Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Red Ferric Oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferric oxide red (Fe2O3), also known as iron (III) oxide, is a coloring agent for tablets and capsules and is used in the pharmaceutical industry. Ferric oxide red occurs naturally as hematite ore and rust. Iron oxides are also commonly used in the cosmetics industry.

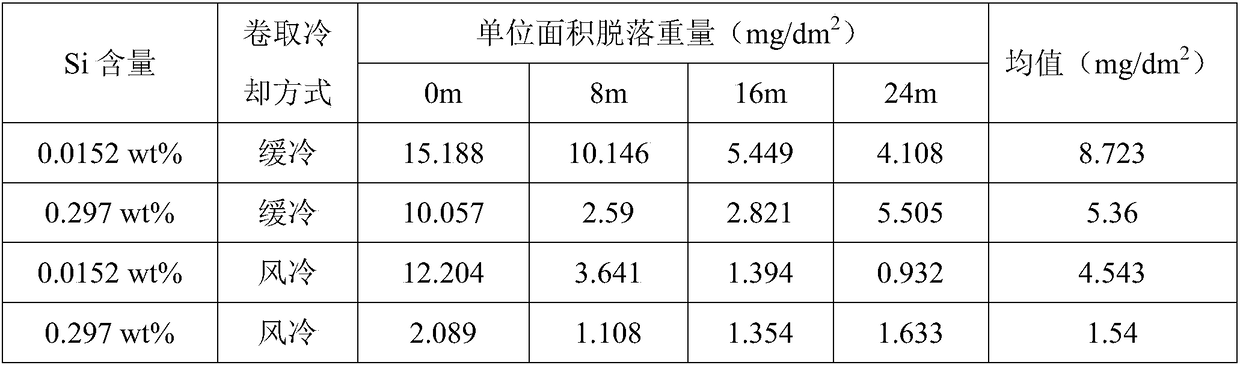

Surface iron scale control method for middle sheet billet continuous casting and rolling steel plate

InactiveCN101012528AReduce generationGood removal effectTemperature control deviceWork treatment devicesThin slabEnergy conservation

The invention discloses a controlling method of iron oxide sheet of rolled band steel surface of middle-thin board blank, which is characterized by the following: controlling component; proceeding heat load directly; heating to remove phosphor; rolling under high temperature; forcing to cool; controlling Si content in the steel; eliminating red ferric oxide on the surface of heat roll steel; fitting for the steel with not more than 0.18%C, not more than 0.20% Si, not more than 1.50% Mn, not more than 0.015% P, not more than 0.01% S and Nb, V and Ti.

Owner:ANGANG STEEL CO LTD

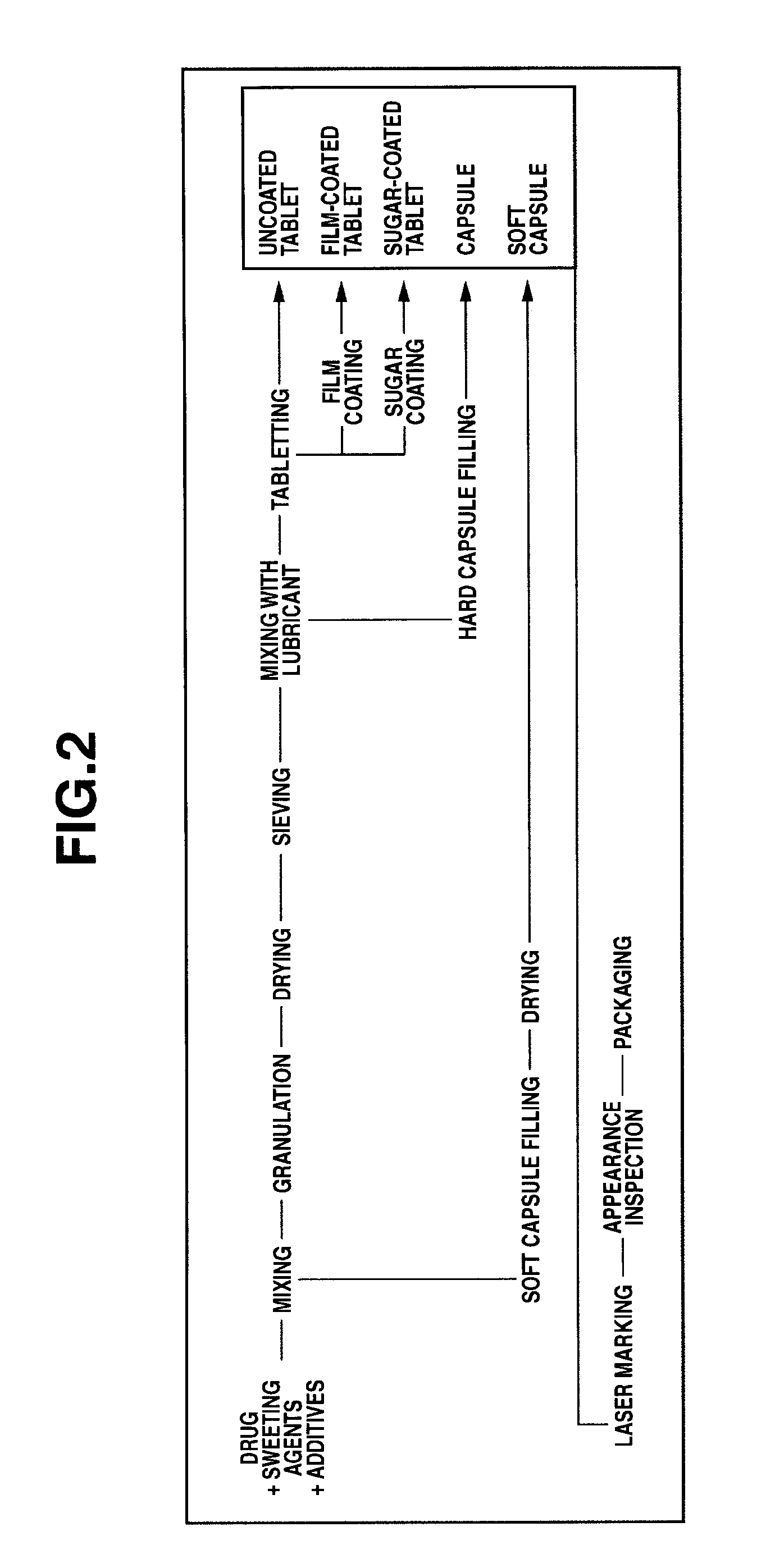

Soft capsules

InactiveUS6893658B1Easily discriminatedImprove securityOrganic active ingredientsBiocideRed Ferric OxideMedicine

An object of the present invention is to provide soft capsule formulations of active vitamins D, well-suited to practical production with easy discrimination of active ingredient levels, in which stability of the active vitamins D3 to light and heat is ensured, and which material is highly safe to the human body. According to the present invention, soft capsule formulations of active vitamins D3 can be obtained-wherein the capsule shell contains a white pigment and yellow iron oxide and / or red iron oxide, or titanium oxide and caramel, or yellow iron oxide.

