Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

387 results about "Iron oxide black" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron oxide black granular pigment and preparation method thereof

InactiveCN101691456APollution suppressionSettling fastPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersityIron oxide black

The invention belongs to the field of chemical pigments, and in particular relates to an iron oxide black granular pigment and a manufacturing method thereof. The iron oxide black granular pigment comprises a main component iron oxide black (Fe3O4) which is coated with an additive coating layer, and the main component iron oxide black is combined with the additive coating layer to form the granular pigment; and the pigment is prepared by the following steps: firstly preparing aqueous solution of an additive, and performing heating until 30 to 100 DEG C; and sending the iron oxide black into a granulator, evenly spraying the prepared aqueous solution of the additive onto powder, gradually forming small granules, and screening and drying the prepared granules with a vibrating screen to prepare a finished product. The granular pigment prepared by the method is not easy to diffuse so as to effectively prevent dust pollution, has high luster retention, good flowability and dispersity, and low cost, and is suitable to be widely applied in industry.

Owner:HANGZHOU XIAOXIANG PIGMENT CHEM

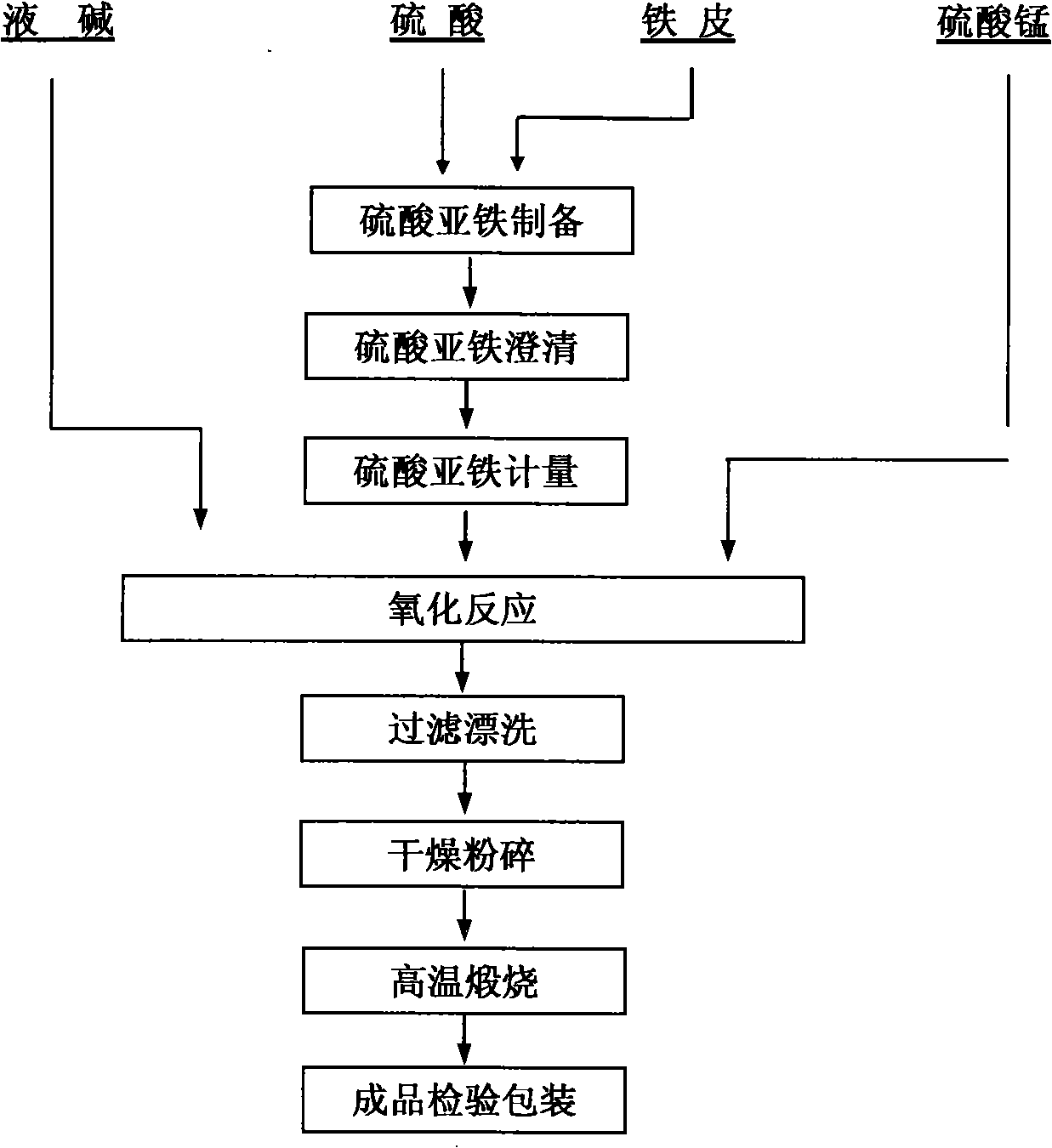

Method for producing iron oxide black

This is the producing method of a kind of oxidized iron oxide black including following contents: prepare ferrite watery solution; use sodium hydroxide as neutralizaing agent and react with ferrite watery solution to produce hydroxide ferrous; use oxygenous gas as oxidant, and react with said hydroxide ferrous to produce iron oxide black; make the prepared iron oxide black water washed, sieved, dried and comminuted orderly to get blue oxidized iron oxide black pigment product. The oxidized iron oxide black produced by this method has high purity and thin crystal grain, the grain size of produced pigment is thin and even, and has saturated blue ink light black and stable effect to light and atmosphere. It also has strong pigmentation strength and hiding power, and can be used in such fine chemical industry products as printing ink and carbon powder. The farther project is using waste residue containing ferrous sulfate and vented in titanium oxide powder production, to produce ferrous sulfate watery solution and produce oxidized iron oxide black, which can adequately use industry waste material to produce oxidized iron oxide black products of high quality, and reduce environmental pollution.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

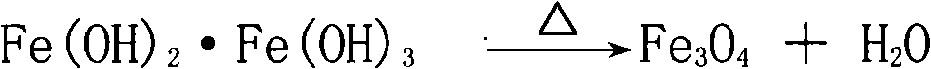

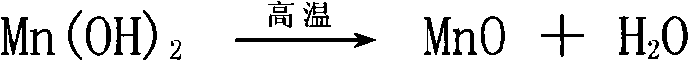

Fire resistant black iron oxide pigment and preparation method thereof

ActiveCN101314678AImprove acid resistanceGood alkali resistanceInorganic pigment treatmentFerric oxidesEngineering plasticManganese oxide

The invention relates to an inorganic iron oxide black pigment, in particular to a heat-resistant iron oxide black pigment (manganese ferrite black) and the preparation method thereof. The heat-resistant iron oxide black pigment comprises manganese ferrite black prepared from ferroferric oxide and manganese oxide by high-temperature lattice reaction, wherein the molar ratio of iron element to manganese pigment in the pigment is 1.5:1 to 5:1. The heat-resistant iron oxide black pigment has high heat resistance up to 700 DEG C or above, and can be widely used for ceramic, engineering plastic, color sand, etc., for products manufactured at high temperature, and for coloring agent for products. Meanwhile, the inorganic iron oxide black pigment has the advantages of high acid resistance, high alkali resistance and high light absorbability.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

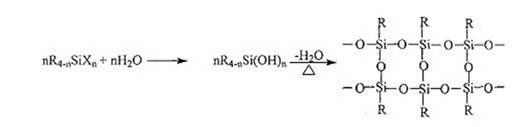

High temperature-resistant ceramics coating for non-stick cookware, and preparation method thereof

The invention discloses a high temperature-resistant ceramics coating for non-stick cookware, and a preparation method of the coating. The coating is prepared by mixing A composition and B composition with the weight ratio of 2.0-2.2:1.0-1.2, wherein the A composition consists of silicon oxide colloidal sol, aluminum oxide colloidal sol, zirconium oxide colloidal sol, mica powder, iron oxide black, high-temperature aluminium oxide, isopropanol, deionized water, carboxymethyl acetic acid, cellulose butyrate and fluoro silicone oil, and the B composition consists of methyltriethoxysilane, dimethoxydimethylsilane, triethoxyphenylsilane, isopropanol and ethanol; the preparation method comprises the steps of: and mixing the A composition and B composition with the weight ratio of 2.0-2.2:1.0-1.2, hermetically stirring and curing under 35 DEG C 150-200rpm state for at least three hours, thus obtaining the coating. For the high temperature-resistant ceramics coating, the high temperature-resistant stability of -Si-O0 bond is mainly utilized, so that the excellent high temperature-resistant performance of the coating is guaranteed.

