotalcite prepared by the above process, 10.2g of rare earth stearate, 16g of zinc acrylate, 20.2g of calcium stearate, 15g of lubricant, 4g of antioxidant...

Embodiment 2

[0040] Weigh 38g MgCl respectively 2 (0.4mol), 13.36g (0.1mol) AlCl 3 and 57.4 g of ZnSO 4 ·7H 2 O, add deionized water to 500ml after mixing to prepare Mg 2+ / Al 3+ Mixed salt solution with a molar ratio of 3; weigh 42.4g Na 2 CO 3 Add (0.4mol) 38.4gNaOH (0.96mol) to 500ml with deionized water, prepare mixed lye and add it to the reaction kettle, add the prepared magnesium-aluminum-zinc salt solution and stir quickly, control the temperature between 90°C and 100°C, and strongly Stir to keep the pH value at 9-11, continue to stir for 30 minutes after the addition is complete, then add stearic acid with a mass fraction of 4%, continue to stir and react for 1 hour, crystallize at 60°C for 8-12 hours, and dry to obtain Intercalation-modified magnesium-aluminum-zinc ternary hydrotalcite.

[0041] 24.6g of ternary hydrotalcite prepared by the above process, 8.1g of rare earth citrate, 26g of zinc stearate, 27.8g of calcium stearate, 90g of lubricant, 2.5g of antioxidant, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com