Owner:CHUGAI PHARMA CO LTD

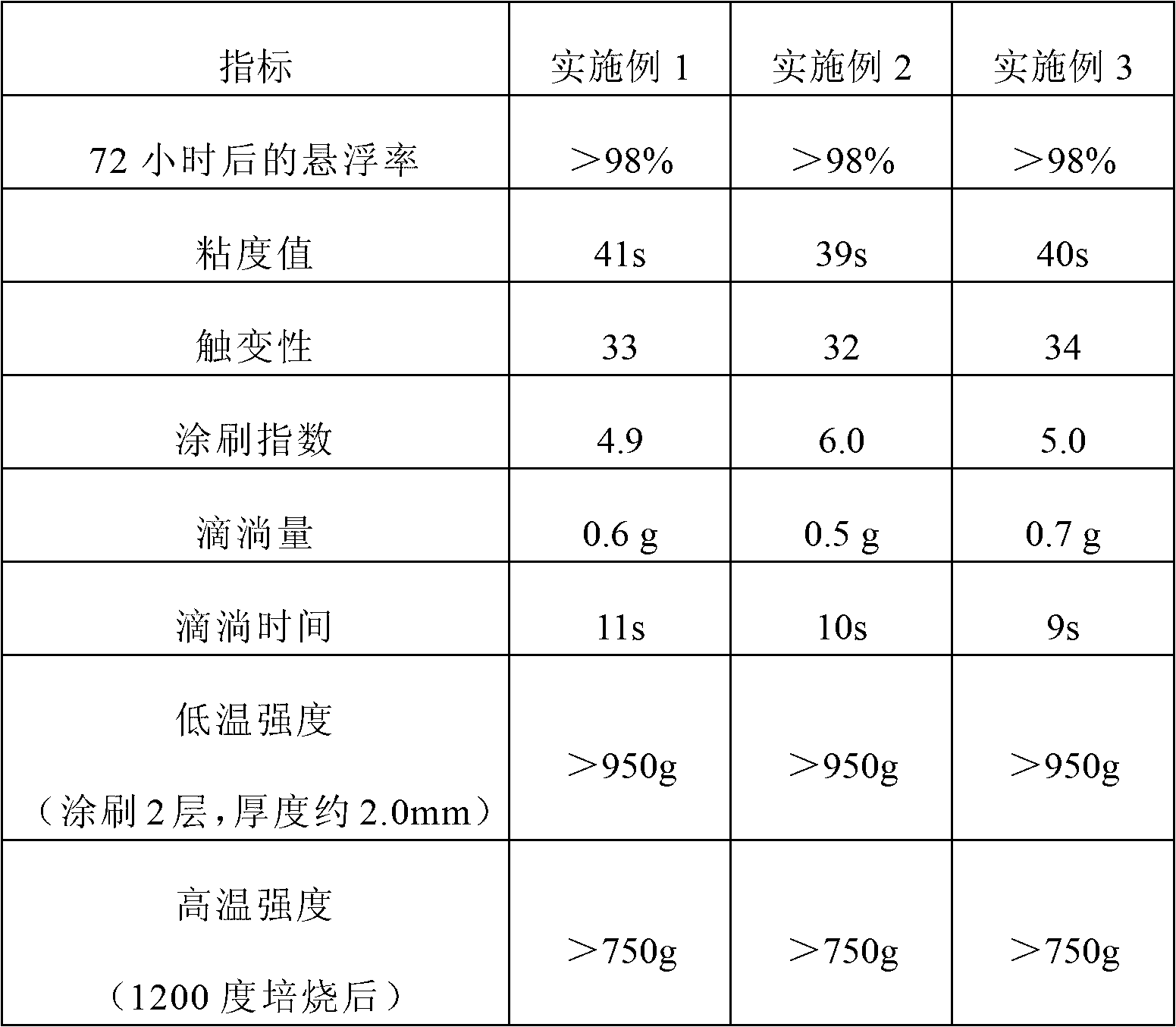

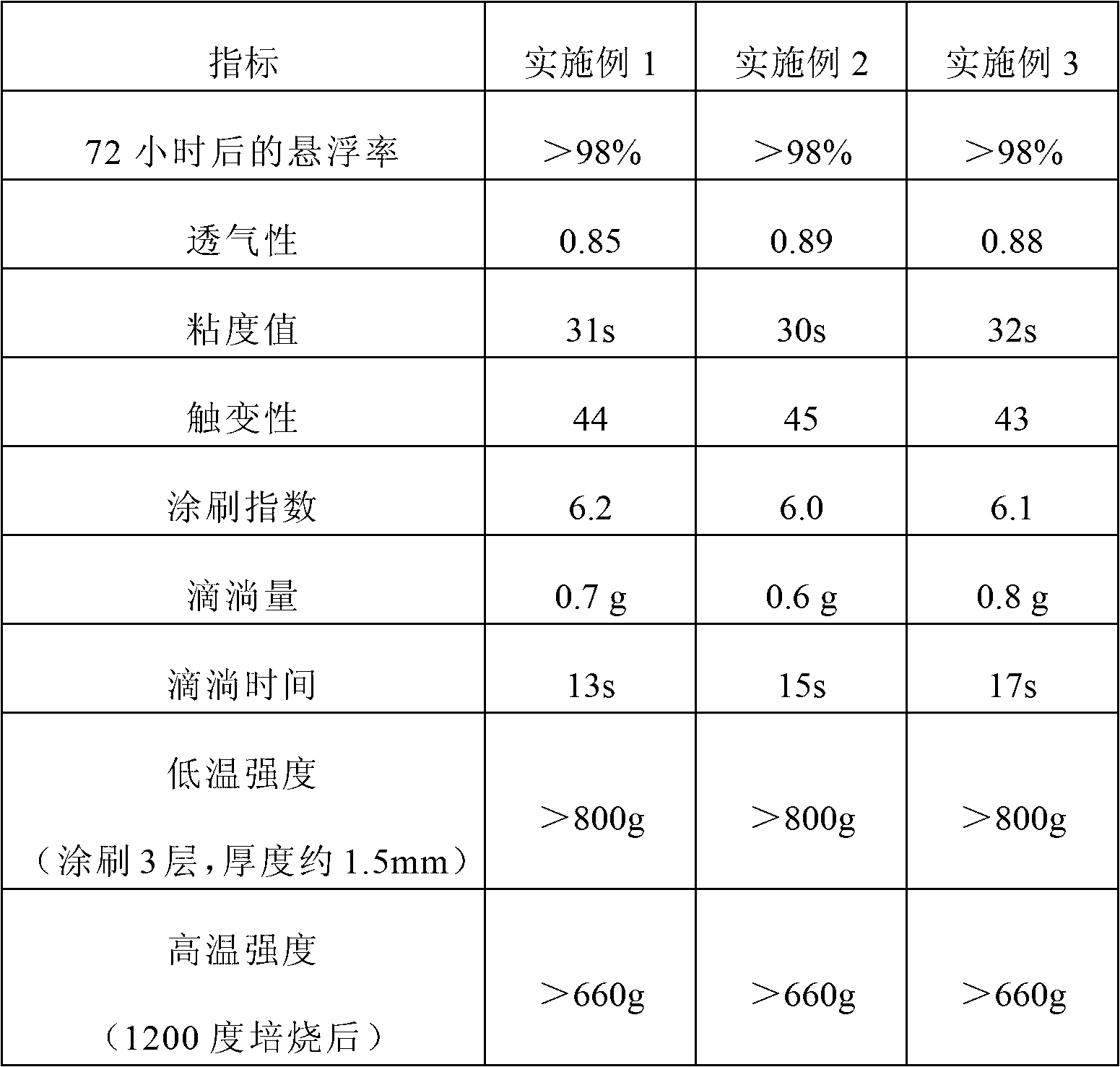

Method for preparing solid-mold casting coating material for large-sized cast parts

InactiveCN103100651AImprove performanceIncrease stiffnessFoundry mouldsFoundry coresRed Ferric OxideCarboxymethyl cellulose

The invention discloses a method for preparing a solid-mold casting coating material for large-sized cast parts. According to the method, the solid-mold casting coating material is prepared from the following ingredients in parts by weight: 68-75 parts of quartz powder, 5-7 parts of wood ash, 5-7 parts of fly ash, 10-12 parts of water glass, 10-12 parts of sodium bentonite, 4-6 parts of nano calcium carbonate, 1-2 parts of lignosulfonic acid, 2-4 parts of carboxymethyl cellulose, 0.3-0.7 part of glycerine, 2-4 parts of sodium borate, 5-7 parts of starch paste, 1.4-1.6 parts of silica sol, 1-2 parts of nanoscale ceramic powder, 0.5-0.8 part of red ferric oxide powder, 1-2 parts of sodium tripolyphosphate, 4-5 parts of potassium feldspar powder and 525-635 parts of water. The solid-mold casting coating material prepared by the method has excellent gas permeability and quick-drying performance in both a high-temperature environment and a low-temperature environment, thereby meeting the production requirements of the large-sized cast parts.

Owner:辽宁佳和精密金属有限公司

Method for preparing high-adhesiveness solid-mold casting coating material

InactiveCN103100649AImprove performanceIncrease stiffnessFoundry mouldsFoundry coresRed Ferric OxideCarboxymethyl cellulose

The invention discloses a method for preparing a high-adhesiveness solid-mold casting coating material. According to the method, the high-adhesiveness solid-mold casting coating material is prepared from the following ingredients in parts by weight: 65-75 parts of bauxite chamotte, 5-7 parts of meerschaum powder, 10-12 parts of corundum powder, 10-12 parts of water glass, 4-6 parts of water glass, 1-2 parts of lignosulfonic acid, 0.8-1.5 parts of sodium carboxymethyl cellulose, 5-7 parts of starch paste, 0.4-0.6 part of sodium benzoate, 1-2 parts of nanoscale ceramic powder, 0.5-0.8 part of red ferric oxide powder, 2-3 parts of olivine powder, 2-3 parts of hollow glass beads and 25-35 parts of water. The solid-mold casting coating material prepared by the method has strong wear resistance, high adhesiveness and excellent gas permeability and quick-drying performance in both a high-temperature environment and a low-temperature environment, thereby meeting the production requirements of large-sized cast parts.

Owner:常州市大华环宇机械制造有限公司

Lost foam coating and preparation method thereof

ActiveCN102836950AImprove breathabilityStrong adhesionFoundry mouldsFoundry coresRed Ferric OxideSodium Bentonite

The invention relates to a lost foam coating and a preparation method thereof. The coating comprises the following components in parts by weight: 45-55 parts of bauxite clinker, 8-15 parts of alundum powder, 20-25 parts of quartz powder, 3-8 parts of flaky graphite, 1-3 parts of sodium-based bentonite, 0.5-1.5 parts of CMC (Carboxyl Methyl Cellulose), 0.5-1.5 parts of polyvinyl alcohol, 1-3 parts of silica sol, 0.1-0.3 part of T-80, 0.2-0.4 part of n-caprylic alcohol and 1-3 parts of red ferric oxide powder. The lost foam coating provided by the invention has better high-temperature permeability and good brushability. The lost foam coating has high permeability, extremely strong adhesion and good brushability on the premise of improving the strength of a foam pattern, the foam pattern can meet the handling requirement of a large-sized casting after being dried, and the sand adhesion resistance is high.

Owner:苏州科博尔机床集团有限公司

Method for preparing solid-mold casting coating material

InactiveCN103100655AImprove performanceHigh anti-sand sticking abilityFoundry mouldsFoundry coresCarboxymethyl celluloseRed Ferric Oxide

The invention discloses a method for preparing a solid-mold casting coating material. According to the method, the solid-mold casting coating material is prepared from the following ingredients in parts by weight: 65-75 parts of rectorite powder, 5-7 parts of diatomite, 10-12 parts of wood ash, 10-12 parts of sodium bentonite, 4-6 parts of nano attapulgite, 1-2 parts of sodium tripolyphosphate, 0.8-1.5 parts of sodium carboxymethyl cellulose, 5-7 parts of starch paste, 1.4-1.6 parts of silica sol, 1-2 parts of nanoscale ceramic powder, 0.5-0.8 part of red ferric oxide powder and 525-535 parts of water. The solid-mold casting coating material prepared by the method has high wear resistance and excellent gas permeability and quick-drying performance in both a high-temperature environment and a low-temperature environment, thereby meeting the production requirements of large-sized cast parts.

Owner:佛山市蓝林新材料科技有限公司

Method for preparing high-wear-resistance solid-mold casting coating material

ActiveCN103100657AImprove performanceHigh anti-sand sticking abilityFoundry mouldsFoundry coresRed Ferric OxideCarboxymethyl cellulose

The invention discloses a method for preparing a high-wear-resistance solid-mold casting coating material. According to the method, the high-wear-resistance solid-mold casting coating material is prepared from the following ingredients in parts by weight: 65-75 parts of quartz powder, 5-7 parts of diatomite, 10-12 parts of wood ash, 10-12 parts of sodium bentonite, 4-6 parts of nano attapulgite, 1-2 parts of lignosulfonic acid, 0.8-1.5 parts of sodium carboxymethyl cellulose, 5-7 parts of starch paste, 1.4-1.6 parts of silica sol, 1-2 parts of nanoscale ceramic powder, 0.5-0.8 part of red ferric oxide powder and 525-535 parts of water. The solid-mold casting coating material prepared by the method has high wear resistance and excellent gas permeability and quick-drying performance in both a high-temperature environment and a low-temperature environment, thereby meeting the production requirements of large-sized cast parts.

