Lignin-based hard carbon/carbon nanotube composite material and preparation method and application thereof in negative electrode materials of lithium ion batteries

A technology of carbon nanotubes and composite materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reduced first-time charge and discharge efficiency, reduced lithium-ion battery capacity, and increased difficulty, achieving good cycle stability, High energy density, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Take 200g of enzymatic lignin as raw material and put it in sodium hydroxide solution, stir at 70°C for 2 hours, and ensure that the pH of the solution is ≥ 12; after the dissolution is complete, filter to remove insoluble impurities and collect the filtrate, and add 50% of the filtrate dropwise Sulfuric acid solution, adjust the pH value of the solution to 2, so that the enzymatic lignin aggregates and settles; let it stand for more than 24 hours, and after the lignin has settled completely, filter, wash, and dry to obtain purified enzymatic lignin (EHL).

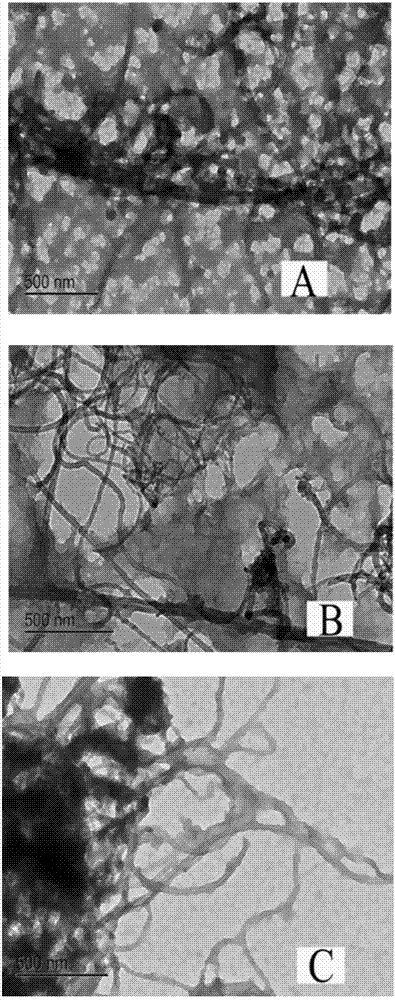

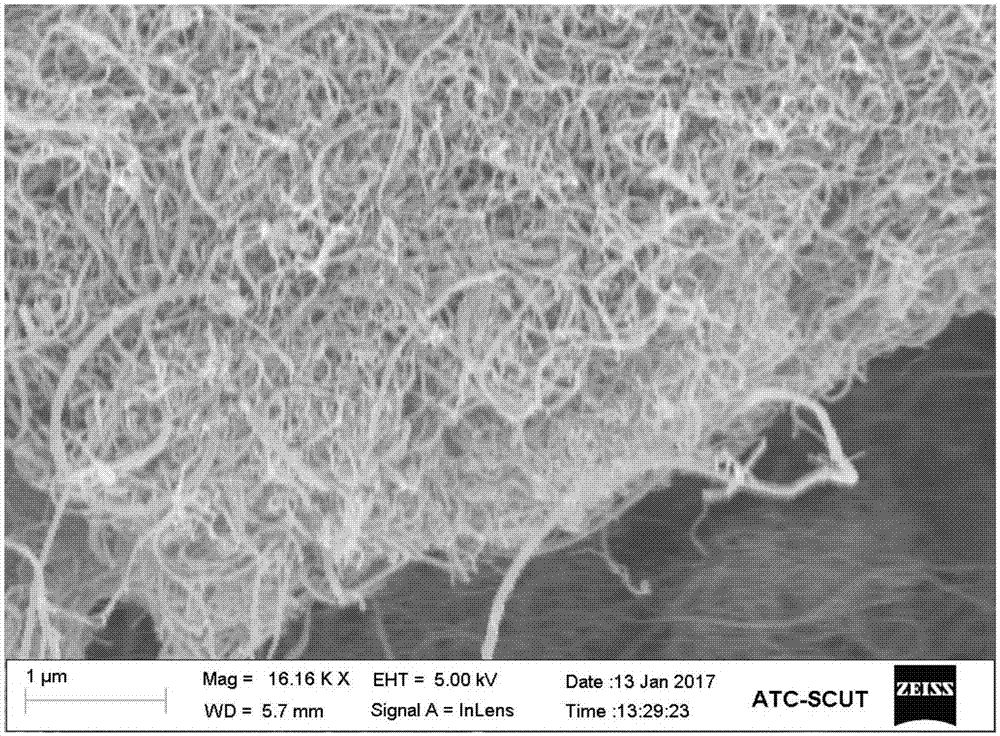

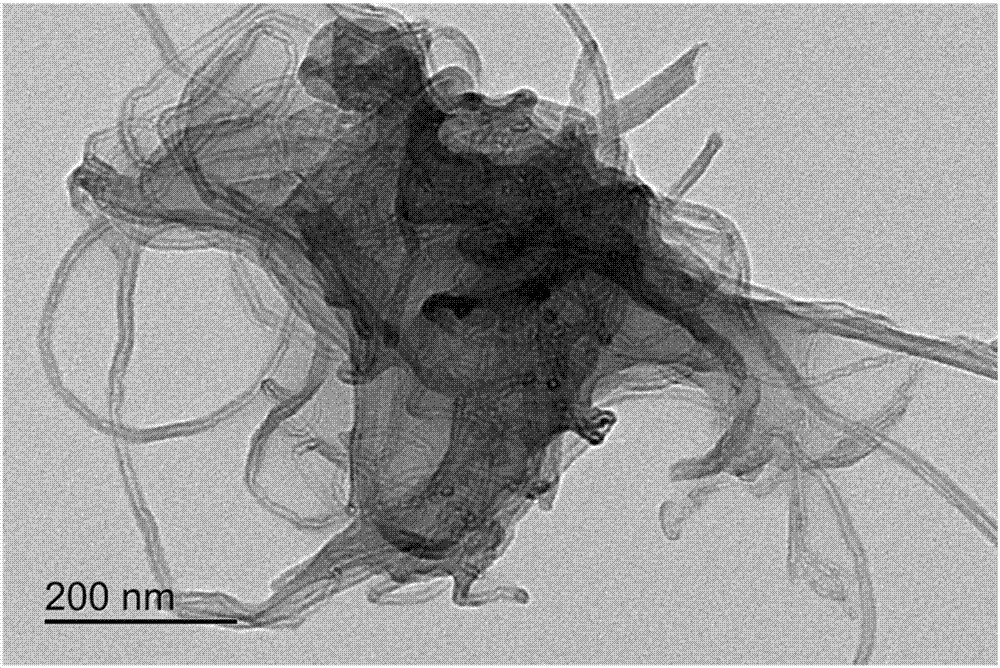

[0061] Take 250 mg of enzymatic lignin and disperse it in 125 mL of aqueous ethanol (V ethanol: V water = 1:4), ultrasonicate for 30 min and stir for 30 min, then repeat the ultrasonic and stirring once; take 100 mg of carbon nanotube solid powder and add it to 50 mL of ethanol aqueous (V ethanol : V water = 1:4), ultrasonically dispersed for 30 minutes and stirred for 30 minutes, and then repeated ultrasonic and sti...

Embodiment 2

