Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

707 results about "Ferric Oxide Red" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferric oxide red (Fe2O3), also known as iron (III) oxide, is a coloring agent for tablets and capsules and is used in the pharmaceutical industry. Ferric oxide red occurs naturally as hematite ore and rust.

Drag-reducing abrasion-resisting solventless coating for pipeline as well as preparation method and application thereof

ActiveCN101974282AStrong adhesionGood flexibilityAnti-corrosive paintsPipe protection against damage/wearEpoxySolvent free

The invention relates to a drag-reducing abrasion-resisting solventless coating for a pipeline as well as a preparation method and application thereof. The drag-reducing abrasion-resisting solventless coating contains an A component and a B component, wherein the mass percentage of raw materials is as follows: the A component includes the following materials in percentage by weight: 30%-40% of epoxy resin, 5%-10% of toughening resin, 4%-8% of active diluents, 4%-8% of zinc phosphate, 0.2%-0.5% of levelling agents, 0.2%-0.5% of defoaming agents, 0.4%-0.8% of dispersing agents, 0.2%-1.0% of anti-settling thickening agents, 8%-20% of ferric oxide red powder, 5%-15% of aluminium triphosphate and 5%-15% of white pottery magnetic powder; the B component includes the following materials in percentage by weight: 5%-20% of modified amine and 2%-10% of modified polyamide; and the A component and the B component are matched for use according to the mass ratio of 3-5:1. The drag-reducing abrasion-resisting solventless coating is prepared through material blending, dispersion, grinding, filtration and packaging and can be applied in delivery pipelines of oil and natural gases. The drag-reducing abrasion-resisting solventless coating does not contain volatile solvents and has the advantages of good adhesive force, flexibility, salt spray resistance and solvent resistant property, smooth coating surface, good drag-reducing abrasion-resisting effect, convenient construction, resource saving and good popularization and application prospect.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

