Elastomer cable material for oil-resistant cold-resistant high-temperature-resistant electric automobile charge piles and preparation method thereof

An electric vehicle and elastomer technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of oil resistance, high temperature resistance, cold resistance and low smoke resistance, and achieve good crystallization performance, excellent low temperature resistance Excellent high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

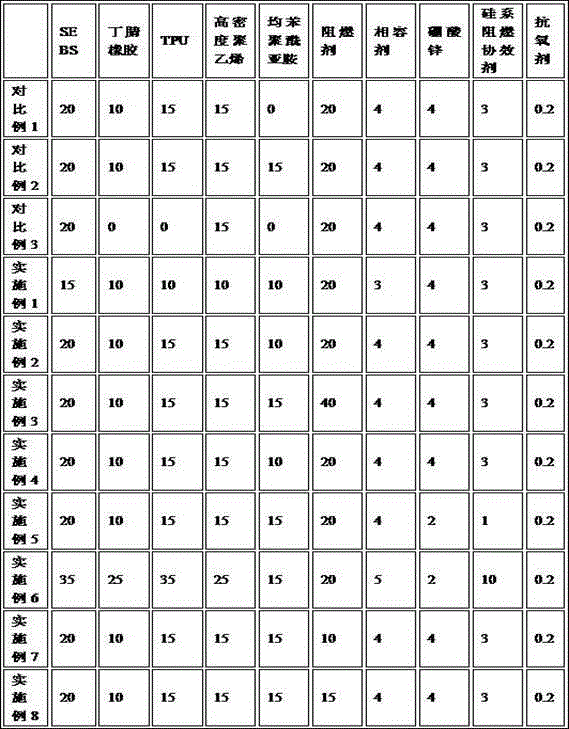

Embodiment 1 to Embodiment 8

[0040] Example 1 to Example 8: An oil-resistant, cold-resistant, and high-temperature-resistant elastomer cable material for electric vehicle charging piles and its preparation method

[0041] Preparation method: comprising the following steps:

[0042] In the first step, the materials are weighed according to the parts by weight of each material in the raw material formula;

[0043] In the second step, add the styrene-based elastomer, thermoplastic polyurethane elastomer rubber, nitrile rubber, reinforcing agent, polyolefin compound, compatibilizer, flame retardant, flame retardant synergist, inhibitor Smoke agent, stir at a speed of 1000~1500 rpm for 8~10 minutes and then stop stirring;

[0044] In the third step, put the mixed material obtained in the second step into a twin-screw extruder for melt kneading and extruding, the extrusion temperature is 190~240°C, the screw speed is 200~500rpm; The molten output extruded from the die head is water-cooled, and the packaging i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com