Ceramic brake pad with high performance for middle-to-high grade sedan

A high-performance, medium-to-high-end technology, applied in the field of automobile brake pads, can solve the problems of low thermal decay resistance, unstable high-temperature friction performance, and low wear resistance of ceramic brake pads, and achieve high strength and good braking performance , enhance the effect of braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

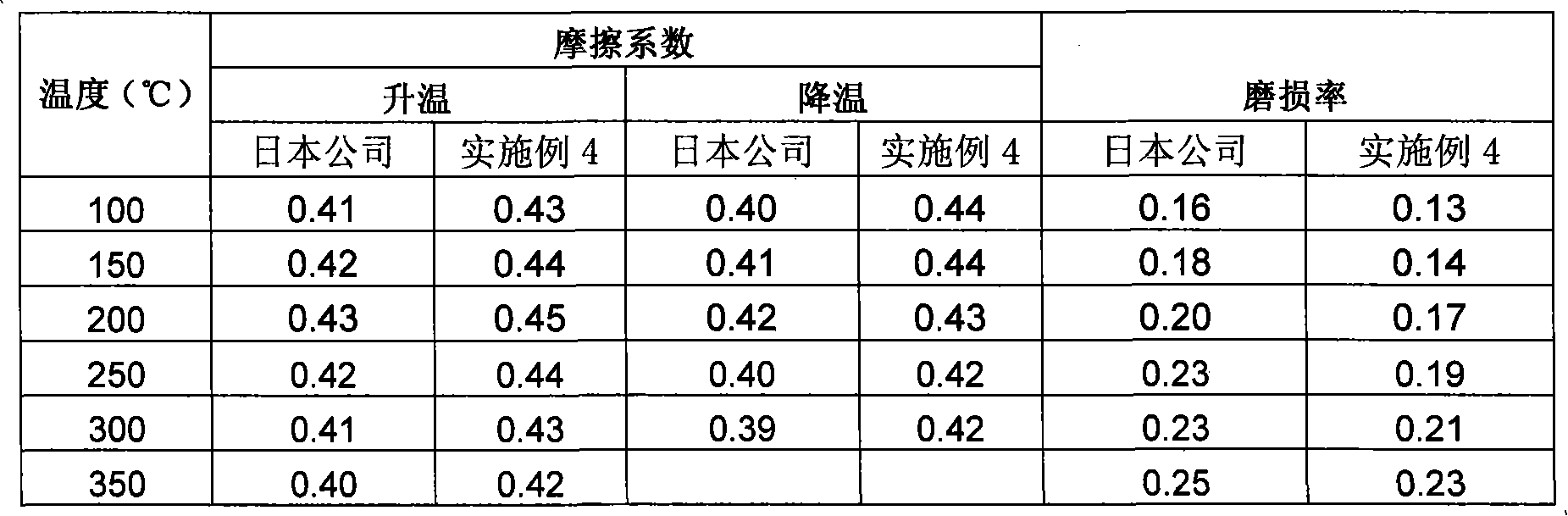

Examples

Embodiment 1

[0015] Example 1: 7% of ceramic fiber, 8% of silicate fiber, 6% of sprayed aluminum silicate fiber, 8% of aramid fiber, 7% of copper fiber, 6% of acicular wollastonite fiber , barite powder 12%, chromite powder 5%, nitrile rubber powder 1%, iron oxide black 2%, graphite particles 7%, zinc oxide 0.2%, calcined petroleum coke 8.5%, expanded graphite 3%, 9% boron phenolic resin, 3% magnetite, 1% heavy magnesium oxide, 0.8% silicon carbide, 4% barium sulfate whisker, 0.4% potassium titanate whisker, and 1.5% alumina fiber into the high-speed disperser , after stirring into powder, take it out and put it into the forming mold for pressing, and then compound with the steel back and put it into a flat vulcanizer at a high temperature of 270 ° C and a pressure of 18 MPa for 15 minutes, then take out the brake pad, remove the burr become a finished product. The components contained in the silicate fibers used in this embodiment and their weight-to-white ratio are: SiO 2 54%, Al 2 O ...

Embodiment 2

[0016] Example 2: 11% of ceramic fiber, 5% of silicate fiber, 9% of sprayed aluminum silicate fiber, 5% of aramid fiber, 10% of copper fiber, 6% of acicular wollastonite fiber , barite powder 8%, chromite powder 4%, nitrile rubber powder 2%, iron oxide black 4%, graphite particles 10%, zinc oxide 0.2%, calcined petroleum coke 4%, expanded graphite 1%, 5% boron phenolic resin, 5% magnetite, 0.8% heavy magnesium oxide, 1.5% silicon carbide, 7% barium sulfate whisker, 0.5% potassium titanate whisker, and 1% alumina fiber into the high-speed disperser , after stirring into powder, take it out and put it into the forming mold for pressing, and then compound with the steel back and put it into a flat vulcanizer at a high temperature of 270 ° C and a pressure of 18 MPa for 15 minutes, then take out the brake pad, remove the burr become a finished product. The components contained in the silicate fibers used in this embodiment and their weight-to-white ratio are: SiO 2 54%, Al 2 O ...

Embodiment 3

[0017] Example 3: 8% of ceramic fiber, 6% of silicate fiber, 7% of sprayed aluminum silicate fiber, 6% of aramid fiber, 8% of copper fiber, 8% of acicular wollastonite fiber , barite powder 9%, chromite powder 7%, nitrile rubber powder 2%, iron oxide black 3%, graphite particles 8.6%, zinc oxide 0.2%, calcined petroleum coke 6%, expanded graphite 2%, 5% boron phenolic resin, 4% magnetite, 1.3% heavy magnesium oxide, 1% silicon carbide, 5% barium sulfate whisker, 0.4% potassium titanate whisker, and 2.5% alumina fiber into the high-speed disperser , after stirring into powder, take it out and put it into the forming mold for pressing, then compound it with the steel back and put it into a flat vulcanizer at a high temperature of 270 ° C and a pressure of 18 MPa for 15 minutes, then take out the brake pads, remove the burrs, that is, become a finished product. The components contained in the silicate fibers used in this embodiment and their weight-to-white ratio are: SiO 2 54%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com