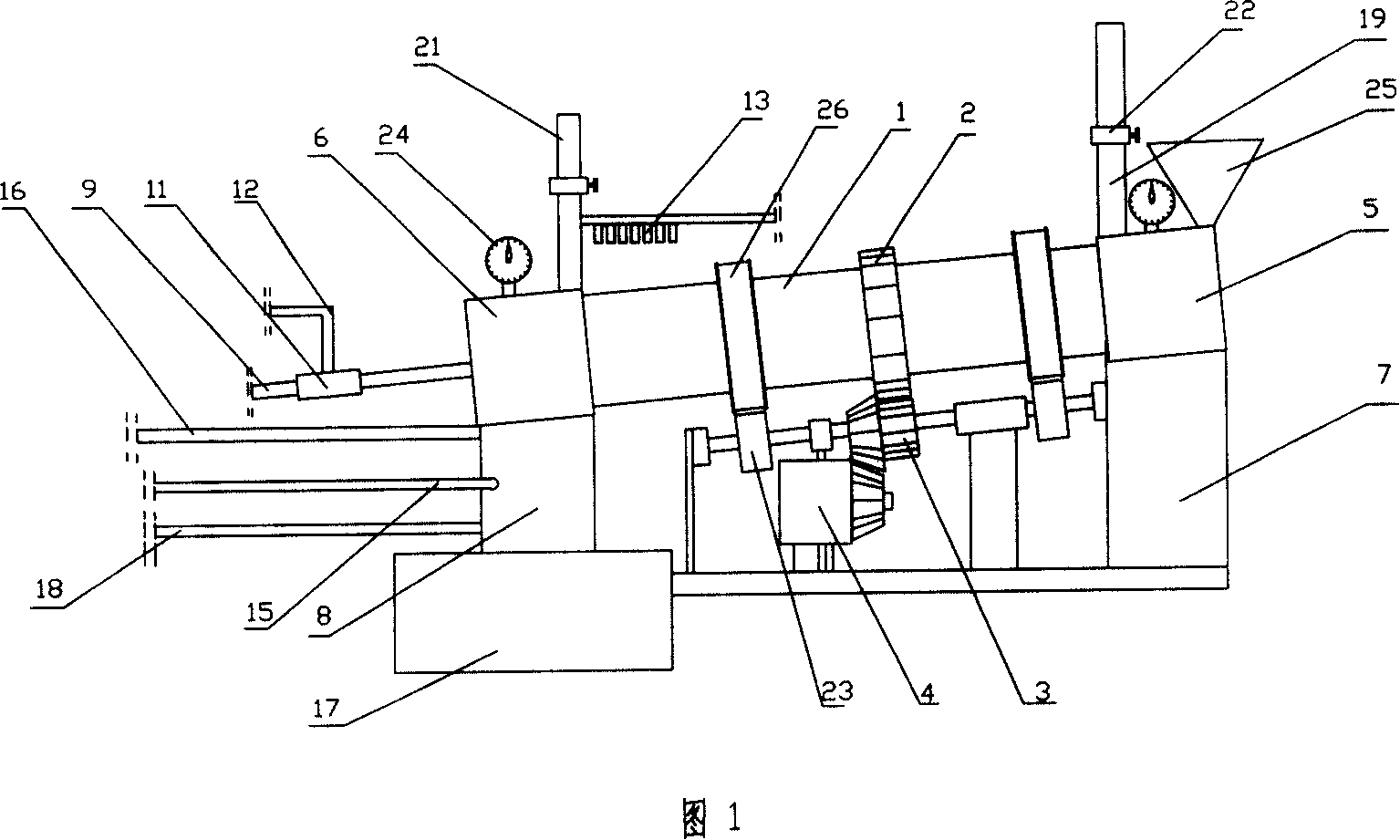

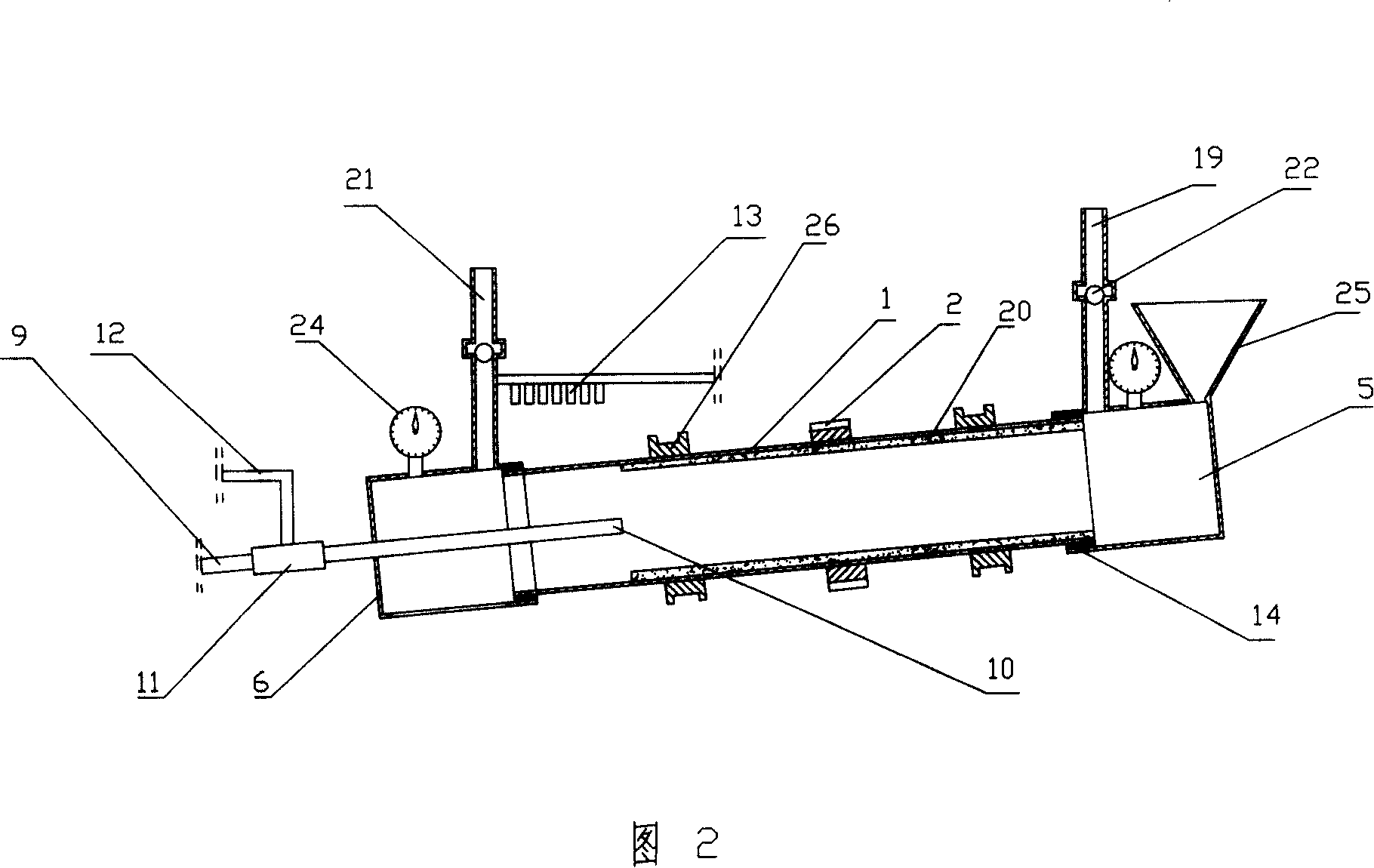

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

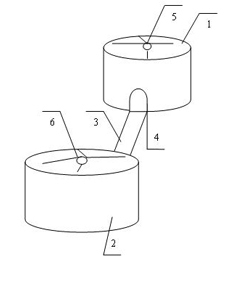

Method for producing iron concentrate by brown hematite and siderite and reduction roaster

The present invention discloses a method for adopting the limonite and the siderite to produce iron powder and a reduction roaster. The material adopts the limonite and the siderite or the specularite, the hematite, and the sulphuric acid slag, the inclined rotary reduction roaster is used, the pressure of the furnace chamber is 250 to 350 Pa, under the deoxidizing atmosphere, the inert solid is rotated and moved to 650 to 900 DEG C from the low temperature, and is cooled and magnetized, and lastly become the iron powder through the dressing by magnetic separation. The present invention is adopted to produce the iron powder, the resources is rich and the production cost is low, and through the utilization of the powder metallurgy art, the iron content of the iron powder is controlled and the activation energy of the iron powder is reduced, and the chemical reaction ability is increased, thereby the output of iron powder is high, the quality is good, the iron powder is loose and porous, the specific surface is big, the apparent density is large, the manufacture cost of pellets sinter and steel smelting can be reduced greatly, and the iron powder can use directly to produce iron oxide red as well as H and N synthetic iron catalyst, or produce ultrapure iron powder.

Owner:郭元杰

Porous ceramicite and preparation method and application thereof

InactiveCN101693631AHigh activityTo promote metabolismWater/sewage treatment by irradiationWater/sewage treatment using germicide/oligodynamic-processRare earthBiological activation

A porous ceramicite and a preparation method and an application thereof in the field of water purifying and filtering technologies, the porous ceramicite comprises the following components in percentage by weight: 2.5%-4.5% of titanium dioxide nanometer grade micro powder, 2%-4.5% of silicon dioxde nanometer grade micro powder, 2.5%-5.5% of zinc oxide nanometer micro powder, 12%-29% of polarity mineral tourmaline powder, 0.5%-1.5% of rare-earth activating agent, 1.5%-3% of ferric oxide red, 3%-10% of feldspar ores, 5%-8% of bergmeal ores, 15%-47% of light clay ores, and the other is water. The method ionizes water into negative ions through realizing infrared, cuts off hydrogen keys through resonance and splits the hydrogen keys into small water molecules (five-six), improves the activation, enables the small molecules into a body, can activate cells, prompts metabolism and acid-base balance, reduces the function of the oxidation-reduction potential ORP value of a water body, and the method can be used for processing water in cups and containers, such as tanks, tower pools, grooves and the like.

Owner:SHANGHAI JIAO TONG UNIV

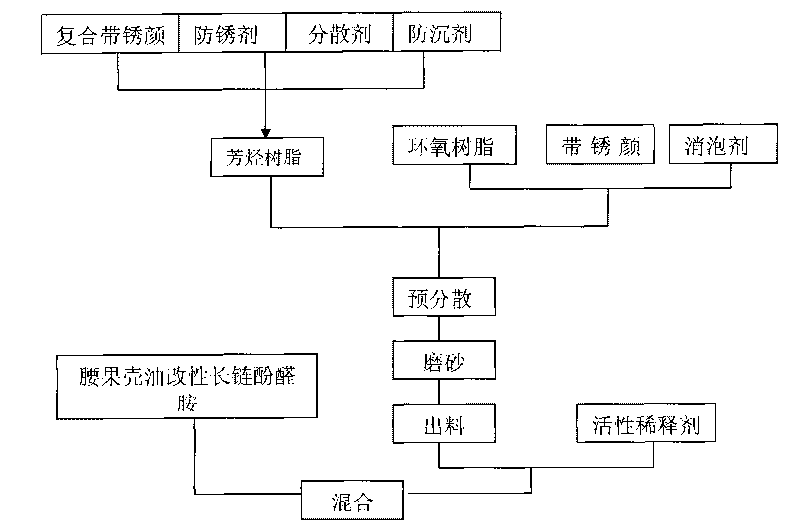

Environment-friendly solvent-free humidified and rusted anticorrosive paint

InactiveCN101747825AEasy pretreatmentConvenient anti-corrosion solutionAnti-corrosive paintsEpoxy resin coatingsOrganic filmSolvent free

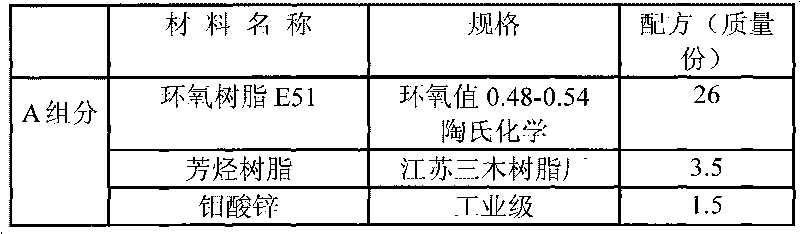

The invention relates to a paint material with formed organic film, in particular to an epoxy solvent-free anticorrosive paint applied to low surface treatment steel structure. The anticorrosive paint is prepared by efficiently compounding rusted coating pigments such as zinc molybdate, zinc phosphate, aluminium trippolyhosphate, iron oxide red and the like, using cashew nut oil modified long-chain amine phenolic aldehyde as, alicyclic glycidyl ether as active diluent, thus overcoming the problems that surface treatment technique in coating construction costs high and heavy anticorrosive paint with high solvent content pollutes the environment, having easy preparation and construction, low cost, fast solidification at high temperature, good mechanical and anticorrosive performance, solvent-free and environment-friendly properties, and being applicable to heavy anticorrosive projects of steel structures such as ship, train, bridge and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Colorized reflection heat insulation coating and color card thereof

ActiveCN102181217AModulation shortcutHigh Solar ReflectanceReflecting/signal paintsMulticolor effect coatingsHigh reflectivityMaterials science

The invention discloses a colorized reflection heat insulation coating. Carbon black, iron oxide red, organic yellow, phthalocyanine green, phthalocyanine blue, and other conventional common pigments are replaced by the pigments, namely nickel iron chromite black, nickel iron chromite red, cobalt blue, titanium yellow and cobalt green, so that the colorized reflection heat insulation coating can meet the demand of the external wall decoration on colors and has high reflectivity to solar energy and a good heat insulation effect. The invention also provides a color card by which a colorized coating is formed by mixing the nickel iron chromite black, the nickel iron chromite red, the cobalt blue, the titanium yellow and the cobalt green, a user can quickly mix the coating of the corresponding colors according to the pigment formula corresponding to each color in the color card, and the color card is convenient to use.

