Novel preparation method of orotic acid hydrate zinc PVC stabilizer by heterogeneous system

A technology of zinc uracil carboxylate and heterogeneous phase is applied in the preparation of zinc uracil carboxylate in a heterogeneous system in the field of thermal stability of PVC, and achieves the effects of reducing initial coloration, readily available raw materials, and simplifying process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

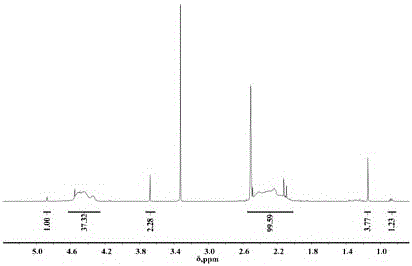

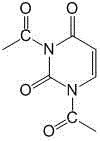

Image

Examples

Embodiment 1

[0027] 100 parts of PVC, 50 parts of dioctyl phthalate, 30 parts of calcium carbonate, 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite and 2 parts of calcium stearate, 2 parts The dry mixture composed of zinc uracil carboxylate was rolled on an open mill at 180°C for 5 minutes. Press the tablet, take the piece and cut it into a 2cm×2cm small square sample. According to the requirements of the GB / T 7141-92 standard, put the PVC sheet into groups in order and place them in an aging oven. The oven aging test is carried out at 190±1°C. Take out the test piece every 10 minutes, observe and record the change of chromaticity of the test piece, and record its yellowness index according to ASTM D1925-70, and the results are shown in Table 1.

Embodiment 2

[0029] 100 parts of PVC, 50 parts of dioctyl phthalate, 30 parts of calcium carbonate, 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite and 2 parts of calcium stearate, 2 parts A dry mixture consisting of zinc uracil carboxylate and 0.2 parts of dibenzoylmethane was rolled on an open mill at 180°C for 5 minutes. Press the tablet, take the piece and cut it into a 2cm×2cm small square sample. According to the requirements of the GB / T 7141-92 standard, put the PVC sheet into groups in order and place them in an aging oven. The oven aging test is carried out at 190±1°C. Take out the test piece every 10 minutes, observe and record the change of the chromaticity of the test piece, and continue until the test piece appears black. According to ASTM D1925-70, record its yellowness index. The results are shown in Table 1.

Embodiment 3

[0031] 100 parts of PVC, 50 parts of dioctyl phthalate, 30 parts of calcium carbonate, 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite and 2 parts of calcium stearate, 2 parts A dry mixture composed of zinc uracil carboxylate and 0.2 parts of 1,3-dimethyl-6-aminopyrimidine was rolled on an open mill at 180°C for 5 minutes. Press the tablet, take the piece and cut it into a 2cm×2cm small square sample. According to the requirements of the GB / T 7141-92 standard, put the PVC sheet into groups in order and place them in an aging oven. The oven aging test is carried out at 190±1°C. Take out the test piece every 10 minutes, observe and record the change of the chromaticity of the test piece, and continue until the test piece appears black. According to ASTM D1925-70, record its yellowness index. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com