High temperature-resistant anticorrosive paint and preparation method thereof

A technology of anti-corrosion coating and high temperature resistance, applied in anti-corrosion coatings, fire retardant coatings, coatings, etc., can solve problems such as harm to the human body, pollute the environment, high temperature resistance, etc., achieve good water resistance, improve adhesion, and improve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

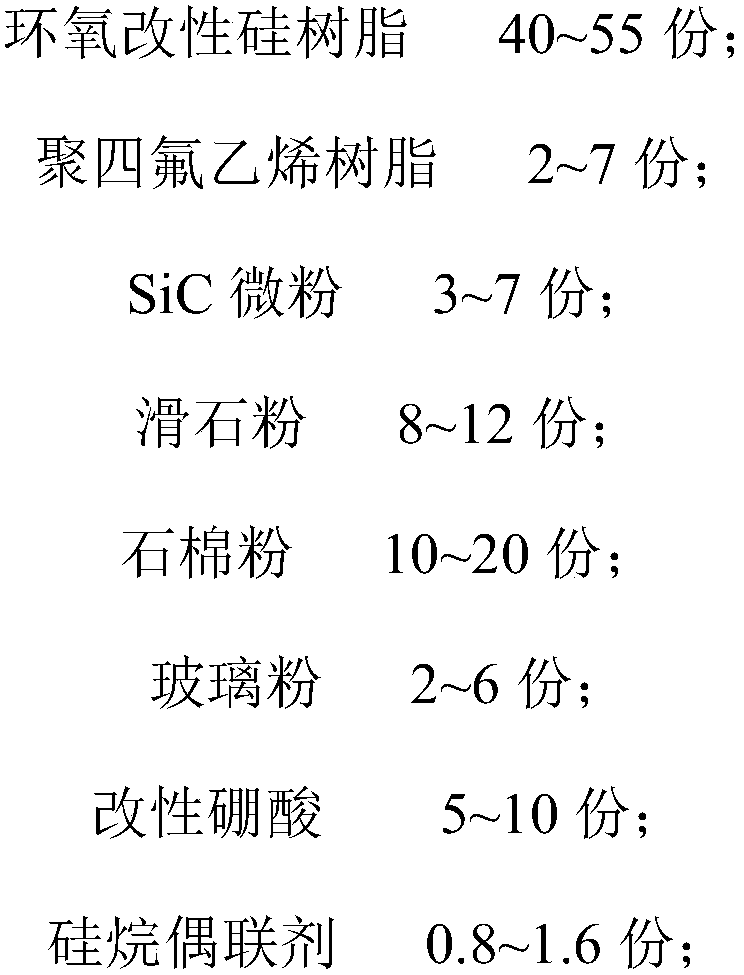

[0027] A high temperature resistant anticorrosion coating, comprising the following raw materials in parts by weight:

[0028]

[0029] The solvent is a mixed solvent composed of ethylene glycol, toluene, and benzene in a volume ratio of 1:1:1; the preparation method of the modified boric acid is: heating the boric acid at 210-230° C. for 0.5-1.0 h, cooling After grinding, the particle size is above 500 mesh.

[0030] The preparation method of described high temperature resistant anticorrosion coating comprises the following steps:

[0031] (1) Add the epoxy-modified silicone resin and polytetrafluoroethylene resin in the formula amount into the solvent, and stir at a high speed of 10000~13000r / min evenly;

[0032] (2) Then add SiC micropowder, talcum powder, asbestos powder, modified boric acid and glass powder, stir evenly at a high speed of 10000-13000r / min, and grind to a fineness below 50μm with a sand mill;

[0033] (3) Finally, add a silane coupling agent, a defoam...

Embodiment 2

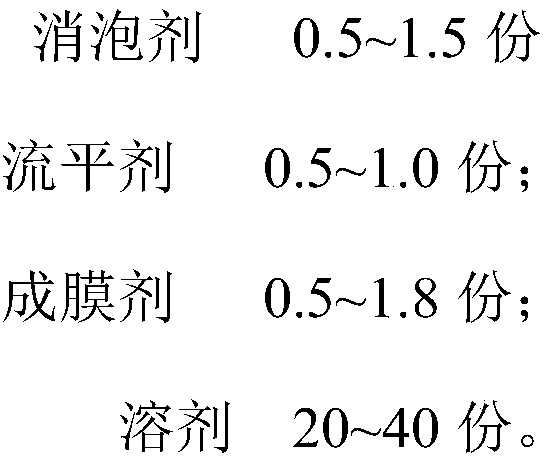

[0035] A high temperature resistant anticorrosion coating, comprising the following raw materials in parts by weight:

[0036]

[0037] The solvent is a mixed solvent composed of ethylene glycol, toluene, and benzene in a volume ratio of 1:1:1; the preparation method of the modified boric acid is: heating the boric acid at 210-230° C. for 0.5-1.0 h, cooling After grinding, the particle size is above 500 mesh.