Owner:NIPPON PAINT GUANGZHOU

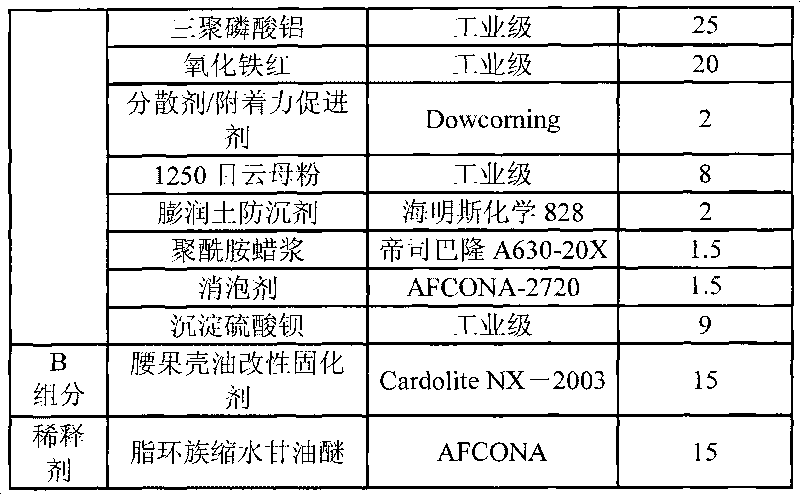

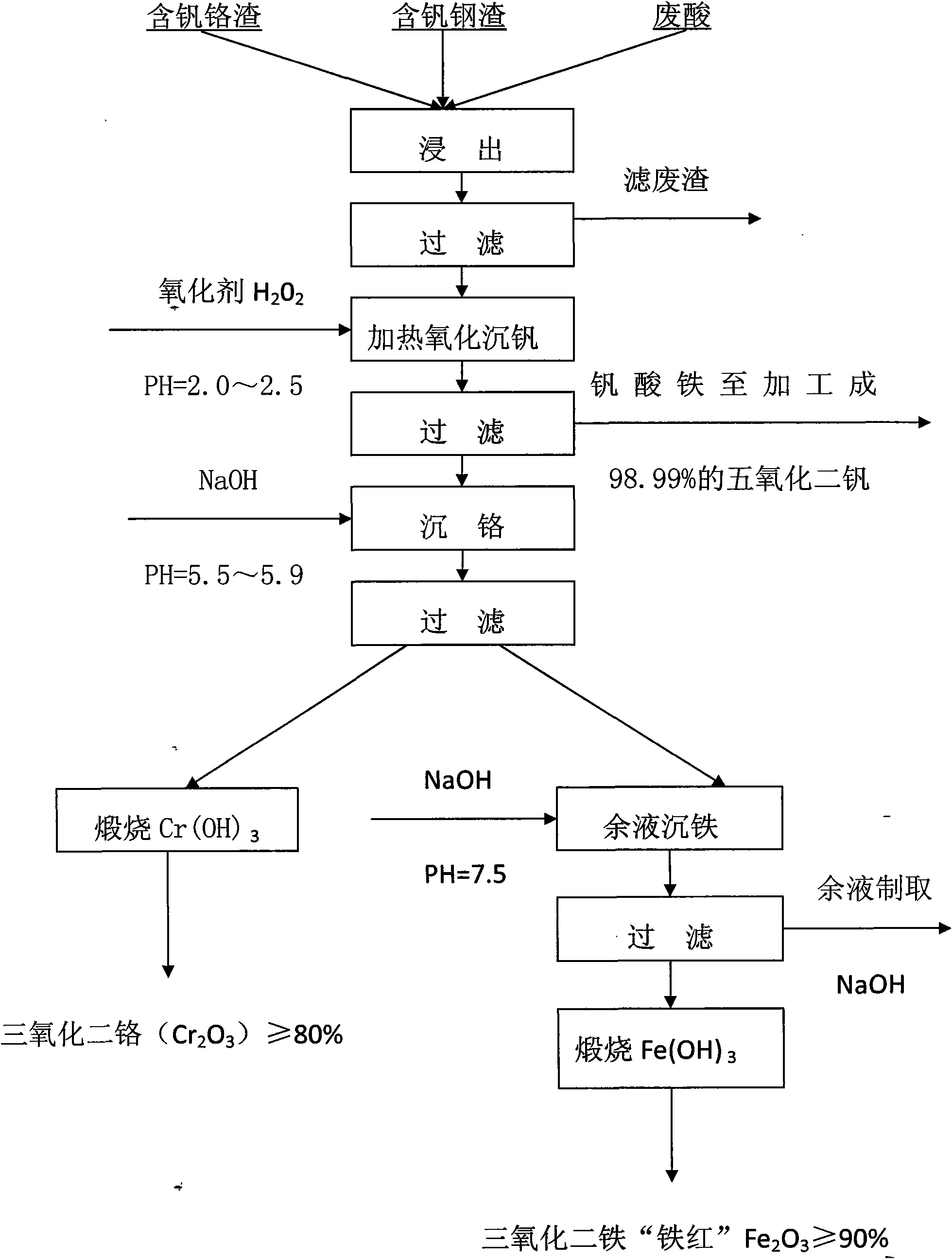

Process for extracting vanadium and chromium from chromic slag by using waste acid of titanium powder plant

InactiveCN101979683AFiltration process goes wellAchieve the purpose of separationProcess efficiency improvementChromium(III) hydroxideSlag

The invention discloses a method for separating and extracting vanadium and chromium. The method comprises the following steps of: (1) producing chromium fine sand (Cr2O3) of which the content is over 80 percent and ferric vandate of which the content is over 20 percent from two waste materials by taking waste acid of a titanium powder plant as a leaching agent and vanadium-chromium slag (containing 2.5 to 4.5 percent of vanadium and 14 to 25 percent of chromium) as a raw material; (2) putting the vanadium-chromium slag into the waste acid to allow the chromium and the vanadium in the slag to form chromium sulfate and vanadyl sulfate which can be dissolved in water very easily, wherein the leaching time is about 6 hours; (3) adding a certain amount of steel making steel slag during leaching to fulfill the aim of generating a great deal of calcium sulfate when a great deal of calcium oxide meets the acid during filtration, and wrapping, adsorbing or and stopping 'silica gel' formed by silicon dioxide in the chromium slag by the calcium sulfate which is used as a filter medium to ensure that the filtration is performed smoothly; (4) adjusting the pH value of the filtrate to be 2.5 by using sodium hydroxide, and then adding an oxidant and oxydol to ensure that the chromium in the solution is oxidized to be hexavalent, the iron is oxidized to be trivalent, and the vanadium is oxidized to be pentavalent; (5) heating the leaching solution to the temperature of between 70 and 90 DEG C to ensure that the vanadium and the iron is combined together to generate water-fast 'ferric vandate', wherein the time for thermal precipitation is about one hour, and the vanadium residual in the solution is not more than 0.4 g / L; (6) adding sodium hydroxide into the solution of which the ferric vandate is filtered out, and fully stirring the mixture until the pH value of the solution is between 5.5 and 5.9 to ensure that the chromium in the solution is completely converted into chromium.

Owner:PANZHIHUA SHUOSHENG IND & TRADING

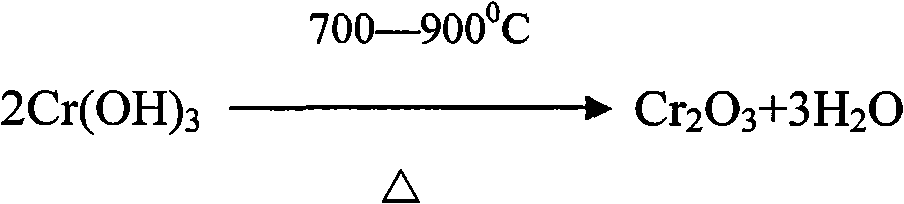

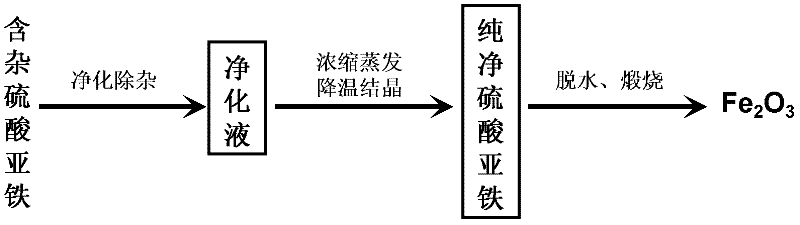

Method for producing iron oxide red by using ferrous sulfate as titanium dioxide byproduct

The invention discloses a method for producing oxide red by using ferrous sulfate as a titanium dioxide byproduct. The method comprises the following process steps of: firstly, dissolving the ferrous sulfate as the titanium dioxide byproduct with water of which the temperature is 50-80DEG C at normal pressure to form an aqueous solution; then adding ammonia water into the aqueous solution; adjusting the pH value of the aqueous solution to 2.2-4.0; adding soluble fluoride into the aqueous solution; reacting at the temperature of 50-80DEG C and normal pressure for 20-60 minutes by stirring; and after the reaction time reaches, separating a precipitation to obtain a purified liquid, wherein the addition mount of the soluble fluoride is 0.3-10 percent of the mass of the ferrous sulfate as the titanium dioxide byproduct; secondly, condensing and crystallizing the purified liquid obtained in the first step to obtain a pure ferrous sulfate crystal; and thirdly, dehydrating the pure ferrous sulfate crystal obtained in the second step at the temperature of 200-350DEG C and normal pressure for 20-60 minutes and calcining the reacted product at the temperature of 800-900DEG C and normal pressure for 1-4h to obtain the iron oxide red.