Owner:太湖汇徽新材料股份有限公司

Method for preparing solid-mold casting coating material for cast aluminum

ActiveCN103100652AImprove performanceHigh anti-sand sticking abilityFoundry mouldsFoundry coresRed Ferric OxideSodium Bentonite

The invention discloses a method for preparing a solid-mold casting coating material for cast aluminum. According to the method, the solid-mold casting coating material is prepared from the following ingredients in parts by weight: 65-75 parts of quartz powder, 5-7 parts of plant ash, 5-7 parts of slag, 10-12 parts of corundum powder, 10-12 parts of sodium bentonite, 4-6 parts of nano attapulgite, 1-2 parts of lignosulfonic acid, 2-4 parts of polyvinyl alcohol, 0.3-0.7 part of n-octanol, 2-4 parts of sodium borate, 5-7 parts of starch paste, 1.4-1.6 parts of silica sol, 1-2 parts of nanoscale ceramic powder, 0.5-0.8 part of red ferric oxide powder and 525-535 parts of water. The solid-mold casting coating material prepared by the method has excellent gas permeability and quick-drying performance in both high-temperature environments and low-temperature environments, thereby being capable of meeting the production requirements of large-sized cast parts.

Owner:深圳市倍耐德材料科技有限公司

Red herbal dentifrice

A dentifrice composition of the invention can be applied to teeth and / or gums by any conventional A dentifrice composition comprises (a) calcium carbonate having properties of particle size and angularity effective to provide mild abrasivity to dental enamel; (b) red iron oxide of low abrasivity in an effective amount on which to impart red color to the composition; and (c) a herbal component comprising at least one botanical or extract thereof, in a total herbal component amount effective to promote oral health.

Owner:COLGATE PALMOLIVE CO

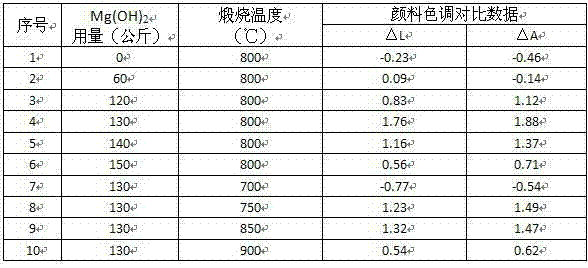

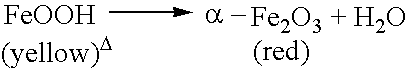

Preparation method of superfine iron oxide red pigment with high glossiness and pure red tone

The invention mainly discloses a preparation method of a superfine iron oxide red pigment with high glossiness and pure red tone. The preparation method comprises the following steps of: preparing a solution from refined ferrous sulfate, neutralizing the solution with a mixed alkaline solution, heating to 40-50 DEG C, and oxidizing to obtain special seed crystals; carrying out secondary oxidization under the condition of existence of seed crystals, depositing generated iron sesquioxide on special crystal nucleus, neutralizing diluted ammonia water with the concentration of about 8 percent by using the generated sulfuric acid, controlling PH of the system to 3.0-5.0, continuously dropwise adding the ferrous sulfate and the diluted ammonia water, and gradually growing the crystal nucleus to form the orange red iron oxide pigment; and pulping an organic red iron oxide filter cake, and calcining at high temperature to obtain the superfine iron oxide red pigment with high glossiness and pure red tone. The preparation method disclosed by the invention has the advantages that: the superfine iron oxide red pigment with high glossiness and pure red tone is prepared by utilizing the preparation method disclosed by the invention; and the preparation method is realized by using a method of reducing the influence degree to the environment and has favorable environment-friendly effect.

Owner:南通宝聚颜料有限公司

Method for preparing quick-drying solid-mold casting coating material

InactiveCN103100656AImprove performanceHigh anti-sand sticking abilityFoundry mouldsFoundry coresRed Ferric OxidePolyvinyl alcohol

The invention discloses a method for preparing a quick-drying solid-mold casting coating material. According to the method, the quick-drying solid-mold casting coating material is prepared from the following ingredients in parts by weight: 65-75 parts of quartz powder, 5-7 parts of plant ash, 10-12 parts of corundum powder, 10-12 parts of sodium bentonite, 4-6 parts of nano attapulgite, 1-2 parts of lignosulfonic acid, 0.8-1.5 parts of polyvinyl alcohol, 5-7 parts of starch paste, 1.4-1.6 parts of silica sol, 1-2 parts of nanoscale ceramic powder, 0.5-0.8 part of red ferric oxide powder and 525-535 parts of water, wherein a binder consists of a normal-temperature binder and a high-temperature binder, and the mass ratio of the normal-temperature binder to the high-temperature binder is 2: 3. The solid-mold casting coating material prepared by the method has excellent gas permeability and quick-drying performance in both high-temperature environments and low-temperature environments, thereby being capable of meeting the production requirements of large-sized cast parts.

