Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Celestine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Celestine or celestite is a mineral consisting of strontium sulfate (SrSO₄). The mineral is named for its occasional delicate blue color. Celestine and the carbonate mineral strontianite are the principal sources of the element strontium, commonly used in fireworks and in various metal alloys.

Carbon crystal composite microporous ceramic filter core and preparation method thereof

ActiveCN103381326AInhibition of reproductionHigh temperature resistantOther chemical processesFiltration separationFiltrationChlorinated paraffins

The invention provides a carbon crystal composite microporous ceramic filter core and a preparation method thereof. The invention is characterized in that the ceramic filter core is prepared from the following raw materials by weight: 12 to 14 parts of light calcium carbonate, 9 to 12 parts of kaolin, 7 to 9 parts of diatomite, 10 to 12 parts of bamboo charcoal powder, 4 to 6 parts of charcoal dust, 1 to 2 parts of straw ash, 12 to 14 parts of celestine powder, 6 to 8 parts of talcum powder, 3 to 5 parts of mica powder, 10 to 12 parts of chlorinated paraffin, 12 to 14 parts of ethanol, 25 to 35 parts of modified bentonite and a proper amount of water. The ceramic filter core provided by the invention has a plurality of functions like filtration, adsorption and suppression of bacterial reproduction and has the protruding advantages of high purification efficiency, high temperature resistance, small pressure loss, corrosion resistance, a long service life, removal of dust in air, etc.

Owner:ANHUI PHOENIX INT CO LTD

Pre-coated sand with high strength and low gas evolution rate and preparation method thereof

InactiveCN103567362AHigh strengthImprove heat resistanceFoundry mouldsFoundry coresSilanesNitrogen gas

The invention discloses pre-coated sand with high strength and a low gas evolution rate and a preparation method thereof. The pre-coated sand with high strength and low gas evolution rate is prepared from the following raw materials in parts by weight: 60-80 parts of quartz sand, 15-20 parts of celestite, 5-10 parts of wollastonite, 0.4-0.8 parts of ethenyl tri(beta-methoxyethyoxyl) silane, 4-6 parts of pentaerythritol oleate, 3-5 parts of epoxy soybean oil, 2-3 parts of nano magnesium oxide, 0.5-1.5 parts of bisphenol A epoxy resin, 1-2 parts of thermosetting phenol resin, 3-6 parts of diaminodiphenyl methane, 5-10 parts of urotropine, 4-8 parts of calcium stearate and 3-5 parts of composite powder. Compared with the conventional pre-coated sand, the pre-coated sand disclosed by the invention is not only high in strength, good in heat resistance, good in mobility and small in roughness, but also good in gas permeability and low in gas evolution rate, so that a casting piece can be effectively prevented from generating defects such as pin holes, nitrogen gas holes and burnt-on sand, and therefore, the yield of the casting piece is greatly improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Powder metallurgy helical gear and preparation method thereof

The invention provides a powder metallurgy helical gear which is formed by compressing the following power stocks in part by weight: 100 parts of iron powder, 1.8 to 2.0 parts of copper powder, 0.5 to 0.8 part of molybdenum powder, 0.1 to 0.3 part of cobalt powder, 0.8 to 1.2 part of nickel powder, 0.5 to 0.8 part of graphite powder, 0.1 to 0.3 part of modified wood ash, 0.2 to 0.6 part of rare earth ferrosilicon alloy, 0.1 to 0.3 part of paraffin, 0.1 to 0.2 part of ethylene bis stearamide, 0.1 to 0.3 part of celestite powder, 0.2 to 0.4 part of yttrium powder, 0.2 to 0.4 part of boron nitride, and 0.4 to 0.5 part of zinc oxide. When in preparation, mixing the powder stocks stepwise firstly, and obtaining the finished product helical gear through compressing and manufacturing, sintering, heat treatment and surface treatment. The produced powder metallurgy helical gear has the advantages that the helical gear is good in abrasion resistance, high in strength and rigidity, good in machinability, is corrosion resistant and less susceptible to breakage, and has a long service life.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

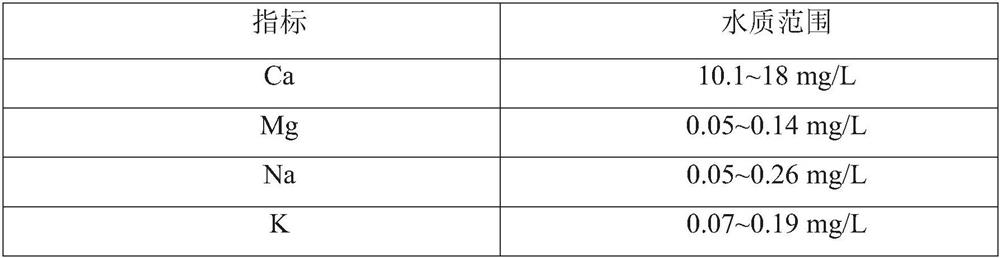

Composite mineral crystal capable of improving water quality, strengthening immunity and facilitating cardiovascular and cerebrovascular diseases and preparation method thereof

