High-efficiency energy-saving grain drying machine and drying method

A grain dryer, high-efficiency and energy-saving technology, applied in dryers, drying, food processing and other directions, can solve the problems of uncontrollable temperature, high drying cost, high heating temperature of electric heating wire, and achieve uniformity, Ensure consistent quality and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

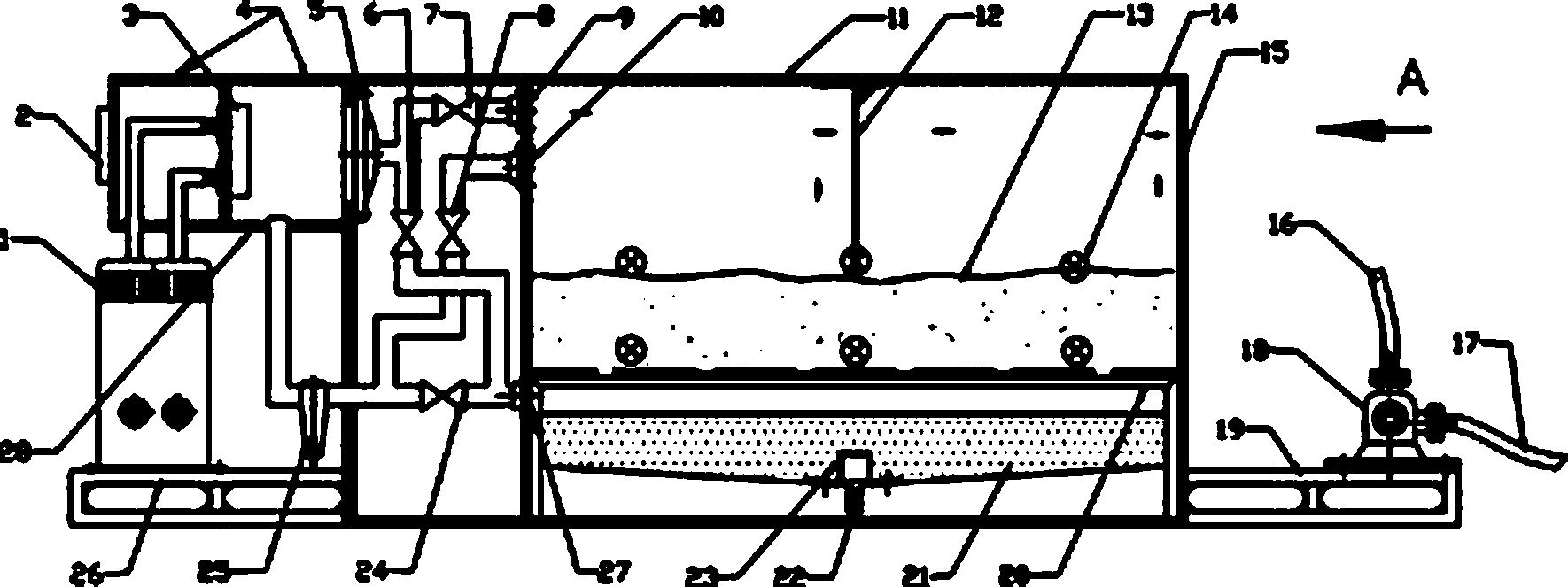

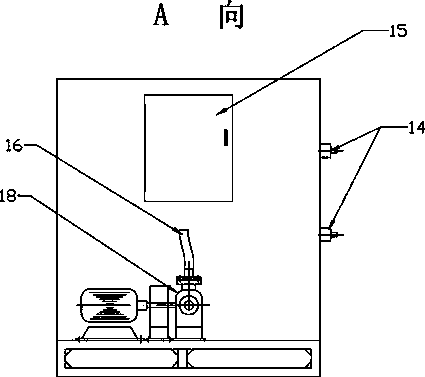

[0070] The high-efficiency and energy-saving grain dryer and drying method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0071] Figure 1~Figure 2 The high-efficiency and energy-saving grain dryer and drying method of the present invention are shown. The dryer adopts a brand-new heat source design provided by an air energy heat pump, which includes an air energy dehumidification heat pump 1, a main room composed of a drying room and an air supply room. Body 11, auxiliary room body 28, heat exchanger 3, fan 5 installed in the air supply chamber, intelligent controller 2 installed on the room body, solenoid valve, temperature and humidity sensor 14, located in The pile bed 20 in the drying room, the dehumidification mechanism below the pile bed and the warehouse door 15 located at the side end of the main room body; The holes are connected, a spring supplementary air door 4 is install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com