Owner:JIANGMEN ANNUOTE COOKING UTENSILS MFG

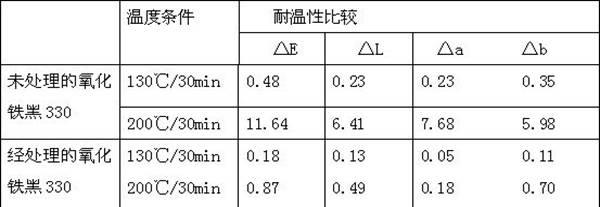

Preparation process of medium temperature resistant iron oxide black

InactiveCN101824236ADoes not change color smallLittle changeInorganic pigment treatmentIron oxide blackThermal insulation

The invention discloses a preparation process of medium temperature resistant iron oxide black; iron oxide black is obtained through an oxidation method, a filter cake which is not dried is directly used, the iron oxide black, the filter cake and the water are added in, a beating machine is controlled to prepare serum with a certain concentration, water-soluble additive is added in during a beating process, neutralizer is added, and the pH value is regulated; and the stirring is continued, iron black is produced through normal steps after heat insulation, dried and beaten into powder, and the medium temperature resistant iron oxide black is obtained. The iron oxide black prepared by the process can stand 260 to 270DEG C, does not discolor or has small color changes; and the iron black has the advantages of good heat resistant performance, and no flammability and no easy discoloring when in transportation and storage, ensures small heating color changes as well as the safety of transportation and storage, and simultaneously can be used at 270DEG C.

Owner:南通宝聚颜料有限公司

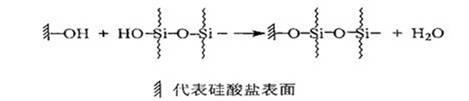

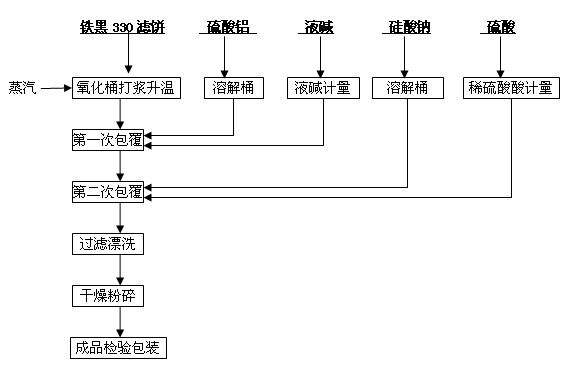

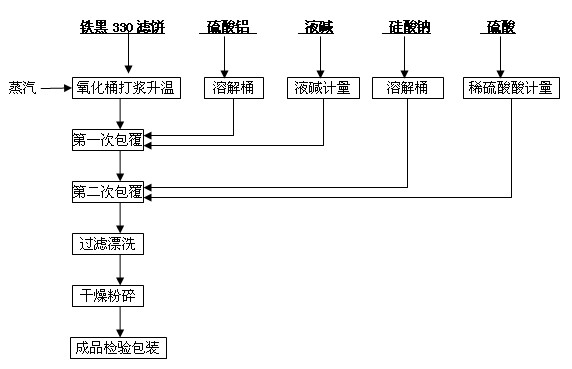

Preparation method of coated iron oxide black with medium temperature resistance

The invention relates to a preparation method of temperature resistant iron oxide black, and discloses coated iron oxide black with medium temperature resistance. According to the preparation method, a plurality of layers of compact films are coated on the surfaces of iron oxide molecules, so that the heat resistance of iron oxide black is improved. The method mainly comprises the steps of firstly stirring iron oxide black filter cake into pulpous state, then adding aluminum ions and silicon ions, ensuring that ion precipitate is gradually coated on the surface of the iron oxide black molecules by adjusting pH value, so as to form a plurality of protecting films to ensure that the heated temperature of coated iron oxide black reaches 200 DEG C. According to the method, coating treatment process is performed on the surface of iron oxide pigment to passivate the surface, the treatment method is advanced, and coated pigment ions are uniform, and have high strength and superior dispersion property. Accessory ingredients such as aluminum sulfate and sodium silicate for coating are easily accessible, and have low costs. The oxide black filter cake is provided by oxide black plants, the coating treatment is performed in middle stage test workshop, the treatment process is short, the energy consumption is low, the technology of the project is mature, samples are approved by customers, and performance indexes of products meet the demands of the customers.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

Dry type asbestos-free friction sheet

The invention relates to a dry-type friction plate without mineral cotton, comprising a metal frame of powder metallurgy and following compositions with weight, 1-5 iron oxide black, 5-10 cashew shell oil resin friction powder, 30-50 barium sulfate, 1-8 vermiculite, 5-10 molybdenum disulfide, 10-20 colloidal graphite, 15-20 binding agent, 20-30 ceramic fiber, 8-10 epoxide resin solidifying agent, and 5-6 antiaging agent, wherein the binding agent is constituted by 60%-70% formaldehyde-phenol resin and 30%-40% cashew shell oil resin friction powder. The preparation method of the friction plate comprises casting the metal frame by utilizing powder metallurgy, smearing the binding agent on the surface of the metal frame, preparing friction material with even mixture according to the composition, directly pressing the even mixing powder on the metal frame, and sintering 3-15 minutes with 200-220kg / mm2 of pressure in 180-210 DEG C of controlling temperature, and then heat pressing to shape.

Owner:杭州汉乐科新材料科技有限公司

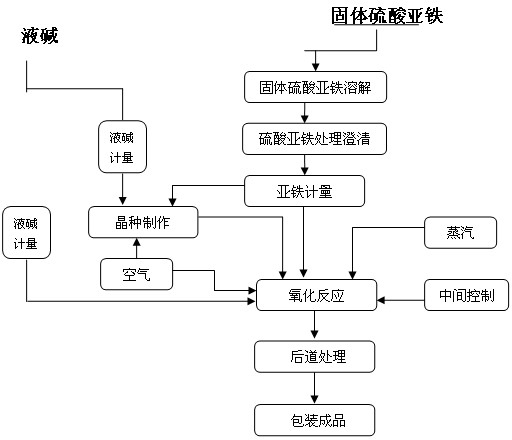

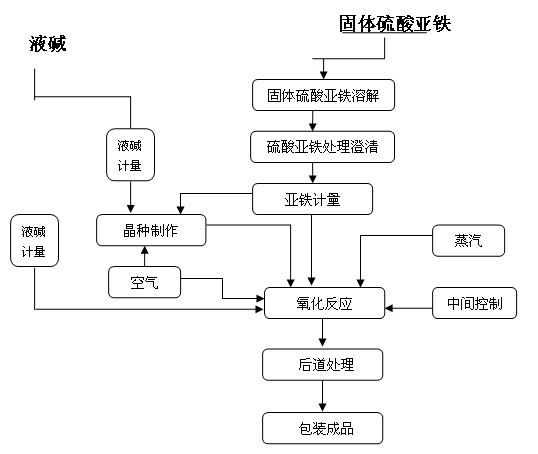

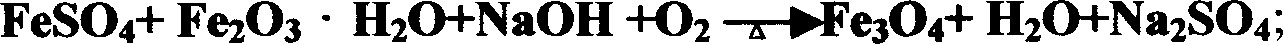

High-purity iron oxide black pigment and production method thereof

ActiveCN102139927AHeavy metal content controlHigh purityFerroso-ferric oxidesIron(II) oxideIron oxide black

The invention relates to a high-purity iron oxide black pigment and a production method thereof. The production method comprises the following steps of: with a crystal seed as a carrier in a liquid phase method production process, carrying out reaction on ferrous sulphate and sodium hydroxide in an oxidation barrel, immediately generating ferrous hydroxide sol under the alkali condition, introducing steam and warming for reaction, introducing air for oxidation after a specified temperature is reached, and reacting for a period of time to obtain the high-purity iron oxide black pigment. The granules of the product obtained by the method are small and uniform compared with a synthetic method, and the yield is high and the coloured light is good; meanwhile, the purity of the product is controlled, thus the operating requirement in the industry is met. The invention also aims at providing the high-purity iron oxide black pigment prepared by adopting the method.