Owner:SICHUAN UNIV

Preparation method for smoky yellow crystal bead blanks

InactiveCN102503126AAchieve lead-freeHigh refractive indexGlass pressing apparatusPotassium carbonatePotassium permanganate

The invention discloses a preparation method for smoky yellow crystal bead blanks. The preparation method for smoky yellow crystal bead blanks aims to overcome shortcomings that existing preparation process for smoky yellow crystal bead blanks needs lead oxide as a raw material, coloring and optical properties of iron ions are poor, coloring property of manganese is unstable, and rhinestone bead blanks are poor in physical and chemical properties. Raw materials of the preparation method do not contain lead oxide, and the crystal bead blanks are good in physical and chemical properties, are proper in hardness and high in corrosion resistance. In the preparation method for the smoky yellow crystal bead blanks, raw materials of the smoky yellow crystal bead blanks include, by weight ratio, from 50 to 65 parts of quartz sand, from 2 to 20 parts of titanium dioxide, from 2 to 10 parts of sodium carbonate, from 7 to 20 parts of potassium carbonate, from 0.3 to 5 parts of potassium nitride, from 0.1 to 5 parts of cerium oxide, equal to or lower than 6 parts of boric acid, equal to or lower than 2 parts of aluminum hydroxide, equal to or lower than 8 parts of zinc oxide, equal to or lower than 10 parts of magnesium carbonate, equal to or lower than 15 parts of barium carbonate, equal to or lower than 2 parts of lithium carbonate, equal to or lower than 2 parts of potassium permanganate, equal to or lower than 4 parts of sodium nitrate and equal to or lower than 3 parts of iron oxide red.

Owner:ZHEJIANG WEIXING CRYSTAL

Particulate ferric oxide red pigment and method for producing the same

InactiveCN1521220ASolving Dispersion ProblemsSolve the problem of easy cakingPigmenting treatmentPolyvinyl alcoholSulfate

The present invention is granular iron oxide red pigment of grain size of 5-100 mesh and its preparation process. The preparation process includes the following steps: compounding water solution of additive in the concentration of 0.3-10 % and heating to 30-100 deg.c; spraying the water solution to iron oxide red in a pelletizing machine to form the granular pigment gradually with the weight ratio of iron oxide red to the water solution being 100 to 15-40; and vibration sieving and stoving to obtain the product. The additive is the combination of two or more of CMCNa, PVA, sodium silicate, glutin, sodium lignosulfonate and ferrous sulfate. The granular iron oxide red pigment has the same performance and use effect as the powdered iron oxide red pigment and is favorable to prevent dust pollution, and may be used to replace powdered iron oxide red pigment.

Method for preparing iron oxide red by byproduct ferrous sulfate of titanium dioxide

InactiveCN101607741AReduce manufacturing costImprove protectionPigmenting treatmentIron oxides/hydroxidesBall millImpurity

The invention discloses a method for preparing iron oxide red by taking byproduct ferrous sulfate of titanium dioxide as a raw material. The method comprises the following steps: purifying the byproduct ferrous sulfate, removing impurities, pouring the purified ferrous sulfate solution into a container, stirring the solution and adding ammonia water, adjusting the pH value of the solution to be between 6.5 and 9, and stopping the addition of ammonia water; washing and filtering the obtained material, and stopping until the pH value of the solution is between 6.5 and 7 to obtain filter cake and filtrate; and calcining the obtained filter cake in a rotary kiln to obtain an iron oxide red semi-finished product, putting the semi-finished product into a ball mill, adding water for ball milling, washing, filtering and drying the obtain material after ball milling, and crushing after drying to obtain an iron oxide red product. The method solves the problem of treating the byproduct for titanium dioxide manufacturers, is favorable for environmental protection, and reduces the production cost of iron oxide red; and the iron oxide red prepared by the method is mainly used in aspects of coloring agents, antirust paint pigment, ceramic pigment of building materials, polishing agents of precision parts, and the like.

Owner:张晓东

Method for preparing solid-mold casting coating material for large-sized cast parts

InactiveCN103100651AImprove performanceIncrease stiffnessFoundry mouldsFoundry coresRed Ferric OxideCarboxymethyl cellulose

The invention discloses a method for preparing a solid-mold casting coating material for large-sized cast parts. According to the method, the solid-mold casting coating material is prepared from the following ingredients in parts by weight: 68-75 parts of quartz powder, 5-7 parts of wood ash, 5-7 parts of fly ash, 10-12 parts of water glass, 10-12 parts of sodium bentonite, 4-6 parts of nano calcium carbonate, 1-2 parts of lignosulfonic acid, 2-4 parts of carboxymethyl cellulose, 0.3-0.7 part of glycerine, 2-4 parts of sodium borate, 5-7 parts of starch paste, 1.4-1.6 parts of silica sol, 1-2 parts of nanoscale ceramic powder, 0.5-0.8 part of red ferric oxide powder, 1-2 parts of sodium tripolyphosphate, 4-5 parts of potassium feldspar powder and 525-635 parts of water. The solid-mold casting coating material prepared by the method has excellent gas permeability and quick-drying performance in both a high-temperature environment and a low-temperature environment, thereby meeting the production requirements of the large-sized cast parts.

Owner:辽宁佳和精密金属有限公司

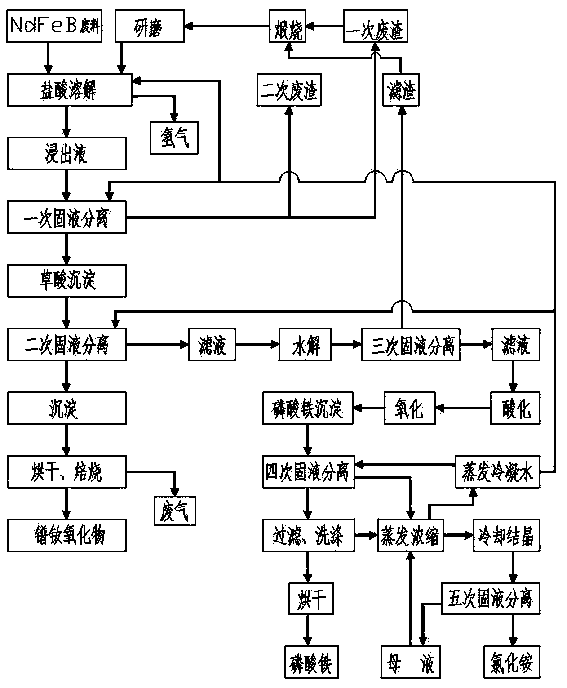

Method for separating and utilizing neodymium iron boron waste materials

ActiveCN103773966AReliable separation and recoveryReduce the cost of separation and recoveryIron compoundsProcess efficiency improvementOXALIC ACID DIHYDRATEPhosphate

Owner:绵竹三人禾科技发展有限责任公司

Water epoxy anticorrosion paint and preparation method thereof

InactiveCN101148557AGood dispersionGood antibacterial effectAnti-corrosive paintsPolyamide coatingsEpoxyPolyamide

