Composite heat stabilizer for PVC, preparation and application thereof

A composite heat stabilizer and preparation process technology, applied in the field of material science application technology development, can solve problems such as poor coloring, difficult control of zinc-magnesium-aluminum hydrotalcite preparation conditions, etc. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

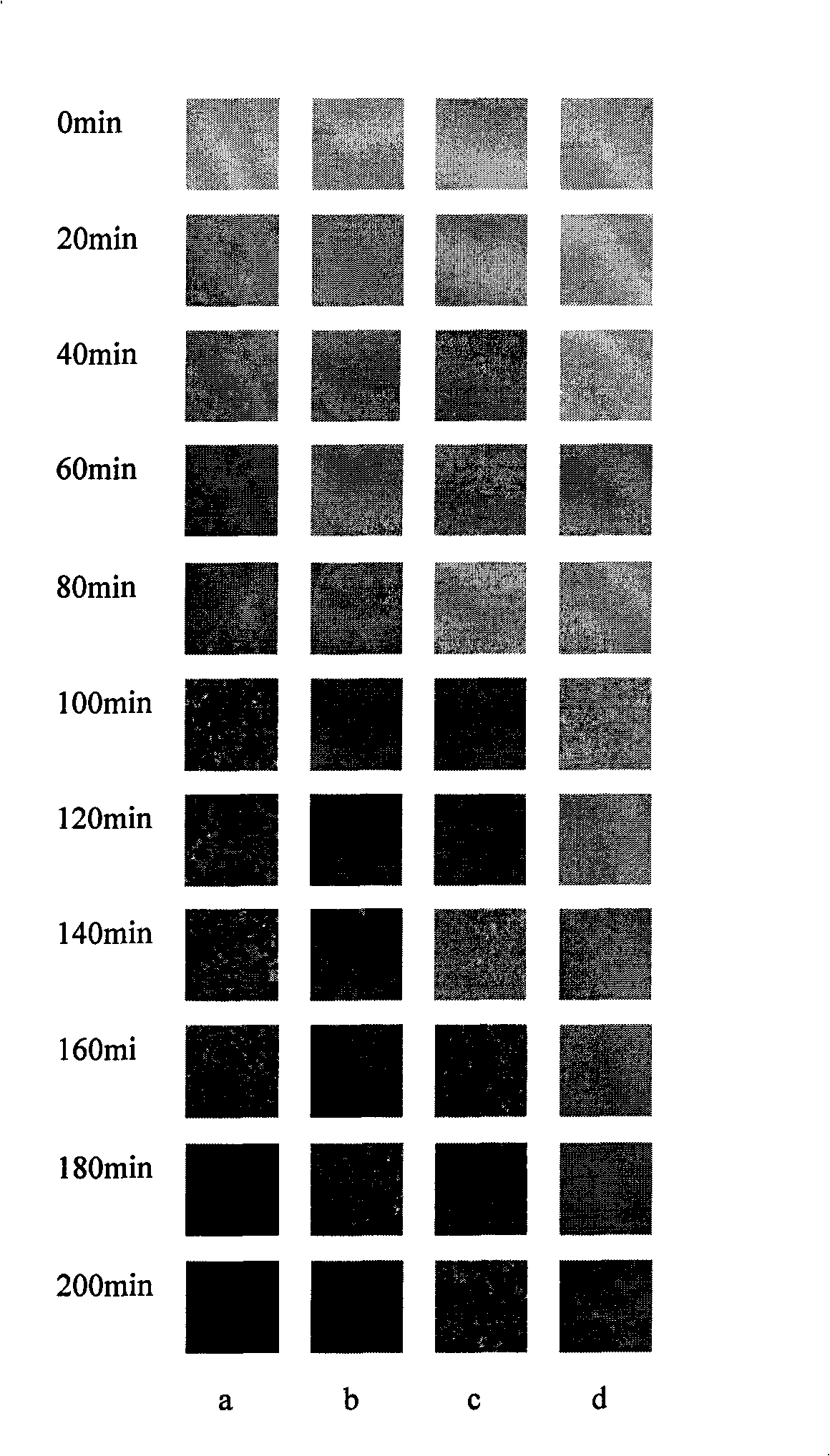

Image

Examples

Embodiment 1

[0036] Example 1: Preparation and modification of magnesium aluminum hydrotalcite with magnesium aluminum molar ratio of 2.0

[0037] Weigh 12.82gMg(NO 3 ) 2 ·6H 2 O(0.05moL) and 8.44gAl(NO 3 ) 3 9H 2 O (0.025moL), add deionized water after mixing to make Mg 2+ The concentration is 1.2mol / L; weigh 1.325gNa 2 CO 3 (0.0125moL) and 6.0gNaOH (0.15moL), after mixing, add deionized water to make CO 3 2- / OH - =0.08; add the above two solutions dropwise into 30mL deionized water, keep the pH value between 9 and 10, stir and react at 85°C, continue to stir for 2 hours after the dropwise addition, and then age at 65°C After 20 hours, filter and wash until pH = 7 to obtain a magnesium aluminum hydrotalcite filter cake.

[0038] Add water about 15 times the solid weight of the filter cake to the magnesium aluminum hydrotalcite filter cake, heat up to 80°C, add stearic acid accounting for 5% of the solid mass of the filter cake, stir for 2 hours, filter, and dry at 80°C , to o...

Embodiment 2

[0039] Example 2: According to the method of Example 1, magnesium aluminum hydrotalcite with a magnesium aluminum molar ratio of 3.0 was prepared.

Embodiment 3

[0040] Example 3: Preparation and modification of zinc-aluminum hydrotalcite with a zinc-aluminum molar ratio of 1.0

[0041] Mix 4.069g of zinc oxide with 4.099g of sodium aluminate aqueous solution, add 4.000g of NaOH and 2.650g of NaOH 2 CO 3 , the pH value was controlled at 11-12, reacted at 90°C for 3 hours with stirring, then reacted in an autoclave at 110°C for 12 hours, and aged at 80°C for 12 hours. Filter and wash to PH=7. Add about 15 times the water of the solid quality of the filter cake to the filter cake, raise the temperature to 80°C, add stearic acid accounting for 5% of the solid mass of the filter cake, stir for 2 hours, filter, and dry at 80°C to obtain the modified zinc-aluminum hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com