Owner:SHENGHUA GROUP DEQING HUAYUAN PIGMENT

Method for producing iron oxide black using desilicified mud cake

InactiveCN1807263AEfficient use ofImprove performanceFerroso-ferric oxidesIron oxide blackEngineering

The disclosed preparation method for Fe2O3 black with desilicated mud cake as material comprises: (1) preparing Fe2+ solution; (2) preparing ferrite-yellow crystal seed; (3) pre-treating the desilicated mud cake; (4) oxidating and slurrying; (5) composing; (6) screening; (7) pressure filtering; (8) drying; (9) checking and packing. This invention is simple, and has low request to the device and little side reaction.

Owner:SHANGHAI BAOQI IRON OXIDE

Antibacterial corrosion-resistant ceramic coating of non-stick pan and preparation method of coating

ActiveCN103483885AImprove mechanical propertiesImprove performanceAntifouling/underwater paintsPaints with biocidesEpoxyPolyester

The invention relates to an antibacterial corrosion-resistant ceramic coating of a non-stick pan and a preparation method of the coating, and belongs to the technical field of ceramic machining. The antibacterial corrosion-resistant ceramic coating comprises the components in parts by weight as follows: 35-40 parts of silicon oxide sol, 5-9 parts of aluminum oxide sol, 1-3 parts of zirconium oxide sol, 5-8 parts of a water soluble polyester modified epoxy resin, 1-3 parts of black iron oxide, 5-8 parts of spherical ceramic micro powder, 8-12 parts of absolute ethyl alcohol, 1-3 parts of silver nitrate, 1-3 parts of aluminum nitrate, 1-3 parts of and fluoride silicone oil and 10-15 parts of deionized water. The preparation method comprises the steps as follows: the materials are mixed according toin the ratio, stirred for 4-6 h in a sealing manner at a temperature of 35-42 DEG C and a rotating speed of 300-350 rpm (revolutions per minute), and then calcinated at a high temperature of 300-350 DEG C; and composite ceramic material powder is composited. The coating of the non-stick pan has good mechanical property, is high in strength, high-temperature-resistant, abrasion-resistant and scratch-resistant, and has an antibacterial function; and the preparation technology is simple, and the coating is non-toxic and harmless to the environment.

Owner:浙江飞哲科技股份有限公司

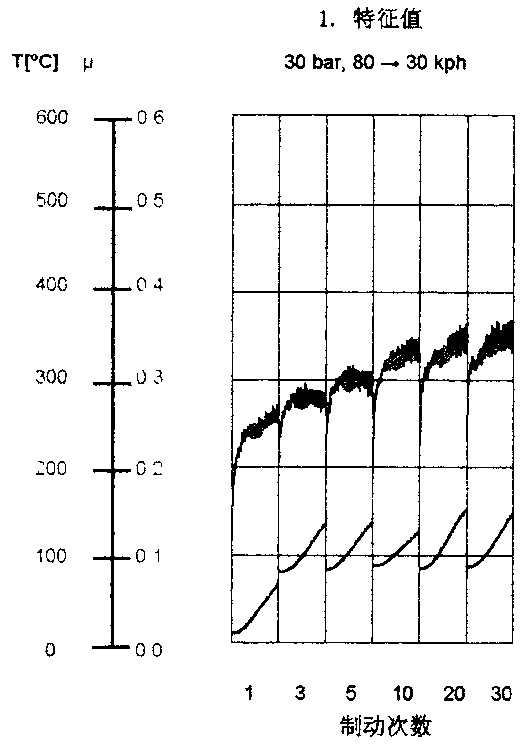

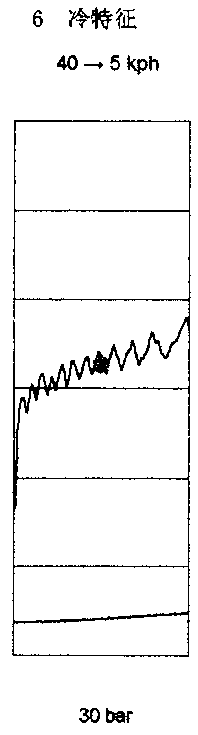

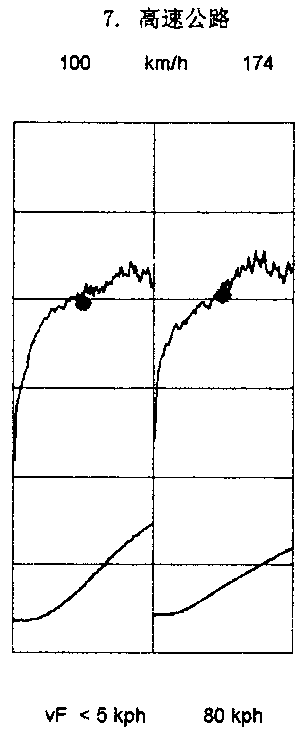

Environmental-protection high-speed car brake sheet and warm-pressing process of brake sheet

ActiveCN102141101ASmall recessionShorter braking distanceFriction liningVulcanizationMaterials science

The invention discloses an environmental-protection high-speed car brake sheet and a warm-pressing process of the brake sheet. A frictional material of the environmental-protection high-speed car brake sheet comprises the following components in parts by weight: 6-8 parts of phenolic resins, 2 parts of acrylonitrile rubber powder, 1-3 parts of Kevlar fibers, 5-7 parts of stannic sulfide, 5-7 parts of artificial graphite, 2 parts of polytetrafluoroethylene, 18-20 parts of steel fibers, 4-6 parts of red copper fibers, 2 parts of aluminum oxide, 3-5 parts of zirconium silicate, 5-7 parts of iron oxide black, 7-9 parts of titanium white, 6-8 parts of mineral fibers, 7-9 parts of white vermiculite, 8-10 parts of grammite and 5-9 parts of barium sulfate. The warm-pressing process of the environmental-protection high-speed car brake sheet comprises the steps of material burdening, material mixing, warm-pressing formation, thermal treatment, grinding and spraying. The high-speed car brake sheet has the advantages of safe and comfortable brake, no noise, low high-temperature and high-speed recession, stable frictional factor, environmental protection, long service life and the like; and the warm-pressing process of the environmental-protection high-speed car brake sheet has the advantages of high rate of finished products, high mechanical degree, high production efficiency and low energy consumption.