The present invention is one kind of water soluble anticorrosive paint and its preparation process, and belongs to the field of paint technology. The water soluble anticorrosive paint consists of two components, including the component A comprising chitin-epoxy resin emulstion 45-50 weight portions, ferric oxide red 20-22 weight portions, antirust pigment 8-10 weight portions, talcum powder 8-10 weight portions, defoaming agent 0.25-0.35 weight portions, leveling agent 0.25-0.35 weight portions, flash rust resistant 0.35-0.45 weight portions and deionized water 8-10 weight portions; and the component B comprising polyamide 650 58-62 weight portions and alcohol ether solvent 38-42 weight portions. The water soluble anticorrosive paint has excellent emulsifying performance, high protecting performance, good antisepsis and anti-mildew performance, high weather resistance and high alkali tolerance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

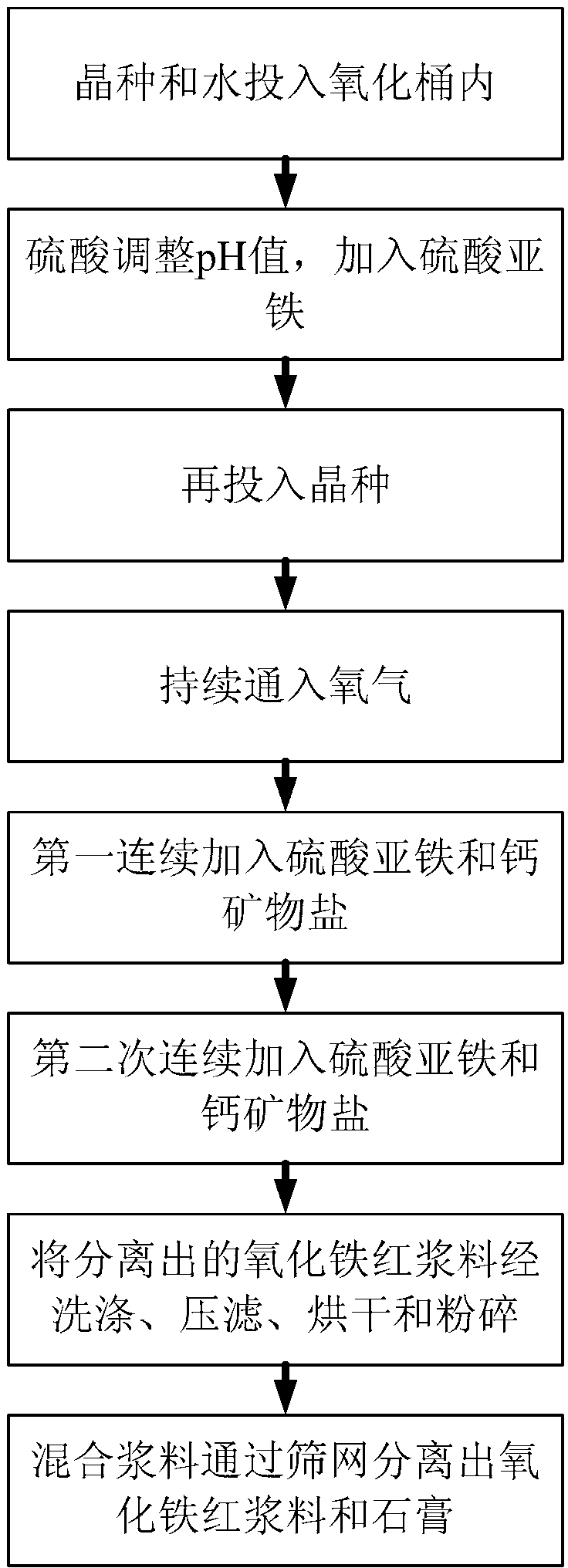

Two-step oxidation production method for iron oxide red pigment

ActiveCN102976413ASolve the costSolve pollutionMaterial nanotechnologyFerric oxidesTwo stepSeed crystal

The invention discloses a two-step oxidation production method for an iron oxide red pigment. According to the method, alpha-FeOOH is used as a seed crystal, a calcium mineral salt is used as a neutralizer in reaction process, and a byproduct obtained in preparation of titanium dioxide, i.e., ferrous sulfate, is used as a raw material; through accurate control of the reaction process, the iron oxide red pigment and a gypsum particle with different particle sizes are finally obtained, a good separation effect on the iron oxide red pigment and the gypsum particle is obtained, and the content of Fe2O3 in a final product is more than 99%; moreover, the particle size of the iron oxide red pigment is at a nanometer level and in a range of 100 to 200 nm, and granularity of the iron oxide red pigment is uniform. The method provided by the invention overcomes the problems of high production cost, secondary pollution to the environment, great potential safety hazards and the like in production of the iron oxide red pigment by using traditional methods; the byproduct ferrous sulfate obtained in preparation of titanium dioxide is utilized, and the raw material is easily available.

Owner:CNMC GUANGXI PGMA

Waterborne antirust paint and preparation method thereof

ActiveCN105238232AImprove densification performanceImprove shielding effectAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention discloses waterborne antirust paint and a preparation method thereof. The waterborne antirust paint is prepared from, by mass, 10-25 parts of waterborne acrylic acid modified epoxy ester, 0.6-1.2 parts of neutralizer, 20-30 parts of deionized water, 0.5-1.5 parts of dispersing agents, 0.2-0.5 part of defoaming agent, 14-18 parts of iron oxide red, 2-4 parts of mica powder, 6-10 parts of modified zinc phosphate, 10-14 parts of precipitated barium sulphate, 1-2 parts of propylene glycol, 10-15 parts of styrene-acrylic emulsion, 0.5-1.0 part of coalescing agent, 0.5-1.0 part of waterborne flush rust prevention agent, 0.5-1.5 parts of thickening agents and 0.2-0.5 part of mildew prevention agent. The waterborne antirust paint is high in film hardness, good in adhesive force and excellent in corrosion-resistant performance and mechanical performance, dryness and initial water resistance of paint films are remarkably improved due to the addition of styrene-acrylic emulsion, and the flush rust restraining performance of paint films is improved due to the addition of the waterborne flush rust prevention agent. Water serves as the diluent for the waterborne antirust paint, VOC emission in production and construction projects is greatly reduced, and the waterborne antirust paint is safe, environmentally friendly and capable of being widely used for paint coating on the aspects of steel structures, pipelines, automobile parts and the like.

Owner:西北永新涂料有限公司

Anti-drag wear-resistant solvent-free coating with low-viscosity for pipeline

ActiveCN102417780AStrong adhesionGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to the technical field of coatings, in particular to an anti-drag wear-resistant solvent-free coating with low-viscosity for a pipeline. The anti-drag wear-resistant solvent-free coating with the low-viscosity comprises a component A and a component B, wherein the component A comprises epoxy resin, an active diluent, a flatting agent, an antifoaming agent, a dispersant, a thixotropic agent 1, a thixotropic agent 2, zinc phosphate, silica, iron oxide red powder, aluminum triphosphate and white pottery powder; the component B comprises modified amine and a thixotropic synergistic agent; and the component A and the component B are used together in the mass ratio of (3-5):1. The solvent-free coating with the low-viscosity has the positive effects of freeness from volatilizable solvent, capability of eliminating coating pin holes, high adhesion, high permeation resistance, high wear resistance, high corrosion resistance, smooth coating surface after being sprayed, good anti-drag and wear-resisting effects, and popularization and application prospects.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

Method for producing pigment-level iron oxide red by using titanium dioxide waste residue ferrous sulfate

ActiveCN102583575ALow costImprove performanceSolid waste disposalFerric oxidesChemical industryIron oxide black

Owner:攀枝花市大牛科技有限公司

Process for preparing iron oxide red by using sulfuric acid crystal seed mixed acid method and products thereby

InactiveCN1699477AReduce consumptionImprove working environmentInorganic pigment treatmentSulphate IonSlurry

The invention relates to a process for preparing iron oxide red by using sulfuric acid crystal seed mixed acid method, which comprises preparing iron oxide red seed crystal with sulfuric acid process, then washing the iron oxide red seed crystal, lowering the content of sulphate and other impurities in the sulfuric acid process iron oxide red seed crystal, preparing iron oxide red slurry through two-step oxidization, finally dewatering, water scrubbing and drying to obtain the end product.