Owner:江苏华业特钢制造有限公司

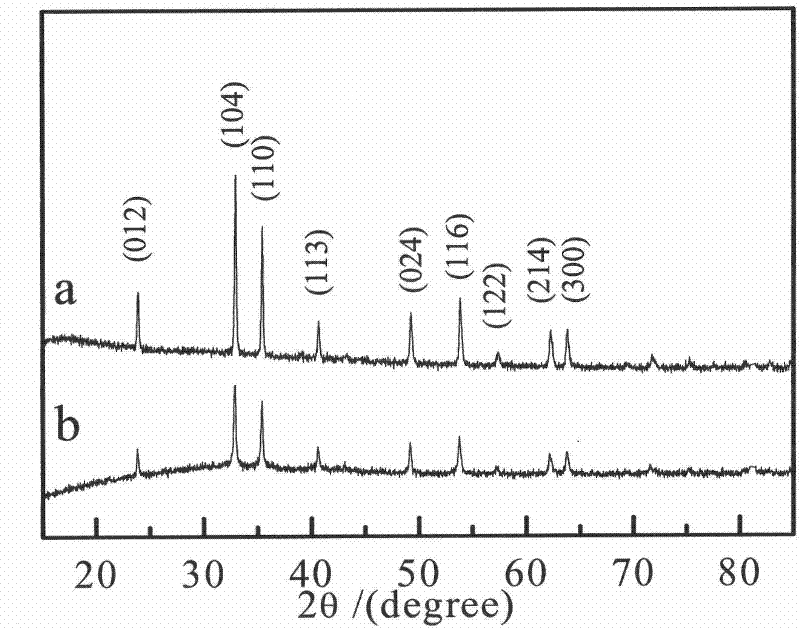

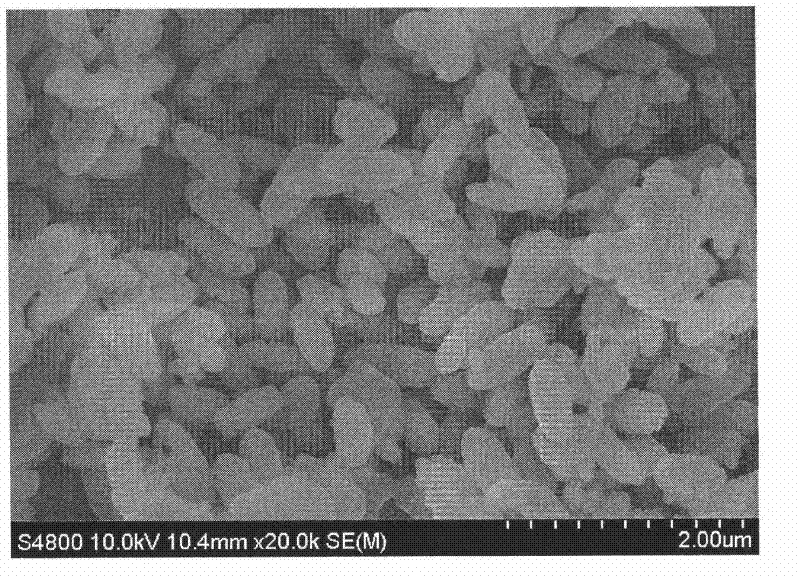

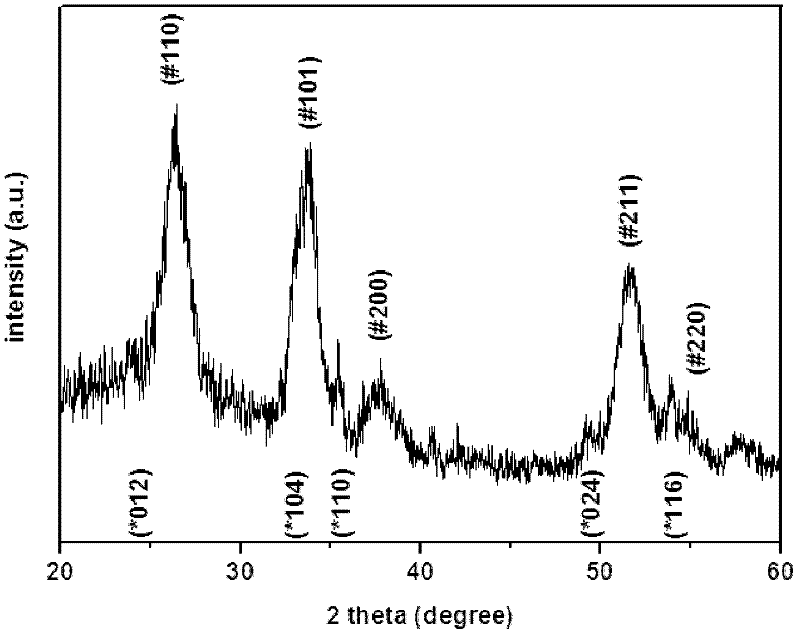

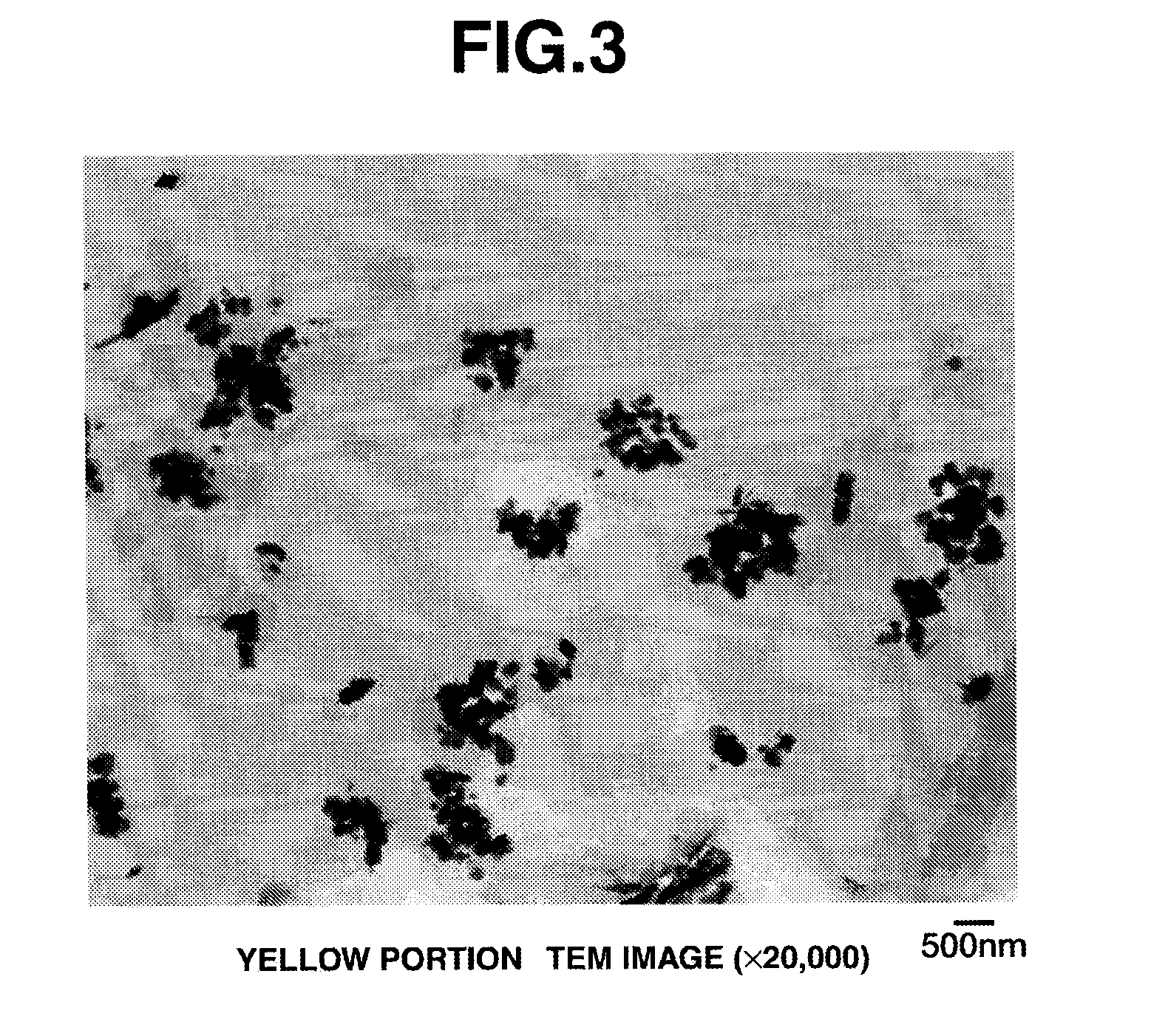

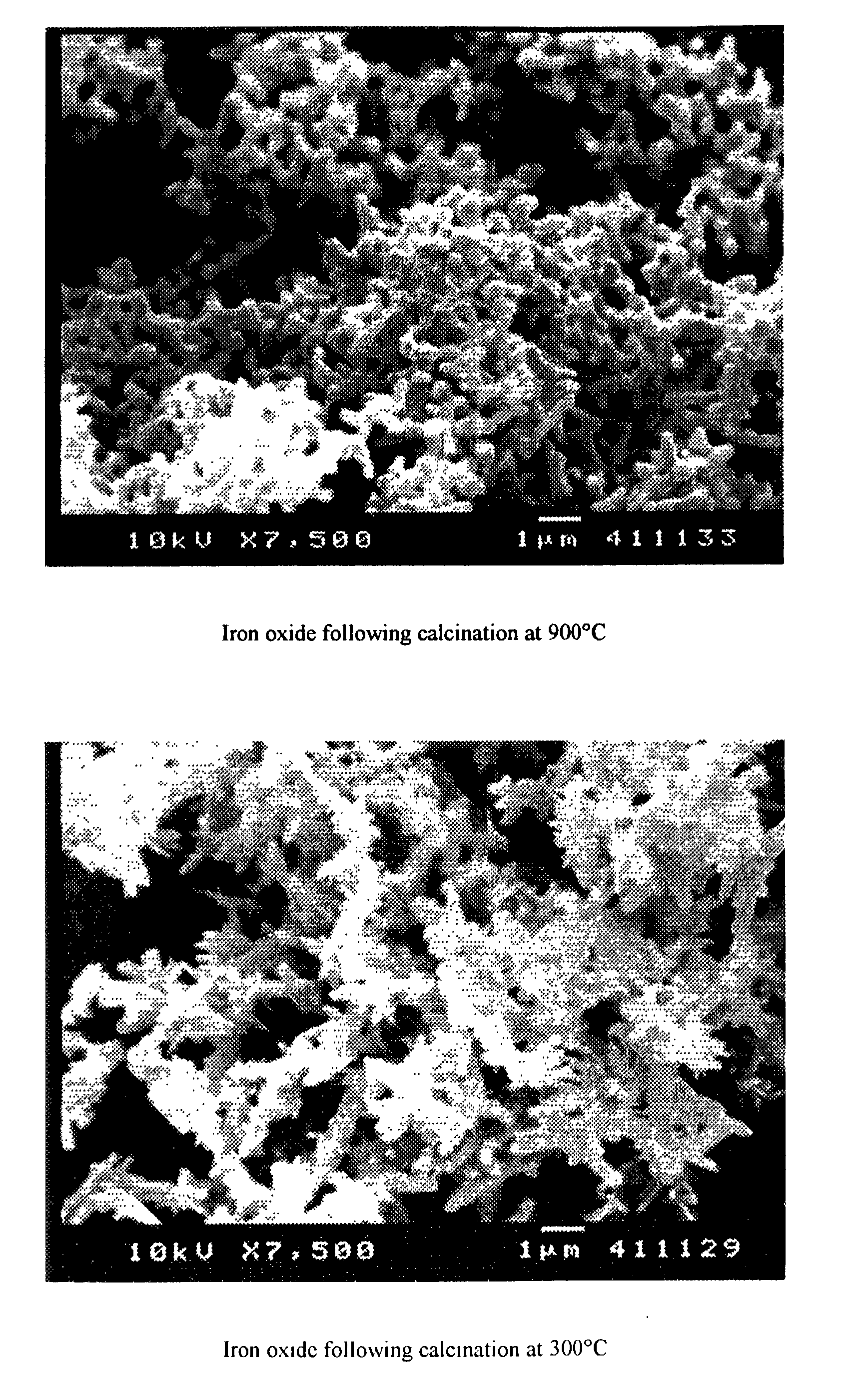

A kind of preparation method and application of rice granular α-ferric oxide

InactiveCN102259933AHigh structural purityImprove electrochemical performanceCell electrodesNanotechnologyIron saltsFreeze-drying

The invention discloses a preparation method and application of rice-like alpha-iron trioxide. The preparation process adopts a hydrothermal reaction method, and the specific steps are as follows: first, mechanical stirring is used to uniformly disperse the iron salt and the surfactant in deionized water to obtain a mixed solution; the mixed solution is placed in a reactor for hydrothermal reaction; finally, the obtained The product is washed and freeze-dried to obtain a precursor; then the precursor is calcined at 200-900° C. for 1-40 hours, cooled to room temperature and ground to obtain red rice-like ferric oxide powder material. The invention has the advantages of wide source of raw materials, simple preparation method, convenient operation, green and pollution-free, and the obtained material has high structural purity, regular morphology and uniform particle size distribution. It can reach more than 1000mAh / g, and has better cycle life.