InactiveCN106219720AIncrease surface areaImprove adsorption capacityWater contaminantsWater/sewage treatment by substance additionDiseaseWater quality

The invention discloses a composite mineral crystal capable of improving water quality, strengthening immunity and facilitating cardiovascular and cerebrovascular diseases. The composite mineral crystal is prepared from the following components in parts by weight: 10 to 15 parts of medical stone, 5 to 10 parts of wooden fish stone, 5 to 10 parts of tourmaline, 30 to 55 parts of activated zeolite, 5 to 10 parts of celestite and 15 to 40 parts of kaolin. Meanwhile, the invention provides a preparation method of the composite mineral crystal. The surface area of the composite mineral crystal is increased by using supplementary strontium element of the added celestite and a secondary honeycomb wrapping burning technology, and the mineralization speed and effect are greatly improved, so that the precipitation of trace elements, particularly the precipitation of the strontium element, is more abundant, heavy metals are absorbed, and the composite mineral crystal has the effects of promoting metabolism, strengthening immunity, improving water quality and facilitating cardiovascular and cerebrovascular diseases.

Owner:刘乙霄

Filter core for adsorbing microparticles and preparation method thereof

InactiveCN103381355AHigh temperature resistantCorrosion resistanceOther chemical processesFiltration separationLow-density polyethyleneCelestine

The invention provides a filter core for adsorbing microparticles and a preparation method thereof, and is characterized in that the filter core is prepared by the following raw materials, in parts by weight: 43-45 parts of kaolin, 20-23 parts of a bamboo charcoal powder, 10-12 parts of a molecular sieve powder, 3-5 parts of sodium hydroxide, 6-8 parts of a potassium feldspar powder, 9-12 parts of a celestite powder, 16-18 parts of low-density polyethylene, 6-9 parts of ethylene glycol, 2-3 parts of freon, 4-6 parts of zirconium diboride, 3-4 parts of lauryl alcohol polyoxyethylene, 6-8 parts of a silane coupling agent KH792, and 30-35 parts of modified bentonite. The filter core for adsorbing the microparticles has the outstanding advantages of high porosity, large adsorption capacity, high purification efficiency, high temperature resistance, low pressure loss, corrosion resistance, long service life and the like, and can also remove micro-dust in air.

Owner:ANHUI PHOENIX INT CO LTD

High weather-resistant and anti-interference anticorrosive paint for power distribution cabinet

InactiveCN104497796AImprove film formationImprove the decorative effectAnti-corrosive paintsEpoxy resin coatingsXylyleneCelestine

The invention discloses a high weather-resistant and anti-interference anticorrosive paint for power distribution cabinets. The anticorrosive paint is characterized by comprising the following raw materials by weight: 22-25 parts of ethylene propylene terpolymer, 30-36 parts of bisphenol A type epoxy resin, 2-3 parts of chlorinated paraffin, 4-6 parts of glycol, 1-2 parts of dibutyl phthalate, 2-4 parts of vermiculite powder, 2-3 parts of celestite powder, 1-2 parts of triphenylmethyl ethylphenol polyoxyethylene ether, 2-3 parts of sodium benzoate, 5-7 parts of talcum powder, 2-3 parts of molybdenum pentachloride, 1-2 parts of vinyl tri(beta-methoxy ethoxy) silane, 1-2 parts of sulfonated lanolin calcium soap, 1-2 parts of carboxymethyl cellulose, 15-17 parts of butyl acetate, 6-9 parts of xylene and 4-7 parts of an aid. The paint provided by the invention has good decorative effect on the power distribution cabinet under natural conditions, and the paint film is smooth and flat, has good gloss and high weather resistance, and is not easy to turn yellowing or chalking; the added additive promotes the film forming ability of the paint, and also has anti-electromagnetic interference effect to prevent the interference on the electronic equipment in the power distribution cabinet, so as to avoid error signal.

Owner:WUHU HONGKUN AUTO PARTS

Deoxidizing agent for steelmaking of electric converter and preparation method thereof

The invention discloses a deoxidizing agent for the steelmaking of an electric converter and a preparation method thereof. The deoxidizing agent is obtained by uniformly mixing raw materials according to certain parts by weight, wherein the raw materials are calcium carbide, calcium oxide, calcium difluoride, coke, magnesium oxide, zinc oxide, straw ashes, kaoline, silicone dioxide, celestite, attapulgite and barium carbonate. The deoxidizing agent is used for the steelmaking of the electric converter, does not contain aluminium and can increase the physical, mechanical and processing properties of steel; and simultaneously, the deoxidizing agent can remove gases, changes a nonmetallic inclusion and can increase the quality and the mechanical property of the steel made by the electric converter.

