Preparation method of porous biomass carbon, porous biomass carbon and application

A technology of biomass carbon and products, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of poor charge and discharge capacity and cycle stability of lithium-ion batteries, achieve resource reuse, prevent oxidation, and reduce prices cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the porous biomass carbon of one embodiment, comprises the following steps:

[0037] Step S110, mixing the straw with the calcium chloride solution and then standing still for 12-24 hours to obtain a mixture, wherein the mass ratio of the straw to the calcium chloride in the calcium chloride solution is 1:1.5-1:3.

[0038] In one embodiment, the stalks are corn stalks. Of course, in other embodiments, the straw can also be the remaining part of wheat, rice, potatoes, rapeseed, cotton, sugar cane or other coarse grain crops after the seeds are harvested.

[0039] In one embodiment, the straw is crushed, and the crushed straw is mixed with a calcium chloride solution.

[0040] In one of the embodiments, the straw is in powder form. Preferably, the particle size of the straw powder is 800-900 microns, preferably 850 microns.

[0041] In one embodiment, the concentration of the calcium chloride solution is 2mol / L˜4mol / L, preferably 3mol / L.

[0...

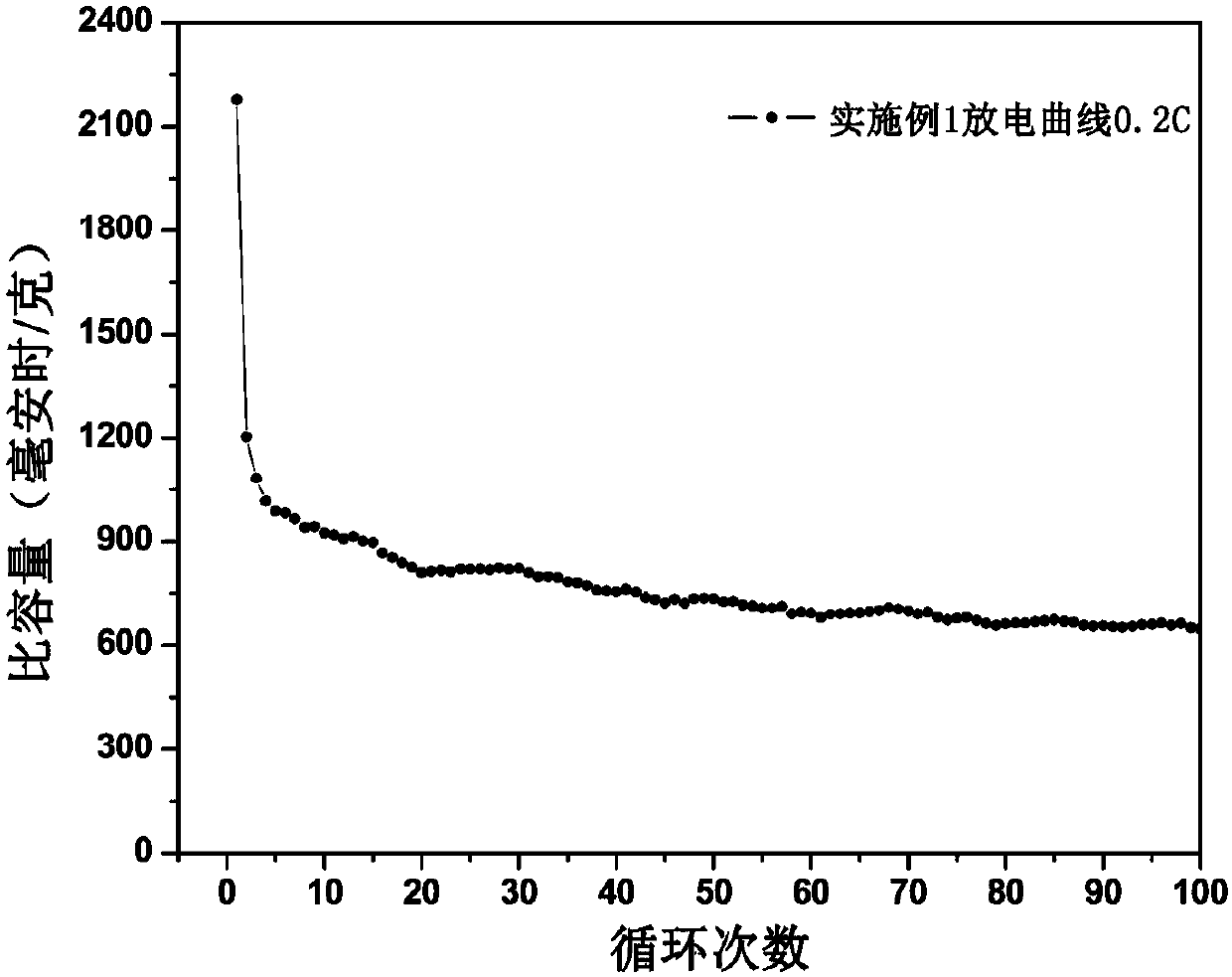

Embodiment 1

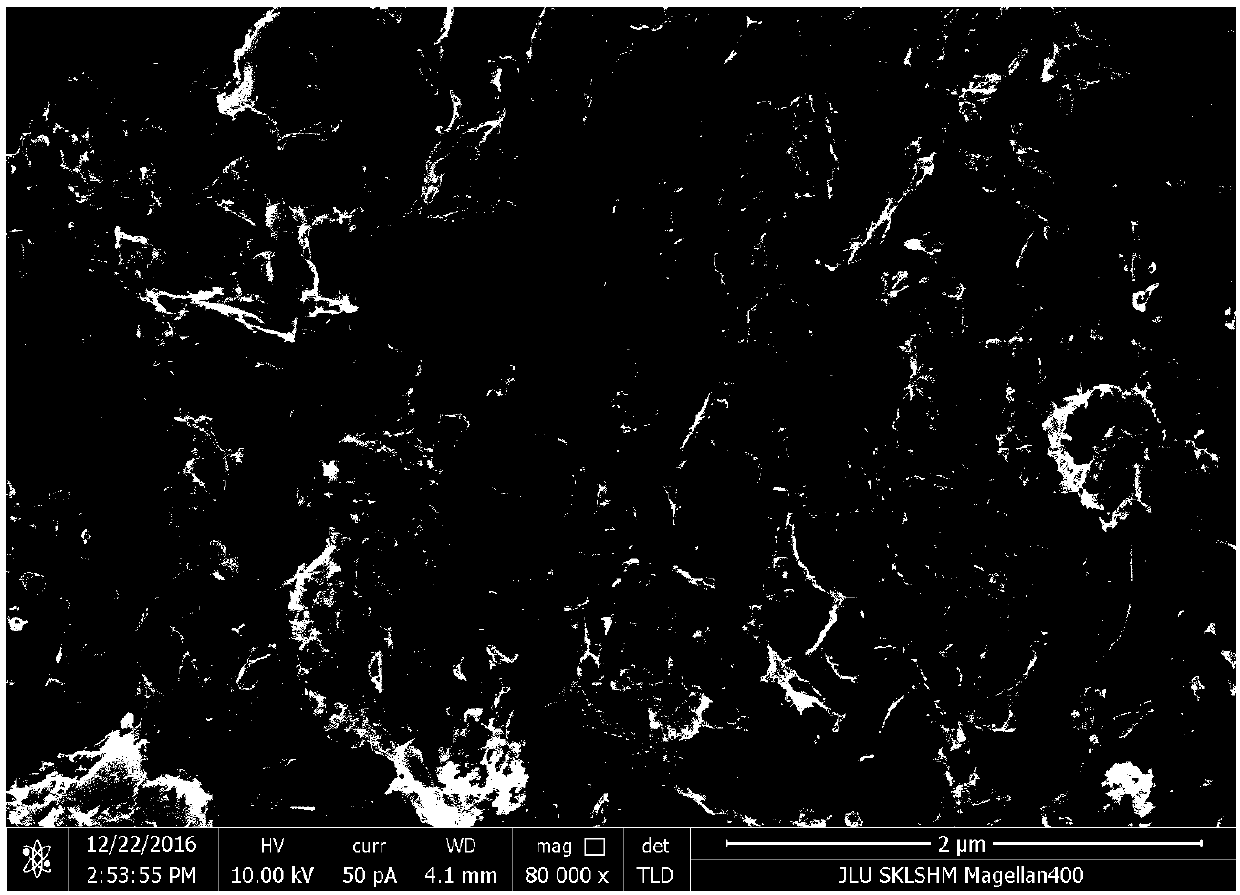

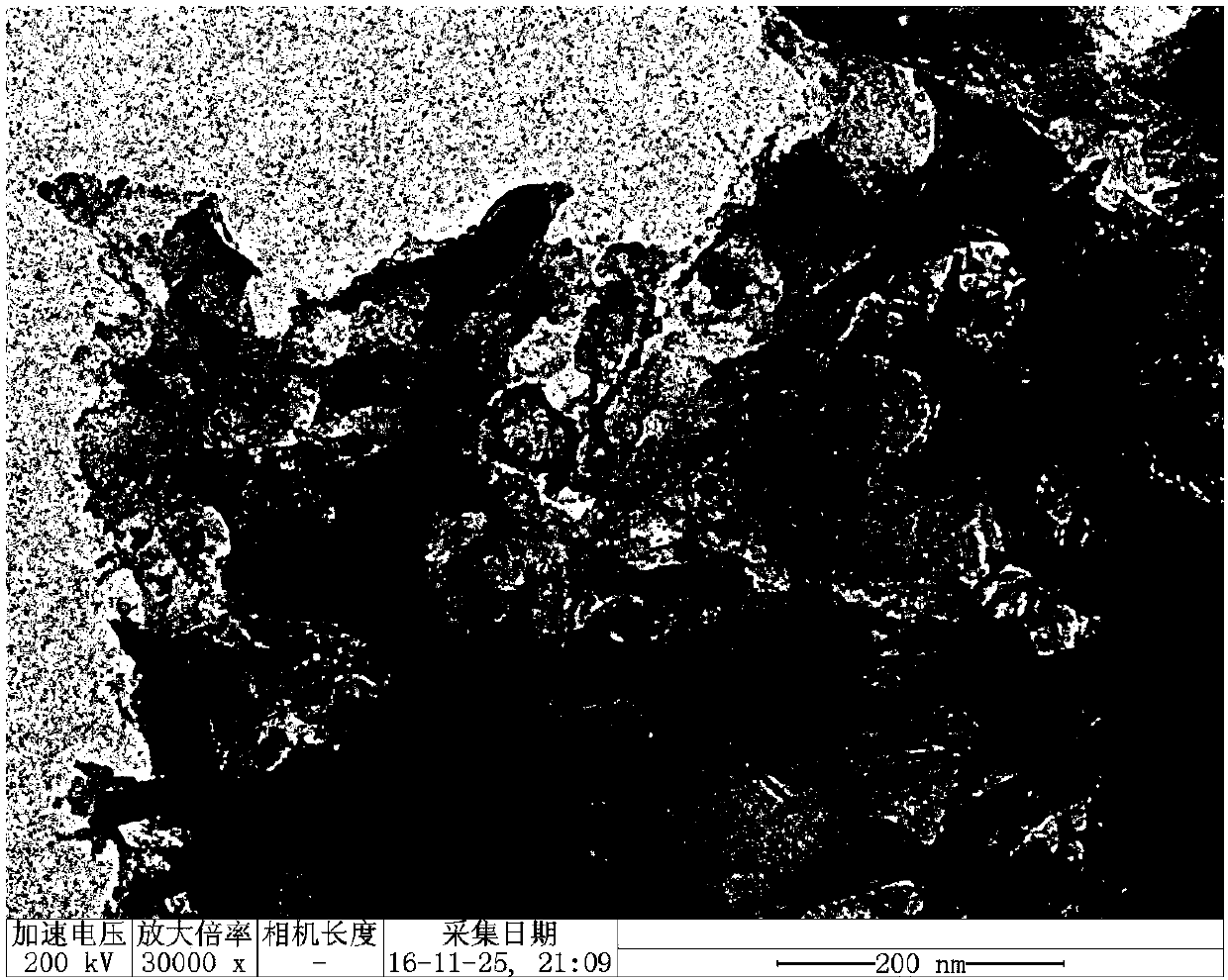

[0087] The preparation of porous biomass carbon includes the following steps:

[0088] Crush corn stalks into powder, mix 20 grams of corn stalk powder with 200 ml of 3mol / L calcium chloride solution, and let stand at room temperature for 24 hours;

[0089] Dry the mixture in an oven at a constant temperature of 60°C and place it in a crucible with a lid, heat it to 300°C in a muffle furnace at a heating rate of 10°C / min, and perform low-temperature carbonization for 3 hours to obtain a low-temperature carbide;

[0090] Continue heating the low-temperature carbide to 600°C in a muffle furnace at a heating rate of 10°C / min for high-temperature activation for 2 hours, and cool naturally to room temperature to obtain a pre-product. Put the pre-product into a beaker and add 100mL of deionized water to wash to obtain the recovered calcium chloride solution;

[0091] Soak the pre-product in 100mL 2mol / L hydrochloric acid solution for 24 hours, then wash it with 70°C deionized water...

Embodiment 2

[0093] The preparation of porous biomass carbon includes the following steps:

[0094] Crush corn stalks into powder, mix 10 grams of corn stalk powder with 200 ml of 2mol / L calcium chloride solution, and let stand at room temperature for 24 hours;

[0095] Dry the mixture in an oven at a constant temperature of 60°C and place it in a crucible with a lid, heat it to 300°C in a muffle furnace at a heating rate of 9°C / min, and perform low-temperature carbonization for 3 hours to obtain a low-temperature carbide;

[0096] Continue heating the low-temperature carbide to 500°C in a muffle furnace at a heating rate of 9°C / min for high-temperature activation for 1 hour, and naturally cool to room temperature to obtain a pre-product. Put the pre-product into a beaker and add 100mL of deionized water to wash to obtain the recovered calcium chloride solution;

[0097] Soak the pre-product in 100mL of 4mol / L hydrochloric acid solution for 24 hours, then wash it with 80°C deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com