Owner:YANTAI WINHERE AUTO PART MFG

Method for producing pigment-level iron oxide red by using titanium dioxide waste residue ferrous sulfate

ActiveCN102583575ALow costImprove performanceSolid waste disposalFerric oxidesChemical industryIron oxide black

Owner:攀枝花市大牛科技有限公司

High temperature heat radiation coating and preparing method thereof

The invention belongs to inorganic fire resistive material field, especially relates to a fire and irradiation resistive coating material and the preparation method. It is characterized in that the comprised materials and their proportion are as follows: aluminium oxide calcined at high temperature 2- 400 units, zirconium oxide 2- 100 units, chromium oxide 5- 100 untis, clinker 1- 100 units, alta-mud 1- 80 uints, hexametaphosphate 0- 100 units, carboxymethyl cellulose 1- 50 uints, silicon carbide 20- 100 units, iron oxide black 0- 60 units, aluminum hydroxide 0- 100 units, cobalt oxide 0- 50 untis, copper oxide 0- 50 units, brown fused alumina 10 -200 uints, silicasol 0- 100 uints, sodium silicate 0- 400uints, the grain size of each components is not less than 360 order. The coating mateiral is calcinated at high temperature and there is one calcination shell on fiber cotton, and the bearing force of calcination layer and fiber cotton are equal. The coating material employs high- emission material and so it can save energy.

Owner:北京北科威斯迈技术发展有限公司

Method for producing iron oxide black

ActiveCN1709984AHigh tinting strengthUniform particle sizePigmenting treatmentReaction rateIron Black

The invention relates to the producing method of a kind of oxidized iron black. It includes following steps: add ferrite watery solution into neutralization action pot, add ammonia and mix round watery solution to neutralize it to prepare hydroxidized ferrous gelatin, transmit the produced gelatin into oxidizing reaction pot; send oxygenous gas and meanwhile heat gelatin to make it oxidated, after reaction we can get oxidized iron oxide black pulp; separate iron oxide black and mother liquor in pulp; make the separated iron oxide black water washed, sieved, dried and comminuted orderly to get finished products. This method adopts liquid phase method to make its reaction rate greatly improved, the particle granularity of oxidized iron oxide black finished products even; it has higher pigmentation strength, and the obtained product contains 96.5% Fe3O4. Compared with the industry appointed standard sample, its pigmentation strength is 200% - 250%; ulteriorly make offal in producing titanium oxide powder as material of this method, which is beneficial to circulation usage of industry waste material and environmental protection, and can greatly reduce producing cost.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Corrosion proof impregnating varnish used for water-based metal components and manufacturing method thereof

ActiveCN101560351ALong-lasting colorHigh hardnessAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a corrosion proof impregnating varnish used for water-based metal components and a manufacturing method thereof. The corrosion proof impregnating varnish is made of de-ionized water, propanediol, dispersant, antifoaming agent, wetting agent, carbon black, iron oxide black, water borne acroid resin, water borne epoxy resin, dipropylene glycol butyl ether, propylene glycol ether and polyaniline water solution, polyaniline carrier particles or polyaniline emulsion. The manufacturing method comprises: the propanediol and the de-ionized water are mixed and stirred, and then added with the dispersant, the antifoaming agent, the wetting agent and the polyaniline water solution or the water solution of emulsion or carrier particles to be evenly mixed together; the carbon black and the iron oxide black are added in to the mixed solution to form uniform pigment paste which is then put into a blending tank after being ground to be evenly stirred; the obtained mixture is added with the water borne acroid resin, the water borne epoxy resin, the dipropylene glycol butyl ether and the propylene glycol ether to be stirred; finally, the stirred mixture is added with the de-ionized water to be diluted and ground. The invention has the advantages of high coating efficiency, stable coating quality, uniform paint film of dip coating, flat and smooth paint film, good hardness, strong adhesive attraction, good corrosion proof performance, excellent painting performance at edges and corners, no leaking painting, good salt mist resistance, environmental protection, low cost, etc.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Ceramic brake pad with high performance for middle-to-high grade sedan

InactiveCN101555921ALow densityImprove wear resistanceFriction liningAluminium silicateGraphite particle

A ceramic brake pad with high performance for middle-to-high grade sedan comprises the following components according to weight percentages: 7%-11% of ceramic fibre, 5-8% of silicate fibre, 6-9% of glued aluminium silicate fibre, 5-8% of aramid fibre, 7-10% of red copper fibre, 6-9% of modified aedelforsite, 7-12% of barite, 4-8% of chromite, 1-2% of butyronitrile rubber, 2-4% of iron oxide black, 7-10% of graphite particle, 0.1-0.2% of zinc oxide, 4-8.5% of calcined petroleum coke, 1-3% of expansion graphite, 5-9% of boron containing phenolic resin, 3-5% of magnetite, 0.8-1.3% of heavy-burned magnesia, 0.8-1.5% of silicon carbide, 4-7.5% of barium sulfate crystal whisker, 0.3-0.5% of potassium titanate crystal whisker and 1-2.5% of alumina fibre; the ceramic brake pad made of the formula has lower density and excellent wear resistance, and is especially suitable for the middle-to-high grade sedan.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

Abrasive block for high-speed multiple unit trains and preparation method

InactiveCN107915951AAvoid high temperature stress cracksAvoid heat cracksBraking elementsTemperature stressCarbon fibers

The invention discloses an abrasive block for high-speed multiple unit trains. The abrasive block is prepared from a composite material composed of phenolic resin, steel fibers, copper-aluminum powder, carbon fibers, tungsten carbide, aramid fibers, iron oxide black, acrylonitrile-butadiene rubber and accelerant. The invention further provides a method for preparing the abrasive block, which prevents the occurrence of high-temperature stress cracks and hot cracks in the process of using the abrasive block by optimizing the component ratio and a processing technique. Moreover, by adopting an intermittent heating method and multiple times of heat treatment, the problems, such as stripping and easy abrasion, which take place in the process of using abrasive blocks at present are optimized.

Owner:上海国由复合材料科技有限公司

Colored oily fertilizer anti-caking agent prepared from inorganic pigment and application of colored oily fertilizer anti-caking agent

The invention relates to a colored oily fertilizer anti-caking agent prepared from inorganic pigment and application of the colored oily fertilizer anti-caking agent. The colored oily fertilizer anti-caking agent comprises the following ingredients in percentage by mass: 2-4% of iron oxide red, iron oxide yellow, iron oxide blue, iron oxide green, iron oxide purple, iron oxide brown or iron oxide black and 98-96% of an oily anti-caking agent, and is prepared by uniformly milling and mixing such ingredients by adopting a horizontal mill. The colored oily fertilizer anti-caking agent is applied to fertilizer coating, and 1.0-1.6 kilograms are used in each ton of a fertilizer, so that a corresponding color of red, yellow, blue, green, purple, brown or black is shown in the appearance of the fertilizer. The colored oily fertilizer anti-caking agent with the corresponding color of red, yellow, blue, green, purple, brown or black is provided for fertilizers with different appearance colors, so that inside and outside colors of the fertilizer are consistent, color difference and materials with inconsistent colors are avoided; the colored oily fertilizer anti-caking agent is stable and uniform in color, strong in coating capability, resistant to light and heat, colorfast and non-discoloring, can also be used as a fertilizer variety distinguishing and anti-counterfeiting mark, and is low in use cost and good in anti-caking performance.

