Method for preventing powdery peeling of hot-rolled pickling-free automobile beam steel scale

A technology of automobile girder steel and iron oxide scale, which is applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of affecting surface quality, cost increase, powder peeling, etc., to improve conversion efficiency and meet the needs of users Requirements, the effect that is not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

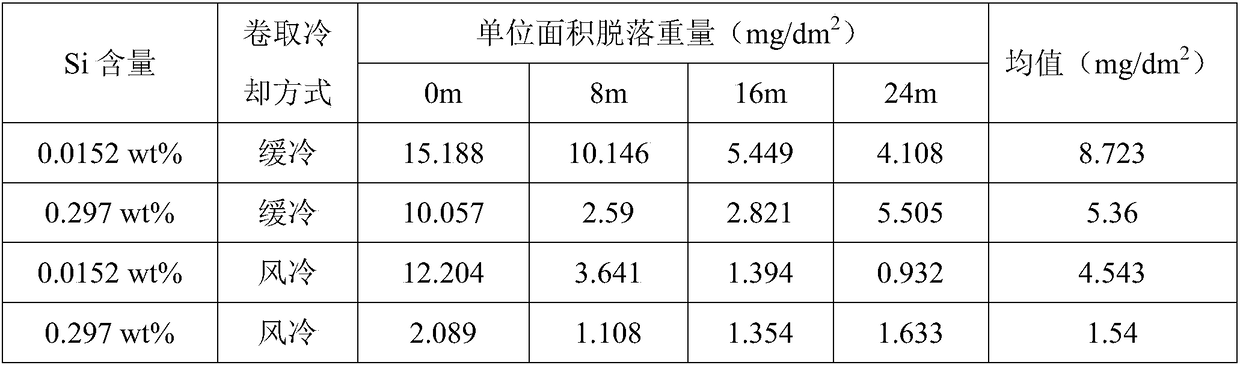

Embodiment 1

[0023] This embodiment comprises the following steps in turn:

[0024] The composition of the hot-rolled pickling-free automobile frame steel with a thickness of 8mm is C: 0.0083wt%; Mn: 0.726wt%; P: 0.0071wt%; S: 0.0031wt%; Al: 0.046wt%. The content of Si is strictly controlled to 0.0152wt%, and the rest is iron and unavoidable trace elements.

[0025] During the billet hot rolling process, the furnace time is strictly controlled to 200 minutes.

[0026] The entrance temperature of finishing rolling is less than 1030℃, the temperature of finishing rolling is controlled at 880℃, and the coiling temperature is controlled at 580℃.

[0027] During the descaling process, the first descaling and the second descaling are fully put into use, and the descaling water between the finishing mill stands is put into use.

[0028] Two-level automatic control of work roll cooling water, and two-level automatic control when the cooling water between racks is used and the water volume is inc...

Embodiment 2

[0032] This embodiment comprises the following steps in turn:

[0033] The composition of hot-rolled pickling-free automobile frame steel with a thickness of 8mm is C: 0.10wt%; Mn: 1.55wt%; P: 0.012wt%; S: 0.002wt%; Al: 0.047wt%; The content of Si is strictly controlled to be 0.297wt%, the content of Cr element is 0.225wt%, and the rest is iron and unavoidable trace elements.

[0034] During the billet hot rolling process, the furnace time is strictly controlled to 200 minutes.

[0035] The entrance temperature of finishing rolling is less than 1030℃, the temperature of finishing rolling is controlled at 880℃, and the coiling temperature is controlled at 580℃.

[0036] During the descaling process, the first descaling and the second descaling are fully put into use, and the descaling water between the finishing mill stands is put into use.

[0037] Two-level automatic control of work roll cooling water, and two-level automatic control when the cooling water between racks is ...

Embodiment 3

[0041] This embodiment comprises the following steps in turn:

[0042] The composition of the hot-rolled pickling-free automobile frame steel with a thickness of 8mm is C: 0.0083wt%; Mn: 0.726wt%; P: 0.0071wt%; S: 0.0031wt%; Al: 0.046wt%. The content of Si is strictly controlled to 0.0152wt%, and the rest is iron and unavoidable trace elements.

[0043] During the billet hot rolling process, the furnace time is strictly controlled to 200 minutes.

[0044] The entrance temperature of finishing rolling is less than 1030℃, the temperature of finishing rolling is controlled at 880℃, and the coiling temperature is controlled at 580℃.

[0045] During the descaling process, the first descaling and the second descaling are fully put into use, and the descaling water between the finishing mill stands is put into use.

[0046] Two-level automatic control of work roll cooling water, and two-level automatic control when the cooling water between racks is used and the water volume is incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com