Rapeseed drying and impurity removal device

A technology for rapeseed and drying barrel, which is applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problem of insufficient drying of rapeseed, and achieve increased labor intensity, improved fatigue resistance, and improved drying. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is further described in detail through specific implementation methods:

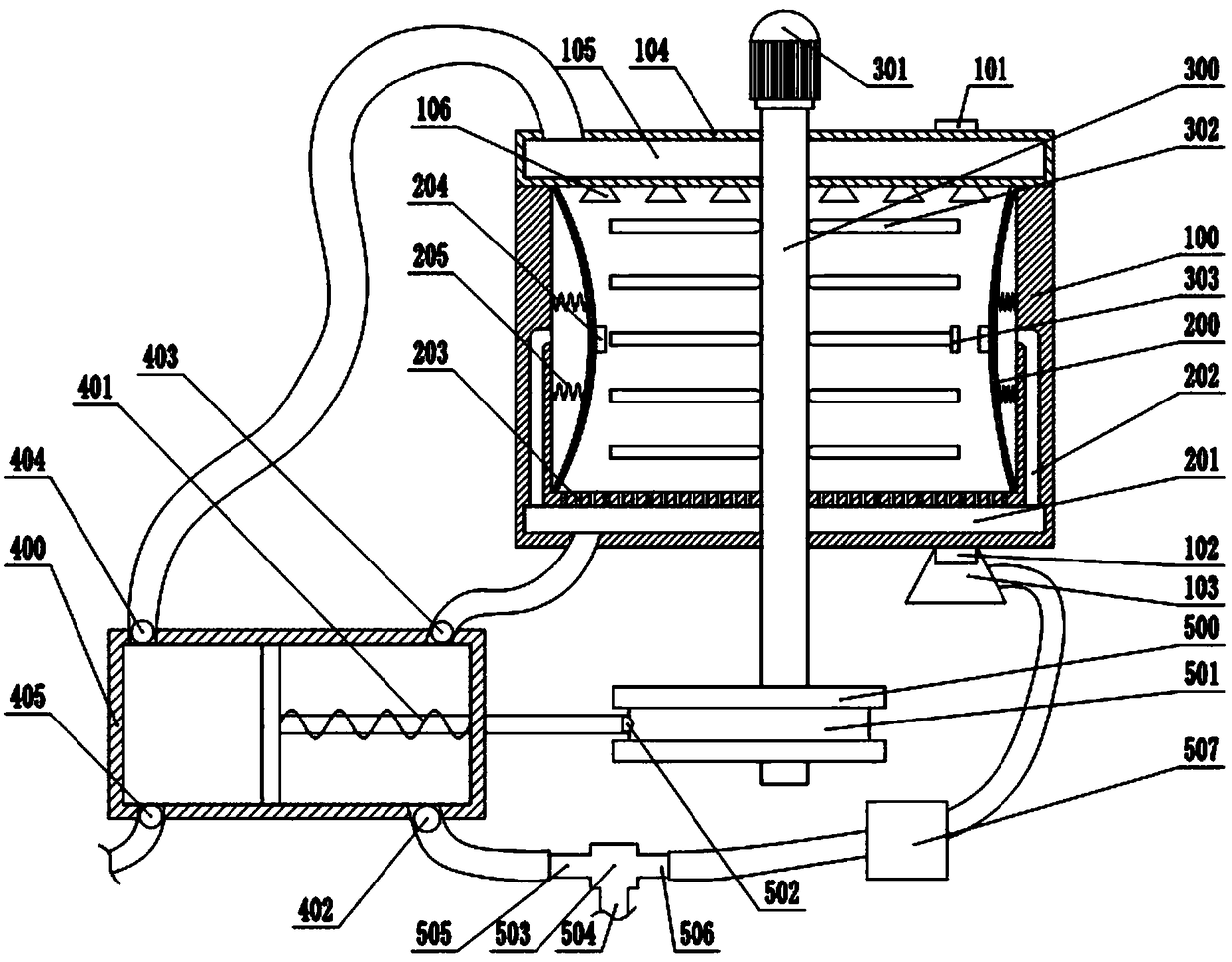

[0031] The reference signs in the drawings of the description include: drying barrel 100, feed valve 101, discharge valve 102, discharge hopper 103, bucket cover 104, dust collection chamber 105, dust suction hood 106, air bag 200, drying chamber 201 , heat pipe 202, air outlet 203, positioning block 204, first spring 205, vertical shaft 300, motor 301, stirring rod 302, magnetic block 303, cylinder 400, second spring 401, air intake check valve 402, air outlet Check valve 403, feed check valve 404, discharge check valve 405, cam 500, positioning groove 501, ball 502, vortex tube 503, air inlet 504, hot air end 505, cold air end 506, gas collection box 507 .

[0032] The embodiment is basically as figure 1 Shown:

[0033] A rapeseed drying and impurity removal device, the device includes a frame and a drying barrel 100 fixed on the frame, wherein a barrel cover 104 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com