Owner:HUBEI FORBON TECH

Dip-coating water-based paint for transmission shaft and preparation method thereof

InactiveCN106867368AWith cleanQuick-drying at room temperatureAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

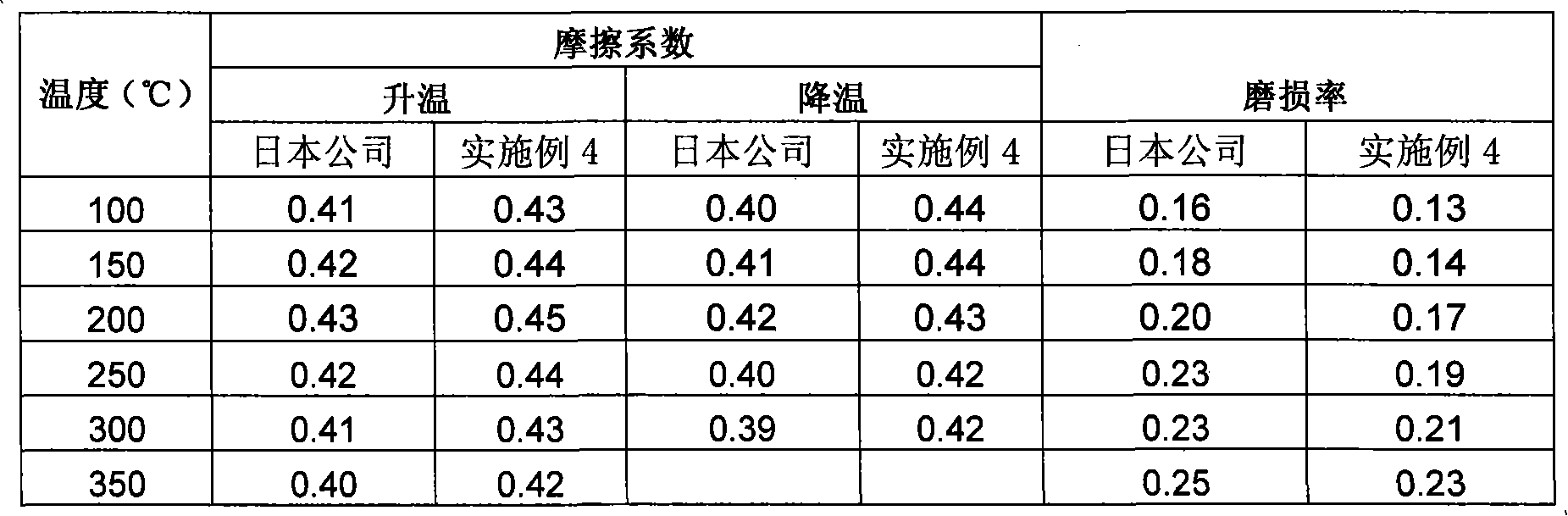

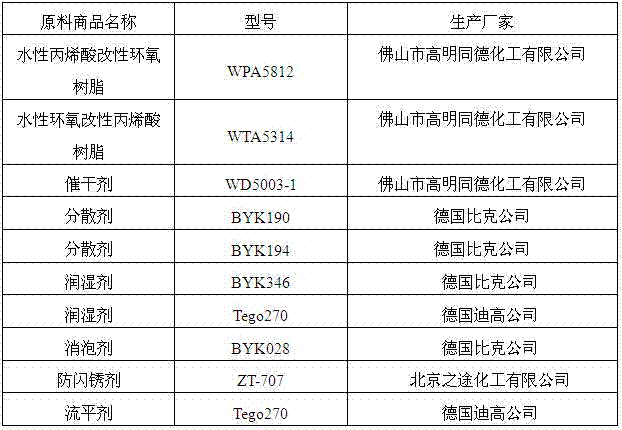

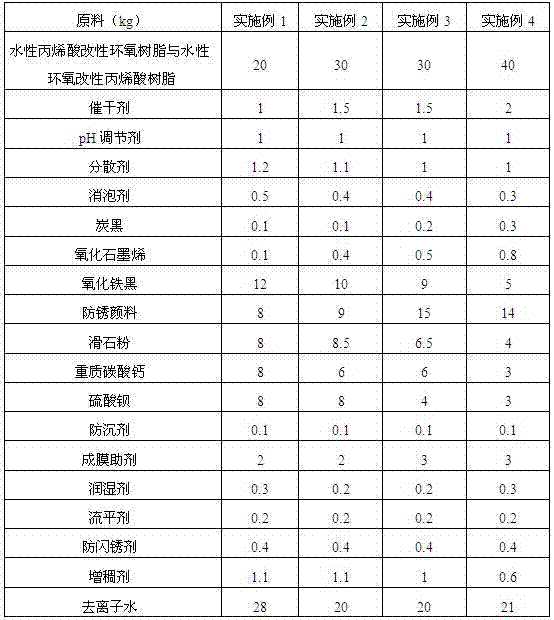

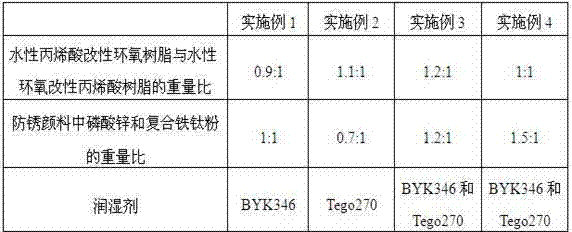

The invention discloses dip-coating water-based paint for a transmission shaft and a preparation method thereof and relates to the technical field of metal water-based paint. The dip-coating water-based paint is prepared from the following raw materials in parts by weight: 20 to 40 parts of waterborne acrylic modified epoxy resin and epoxy modified acrylic resin, 0.3 to 3 parts of a drier, 0.4 to 1.5 parts of a pH (Potential of Hydrogen) regulator, 0.6 to 1.5 parts of a dispersant, 0.3 to 0.5 part of a de-foaming agent, 0.05 to 3 parts of carbon black, 0.01 to 1 part of graphene oxide, 4 to 12 parts of iron oxide black, 2 to 20 parts of antirust pigment, 3 to 8 parts of talcum powder, 0.5 to 8 parts of heavy calcium carbonate, 3 to 8 parts of barium sulfate, 0.05 to 0.15 part of an anti-sedimentation agent, 2 to 3 parts of a film forming auxiliary agent, 0.1 to 0.5 part of a wetting agent, 0.1 to 0.5 part of a leveling agent, 0.1 to 0.5 part of a flash-rust resisting agent, 0.1 to 1.2 parts of a thickener and 10 to 28 parts of water. The water-based paint has the advantages of easiness of improving a film thickness, high rigidity, good wear-resisting and corrosion-preventing effects, capability of being rapidly dried at room temperature and extremely low VOC (Volatile Organic Compounds) content.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Aluminum-based composite radiating material for LED (light-emitting diode) doped neodymium oxide

The invention relates to a lamp radiating material and specifically relates to an aluminum-based composite radiating material for LED (light-emitting diode) doped neodymium oxide and a production method thereof. The radiating material is prepared from the following materials in parts by weight: 73-75 parts of aluminum, 10-12 parts of aluminum nitride, 4-5 parts of iron oxide black, 2-3 parts of neodymium oxide, 6-8 parts of steel slag, 10-12 parts of metakaolin, 6-8 parts of sodium silicate, 2-3 parts of ferrous sulfate, 2-5 parts of sucrose fatty acid ester and 4-5 parts of auxiliaries. The radiating material disclosed by the invention has integrated advantages of components such as aluminum, aluminum nitride, metakaolin, and the like, has good heat conduction and insulating performances; all materials are mixed and ground in sodium silicate aqueous liquor to increase compatibility of materials, so that the materials are easier to form; the doped neodymium oxide can improve radiating and temperature-resisting performances of the material; and the radiating material prepared in the invention is compact in structure, bright in color and luster, light and firm, good in thermal stability, durable, and efficient and lasting in radiating capacity, so that the LED lamp is effectively protected, and service life of the lamp is greatly prolonged.