Owner:芜湖县天海耐火炉料有限公司

Continuous casting crystallizer casting powder for high-manganese wear-resistant steel

The invention discloses a continuous casting crystallizer casting powder for high-manganese wear-resistant steel. The continuous casting crystallizer casting powder is obtained by breaking, mixing, pulping and granulating the flowing raw materials: pre-melted materials, modifying fly ashes, vermiculite, industrial sodium carbonate, fluorite, celestites, lithium carbonate and charcoals. The casting powder comprises the following components by weight percent: 32.3-37.8% of SiO2, 31.0-40.0% of CaO, 3.0-6.0% of Al2O3, 5.5-7.5% of Li2O, 10.5-18.5% of Na2O, 4.5-6.5% of TC, 5.0-6.8% of SrSO4, smaller than or equal to 2% of K2O, smaller than or equal to 1% of MnO2 and other minor components. According to the continuous casting crystallizer casting powder, the fly ashes are adopted for modifying, the dispersibility is improved, the superficial area is increased, furthermore, the heat insulation and the flowing property are promoted, and the nano ore powders also play the role of purifying molten steel and absorbing the impurities in the molten steel.

Owner:马鞍山科润冶金材料有限公司

Low-temperature resistant high-toughness PVC (polyvinyl chloride) pipe

InactiveCN103554770AImprove toughnessHigh mechanical strengthGeneral water supply conservationRigid pipesCelestineBoride

The invention discloses a low-temperature resistant high-toughness PVC (polyvinyl chloride) pipe which is characterized by consisting of the following raw materials in parts by weight: 76-80 parts of PVC resin, 8-12 parts of thermoplastic polyurethane elastomer, 2-3 parts of stearic acid, 2-3 parts of mannitol, 1-2 parts of dimolybdenum boride, 3-4 parts of polyvinyl butyral ester, 0.3-1 part of sodium methylene dinaphthalenesulfonate, 1-2 parts of tall oil, 2-3 parts of silicon nitride, 3-5 parts of celestite powder, 1-2 parts of octylisothiazolinone and 6-10 parts of composite filler. The PVC pipe disclosed by the invention has excellent toughness, good mechanical strength, strong wear and impact resistance and strong weather resistance; particularly, with good low-temperature resistance, the PVC pipe is not easily fractured, damaged and the like under a low-temperature condition.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

Process for balling by mixing 200 meshes of celestite mineral powders and reduction coals

The invention relates to a process for balling by mixing 200 meshes of celestite mineral powders and reduction coals. The process comprises the steps of (1) stirring and uniformly mixing the celestite mineral powders, the reduction coals and bentonite to obtain a raw material; (2) stirring industrial polypropylene glycol by water so as to completely dissolve the polypropylene glycol, and configuring the polyvinyl alcohol to be 20g / L of polypropylene glycol solution, then adding water and diluting the polypropylene glycol solution to be 2-4g / L of polyvinyl alcohol solution; and (3) spraying and adding the polypropylene glycol solution into the raw material, stirring and mixing uniformly, then extruding and balling on a ball pressing machine until the grain size of a ball body is 15mm, and the water content of the ball body accounts for 5-7% of the total weight of the ball body; and (4) drying the ball body obtained from the step (3) to constant weight, and roasting the dried ball body according to a conventional process to be used for producing strontium carbonate. According to the process, few devices are invested, the cost is low, the process is simple, and impurities capable of affecting the quality of strontium carbonate are not introduced into the raw materials.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

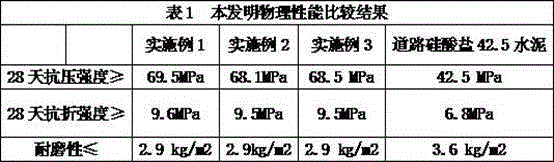

Concrete repairing agent for bridge pavement and preparation method of concrete repairing agent

The invention relates to a concrete repairing agent for a bridge pavement. The concrete repairing agent is prepared from the following raw materials in parts by weight: 10 parts of szaibelyite, 7 parts of forsterite, 11 parts of celestite, 3 parts of zinc hydroxide, 75 parts of ordinary Portland cement, 1.5 parts of a polycarboxylate high-performance water reducer, 2 parts of methyl benzotriazole, 6 parts of hydroxypropyl methyl cellulose, 4 parts of annular polydimethylsiloxane, 5 parts of triisopropanolamine and 42 parts of water. The repairing agent is prepared from the polycarboxylate high-performance water reducer, 42.5 ordinary Portland cement, compound active powder which is prepared from szaibelyite, forsterite, celestite and zinc hydroxide and an additive which is prepared from methylbenzotriazole, hydroxypropyl methyl cellulose, annular polydimethylsiloxane and triisopropanolamine. The repairing agent provided by the invention has relatively high strength and toughness, and is hardly corroded, excellent in anti-scouring performance and very suitable for repairing the concrete pavement.

