Color glass-reinforced plastic profile material made from novel reclaimed material

A technology of recycled materials and plastic steel, applied in the field of material processing, can solve the problems of environmental impact, white pollution, improper recycling of plastic steel profiles, etc., and achieve the effect of good toughness, smooth surface and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

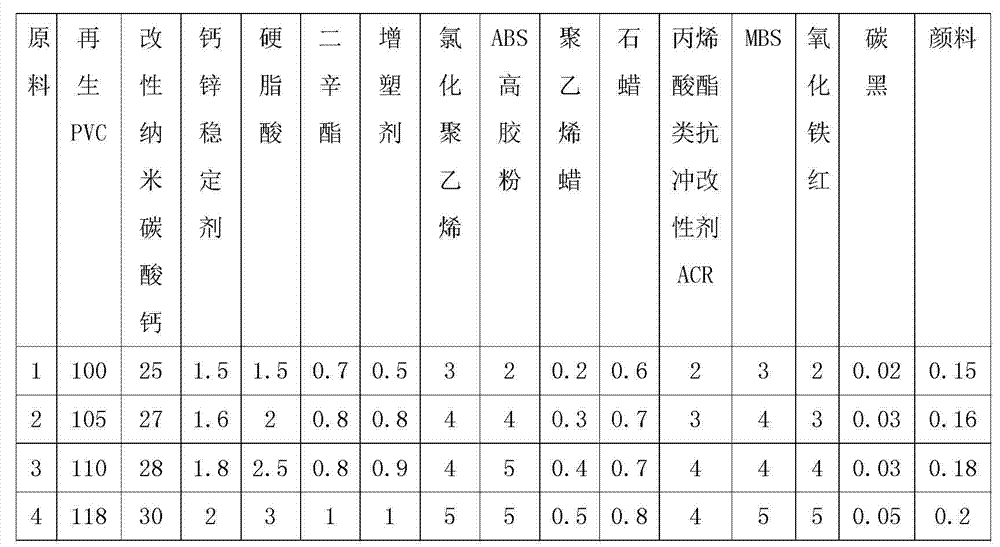

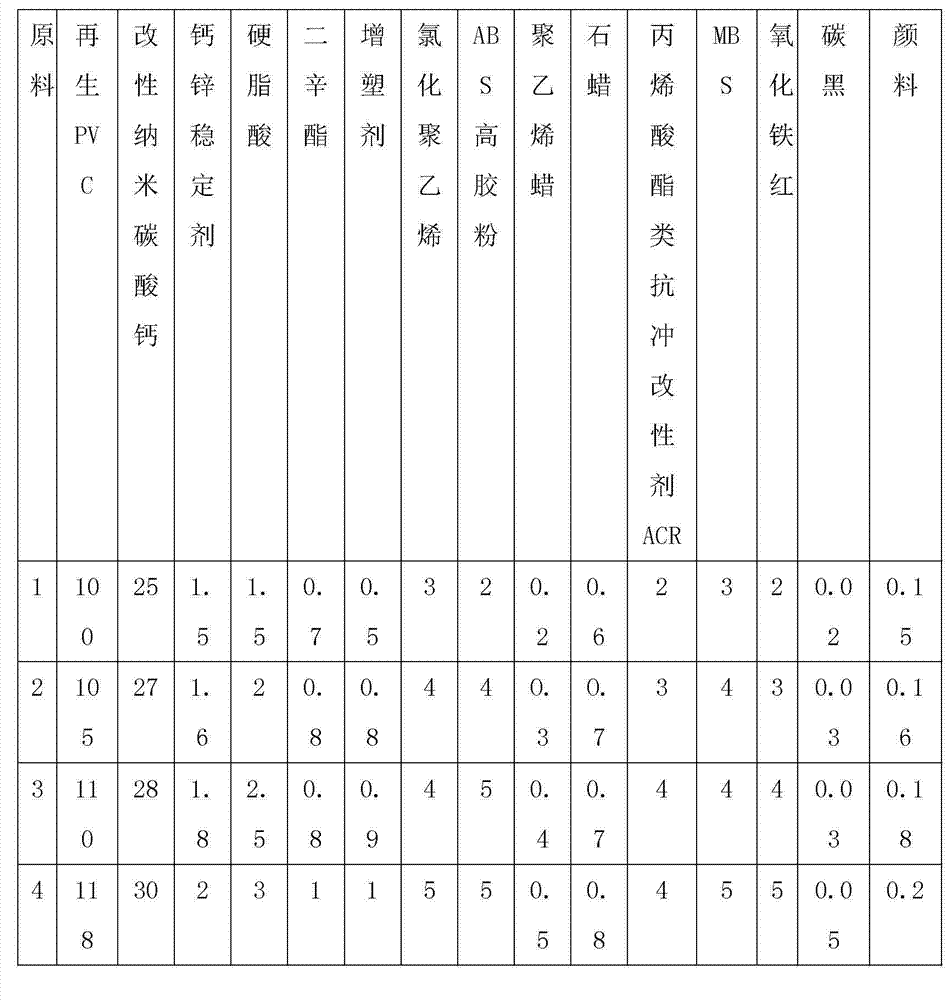

Embodiment 1

[0025] The new recycled material colored plastic steel profile is made of the following raw materials in parts by weight: recycled PVC 100, modified nano-calcium carbonate 25, calcium zinc stabilizer 1.5, stearic acid 1.5, dioctyl 0.7, plasticizer 0.5, chlorinated polyvinyl chloride Ethylene 3, ABS high rubber powder 2, polyethylene wax 0.2, paraffin wax 0.6, acrylate impact modifier ACR 2, MBS 3, iron oxide red 2, carbon black 0.02, pigment 0.15. Described plasticizer is epoxy fatty acid methyl ester. The modified nano-calcium carbonate is prepared by the following method: Calcium carbonate is burnt at 600-700°C for 4-5 hours, then ground into nano-powder, and mixed with bis(dioctyloxypyrophosphate) equivalent to 1% of the powder weight base) ethylene titanate, 2% propylene glycol sebacate, stirred evenly, dried, and crushed into powder.

[0026] The manufacturing process of the new colored plastic-steel profiles made of recycled materials includes the following steps:

[0...

Embodiment 2