Owner:SOUTH CHINA UNIV OF TECH

Anti-rust primer for elementary surface treatment of steel material, and manufacturing method thereof

InactiveCN101298536AImprove adhesionImprove rust resistanceLiquid surface applicatorsAnti-corrosive paintsPolyesterLacquer

The invention relates to an antirust primer with rust and with elementary surface treatment used for steel materials and a manufacturing method, wherein, fluid A is made by mixing, agitating and grinding bisphenol-A epoxy resin, dimethylbenzene, n-butyl alcohol, tannin, precipitated barium sulfate, zinc phosphate, saponite, iron oxide red, simethicone, polyester modified polyphosphonate compound and polyamide wax micropowder, while fluid B is made from polyamide resin, the dimethylbenzene and the n-butyl alcohol; when in use, mix and cure the fluid A and the fluid B to form the coating film. The antirust primer with rust and with elementary surface treatment has excellent adhesion and corrosion resistance, which can be coated on steel surfaces with uneven rust, solid oxide scale residuals or old paint, and can be directly used and matched as a primer with other finish paints without using any other primers.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

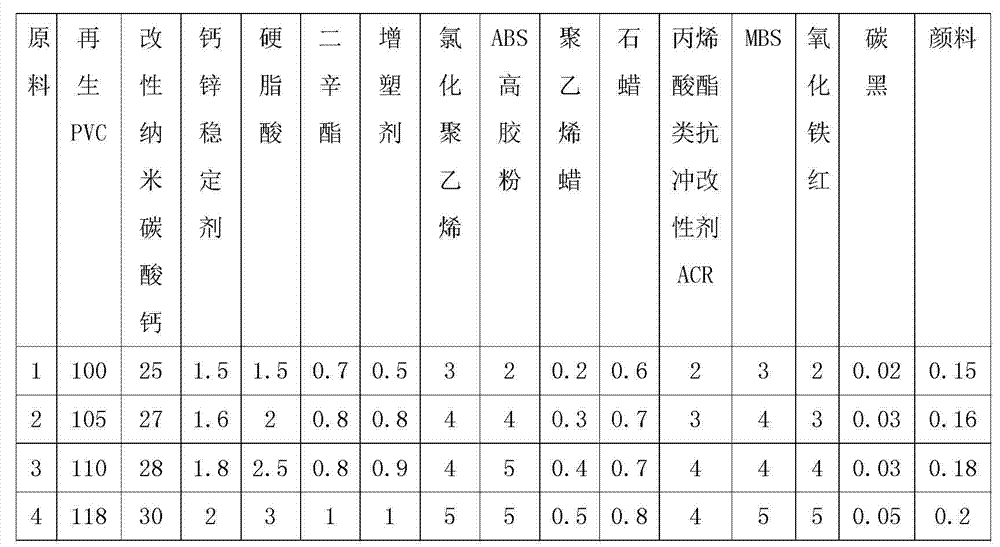

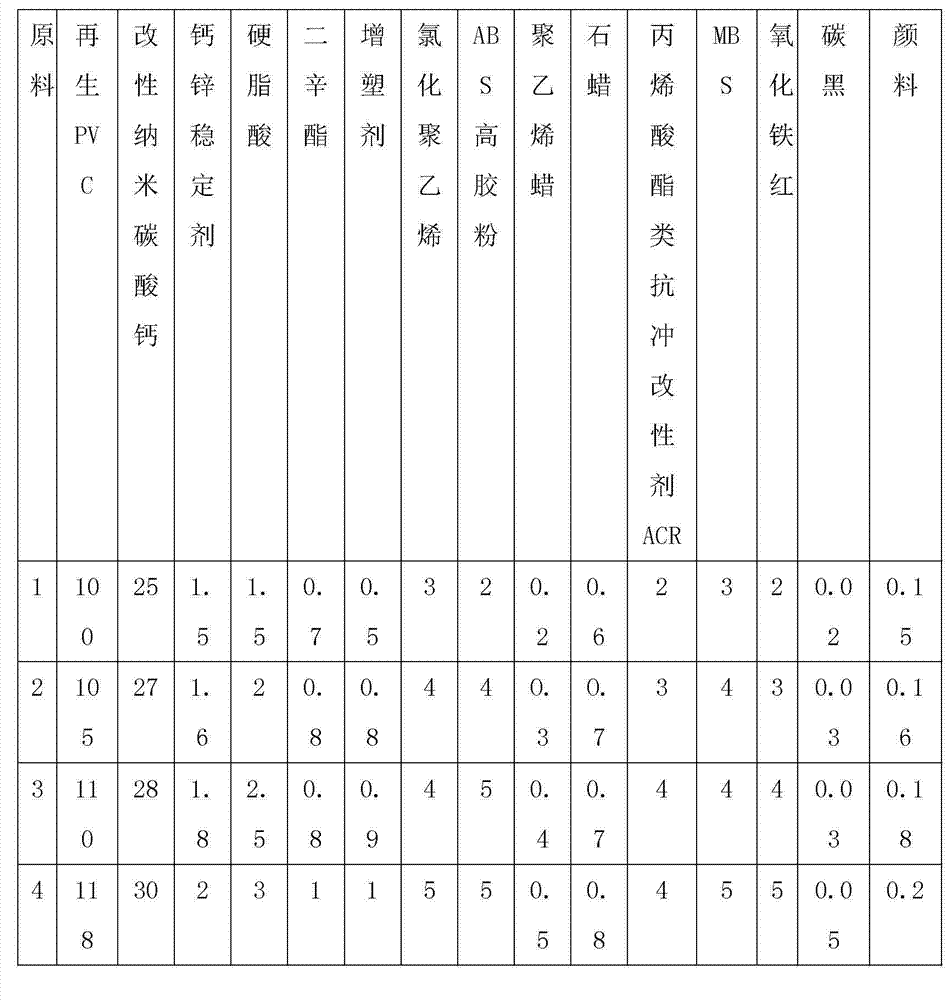

Color glass-reinforced plastic profile material made from novel reclaimed material

The invention discloses a color glass-reinforced plastic profile material made from a novel reclaimed material. The color glass-reinforced plastic profile material is made from raw materials, such as recycled PVC (polyvinyl chloride), modified nano calcium carbonate, a calcium zinc stabilizer, stearic acid, di-n-octyl phthalate, plasticizer, chlorinated polyethylene, ABS (acrylonitrile-butadiene-styrene) high rubber powder, polyethylene wax, paraffin, acrylate impact modifier ACR, MBS (methyl methacrylate), iron oxide red, carbon black and a pigment. According to the color glass-reinforced plastic profile material, the calcium zinc stabilizer substitutes a lead salt stabilizer, so that the color glass-reinforced plastic profile material is safer and harmless and does not affect the health of human bodies. A waste glass-reinforced plastic profile material or an unqualified glass-reinforced plastic profile material is effectively utilized, so that the reutilization of the glass-reinforced plastic profile material is realized, a large number of raw materials are also saved in a production process, white pollution is reduced, our natural environment is more protected, and the policy requirements of energy conservation and environment friendliness are met. The profile material made from the recycled PVC has all the characteristics of the profile material made from the raw materials as well as the characteristics of smoother surface, better density, better toughness and the like.

Owner:SHUCHENG ANTAI PLASTIC PROD

Polycarbonate/ABS alloy, its preparation method and its application

The invention discloses a polycarbonate / ABS alloy, its preparation method and its application. A raw materials formula of the polycarbonate / ABS alloy comprises the following components by weight parts: 25-50 parts of PC, 20-50 parts of PC reworked material, 20-30 parts of ABS reworked material, 5-10 parts of MBS, 5-8 parts of TPP, 0.3-0.5 part of FR2025 fire retardant, 0.5-2 parts of titanium dioxide, 0.1-0.5 part of anti-oxidant1010, 0.1-0.5 part of anti-oxidant168, 0.1-0.5 part of ultraviolet resistance agentUV-531, 0.03-0.08 part of proliferation powderEBS, 0.02-0.06 part of ultramarine powder, 0.02-0.4 part of iron oxide red powder and 0.005-0.01 part of high temperature resistance fluorescent yellow powder. The alloy of the invention has the characteristics of high performance, high flame retardation, high impact, high stability, antistatic property and the like, and can be used for producing intelligent ammeter housing and terminal strips.