Owner:河南省交通运输厅京珠高速公路新乡至郑州管理处

Process for preparing catalyst and carrier used in synthesizing 4-methyl amylene-1

InactiveCN1465437AIncrease loadImprove adsorption capacityPhysical/chemical process catalystsMetalloleGraphite

The preparation method of catalyst carrier for synthesizing 4-methyl pentene-1 includes the following steps: adding graphite or carbon black and celestine powder in alkali metal carbonate, in which the added quantity of graphite or carbon black is 0.1-5% of weight of alkali metal carbonate and the added quantity of celestine powder is 0.1-10% of the weight of alkali metal carbonate, tabletting, pulverizing, screening and roasting by introducing air at 100-600 deg.C.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-refractive-index glass micro-beads for reflective film and preparation method thereof

InactiveCN104973789AImprove mechanical propertiesImprove aging resistanceGlass shaping apparatusCelestineRefractive index

The invention discloses a high-refractive-index glass micro-beads for a reflective film and a preparation method thereof, wherein the glass micro-beads are prepared from the following raw materials in parts by weight: 27-34 parts of datholite, 16-29 parts of celestine, 5-8 parts of potassium tartrate, 8-12 parts of molybdenum oxide, 23-37 parts of apophyllite, 18-32 parts of titanaugite, 12-18 parts of barium carbonate, 4-7 parts of sodium hydrogen sulfite, 6-9 parts of a petroleum coke powder, 20-30 parts of waste molding sand, 14-22 parts of laterite, 4-6 parts of sodium sulphate anhydrous, and 7-10 parts of an additive. With datholite, celestine, apophyllite, titanaugite and waste molding sand as the main raw materials, and with addition of a right amount of molybdenum oxide, potassium tartrate, barium carbonate and other raw materials, the prepared glass micro-beads also have relatively high refractive index reaching 1.95 or more while having excellent mechanical properties and excellent aging resistance, and can be widely used in preparation of the reflective film.