Owner:CHINA UNIV OF MINING & TECH

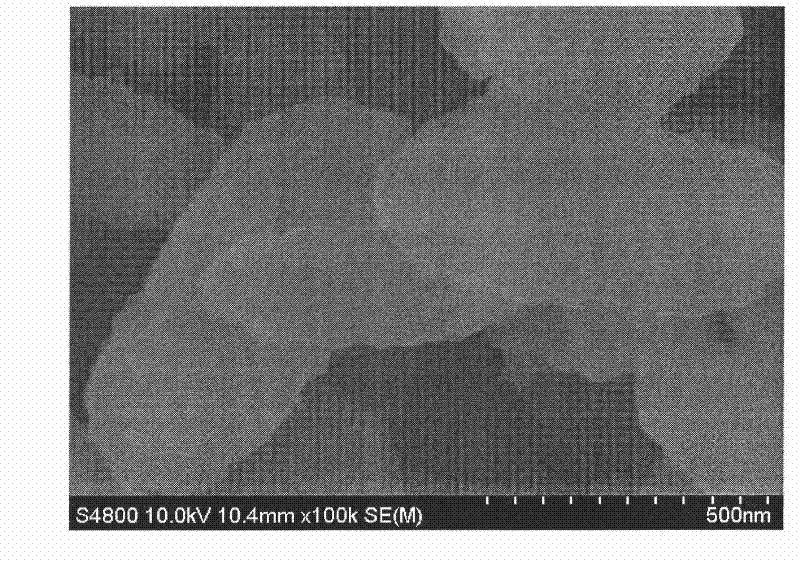

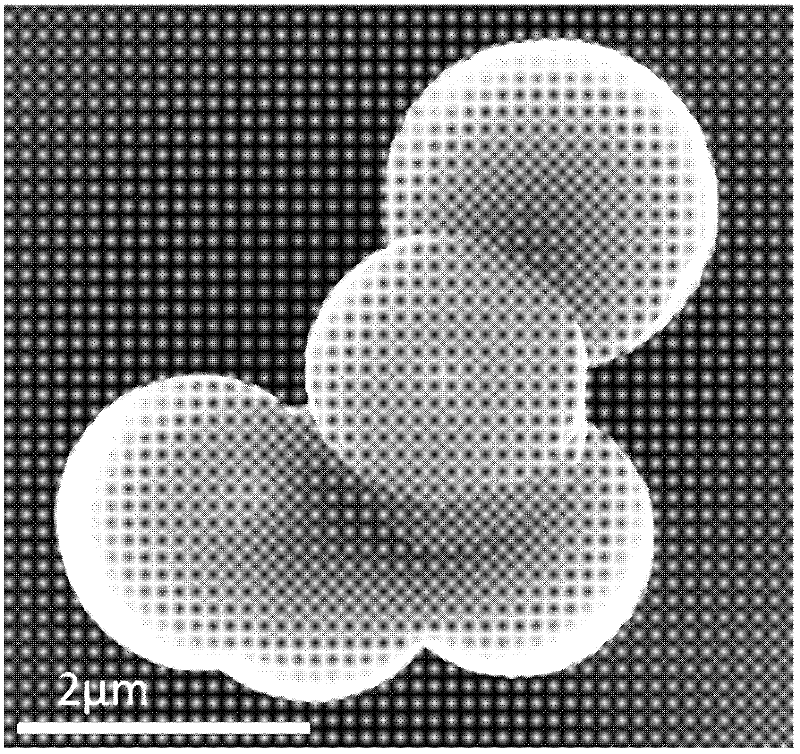

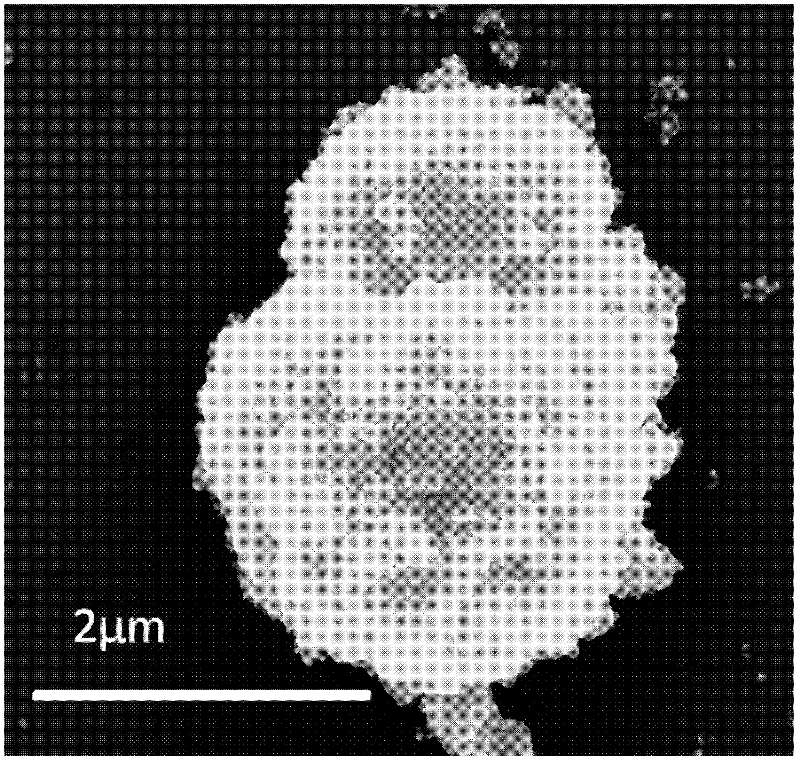

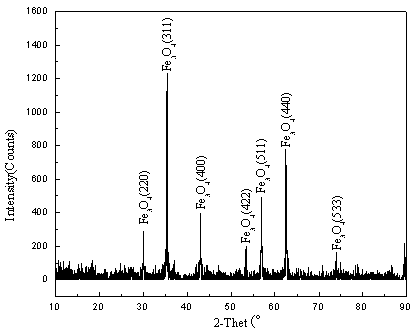

Preparation method for ferric oxide coated tin dioxide nanometer polycrystalline microballoon

The invention relates to a preparation method for ferric oxide coated tin dioxide nanometer polycrystalline microballoons, and belongs to the technical field of preparation of new energy materials of inorganic compounds. The ferric oxide coated tin dioxide nanometer polycrystalline microballoons are prepared by the hydrothermal method with cane sugar, urea, tin tetrachloride and ferric trichloride as raw materials. The method comprises the following steps: dissolving tin tetrachloride in water, adding cane sugar, carrying out stirring for 0.5 hour at room temperature, putting the obtained solution into a hydro-thermal vessel with a volume of 45 ml, heating the solution to a temperature of 180 DEG C for a hydro-thermal reaction for 24 hours, carrying out centrifugal separation when the reaction is finished, and carrying out rinsing with considerable deionized water so as to obtain black powder; dissolving ferric trichloride and urea in a mixed solution of ethanol and water, adding the black powder into the solution, carrying out stirring and ultrasonic treatment, putting the obtained liquid into the hydro-thermal vessel with a volume of 45 ml, and heating the liquid to a temperature of 60 DEG C for a hydro-thermal reaction for 48 hours; carrying out centrifugal separation when the reaction is finished, and carrying out rinsing with considerable deionized water and sintering at a temperature of 500 DEG C in air for 4 hours so as to obtain red ferric oxide coated tin dioxide nanometer polycrystalline microballoons. The invention has the advantages of simple operation, cheap raw materials, environmental protection, high yield, etc.

Owner:BEIHANG UNIV

Water-based antirust paint and preparation method thereof

ActiveCN103555109AImprove rust resistanceIncreased durabilityAnti-corrosive paintsRed Ferric OxideWater based

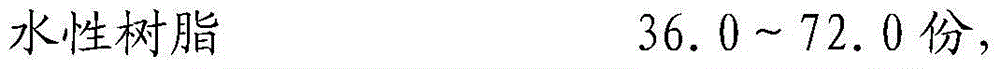

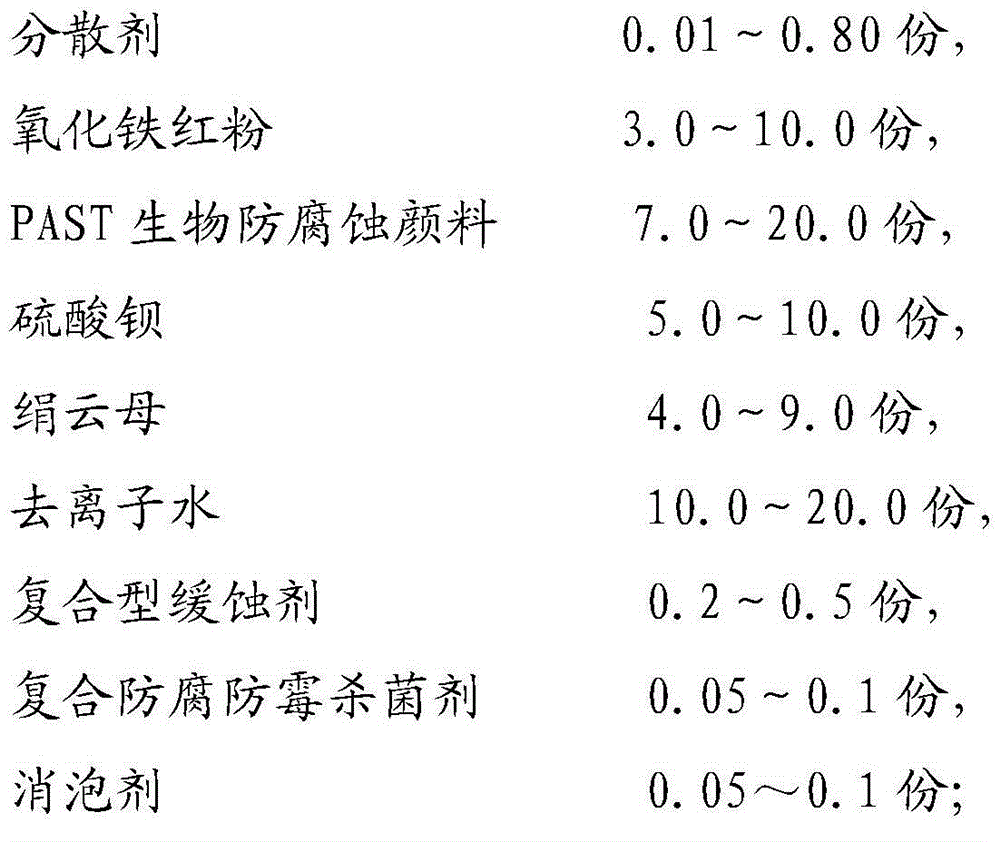

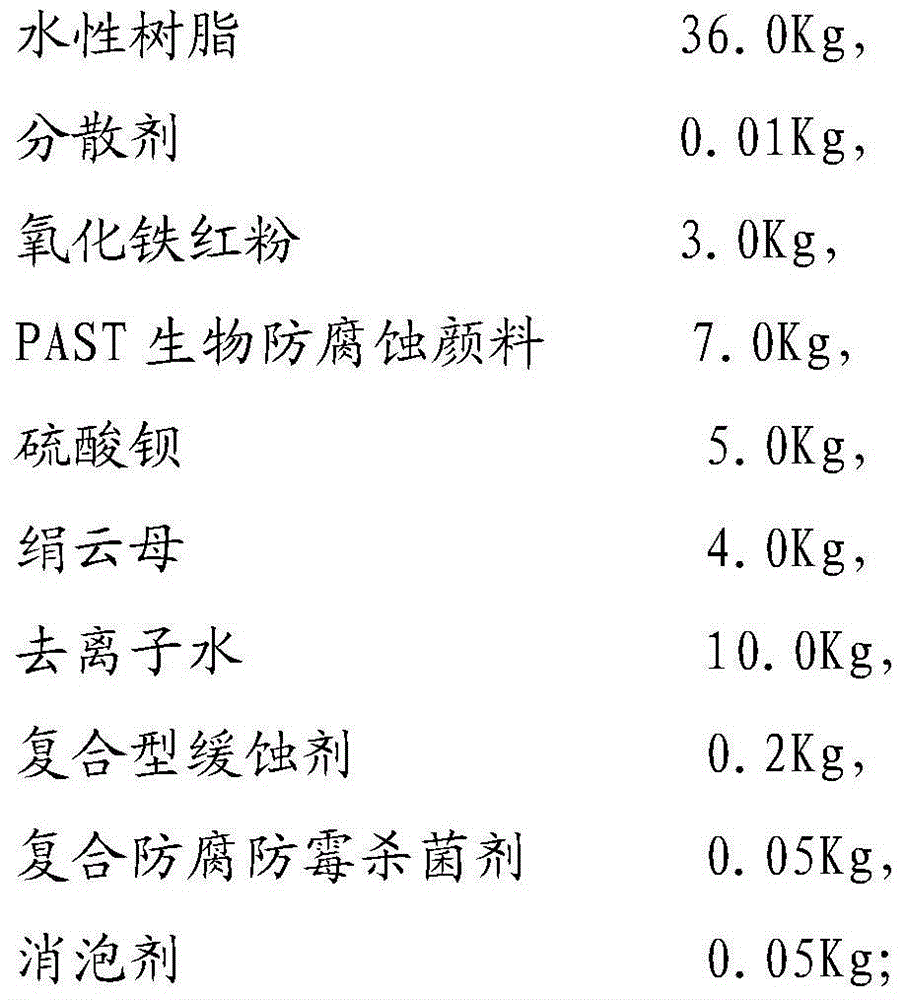

The invention discloses a water-based antirust paint and a preparation method thereof. The water-based antirust paint comprises the following active ingredients in parts by weight: 36.0-72.0 parts of water-based resin, 0.01-0.80 part of a dispersing agent, 3.0-10.0 parts of red ferric oxide powder, 7.0-20.0 parts of PAST-2 biological anti-corrosion pigment, 5.0-10.0 parts of barium sulfate, 4.0-9.0 parts of sericite, 10.0-20.0 parts of deionized water, 0.2-0.5 part of a composite type corrosion inhibitor, 0.05-0.1 part of composite anti-corrosion mould-proof bactericide, and 0.05-0.1 part of a defoaming agent. The preparation method comprises the following steps of adding the dispersing agent, composite anti-corrosion mould-proof bactericide, composite type corrosion inhibitor and the defoaming agent into the deionized water, stirring and dissolving, then adding red ferric oxide powder, PAST-2 biological anti-corrosion pigment, barium sulfate and sericite, and stirring at high speed and dispersing to obtain color paste; carrying out ball milling on the color paste, then adding the water-based resin, and evenly dispersing to obtain the water-based antirust paint.