Owner:扬州瑞邦化工技术有限公司

Clay green sand for high-pressure molding and preparation method thereof

The invention discloses clay green sand for high-pressure molding and a preparation method thereof. The clay green sand is prepared from the following raw materials in parts by weight: 50-70 parts of zircon sand, 30-40 parts of chromite sand, 8-12 parts of bentonite, 5-10 parts of pottery, 3-6 parts of calcium sulfate crystal whiskers, 2-3 parts of calcium lignosulphonate, 1-2 parts of lauryl alcohol polyoxyethylene, 1.5-2.5 parts of polyoxyethylene, 1-2 parts of iron oxide red, 4-8 parts of stove ash slag, 3-5 parts of aluminum silicate fibers, 2-4 parts of composite powder and 5-10 parts of water. The molding sand disclosed by the invention is added with the aluminum silicate fibers and the calcium sulfate crystal whiskers, so that strength and toughness of the molding sand can be improved, damages to a sand mould during drawing are reduced; moreover, the molding sand further has good ability of preventing burnt-on sand and sand inclusion as well as low evolution rate, good gas permeability, and the like, can be used for effectively avoiding the defects such as gas pores and sand inclusion of a casting piece, and improving the production efficiency of a high-pressure molding line and the quality of the casting piece.

Owner:TONGLING JINGWEI FLUID SCI & TECH

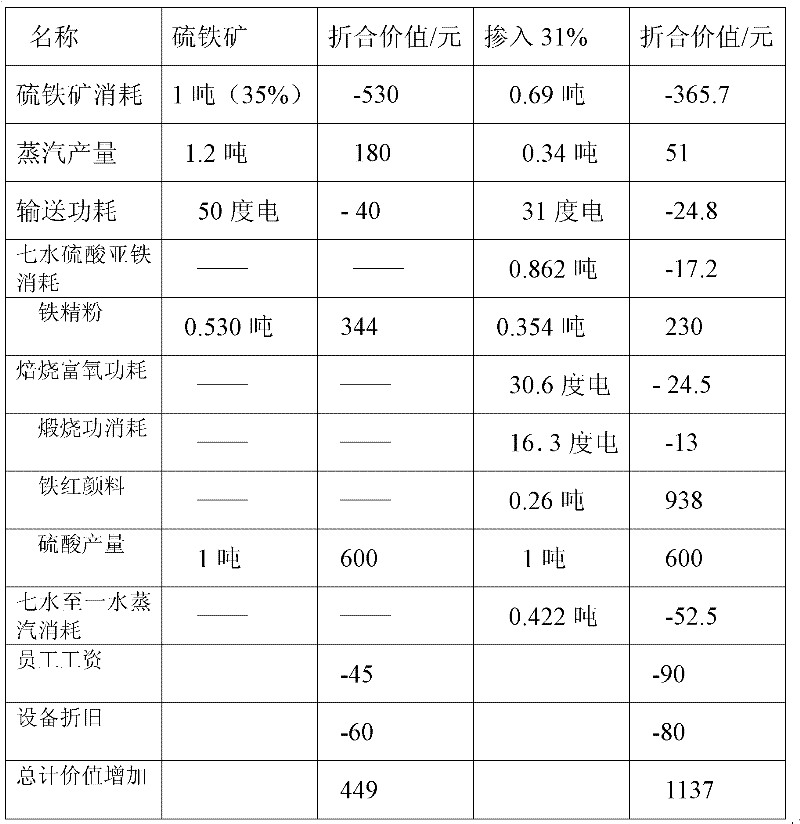

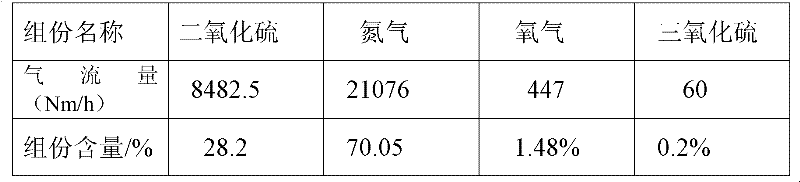

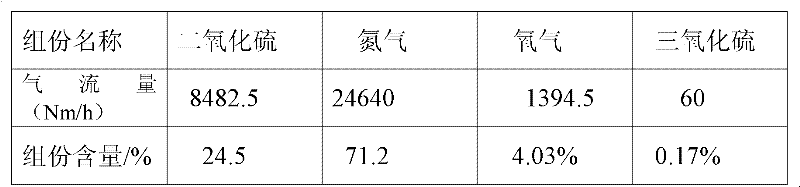

Process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite

ActiveCN102344124AIncrease incorporationImprove Pigment PerformanceSulfur compoundsEnergy inputResource utilizationFractionation

The invention provides a process for co-producing sulfuric acid, fine iron powder and iron oxide red by ferrous sulfate heptahydrate and pyrite and relates to the process technology of resource utilization of titanium dioxide byproduct solid waste ferrous sulfate. The process comprises the following steps: adopting titanium dioxide byproduct ferrous sulfate heptahydrate and pyrite as raw materials; increasing the mixing amount of the ferrous sulfate heptahydrate as much as possible through transforming the ferrous sulfate heptahydrate into ferrous sulfate monohydrate, oxygen-enriched roasting, preheating air in front of a furnace, controlling the sulfur content of the pyrite entering the furnace and the moisture and other technical means; and realizing the integrated co-production of the sulfuric acid, the fine iron powder and iron oxide red pigments through cinder fractionation, oxygen-enriched calcining and other process technologies. The process effectively improves the economic value of the heptahydrate ferrous sulfate and has an important significance on efficient and comprehensive utilization of the titanium dioxide byproduct solid waste ferrous sulfate heptahydrate.

Owner:HUNAN HENGGUANG TECH

Manufacturing method of underglaze white double crystal fancy glaze

The invention relates to a manufacturing method of an underglaze white double crystal fancy glaze. The method comprises the steps of preparing materials according to a formula, manufacturing a frit, sieving by using a ball mill and modulating, wherein the frit is made from borax, potash feldspar and quartz; a ground glaze is made from potash feldspar, zinc oxide, calcite, quartz and frit; and an overglaze is made from frit, barium carbonate, iron red, potash feldspar, titanium oxide, zinc oxide, bentonite, quartz, iron oxide red and zirconium silicate; dry grinding frit materials, burning the frit materials at 1250 DEG C, and cooling fast to obtain the frit; sieving ground glaze and overglaze materials by using the ball mill; wet ball milling, and sieving by using a 250 mesh sieve; modulating the ground glaze and the overglaze: mixing the crushed frit respectively with the ground glaze and overglaze materials which are sieved and wet ball milling mixtures so as to modulate the mixtures into slurries at 45-50 baume degree; burning: spraying glaze on a green body, wherein the thickness of the ground glaze is 0.4-0.7mm, the thickness of the overglaze is 0.3 mm, and feeding the green body into a roller way to be burnt into the underglaze white double crystal fancy glaze in an oxidizing atmosphere; after burning, natural, smooth and crystal clear decorative patterns can be generated.

Owner:湖南泉湘陶瓷有限公司

Compound water-based inorganic anticorrosive paint and preparation method

InactiveCN104877402ANo changeNon-foamingAnti-corrosive paintsElectrically-conductive paintsSilicic acidPotassium silicate

The invention relates to an anticorrosive paint, particularly to a compound water-based inorganic anticorrosive paint with the functions of cathode protection and anti-static electricity and a preparation method. The compound water-based inorganic anticorrosive paint comprises the following components in mass percent: 0.1-4% of oxidized graphene, 22-34% of zinc powder, 1-3% of attapulgite AT, 15-18% of potassium silicate, 11% of iron oxide red, 30-45% of distilled water and 0.2-0.8% of sodium polyacrylate. The anticorrosive paint has the characteristics that oxidized graphene and zinc powder are used as the main raw materials of the anticorrosive paint, the use amount of zinc powder is greatly reduced, the electrical conductivity and hardness of the paint are improved, the technology is simple, the anticorrosive paint is green, environment-friendly and good in corrosion resistance, and can be applicable to anticorrosive painting of various metal pipelines and metal members.