Owner:HEFEI DINGLIANG OPTICAL TECH

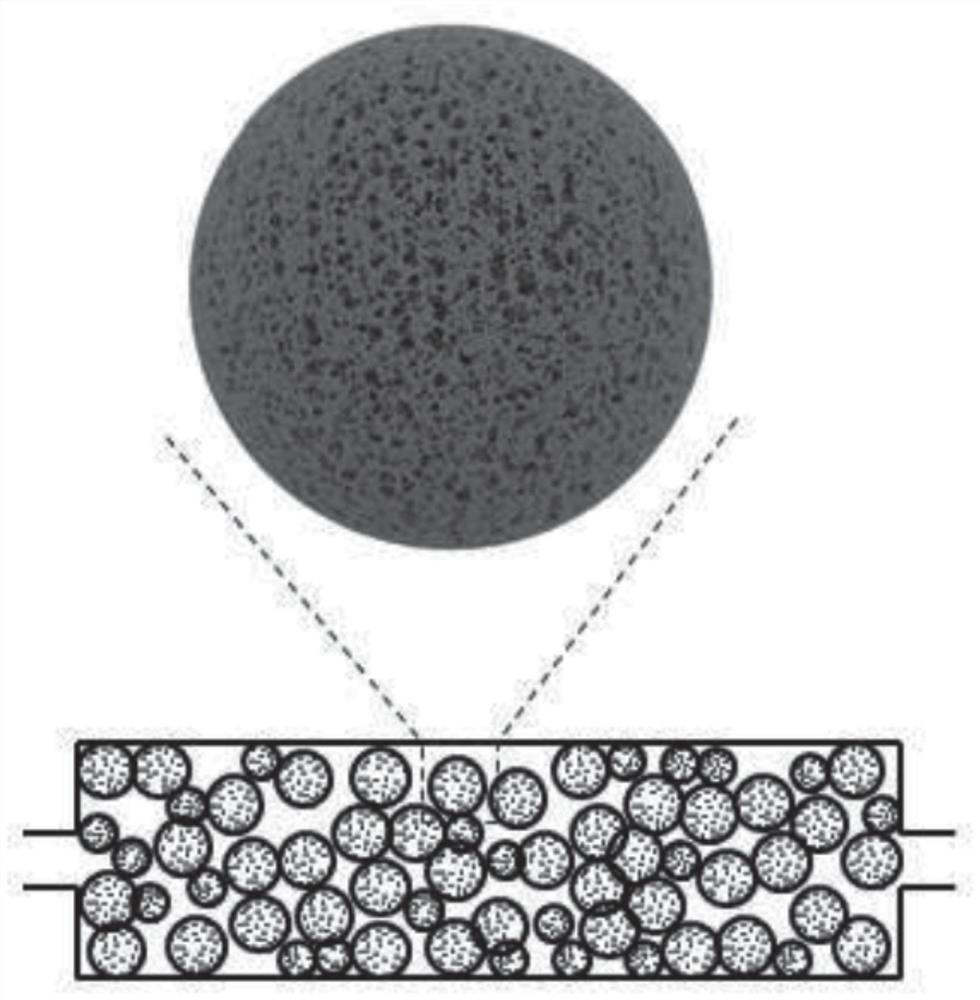

Porous ore filter element material and preparation method thereof

PendingCN114715997AStable structureHigh compressive strengthWater/sewage treatment by neutralisationSustainable biological treatmentCelestineAdhesive

The invention provides a porous ore filter element material and a preparation method thereof, and the porous ore filter element material is prepared from the following raw materials: a main material, an adhesive and a pore forming agent, the main materials are selected from the following raw materials: medical stone, limonite, selenium ore, celestite, shell, silicate ore and magnesium ore; the adhesive is selected from the following components: sodium silicate, clay, shellac, rosin, dextrin and synthetic resin; the pore-forming agent is selected from the following components: ammonium bicarbonate, sodium bicarbonate, sodium carbonate and calcium carbonate. The filter element material disclosed by the invention is used for optimizing drinking water mineralization treatment, so that selenium and strontium elements in effluent quality can simultaneously reach the level of natural mineral water; the material is formed by secondary modification processing of natural ore with high mineral dissolution, the specific surface area of the material is increased through modification, and the dissolution performance of the natural ore is improved.

