Friction block and preparation method thereof and brake pad

A friction block and brake pad technology, applied in the field of brake pads, friction blocks and their preparation, can solve the problems of complicated and difficult processing technology, large braking noise and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present application also provides a method for preparing the above-mentioned friction block in the brake pad, comprising the following steps:

[0040] 1) Prepare each raw material properly according to the above component formula, and then pass the powder of other raw materials except lignin fiber and phenolic resin or boron-modified phenolic resin or melamine-modified phenolic resin through the mixer Mix and stir, and then disperse the mixed and stirred raw material mixture through an ultrasonic disperser to make the components evenly dispersed;

[0041] 2) Mix lignin fiber with phenolic resin or boron-modified phenolic resin or melamine-modified phenolic resin: Divide lignin fiber into 4 equal parts, add one part at 4 different positions of the mixer one by one every 6 minutes Mix in phenolic resin or boron-modified phenolic resin or melamine-modified phenolic resin, and mix for 6 minutes after the fourth part is added;

[0042] 3) Add the raw material mixture pr...

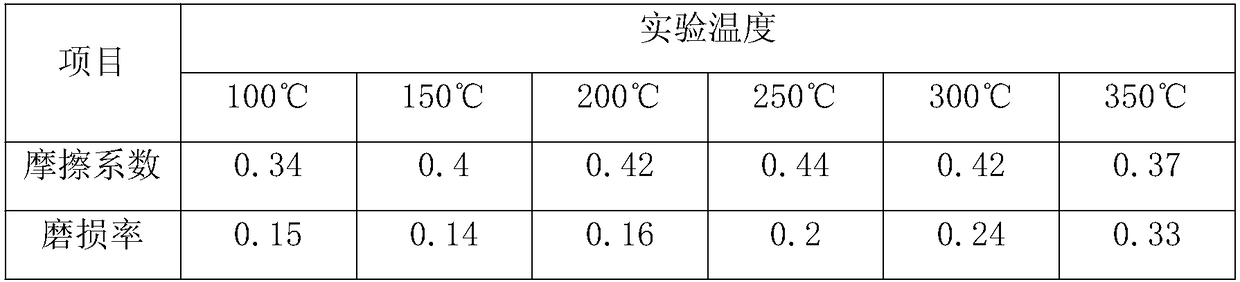

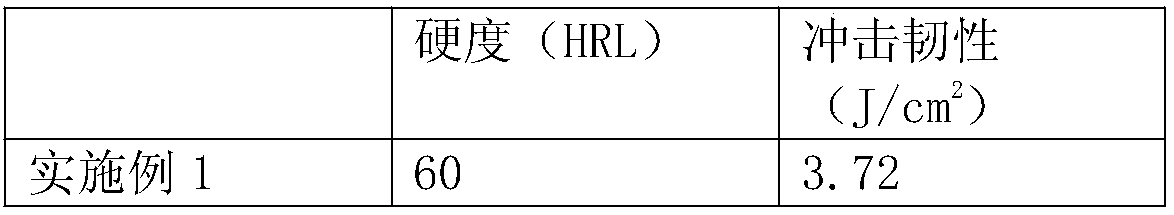

Embodiment 1

[0056] A friction block in a brake pad, made of raw materials of the following qualities:

[0057] 9 grams of phenolic resin, 6 grams of nitrile rubber powder, 12 grams of lignin fiber, 2 grams of activated carbon, 8 grams of expandable graphite, 3 grams of molybdenum disulfide, 23 grams of barium sulfate, 6 grams of carbonic acid Calcium, 3 grams of silicon carbide, 3 grams of calcium sulfate whiskers, 4 grams of yellow iron oxide, 2 grams of aluminum oxide, 5 grams of superfine iron oxide red powder, 6 grams of wollastonite, 6 grams of vermiculite powder And 2 grams of high wear-resistant furnace black.

[0058] The above-mentioned preparation method of the friction block in the brake pad comprises the following steps:

[0059] 1) Prepare each raw material according to the component formula in Example 1, then mix and stir the powder of other remaining raw materials except lignin fiber and phenolic resin through a mixer, and then mix and stir the mixed and stirred The raw m...

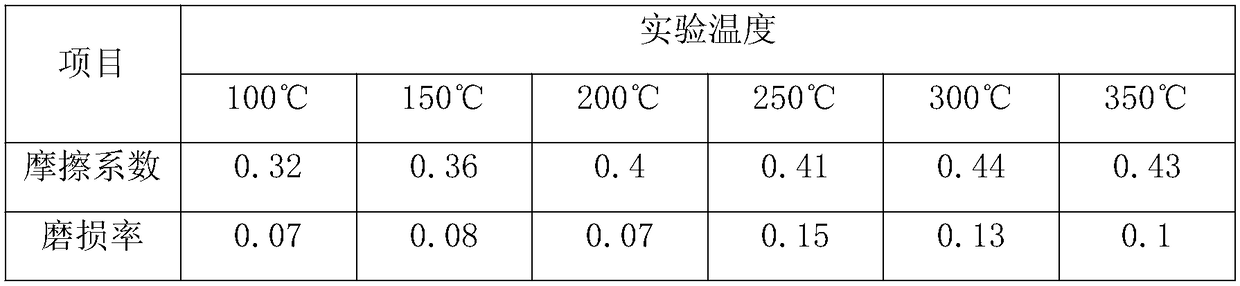

Embodiment 2

[0076] A friction block in a brake pad, made of raw materials of the following qualities:

[0077] 9 grams of boron-modified phenolic resin, 6 grams of nitrile rubber powder, 12 grams of lignin fiber, 2 grams of activated carbon, 8 grams of expandable graphite, 3 grams of molybdenum disulfide, 23 grams of barium sulfate, 6 gram of calcium carbonate, 3 grams of silicon carbide, 3 grams of calcium sulfate whiskers, 4 grams of iron oxide yellow, 2 grams of aluminum oxide, 5 grams of superfine iron oxide red powder, 6 grams of wollastonite, 6 grams Vermiculite powder and 2 grams of high wear-resistant furnace black.

[0078] The above-mentioned preparation method of the friction block in the brake pad comprises the following steps:

[0079] 1) Prepare each raw material according to the component formula in Example 2, then mix and stir the powder of other remaining raw materials except lignin fiber and boron-modified phenolic resin by a mixer, and then mix the The stirred raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com