Owner:YANYANG LAMP SET TIANCHANG CITY

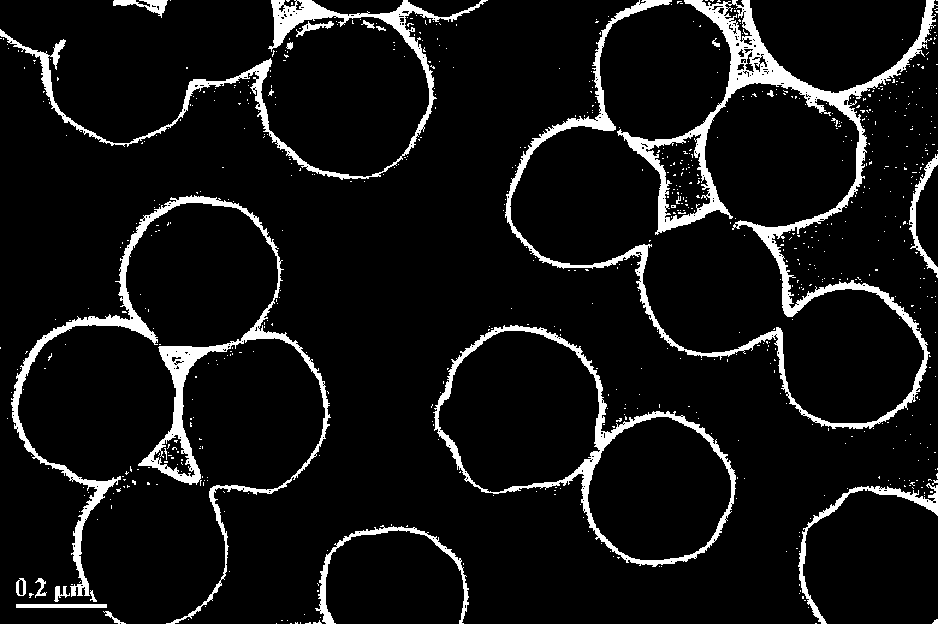

Preparation method and application of core-shell magnetic composite microsphere rich in boron ester

InactiveCN103435762AGood effectUniform particle size distributionPeptide preparation methodsOrganic/organic-metallic materials magnetismPolymer networkMagnetite Nanoparticles

The invention provides a preparation method and an application of a core-shell magnetic composite microsphere capable of separating glycoprotein. The preparation method is characterized in that a core of the core-shell magnetic composite microsphere is a magnetic iron oxide black nanoparticle cluster and a shell is a crosslinked polymer network rich in carboxyl, then carboxyl and aminobenzene boron ester carry out amidation to carry out surface modification, and glycoprotein can be quickly separated and enriched under the physiological conditions via plenty of surface immobilized boron esters. The preparation method comprises the following steps of: firstly preparing a magnetic nanoparticle cluster with stable sodium citrate, secondly adopting a sol-gel method to modify the surface of the magnetic cluster with active vinyl functional groups, thirdly preparing high-magnetic-responsiveness monodispersed core-shell magnetic polymer composite microsphere rich in carboxyl on the surface via reflux precipitation polymerization, fourthly carrying out amidation on aminobenzene boron ester and carboxyl to modify the surface of the core-shell magnetic composite microsphere with plenty of boron ester groups and finally carrying out separation and enrichment on glycoprotein. The method provided by the invention is simple, is controllable in process, has higher glycoprotein separation and purification efficiency and can carry out separation and enrichment under the physiological conditions.

Owner:FUDAN UNIV

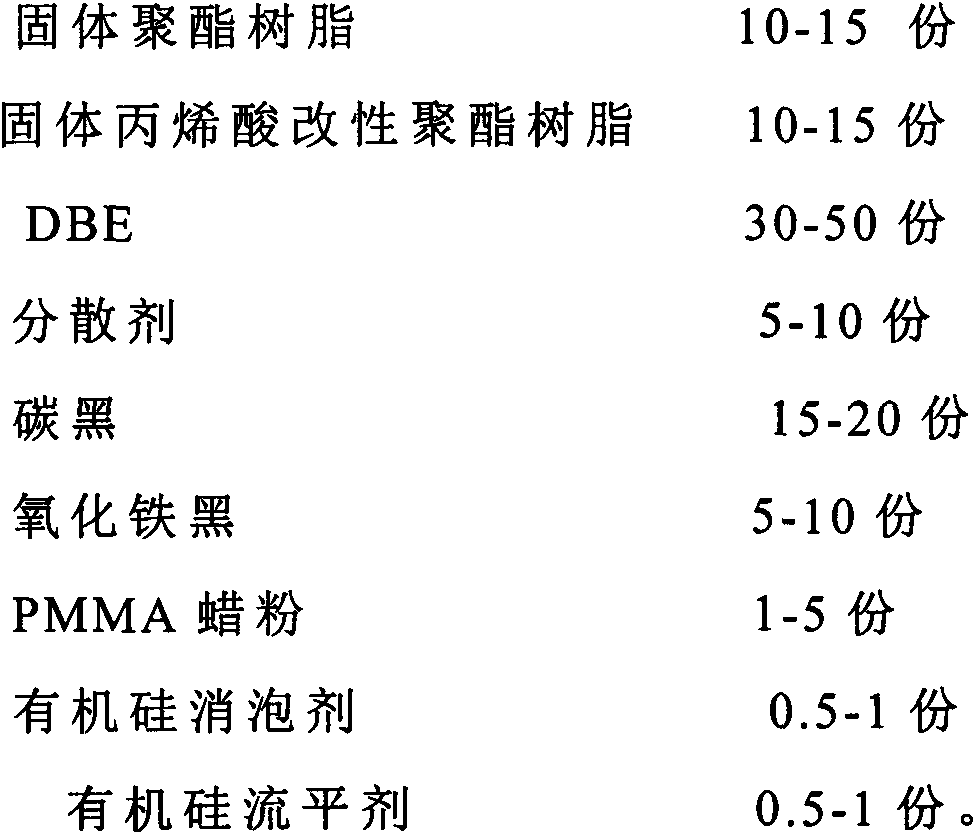

High-covering black matte silk-screen printing ink for PET base material

The invention discloses high-covering black matte silk-screen printing ink for a PET base material. The high-covering black matte silk-screen printing ink for the PET base material is prepared by the following steps of: mixing a solvent DBE with a dispersing agent, and dispersing; then sequentially adding solid polyester resin, solid acrylic acid modified polyester resin, carbon black and iron oxide black; stirring the ingredients uniformly to obtain a mixture; grinding the mixture; adding PMMA wax powder, an organic silicon antifoaming agent and an organic silicon leveling agent into the ground mixture; and uniformly dispersing and grinding the ingredients to obtain the high-covering black matte silk-screen printing ink for a PET base material. In the high-covering black matte silk-screen printing ink for the PET base material disclosed by the invention, the composition is reasonable, the components are in good coordination, the overall performance of the system is excellent, the viscosity is suitable for silk-screen printing, and the storage performance is good. In the system disclosed by the invention, the dosage of the components such as carbon black and matting powder is not increased, and adverse impact on the appearance and shading property of the product is avoided; moreover, only through once printing, the shading requirement of the product is met with thickness of 5 microns, and thus industrial application is facilitated.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

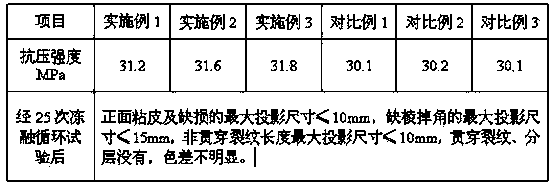

Antique brick and production method thereof

ActiveCN104177009AHigh compressive strengthImprove freeze-thaw resistanceSolid waste managementIron oxide blackBrick

The invention relates to an antique brick and a production method thereof. The antique brick is prepared from the following raw materials in parts by weight: 290-305 parts of cement, 960-1100 parts of fly ash, 280-300 parts of corundum and / or quartz sand, 370-390 parts of mine slag or steel slag, 3.8-4.2 parts of chloride early-strength admixture and 0.5-0.8 part of iron oxide black. The production method comprises the following steps: mixing, adding water, and stirring uniformly to prepare a mixture with the water content of 0.6-1.0 wt%; adding the mixture into a mold, and carrying out pressure vibratory compaction or static pressure molding in a forming machine; stripping; and curing.