[0032] The new colored plastic steel profile made of recycled materials is made of the following raw materials in parts by weight: recycled PVC 105, modified nano calcium carbonate 27, calcium zinc stabilizer 1.6, stearic acid 2, dioctyl 0.8, plasticizer 0.8, chlorinated polyvinyl chloride Ethylene 4, ABS high rubber powder 4, polyethylene wax 0.3, paraffin wax 0.7, acrylate impact modifier ACR 3, MBS 4, iron oxide red 3, carbon black 0.03, pigment 0.16. Described plasticizer is n-butyl methacrylate. The modified nano-calcium carbonate is prepared by the following method: Calcium carbonate is burnt at 600-700°C for 4-5 hours, then ground into nano-powder, and mixed with bis(dioctyloxypyrophosphate) equivalent to 1% of the powder weight base) ethylene titanate, 2% propylene glycol sebacate, stirred evenly, dried, and crushed into powder.

[0033] The manufacturing process of the novel recycled material colored plastic-steel profile is the same as in Example 1.

Embodiment 3

[0035] The new recycled material colored plastic-steel profile is made of the following raw materials in parts by weight: recycled PVC 110, modified nano calcium carbonate 28, calcium zinc stabilizer 1.8, stearic acid 2.5, dioctyl 0.8, plasticizer 0.9, chlorinated polyvinyl chloride Ethylene 4, ABS high rubber powder 5, polyethylene wax 0.4, paraffin wax 0.7, acrylate impact modifier ACR 4, MBS 4, iron oxide red 4, carbon black 0.03, pigment 0.18. Described plasticizer is glycerol triglyceride. The modified nano-calcium carbonate is prepared by the following method: Calcium carbonate is burnt at 600-700°C for 4-5 hours, then ground into nano-powder, and mixed with bis(dioctyloxypyrophosphate) equivalent to 1% of the powder weight base) ethylene titanate, 2% propylene glycol sebacate, stirred evenly, dried, and crushed into powder.

[0036] The manufacturing process of the novel recycled material colored plastic-steel profile is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com