[0038] The preparation method of described high temperature resistant anticorrosion coating comprises the following steps:

[0039] (1) Add the epoxy-modified silicone resin and polytetrafluoroethylene resin in the formula amount into the solvent, and stir at a high speed of 10000~13000r / min evenly;

[0040] (2) Then add SiC micropowder, talcum powder, asbestos powder, modified boric acid and glass powder, stir evenly at a high speed of 10000-13000r / min, and grind to a fineness below 50μm with a sand mill;

[0041] (3) Finally, add a silane coupling agent, a defoam...

Embodiment 3

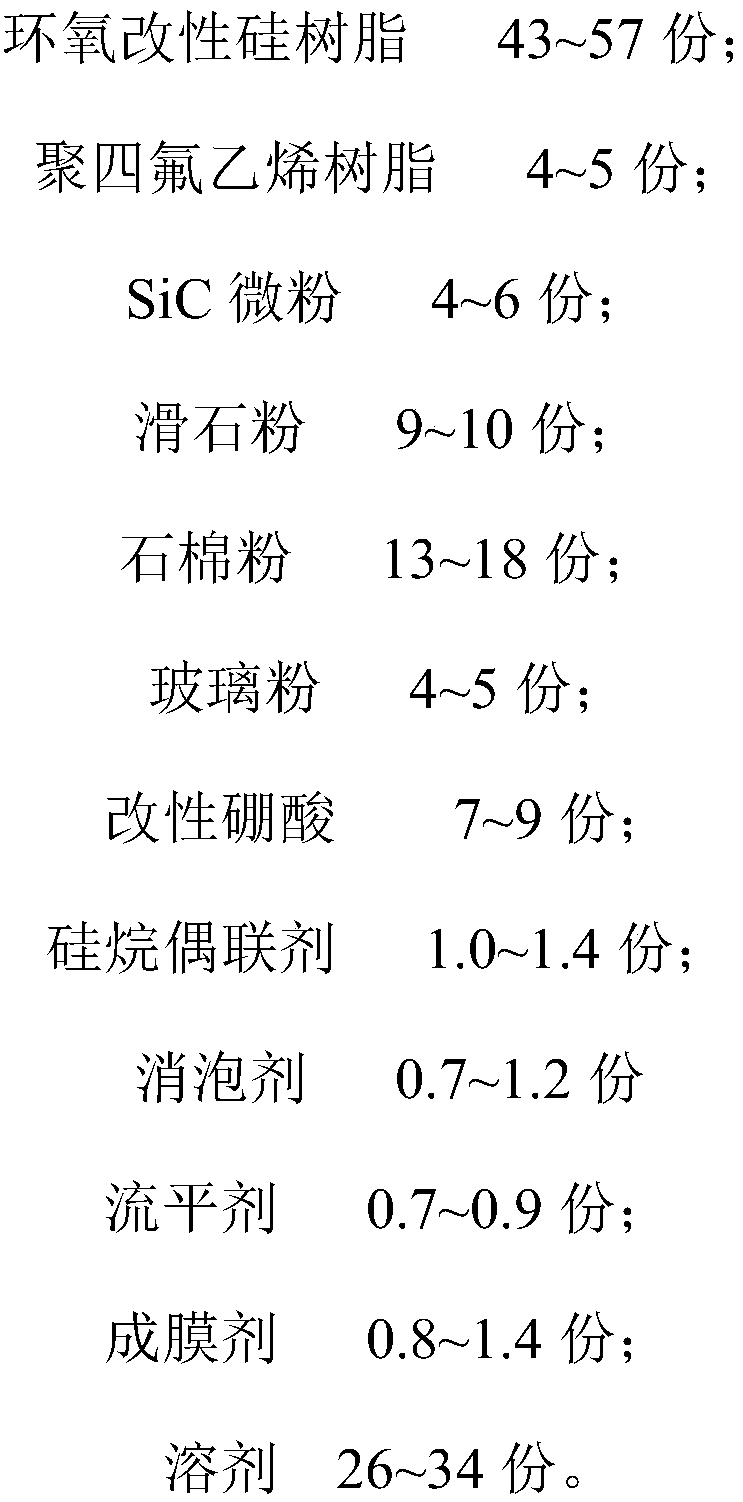

[0043] A high temperature resistant anticorrosion coating, comprising the following raw materials in parts by weight:

[0044]

[0045] The solvent is a mixed solvent composed of ethylene glycol, toluene, and benzene in a volume ratio of 1:1:1; the preparation method of the modified boric acid is: heating the boric acid at 210-230° C. for 0.5-1.0 h, cooling After grinding, the particle size is above 500 mesh.

[0046] The preparation method of described high temperature resistant anticorrosion coating comprises the following steps:

[0047] (1) Add the epoxy-modified silicone resin and polytetrafluoroethylene resin in the formula amount into the solvent, and stir at a high speed of 10000~13000r / min evenly;

[0048] (2) Then add SiC micropowder, talcum powder, asbestos powder, modified boric acid and glass powder, stir evenly at a high speed of 10000-13000r / min, and grind to a fineness below 50μm with a sand mill;

[0049] (3) Finally, add a silane coupling agent, a defoam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com