Owner:HUNAN ZHITONGXING ENVIRONMENTAL BUILDING MATERIALS

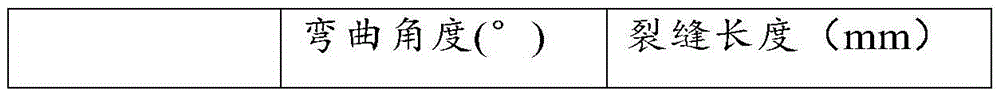

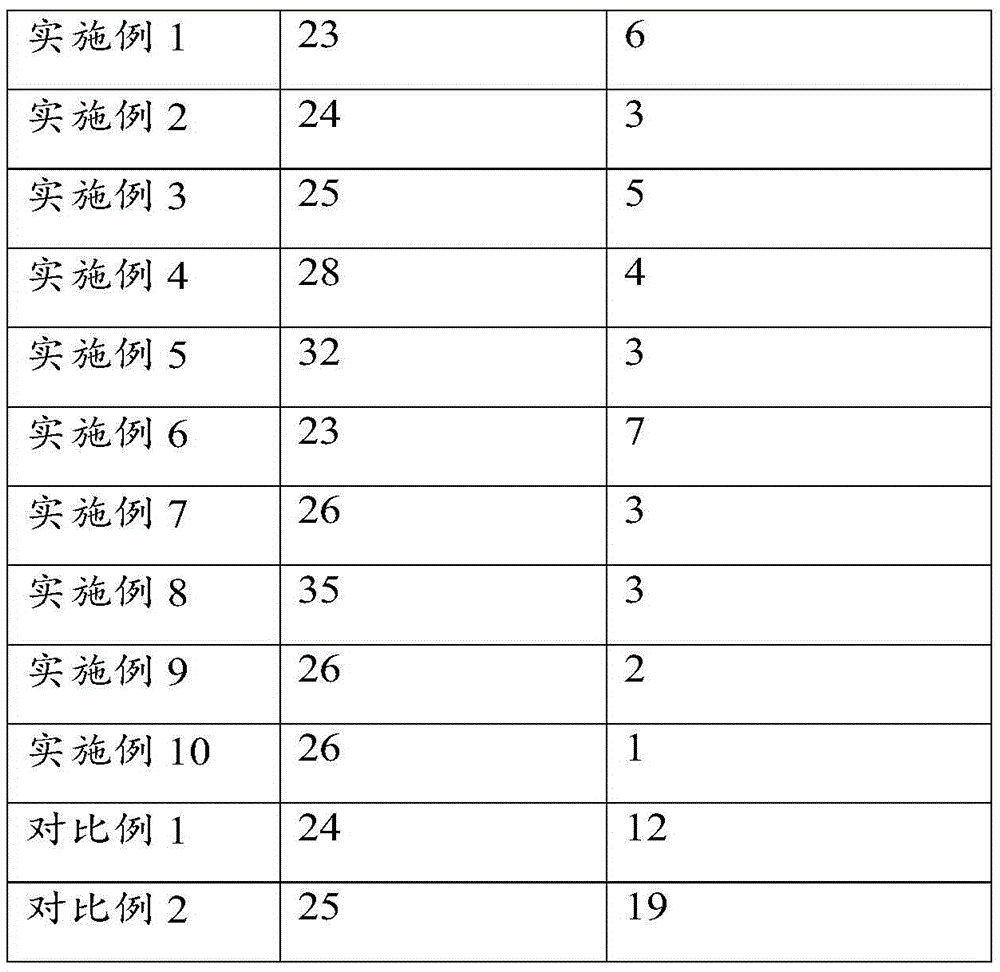

Reduction- and oxidation-stable iron oxide black pigments having high colour strength for colouring plastics and building materials, their preparation and their use

The present invention relates to reduction- and oxidation-stable iron oxide black pigments having high color strength, the preparation thereof and the use thereof.

Owner:LANXESS DEUTDCHLAND GMBH

Special diatom ooze paint for children as well as application and application method thereof

InactiveCN102603228AProtect physical and mental healthSimple production processFiberIron oxide black

The invention relates to a special diatom ooze paint for children as well as application and an application method of the paint. The paint comprises the following component in percentage by mass: 3-5% of adhesive powder, 20-35% of siliceous sand, 5-8% of wood fiber, 20-35% of diatomite, 10-15% of loess, 3-5% of clay, 5-8% of medical stone, 3-5% of zeolite, 2-3% of lazurite, 2-2.5% of onyx, 0.1-0.3% of emerald, 0.1-0.3% of jade, 0.3-0.5% of topaz, 1-1.5% of biotite, and 0.2-1% of toner, wherein the toner is one or more of iron red, ferrite yellow, iron oxide black and ultramarine. The invention also relates to application and the application method of the special diatom ooze paint for children in the children living environment. The paint can adjust the indoor air humidity, purity air and insulate sound and heat.

