Resin bendable grinding wheel and preparation method and device

A grinding wheel and bending technology, applied in the field of resin bendable grinding wheel and preparation, can solve the problems of sacrificing anti-aging ability, carbonization, sticking to the pan, etc., and achieve the effect of accelerating the resin decomposition reaction, improving the yield of finished products, and improving the adhesion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

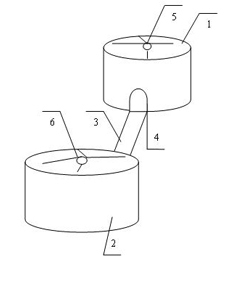

[0022] a. After mixing 60kg of brown corundum, 10kg of calcined corundum, 20kg of white corundum, and 10kg of black silicon carbide, put them into a small mixing pot 1, then add 6kg of phenolic resin solution, stir evenly with a small stirrer 5, and then mix the ice crystals Add 6kg of stone, 2kg of barium sulfate, 5kg of pyrite, and 2kg of red iron oxide and stir evenly with a small agitator 5. After the mixed materials are fully wetted, open the valve 4 and put the mixed materials into the large mixing tank through the feeding tank 3. In the mixing pot 2, add 18 kg of phenolic resin powder into the large mixing pot 2 and stir with the large agitator 6 until each grain of sand is evenly wrapped by the phenolic resin powder, and then put it into the material box;

[0023] b. Put the material box in the preheating constant temperature room for 3 hours, then take out the mixed material, beat loose, and sieve it into sand material, put the sieved sand material into the spreader, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com