Owner:山东乐化漆业股份有限公司

Method for extracting and preparing nickel carbonate, nickel sulfate and red ferric oxide from serpentine and tailings thereof

ActiveCN102616867AHigh recovery rateEfficient use ofFerric oxidesNickel sulfatesRed Ferric OxideFractional Precipitation

The invention discloses a method for extracting and preparing nickel carbonate, nickel sulfate and red ferric oxide from serpentine and tailings thereof. The serpentine and tailings thereof are used as raw materials. The method comprises the following unit processes of: pre-treating; performing acid leaching; performing fractional precipitation; performing ammonia leaching; acidifying; preparing nickel carbonate; preparing nickel sulfate; and calcining. According to the method, useful components such as nickel and iron in the serpentine can be fully and effectively utilized, products such as nickel carbonate, nickel sulfate and red ferric oxide with tight market demand can be produced, and higher nickel and iron recovery rate can be obtained. The purity of the nickel carbonate is 47.93 percent in terms of nickel and the yield is 90.10 percent; the purity of the nickel sulfate is 22.12 percent in terms of nickel and the yield is 85.73 percent; and the purity of the red ferric oxide is 92.40 percent in terms of Fe2O3 and the yield is 92.94 percent.

Owner:HEFEI UNIV OF TECH

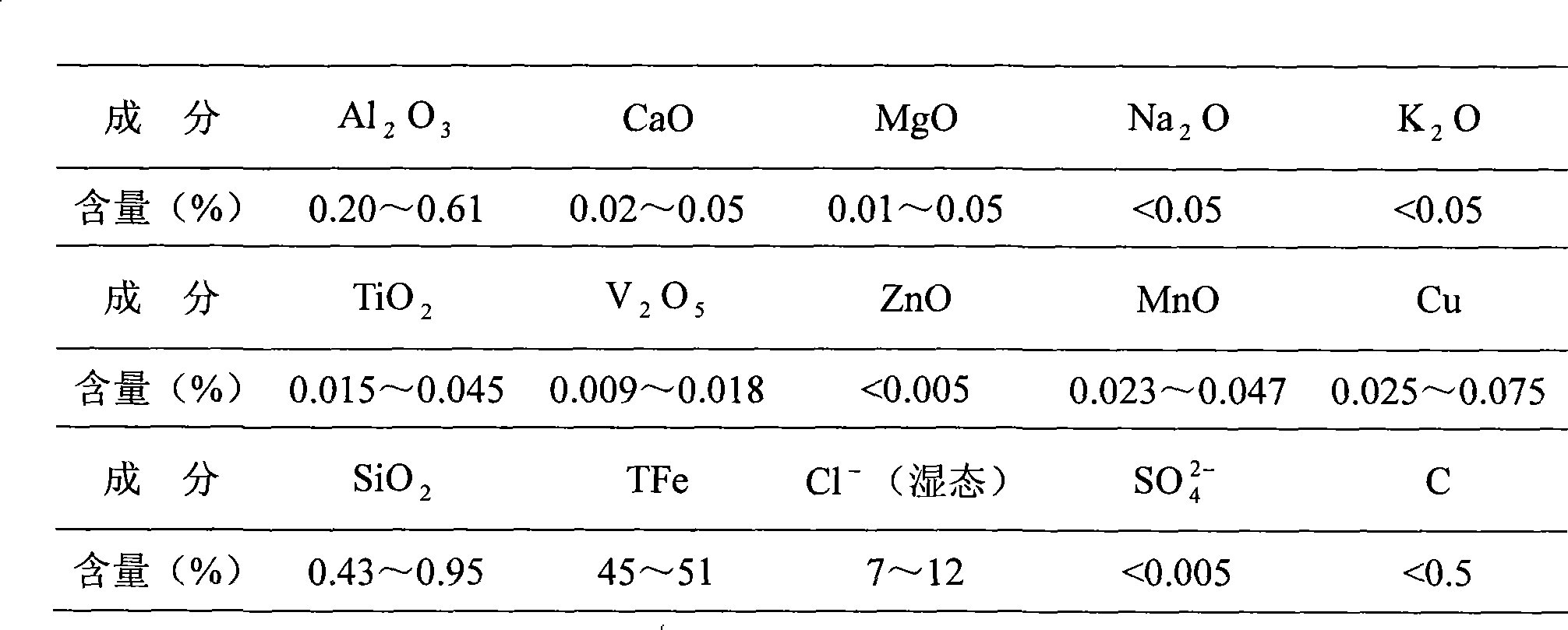

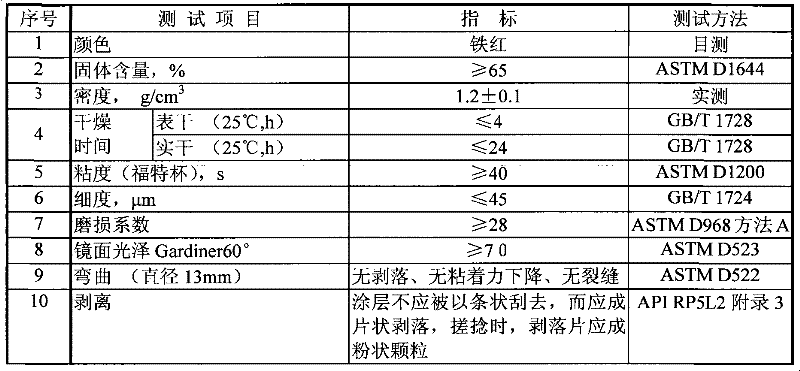

Anti-drag and abrasion-resistant paint for natural gas line

ActiveCN101698773AHigh surface glossPromote wettingEpoxy resin coatingsFerric oxide yellowMicrosphere

The invention discloses an anti-drag and abrasion-resistant paint for a natural gas line. Raw materials of the paint comprise two components A and B, wherein the component A comprises a phenolic aldehyde amine curing agent, a flatting agent, a defoaming agent, a dispersant, a thickening agent, white ceramic powder, red ferric oxide powder, mica ferric oxide, yellow iron oxide powder, light calcium carbonate and an environmentally-friendly mixed solvent; and the component B comprises epoxy resin, the flatting agent and the environmentally-friendly mixed solvent. The anti-drag and abrasion-resistant paint has the following advantages that: 1, compared with the conventional polyamide curing agent, the phenolic aldehyde amine curing agent has the advantages of more convenient construction in winter, better wettability for base materials, high coating crosslinking density, no pinhole and stronger solvent resistance and corrosion resistance; 2, the coating surface of the paint is smooth and specular gloss can reach more than 70 and is improved by15 to 30 percent compared with that of the like products; and 3, the paint is added with an abrasion-resistant filler, such as white ceramic, hollow microsphere and the like, so the abrasion resistance of the coating is greatly improved.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

Hot rolled strip surface processing method

InactiveCN107790506AReduce breakageReduce thicknessTemperature control deviceWork treatment devicesRed Ferric OxideMaterials science

A surface treatment method for hot-rolled steel strips, which is carried out in the following steps: (1) heating the slab to 1220-1250 ° C, descaling after heat preservation; (2) rough rolling, the cumulative reduction is 75-77%, Hot coiling at 1000~1100°C to obtain the intermediate billet; (3) second descaling, the temperature is 1100~1300°C; then finish rolling, the cumulative reduction of finish rolling is 80~90%; (4) with 10~ Cool at a speed of 12°C / s to 500~520°C, and then coil. The process of the present invention can effectively reduce FeO fragmentation during the rolling process, avoid the subsequent generation of red scale, and at the same time effectively reduce the thickness of scale, and finally realize the flexible production of scale control.

Owner:王刚

Water-soluble epoxy red ferric oxide primer and method of preparing same

InactiveCN101333404AGood emulsificationEasy to emulsifyAnti-corrosive paintsEpoxy resin coatingsBisphenolBisphenol A

The invention relates to waterborne epoxy iron red shop primer and a preparation method thereof. The waterborne epoxy iron red shop primer contains two compositions; A composition is prepared by the steps of dissolving epoxy-modified waterborne amine hardener in deionized water, then adding wetting dispersant, polymethyl siloxane, iron oxide red, precipitated barium sulfate, sericite, compound ferrotitanium powder, and aluminium triphosphate, and mixing, blending and grinding the mixture; B composition is prepared by mixing and blending bisphenol-a-type epoxy resin and butyl glycidyl ether. The waterborne epoxy iron red shop primer is safe and environment-friendly and can be used as anticorrosive shop primer for interior and exterior walls of steel oil storage tanks in oil fields.

Owner:CNPC RES INST OF ENG TECH

Process for producing red iron oxide

Owner:ROCKWOOD ITALA

Method for preparing superfine iron oxide red pigment by utilizing discarded selenium drum powdered ink

InactiveCN102796402AEvenly dispersedPrevent precipitationPigment treatment with macromolecular organic compoundsDispersityMuffle furnace

The invention relates to a method for preparing a superfine iron oxide red pigment by utilizing discarded selenium drum powdered ink. The method comprises the following steps of: putting a discarded selenium drum into a waste selenium drum crushing and magnetic separation device, and performing crushing, magnetic separation, wind-force separation and the like to obtain metal (iron and aluminum) and plastics sequentially, and collecting to obtain black organic powdered ink; putting the collected powdered ink into a crucible, calcining in a muffle furnace at the temperature of 500 DEG C for 3 hours, and cooling naturally to obtain dark red iron oxide powder; adding 50 milliliters of water into a 100-milliliters flask, adding soda in an amount which is 1 to 1.5 percent of the mass of the water into the flask, and stirring uniformly to obtain a clarified solution; weighing 40 to 70 grams of dark red powder, adding the dark red powder into the clarified solution, and stirring by using a stirrer quickly; and adding polyvinyl pyrolidone (PVP) which accounts for 0.5 to 1 percent of the total mass (which is dissolved by using a solution of methanol and water in a volume ratio of 1:1), and continuing to stir to obtain red pigment paste which is uniform and high in dispersity. According to the superfine iron oxide pigment, a treatment process is simple, the wastes can be recycled, the discharge of the wastes is reduced, and environmental protection is facilitated.