[0078] Take 200g of enzymatic lignin as raw material and put it in sodium hydroxide solution, stir at 70°C for 2 hours, and ensure that the pH of the solution is ≥ 12; after the dissolution is complete, filter to remove insoluble impurities and collect the filtrate, and add 50% of the filtrate dropwise Sulfuric acid solution, adjust the pH value of the solution to 2, so that the enzymatic lignin aggregates and settles; let it stand for more than 24 hours, and after the lignin has settled completely, filter, wash, and dry to obtain purified enzymatic lignin (EHL).

[0079] Take 300 mg of enzymatic lignin and disperse it in 150 mL of aqueous ethanol (V ethanol: V water = 1:4), sonicate for 30 min and stir for 30 min, then repeat the ultrasonic and stirring once; take 80 mg of carbon nanotube solid powder and add it to 40 mL of ethanol water (V ethanol : V water = 1:4), ultrasonically dispersed for 30 minutes and stirred for 30 minutes, and then repeated ultrasonic and stirred onc...

Embodiment 3

[0084] Dissolve 200g of raw material enzymatic lignin in sodium hydroxide solution, stir at 70°C for 2 hours, and ensure that the pH of the solution is ≥ 12; after the dissolution is complete, filter to remove insoluble impurities and collect the filtrate, and add 50% of Sulfuric acid solution, adjust the pH value of the solution to 2, so that the enzymatic lignin aggregates and settles; let it stand for more than 24 hours, and after the lignin has settled completely, filter, wash, and dry to obtain purified enzymatic lignin (EHL).

[0085] Take 250 mg of enzymatic lignin and disperse it in 125 mL of aqueous ethanol (V ethanol: V water = 1:4), ultrasonicate for 30 min and stir for 30 min, then repeat the ultrasonic and stirring once; take 100 mg of carbon nanotube solid powder and add it to 50 mL of ethanol aqueous (V ethanol : V water = 1:4), ultrasonically dispersed for 30 minutes and stirred for 30 minutes, and then repeated ultrasonic and stirred once. The above lignin dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com