Water-based primer for railroad bridge and preparation method thereof

A primer, water-based technology, applied in the field of paint, can solve problems such as damage to the environment, harm, consumption of manpower, material resources, etc., to achieve the effect of strong anti-corrosion ability, excellent salt water resistance, and fast drying speed

Inactive Publication Date: 2015-04-01

成都拜迪新材料有限公司

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] As people's awareness of environmental protection is increasing, the requirements for environmental protection of coating products are also getting stronger and stronger. Now 80% of the steel structure manufacturers in the market still use traditional oil-based anti-rust paint, and invest

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

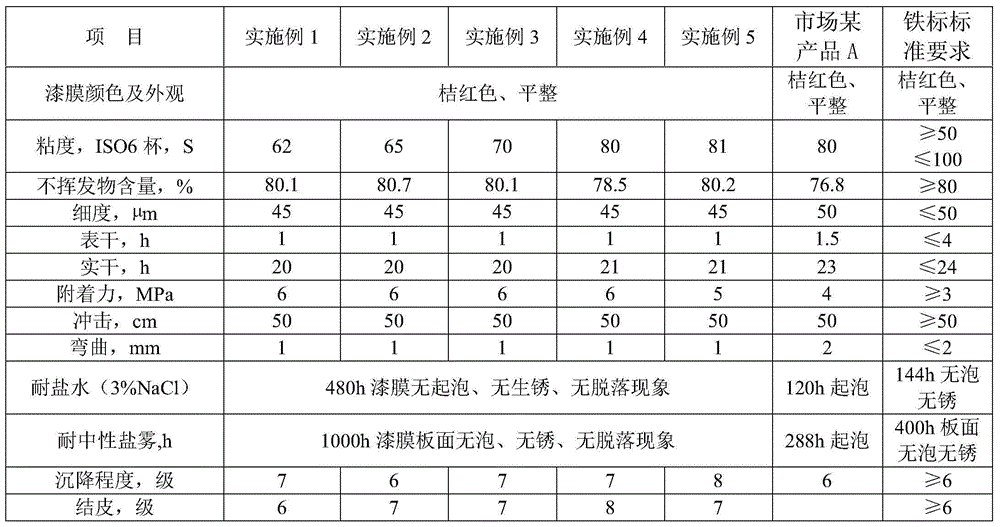

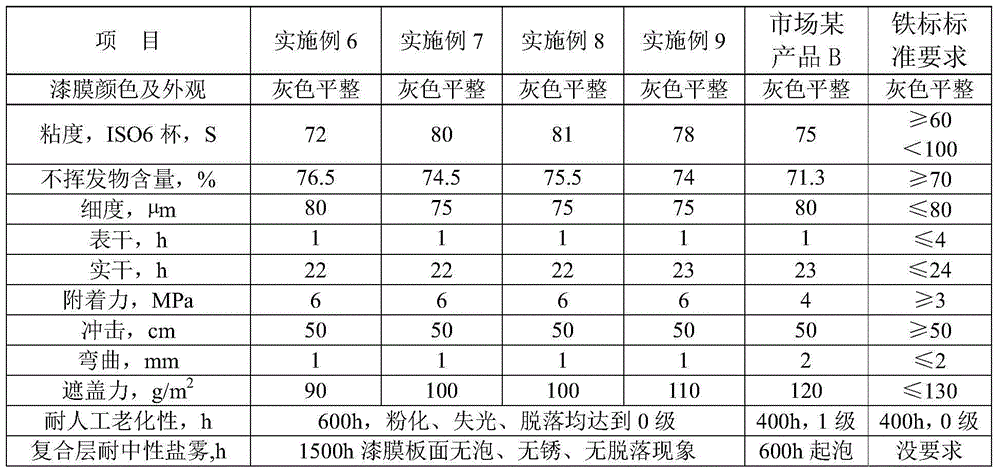

The invention provides a water-based primer for a railroad bridge. The water-based primer comprises water-based red lead alkyd antirust primer and water-based ash cloud iron alkyd finishing coat, wherein the water-based red lead alkyd antirust primer comprises the following components in percentage by weight: 25%-30% of water-based alkyd resin, 35%-43% of national standard red lead powder, 5%-6% of environment-friendly zinc phosphate, 5%-8% of super zinc phosphate, 5%-8% of precipitated barium sulfate, 0.2%-0.3% of water-based dispersing agent, 0.1%-0.2% of water-based defoaming agents, 0.1%-0.2% of water-based foam inhibitors, 1%-2% of hydrated magnesium silicate, 0.5%-1% of water-based composite drying agents, 0.2%-0.4% of water-based anti-skinning agents, 0.5%-1% of water-based thickening agents, 0.5%-1% of neutralizing agents, 0.5%-1% of flash-rust inhibitors, 1%-2% of film-forming auxiliary agents, 0.1%-0.2% of water-based wetting agents and 7.0%-9.0% of deionized water. The product provided by the invention has the advantages of fastness in drying, high corrosion-resistant capacity and salt-fog resistant property, can achieve no blistering or rusting on a surface for more than 1000 h, is very excellent in salt-water resistant property and generates no phenomenon of blistering and rusting after being soaked into a 3% sodium chloride solution for 480 hours.

Description

technical field [0001] The invention relates to the field of paint making, in particular to a water-based primer for railway bridges and a preparation method thereof. Background technique [0002] As people's awareness of environmental protection is increasing, the requirements for environmental protection of coating products are also getting stronger and stronger. Now 80% of the steel structure manufacturers in the market still use traditional oil-based anti-rust paint, and invest in expensive shot blasting. The equipment is shot blasted to achieve anti-rust ability, but now this operation method is very harmful to the environment and personnel, consumes a lot of manpower and material resources, and greatly damages the environment to achieve the purpose of product coating . [0003] Under the pressure of smog, the National People's Congress revised the Environmental Protection Law for the first time in 25 years. The revision of the "Environmental Protection Law" was passed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D167/08C09D7/12C09D5/08

CPCC08K3/08C08K3/30C08K3/32C08K3/34C08K2003/0806C08K2003/0812C08K2003/3045C08K2003/328C09D5/103C09D167/08C09D7/61

Inventor 任明华江拥孙迎春

Owner 成都拜迪新材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com