Preparation method of superfine iron oxide red pigment with high glossiness and pure red tone

A red iron oxide, high-gloss technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of high oil absorption, difficulty in obtaining iron oxide red, and huge waste gas treatment equipment, and achieve good environmental protection effect. Effects that increase luster and redness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

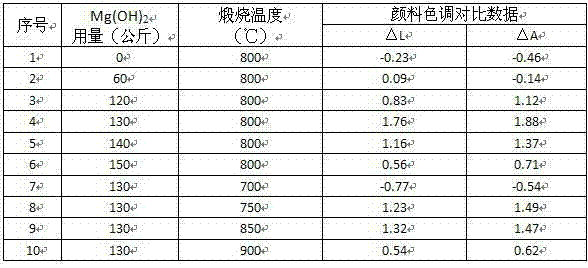

[0027] Embodiment 1 (the sequence number in the table is 4):

[0028] In a reaction barrel of 60 cubic meters equipped with stirring, heating device and air distributor, add 30 cubic meters of titanium dioxide by-product ferrous sulfate solution with a content of 5% after purification treatment, and then add hydrogen oxide under stirring. 130 kg of magnesium and 884 kg of 30% sodium hydroxide (the remaining ferrous sulfate is neutralized by sodium hydroxide) mixed solution (diluted to 2.5 cubic meters), so that the pH of the solution is 10 (if the pH value is low, 30% hydrogen can be used Sodium oxide solution for fine-tuning), after the temperature rises to 41 degrees Celsius, air is introduced for oxidation, and the air volume is 15 cubic meters per minute, during which the temperature is kept at 40 to 50 ° C, and the pH is 9-10. After 4 hours, the air is stopped. Inject air and stir to obtain a suspended seed liquid. Pump the seed crystal suspension into a 120 cubic meter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com