Owner:SHANGHAI UNIV +1

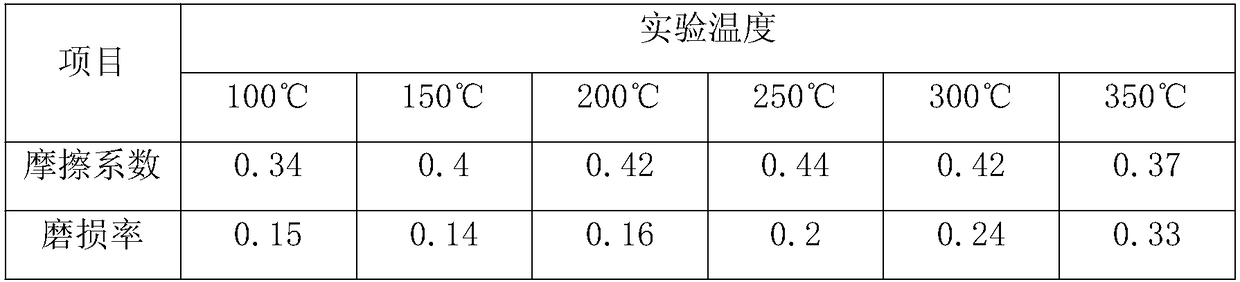

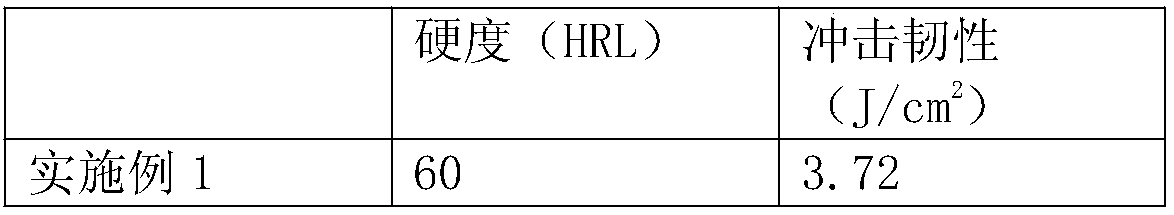

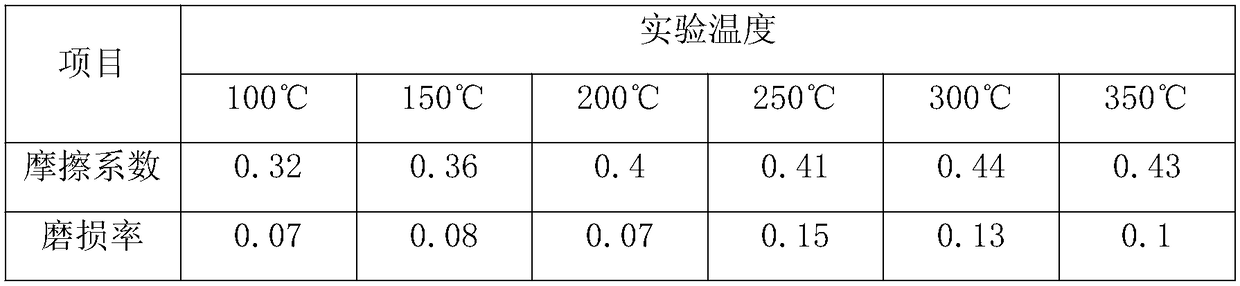

Friction block and preparation method thereof and brake pad

InactiveCN108506387AIncrease coefficient of frictionHigh hardnessOther chemical processesFriction liningFiberHeat conducting

The invention provides a friction block in a brake pad. The friction block is prepared from phenolic resin or boron modified phenolic resin or melamine modified phenolic resin, nitrile butadiene rubber powder, lignin fiber, activated carbon, expandable graphite, molybdenum disulfide, barium sulfate, calcium carbonate, calcium sulfate whisker, iron oxide yellow, aluminum oxide, red ferric oxide powder, silicon carbide, wollastonite, vermiculite powder and high abrasion furnace black. The invention further provides a preparation method of the friction block based on the component formula. The preparation method conducts ingredient strengthening and technology strengthening for the friction block, ingredient strengthening and technology strengthening realize powerful combination, and therefore the comprehensive performances comprising the friction coefficient, hardness, wear-resisting property, impact toughness, heat-conducting property, resistance to high temperature and corrosion resistance of the friction block in the brake pad are improved so as to meet the use requirements under the high-load, high-temperature, high-speed and high-corrosive environment. The invention further provides the brake pad comprising the friction pad.

Owner:UNIV OF JINAN

Moist cup-staining-free colorfast lip glaze and preparation method thereof

InactiveCN107661231AGood colorAvoid heavy feelingCosmetic preparationsMake-upStainingAdditive ingredient

The invention relates to moist cup-staining-free colorfast lip glaze. The moist cup-staining-free colorfast lip glaze is prepared from major ingredients of water, diphenyl isopropyl polydimethylsiloxane, tridecyl trimellitate, cetostearyl alcohol, cetostearyl alcohol, sucrose laurate, propanediol, hyaluronic acid, phenoxyethanol, ethylhexylglycerin, vitamin E, titanium dioxide, red iron oxide, yellow iron oxide, black iron oxide, acid red and carminic acid; a finished product is prepared through a serious of production processes of stirring melting, grinding, cooling, stirring and mixing, filling, packaging and the like. the decorous feeling of conventional lip glaze is avoided. Compared with conventional lip glaze, the lip glaze has the advantages that the removal is easy; secondary injury cannot be caused on the lips; the coloring degree is high; the cup staining is avoided; the colorfast effect is achieved; good use experience can be brought.

Owner:达威控股有限公司

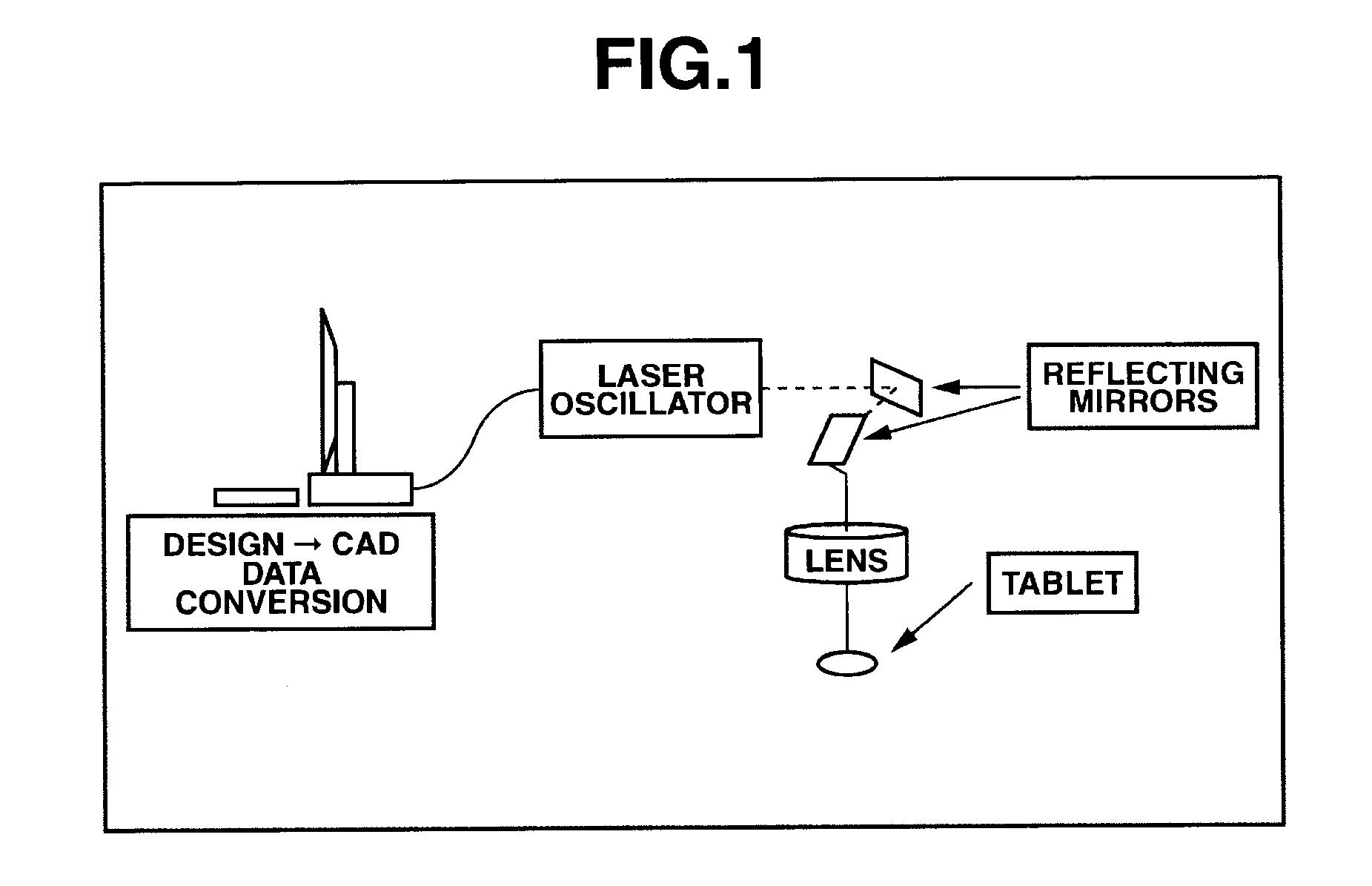

Method of marking a composition for use in oral administration

InactiveUS20090304601A1Improve security levelWithout reducing productivityPharmaceutical non-active ingredientsCapsule deliveryIntrathecalBuccal administration

There is provided a marking method that is highly productive and enables production of easily-identifiable compositions for use in oral administration such as drugs and foods without damaging the quality of the oral composition. The marking method according to the present invention is a method for marking such a composition for use in oral administration and includes the steps of: dispersing a change in color-inducing oxide in the composition for use in oral administration; and scanning a surface of the composition for use in oral administration with a laser beam at wavelengths of from 200 nm to 1100 nm and with from 0.1 W to 50 W average power in to make the particles of the change in color-inducing oxide agglomerate so as to become discolored. The change in color-inducing oxide used in the present invention is at least one selected from the group consisting of titanium dioxide, yellow ferric oxide, and red ferric oxide.

