Method for manufacturing bricks by mixing domestic mud and bottom mud of rivers and lakes

A domestic sludge and mixing technology, which is applied in the direction of mixing operation control, chemical instruments and methods, mixing operation control devices, etc., can solve problems such as incompleteness, and achieve the effect of saving terrestrial land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

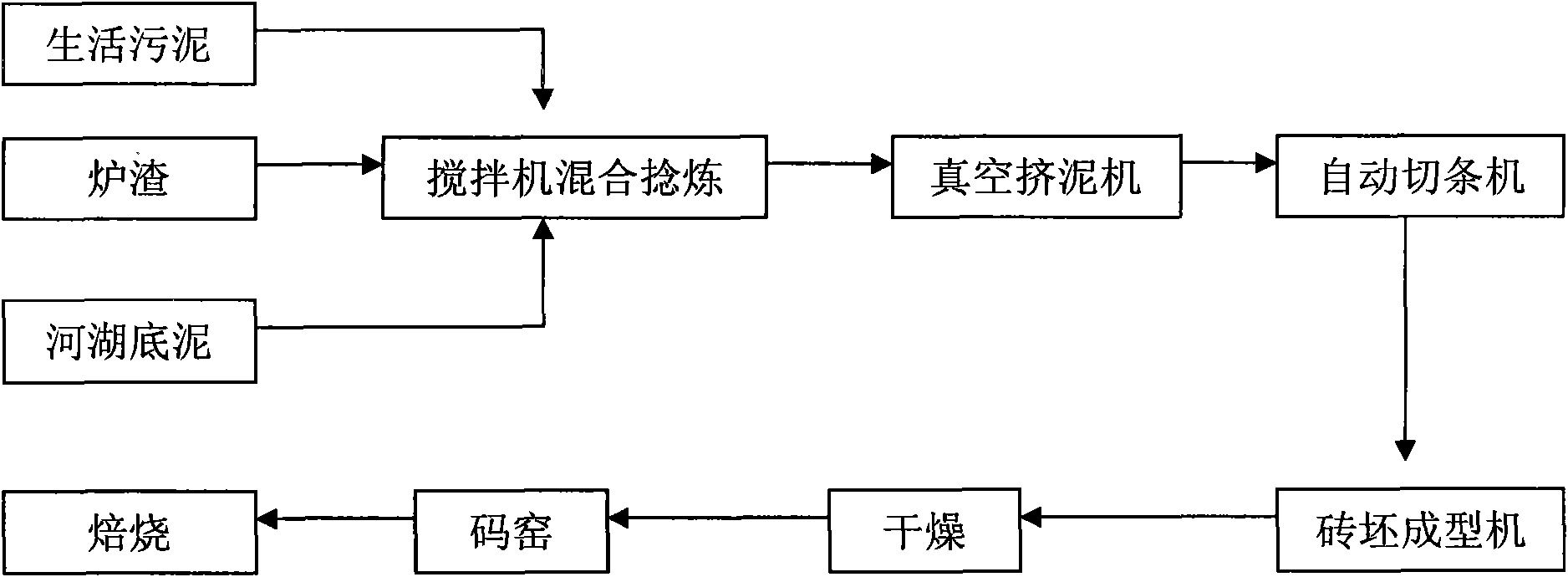

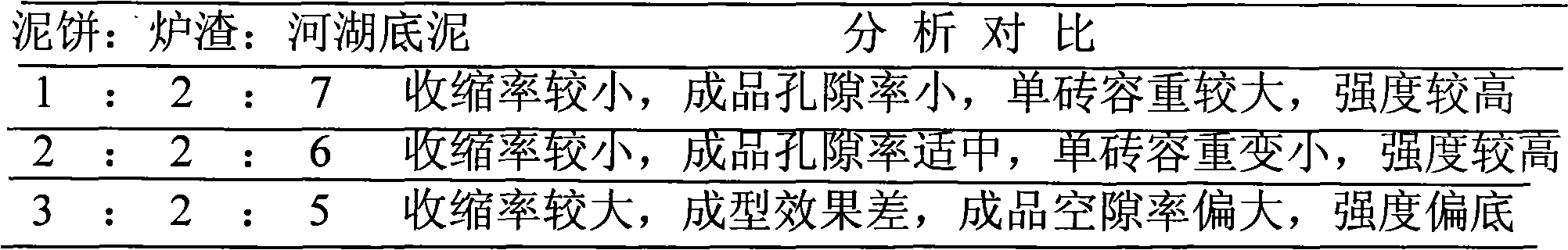

[0021] The method for making bricks by mixing domestic sludge and river and lake bottom mud comprises the following steps:

[0022] a. Disposal of domestic sludge: The liquid sludge in the sewage treatment plant is made into a mud cake through traditional flocculation dehydration and pressure filtration (that is, the liquid sludge is first flocculated with a cationic flocculant, the supernatant flows out, and the flocculated sludge is passed through After vacuum suction filtration, it is sent to a filter press device by a conveyor belt for mechanical pressure filtration, and at this time a mud cake with a moisture content of about 80% is obtained); then squeezed by a twisted cage filter press to obtain a mud cake with a mud content of about 60%. sludge cake.

[0023] b. Treatment and disposal of river and lake bottom mud: using the mud-water separation process of river and lake bottom mud, the muddy water with a mud content of 10-15% in rivers and lakes is transported to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com