Owner:中南水务科技有限公司 +1

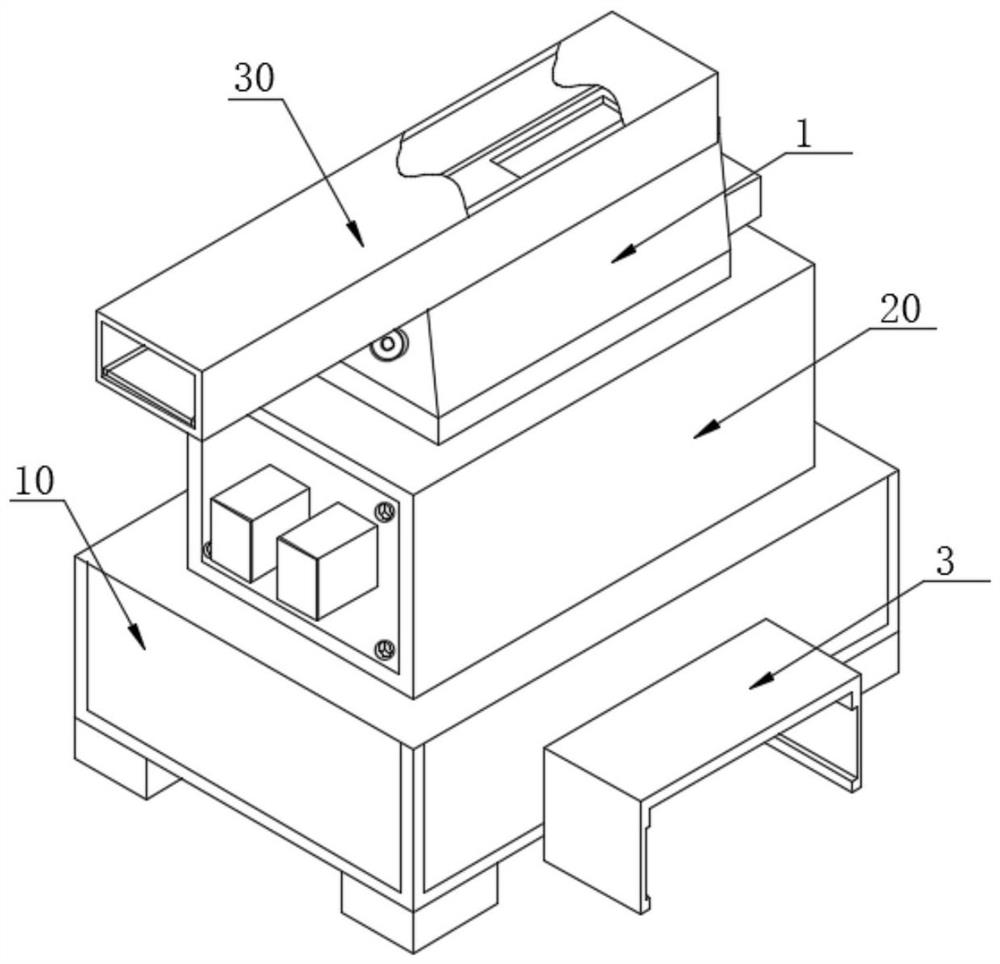

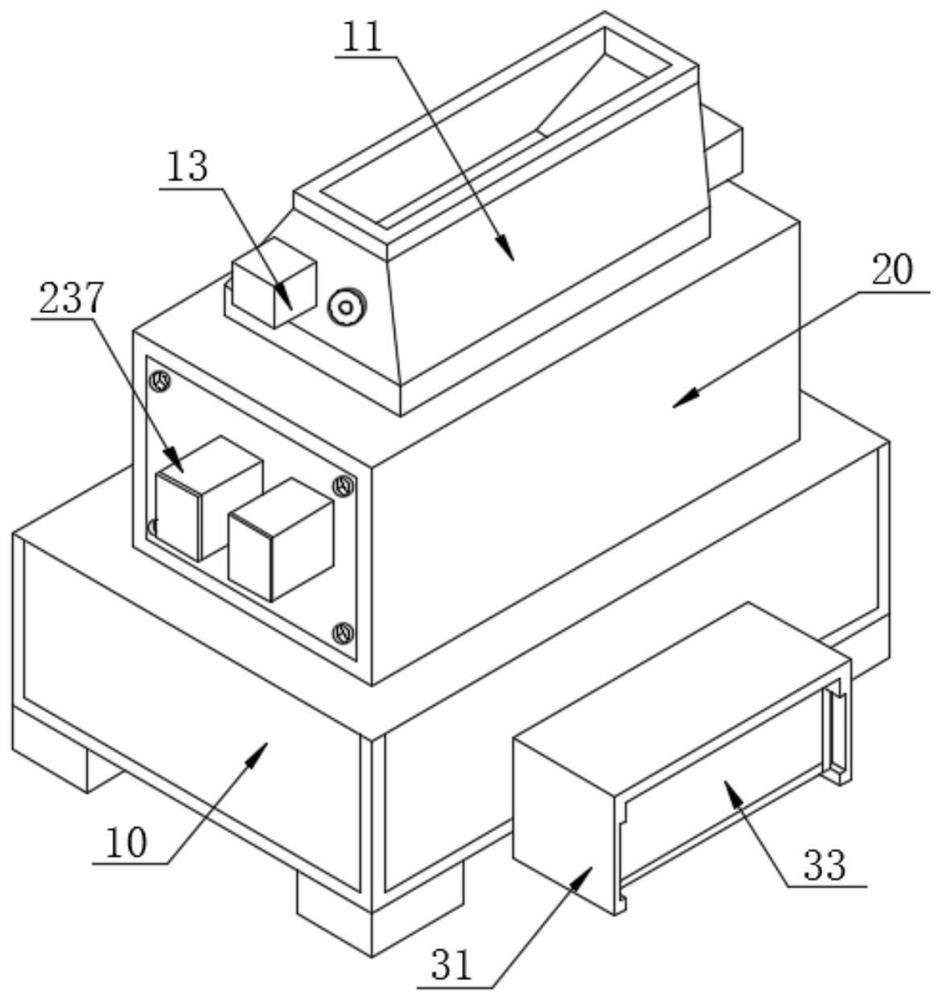

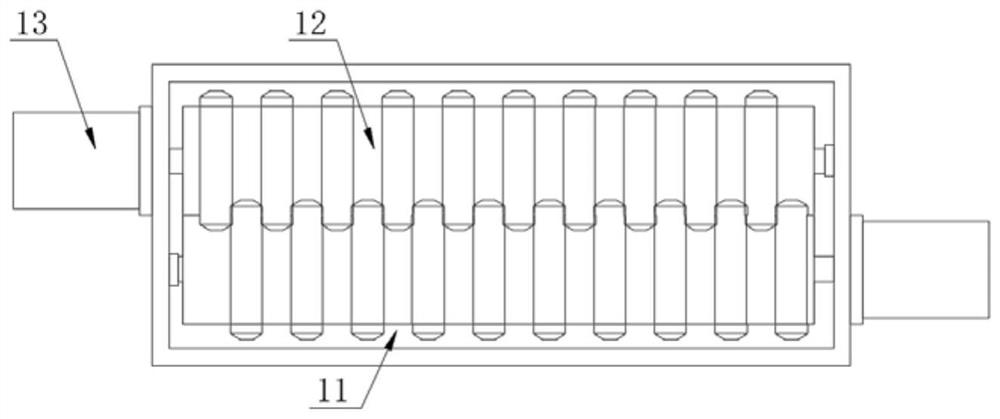

Barite or celestite raw ore grinding process and equipment

PendingCN113262844ASmall and uniform powderMeet production requirementsDirt cleaningGrain treatmentsCelestineMining engineering