Owner:CHANGZHOU UNIV

Waterborne anticorrosive coating and preparation method

InactiveCN105176313AReduce surface tensionIncrease wettabilityAnti-corrosive paintsEpoxy resin coatingsMeth-Sodium phosphates

The invention discloses a waterborne anticorrosive coating. The waterborne anticorrosive coating comprises the following components: waterborne epoxy resin emulsion, a pigment filler, a film forming assistant, a leveling agent, a defoaming agent, a thickening agent, a dispersing agent, water and a curing agent, wherein the pigment filler is mixture of iron oxide red and zinc phosphate which are mixed according to a mass ratio of 1:1; the film forming assistant is glycol; the leveling agent is polyacrylic acid or hydroxymethyl cellulose; the defoaming agent is tributyl phosphate; the thickening agent is hydroxymethyl cellulose; the dispersing agent is sodium hexametaphosphate; the curing agent is one of diethylenetriamine, m-phenylenediamine, modified phenolic amine and diamino diphenyl sulfone (DDS). The invention further discloses a preparation method of the waterborne anticorrosive coating, the coating has good anticorrosive performance, the preparation method is simple and feasible and the cost is low.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Release agent of sand mould and sand core and preparing process thereof

InactiveCN101199984AReduce manufacturing costExcellent mold releaseFoundry mouldsFoundry coresChemical compositionSolvent

Disclosed is a release agent used for sand mold and sand core, which is characterized in that the release agent is made from the compound of stearate, iron oxide red, organobentonite paste, binder and solvent oil. The quality percentage of the main chemical composition is: stearate:12 to 49, iron oxide red: 2 to 8, organobentonite paste: 10 to 40, binder: 0.3 to 2; and the rest is solvent oil. Using the release agent can greatly reduce the bonding power and the mold release resistance of mold and core on the die set. Thus the using period of the die set is increased.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

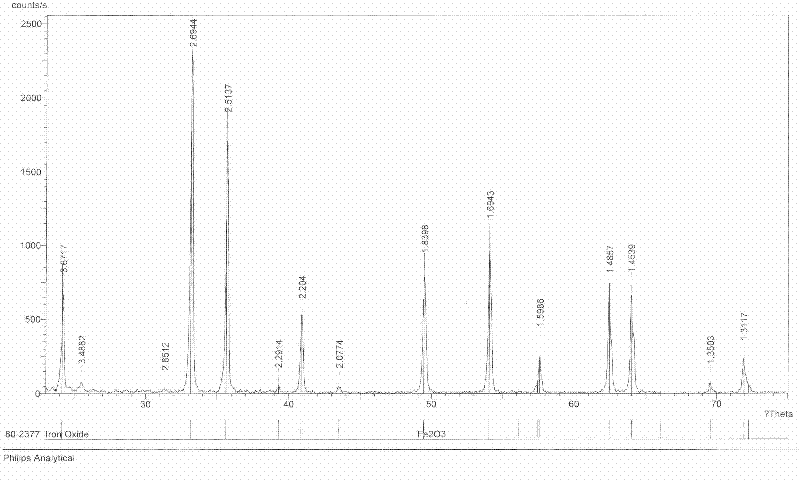

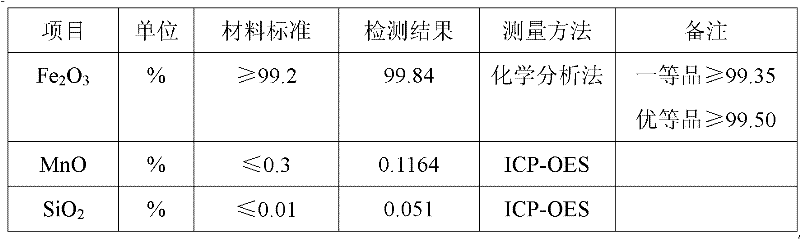

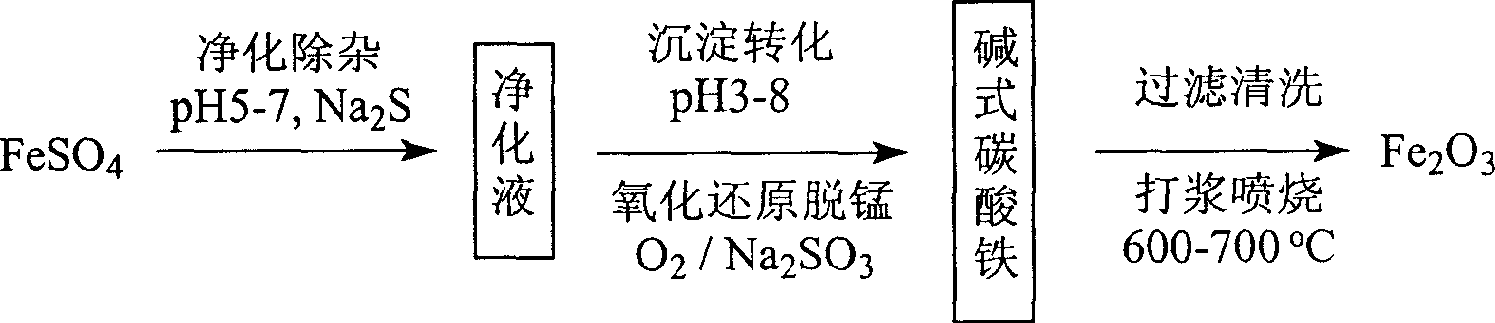

Process for preparing ferric oxide red powder

InactiveCN1491997ASolve the separation problemEasy to producePigmenting treatmentSulfateWhite powder

The present invention relates to the preparation process of ferric oxide red powder. Unlike available technology, which has the demerits of high production cost and low product purity of processed ferrous permanganate, the present invention uses ferrous sulfate as the side product of titanium white powder production as material and produces high purity ferric oxide red powder via purification to eliminate impurity, precipitation to eliminate manganese, water washing, spray burning and other steps. The ferric oxide red powder has impurity content of Si, Al, Ca, Mg, etc. less than 80 ppm, Mn content lower than 0.2 wt% and Fe2O3 content over 99.5 wt%, and is used as soft magnetic material. The present invention has simple technological process, low production cost and high product quality, and may be used in industrial production.

Owner:FUDAN UNIV +1

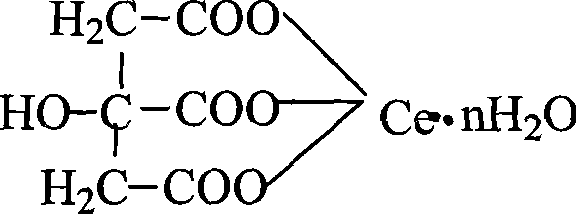

Cerium citrate nontoxic rust-preventive pigment and coating thereof

InactiveCN101481510AGood anti-corrosion effectImprove corrosion resistanceLiquid surface applicatorsAzo dyesSpecific gravityBrown iron oxide

The invention relates to a nontoxic rust-proof paint and a coating. The nontoxic rust-proof paint is cerous citrate, and has the molecular formula CeC6H5O7.nH2O, wherein n is 1 to 4, the cerous citrate is white, the specific gravity of the cerous citrate is 2.0 to 2.2, the oil absorption amount is 65 to 70 milliliters per g, and the pH is 6 to 7. An anti-corrosive paint comprises the following components by weight portion: 20 to 30 portions of 50 percent epoxy ester, 5 to 20 portions of cerous citrate, 5 to 15 portions of aluminum triphosphate, 5 to 10 portions of zinc molybdate, 5 portions of red iron oxide, 20 to 40 portions of dimethyl benzene, 2 portions of dispersant DA-01, 0.1 portion of antifoaming agent BYK-022, 0.15 portion of cobalt drier, and 6 portions of rare-earth drier. According to the measurement of GB / T1763-79, the salt water resistance (d) of the paint is 45 days; and according to the neutral salt mist (h) experiment of GB / T1771-91, the paint is in good condition after 1,030 hours.

Owner:丁忠 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com