Owner:刘娜

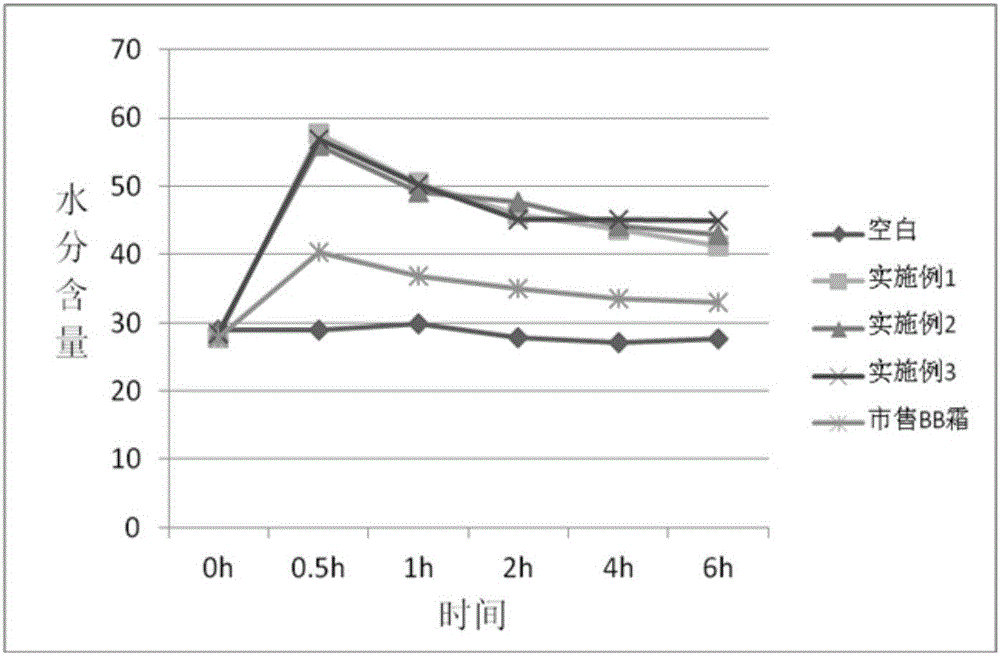

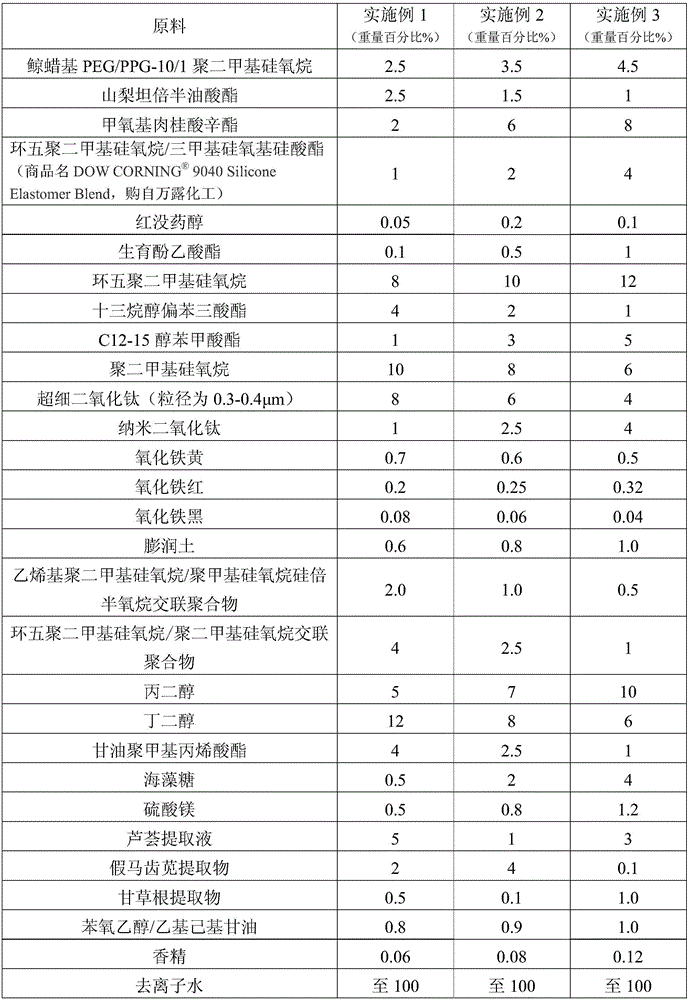

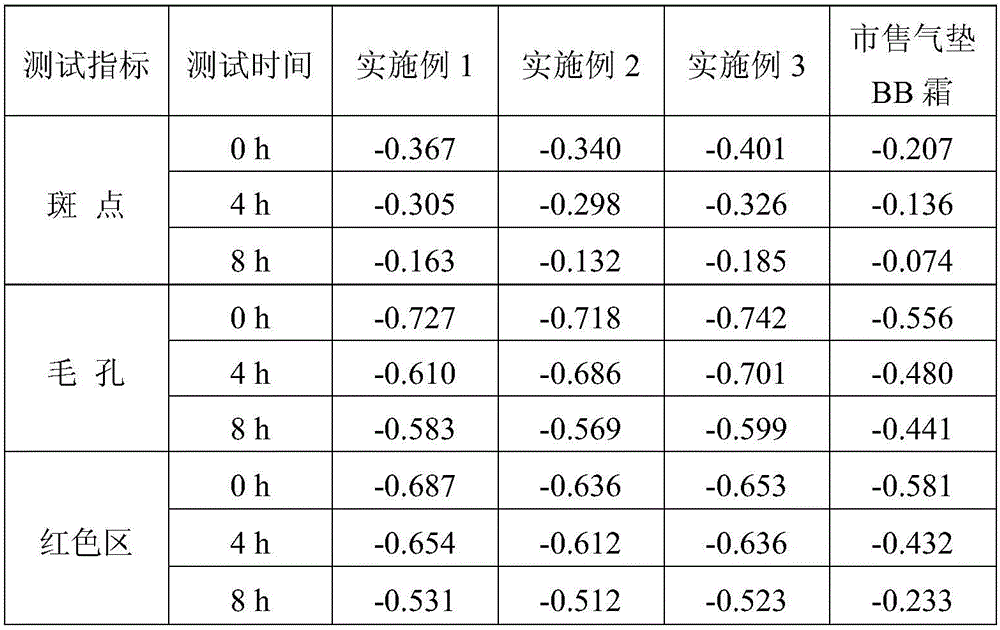

Air cushion BB cream and preparation method thereof

InactiveCN105687045AImprove efficacyHigh oil absorptionCosmetic preparationsMake-upSodium BentoniteC12-15 Alkyl benzoate

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

Method for preparing iron oxide black water-based color paste with high performance-price ratio

ActiveCN103031023AImprove dispersion stabilityPromote environmental protectionPigment pastesWater basedIron oxide black

The invention relates to a method for preparing an iron oxide black water-based color paste with high performance-price ratio. The fundamental formula of the iron oxide black water-based color paste comprises the following component in percentage by weight: 15-30 percent of water, 3-10 percent of humectant, 1.5-3 percent of wetting agent, 4-7 percent of dispersant, 0.2-0.5 percent of AMP-95 multifunctional additive, 40-60 percent of iron oxide black powder, 0.2-0.5 percent of thickening anti-settling agent, 0.1-0.3 percent of bactericidal agent and 0.1-0.5 percent of antifoaming agent. The iron oxide black water-based color paste has the characteristics of excellent storage stability, high dyeing power, good compatibility and the like, has high performance, economical efficiency and an environmental-protection effect, and is the iron oxide black water-based color paste with high performance-price ratio; and the iron oxide black water-based color paste is widely used for coloring of water-based building coatings, water-based woodwork coatings, water-based automobile coatings, water-based paper coatings, water-based plastic coatings, water-based glass coatings, water-based leather coatings, water-based ink and the like.

Owner:英德科迪颜料技术有限公司

Four-layer-color synthetic resin block and preparation method thereof

ActiveCN103273713AEasy to processGood dimensional stabilitySynthetic resin layered productsArtificial teethPolymer scienceIron oxide black

The invention discloses a four-layer-color synthetic resin block and a preparation method thereof. The four-layer-color synthetic resin block is formed by four layers of structures sequentially, each layer of the structures comprise components as follows: polymethyl methacrylate, iron oxide red, iron oxide black, iron oxide yellow, titanium white, methyl methacrylate and ethylene glycol dimethacrylate. The preparation method comprises the steps as follows: polymethyl methacrylate powder is dried at a temperature of 80-90 degrees; four layers of materials are prepared in proportion respectively, and each layer of the materials are required to be mixed uniformly and kneaded until doughing time, so that a plastic dough material is formed; four layers of the plastic dough material are subjected to hot-pressing and bounded together in order in a die, the hot-pressing temperature is 110-130 DEG C, and the hot-pressing time is 10-20 min; and the four-layer-color synthetic resin block after hot-pressing is subjected to heat treatment at a temperature of 80-90 DEG C for 10-12 h, so that a four-layer-color synthetic resin block product is obtained. A dental model or temporary crown bridge, which is processed through the four-layer-color synthetic resin block, is natural and vivid in developing, and the preparation method is simple.

Owner:SHANDONG HUGE DENTAL MATERIAL CO LTD

Waterproof liquid foundation formula and preparation method thereof

InactiveCN110051553ANon-irritatingHas the effect of isolating external damageCosmetic preparationsBody powdersSkin complexionGlycerol

Owner:广州蔓缇化妆品有限公司

A manufacturing method of a friction plate

InactiveCN105524593ARaise the ratioImprove bindingOther chemical processesFriction liningAntimonyFlake graphite

A manufacturing method of a friction plate is disclosed. The method includes a step of weighing and mixing materials, namely a step of weighing cellulosic fiber, aramid fiber pulp, phenolic resin, zinc stearate, zirconium silicate, potassium feldspar powder, calcium carbonate, biotite powder, fluorite powder, magnesium oxide, barium sulfate, antimony sulfide, micaceous iron oxide, iron oxide black, potassium hexatitanate whiskers, copper fiber, frictional powder, rubber powder, crystalline flake graphite, electrolytic copper powder and zinc powder, and mixing to obtain a material mixture, a step of subjecting a metal substrate to surface treatment, namely a step of subjecting the metal substrate to shot blasting, cleaning the metal substrate with a diluted acid solution, cleaning the metal substrate with clear water, drying the metal substrate and cooling the metal substrate, a step of cold press molding, a step of glueing, and a step of vulcanization. The manufactured friction plate is high in inner bonding strength and high in adhesive strength. Continuity of friction materials is maintained. Torque transmission capacity and mechanical strength of the friction plate are improved. The service lifetime of the friction plate is prolonged.

Owner:JIANGJIN BRANCH CHONGQING DESBUTE FRICTION MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com