The invention discloses a barite or celestite raw ore grinding process and equipment. The equipment comprises a rack and a case, wherein the top of the rack is fixedly connected with the bottom of the case; a feeding mechanism is arranged at the top of the case; a feeding frame is arranged at the top of the feeding mechanism; a crushing mechanism is arranged in the case; and a discharging mechanism is arranged in the rack. According to the barite or celestite raw ore grinding process and equipment, two transmission gears III rotate in opposite directions, so that two crushing rollers III rotate in opposite directions, and two crushing rollers I, two crushing rollers II and two crushing rollers III rotate in opposite directions; and crushing gaps with different sizes are reserved among the two crushing rollers I, the two crushing rollers II and the two crushing rollers III, so that after celestite is crushed for three times, powder with small and uniform particles can be obtained, and a barite or celestite raw ore powder product meeting the production requirements of subsequent processing and extraction is obtained.

Owner:仝六斗 +1

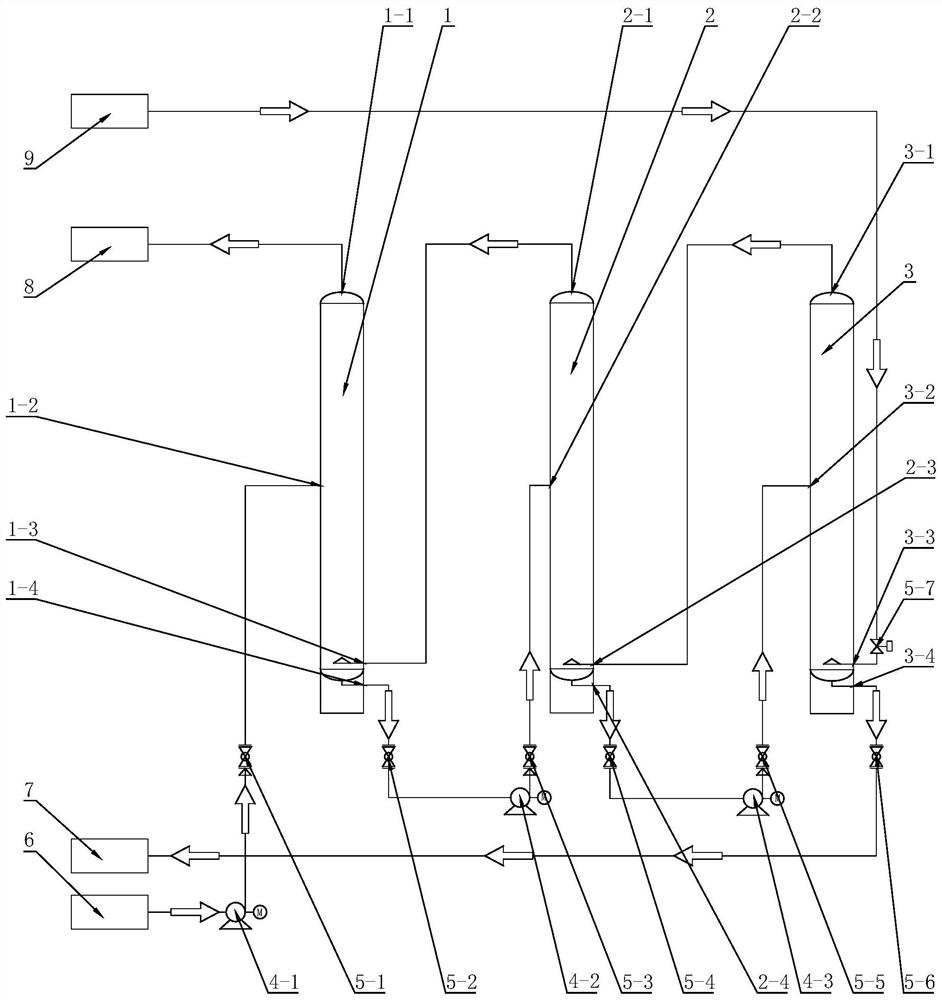

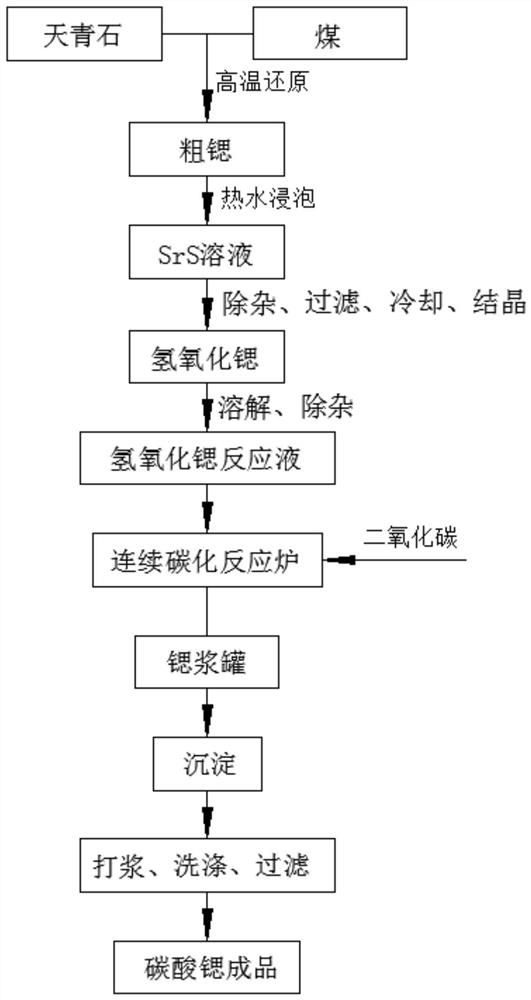

Continuous carbonization reaction system and production process for producing high-purity large-particle-size strontium carbonate

PendingCN112678859ALarge particle sizeHighly stable particle sizeCalcium/strontium/barium carbonatesCelestineStrontium carbonate

The invention discloses a continuous carbonization reaction system and production process for producing high-purity large-particle-size strontium carbonate. The production process comprises the following steps of: carrying out high-temperature reduction on celestite to obtain strontium sulfide; soaking the strontium sulfide in hot water; performing filtering, impurity removing, cooling and crystallizing to obtain strontium hydroxide crystals; dissolving the strontium hydroxide crystals to remove impurities, thereby obtaining a strontium hydroxide reaction solution; introducing the strontium hydroxide reaction solution into a continuous carbonization reaction tower which is provided with three reaction towers communicated with one another; introducing the strontium hydroxide reaction solution and carbon dioxide gas into the reaction towers; and keeping the liquid level of each reaction tower stable, thereby obtaining the high-purity large-particle-size strontium carbonate, The production process of the invention is simple; a continuous production mode is adopted; the strontium sulfide is directly used for producing the large-particle-size strontium carbonate, and barium hydroxide can also be used for producing barium carbonate; and high stability of the liquid level in the reaction process is guaranteed by controlling the concentration and impurity content of the reaction solution, and the produced high-purity strontium carbonate or barium carbonate product is large in particle size and stable in quality; large-scale production is facilitated.