Owner:EISIA R&D MANAGEMENT CO LTD

Method for electrolyzing ferric oxide by using deep eutectic solvent to prepare ferroferric oxide

InactiveCN104233361ALow costWide variety of sourcesElectrolysis componentsElectrolysisHydrometallurgy

Owner:KUNMING UNIV OF SCI & TECH

Process for producing red iron oxide

The present invention relates to a process for producing red iron oxide with only marginal goethite content, wherein a ferrous chloride feedstock is employed as starting material. The process comprises precipitating lepidocrocite seeds having a high BET surface area by mixing the ferrous chloride feedstock with an alkali and oxidizing the obtained mixture, and growing the lepidocrocite seeds, whereby the lepidocrocite converts into red iron oxide.

Owner:ROCKWOOD ITALA

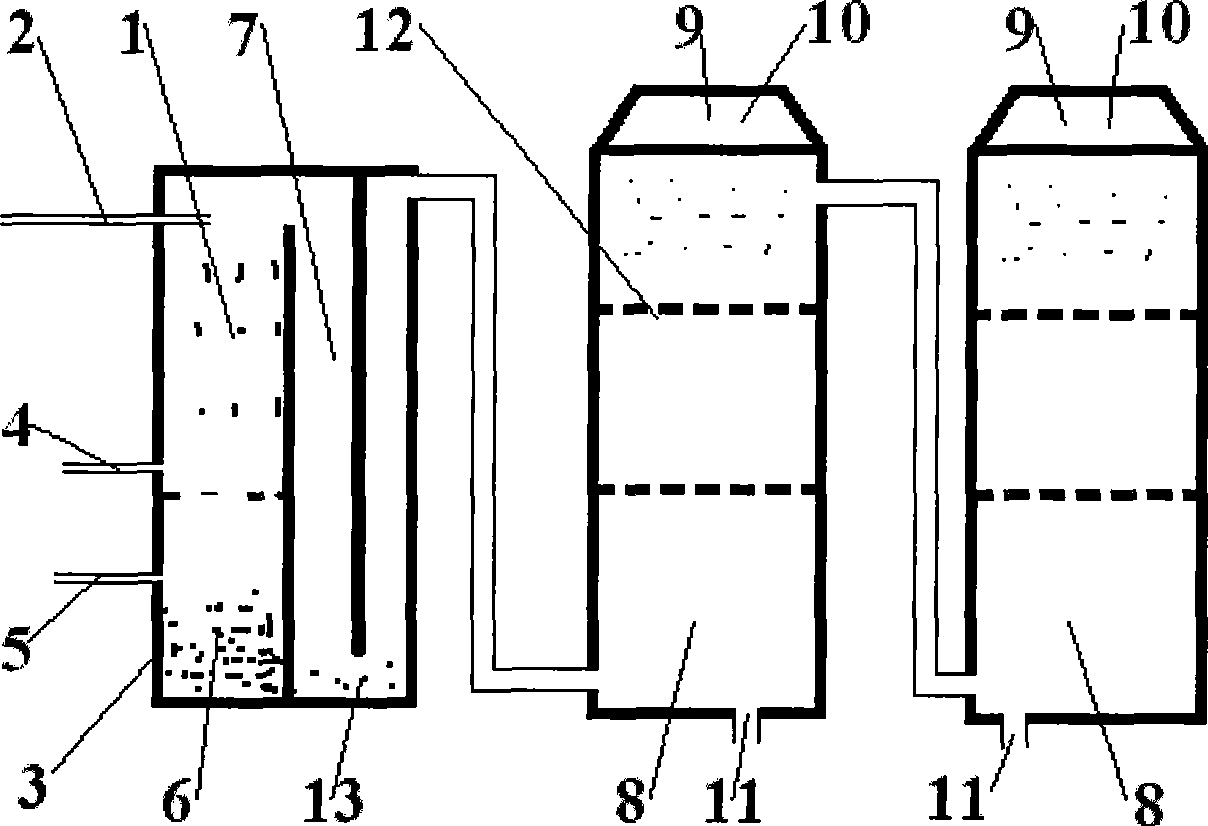

Acid washing iron red desilication filter cake treating device and treating method

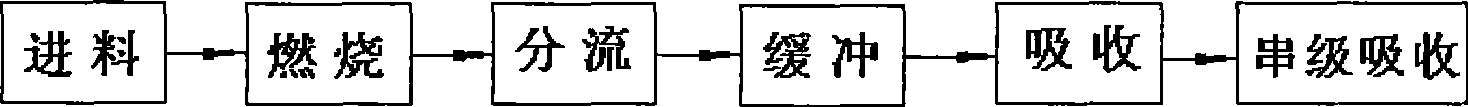

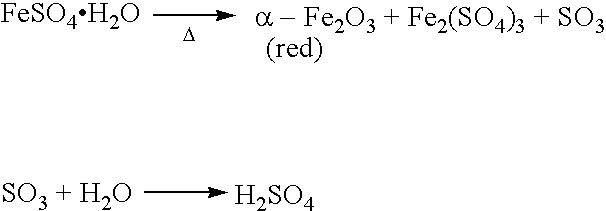

ActiveCN101367085ALess investmentSimple operation and maintenanceSolid waste disposalLiquid wasteProcess equipment

The invention belongs to the technical field of the metallurgical industry and discloses a device for treating a pickling red ferric oxide desiliconized filter mass, which is used for carrying out harmless treatment to the pickling red ferric oxide desiliconized filter mass. The treatment device is characterized in that according to a process sequence, the device is provided with a heating device and a reclaiming device which are communicated with each other; the heating device heats and decomposes the pickling red ferric oxide desiliconized filter mass; and the reclaiming device respectively reclaims a solid material and a gas material decomposed and produced by the heating device. The invention also discloses a treatment method adopting the treatment device. With the technical proposal, the harmless treatment is carried out to the filter mass with certain toxicity and harmfulness; the full ferric content of an obtained solid is over 64 percent; the property of the solid is close to the property of concentrated iron powder; the solid can be returned to a sintering system for use and can be also used as a desiliconizing agent for the pretreatment of molten iron; the obtained industrial hydrochloric acid can be used for other applications; and the whole production process produces no waste liquid and no toxic gas. The device has small investment for process equipment, simple operation and maintenance and good economical benefit.

Owner:MAANSHAN IRON & STEEL CO LTD

Anti-drag and abrasion-resistant paint for natural gas line

The invention discloses an anti-drag and abrasion-resistant paint for a natural gas line. Raw materials of the paint comprise two components A and B, wherein the component A comprises a phenolic aldehyde amine curing agent, a flatting agent, a defoaming agent, a dispersant, a thickening agent, white ceramic powder, red ferric oxide powder, mica ferric oxide, yellow iron oxide powder, light calcium carbonate and an environmentally-friendly mixed solvent; and the component B comprises epoxy resin, the flatting agent and the environmentally-friendly mixed solvent. The anti-drag and abrasion-resistant paint has the following advantages that: 1, compared with the conventional polyamide curing agent, the phenolic aldehyde amine curing agent has the advantages of more convenient construction in winter, better wettability for base materials, high coating crosslinking density, no pinhole and stronger solvent resistance and corrosion resistance; 2, the coating surface of the paint is smooth andspecular gloss can reach more than 70 and is improved by15 to 30 percent compared with that of the like products; and 3, the paint is added with an abrasion-resistant filler, such as white ceramic, hollow microsphere and the like, so the abrasion resistance of the coating is greatly improved.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

Low sulfur red iron oxide useful as a catalyst or catalyst component and a process for making low sulfur red iron oxide

InactiveUS20040194664A1Easy and inexpensive processImprove propertiesPigmenting treatmentFerric oxidesRed Ferric OxideSulfur

A process for making red iron oxide containing less than 1500 ppm sulfur is described. The iron oxide is useful as a catalyst or catalyst ingredient in a wide variety of processes and in a preferred embodiment has an acicular shape.

Owner:ELEMENTIS PIGMENTS

Method for preventing powdery peeling of hot-rolled pickling-free automobile beam steel scale

ActiveCN108262357AImprove conversion efficiencyImproves powdery flakingTemperature control deviceWork cooling devicesRed Ferric OxideSuperficial mass

The invention discloses a method for preventing powdery peeling of hot-rolled pickling-free automobile beam steel scale, and belongs to the technical field of steel rolling. The composition and ratioof Fe3O4 and FeO are adjusted by controlling the content of the silicon element to be within the range of 0.28-0.30wt%, and 0.200-0.225wt% of chrome element is added for preventing red scale from being produced. By optimizing temperature technology parameters, a set of fans are added in the rolling cooling process, the blast capacity is 40000 m<3> / h, air pressure is 255 Pa, the cooling speed in the rolling process is improved, and therefore the FeO-Fe3O4 conversion efficiency in the rolling process is improved. By means of the method, the content of Fe3O4 generated in pickling-free steel is about 80%, the content of FeO is about 4%, the surface quality is greatly improved, the phenomenon of powdery peeling of hot-rolled pickling-free automobile beam steel scale is effectively prevented, and meanwhile scale plasticity is improved.

Owner:UNIV OF SCI & TECH BEIJING

Lost foam coating and preparation method thereof

ActiveCN102836954AExcellent peelabilityImprove breathabilityFoundry mouldsFoundry coresSodium BentonitePolyvinyl alcohol

The invention relates to a lost foam coating and a preparation method thereof. The coating comprises the following components in parts by weight: 30-40 parts of bauxite clinker, 15-25 parts of magnesium oxide powder, 1-3 parts of sodium-based bentonite, 0.5-1.5 parts of CMC (Carboxyl Methyl Cellulose), 0.5-1.5 parts of polyvinyl alcohol, 0.3-0.8 part of phenol-formaldehyde resin, 0.2-0.4 part of n-caprylic alcohol and 0.5-1.5 parts of red ferric oxide powder. The lost foam coating provided by the invention has an excellent stripping effect and superior permeability, i.e., phenomena of air pores and slag inclusion can be effectively prevented, the quality of a casting is improved, subsequent treatment is simple, and a large amount of labor is saved.

Owner:苏州科博尔机床集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com