Centralized drying system of high-humidity grain and drying method thereof

A drying system and grain technology, which is applied in the fields of seed preservation through drying, food processing, climate change adaptation, etc., can solve the problems of lack of high humidity, high drying energy consumption, and low drying efficiency, and achieve obvious drying and energy saving effects , Improve drying efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Principle of the invention

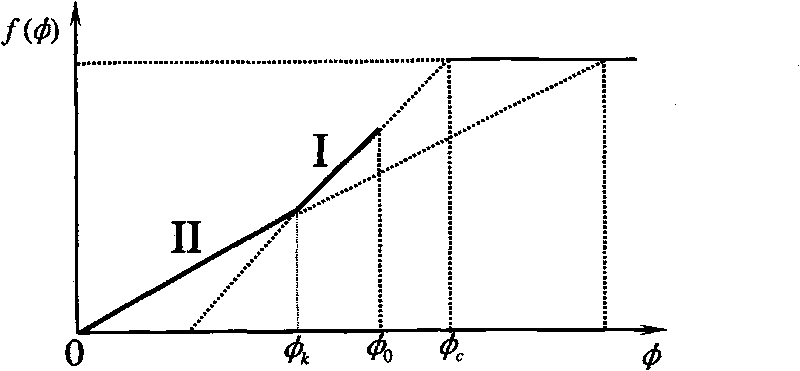

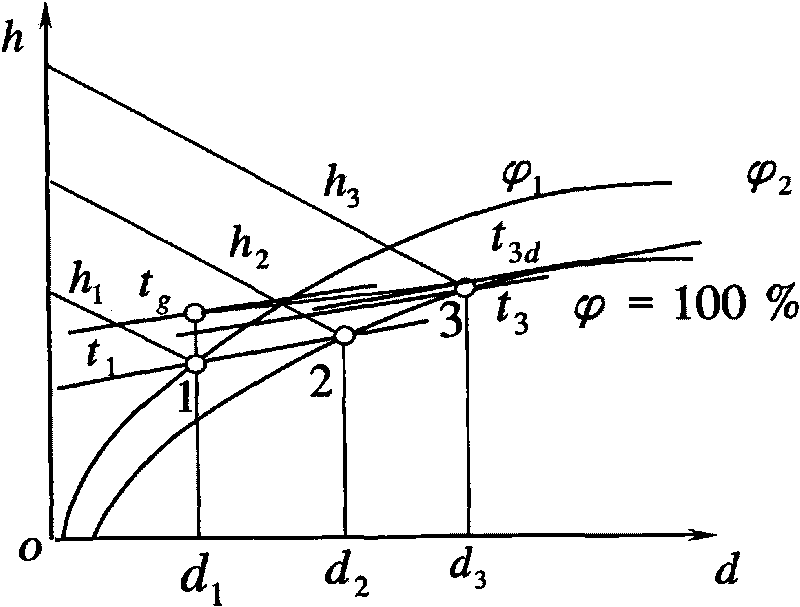

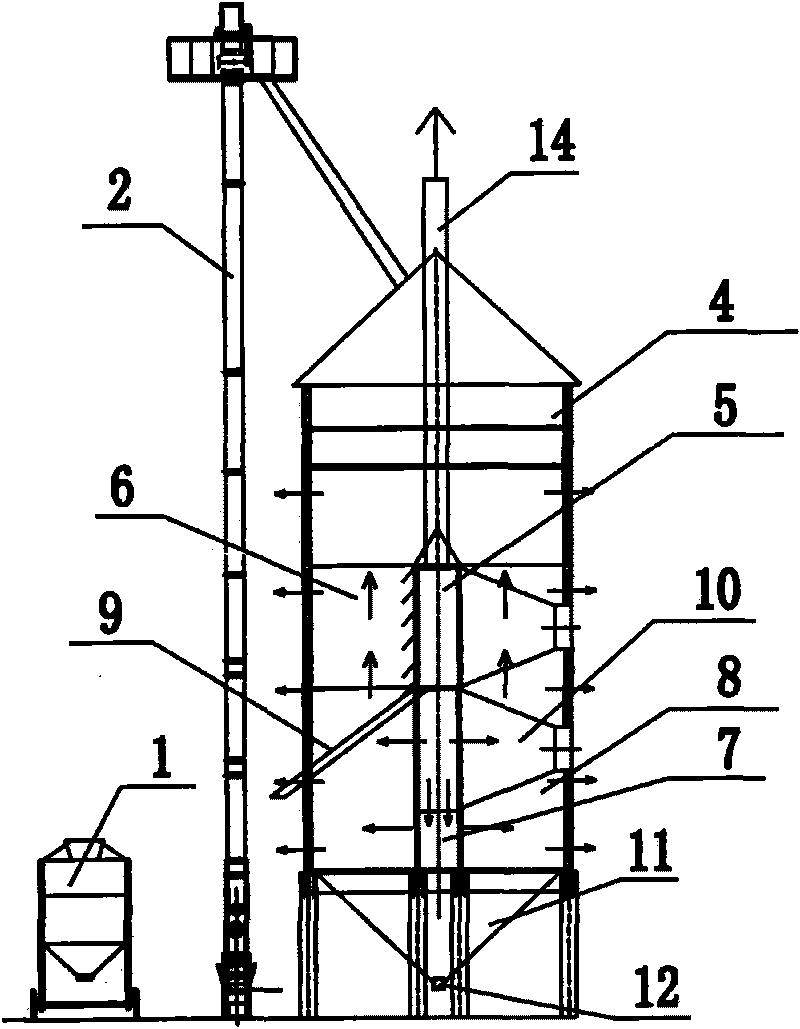

[0031] Principle of the present invention is shown in Fig. 1, Fig. 2. Figure 1 represents the drying process of high-humidity grain above the maximum moisture absorption moisture content and the second-stage deceleration. The ordinate is the maximum drying rate ratio f(φ), and the abscissa is the free moisture ratio φ. φ = M - M e M 0 - M e , In the formula, the moisture content of M-grain%, M 0 - Moisture content % of the grain at the initial stage of drying, M e - Equilibrium moisture content of the grain in %. When the moisture content of the grain is at the first drying rate reduction stage and above, there is free water on the surface, and the drying rate is relatively high. Since the evaporatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com