Owner:CHONGQING KINGLONG FINE STRONTIUM CHEM

Wear-resistant high-hardness ceramic and processing technology thereof

The invention discloses a wear-resistant high-hardness ceramic and a processing technology thereof, wherein the wear-resistant high-hardness ceramic comprises the following raw materials in parts by weight: 13-16 parts of aluminum hydroxide, 21-26 parts of polycrystalline silicon, 33-42 parts of iron oxide, 35-42 parts of celestite, 12-15 parts of graphite, 15-17 parts of indium, 20-55 parts of aluminum oxide, 14-29 parts of porcelain powder, 8-15 parts of feldspar, 4-7 parts of clay, 5-10 parts of Suzhou soil, 9-18 parts of zirconium oxide, 3-6 parts of zinc oxide, 2-4 parts of magnesium carbonate, 1-2 parts of rock crystal, and 2.4-4.7 parts of spodumene. According to the invention, by adding zirconium oxide into the formula, the whole ceramic has advantages of high toughness, high bending strength, high wear resistance, excellent heat insulation performance, thermal expansion coefficient close to the thermal expansion coefficient of steel, and the like, can meet a large number of industrial requirements, has wide application range compared with common ceramics, is suitable for severe use environments, and is simple in whole processing method, low in processing method cost and worthy of popularization.

Owner:EZHOU JINFENG SUPERHARD MATERIALS CO LTD

High-performance building ceramic

The invention relates to high-performance building ceramic. The high-performance building ceramic is prepared from the following raw materials in parts by weight: 9-15 parts of barium titanate, 6-10 parts of silicon oxide, 5-9 parts of polyacrylamide, 7-9 parts of clay, 6-8 parts of boron nitride, 4-9 parts of isopropyl alcohol, 6-11 parts of polyvinyl butyral, 5-8 parts of polyethylene glycol, 6-10 parts of R-140 epoxy resin, 3-6 parts of cerium oxide, 8-15 parts of niobium hydroxide, 6-11 parts of silicon carbonate, 5-10 parts of diethylenetriamine, 1-3 parts of titanium oxide, 2-7 parts of aluminum oxide, 3-8 parts of hydroxyalkylamide, 4-11 parts of diopside, 5-12 parts of linear low density polyethylene, 3-6 parts of celestite and 6-11 parts of magnesite. The high-performance building ceramic has beneficial effect of good hydrophobicity as well as good hardness, is porous and can be widely used in the construction industry.

Owner:QINGDAO ZHIGU INNOVATION TECH

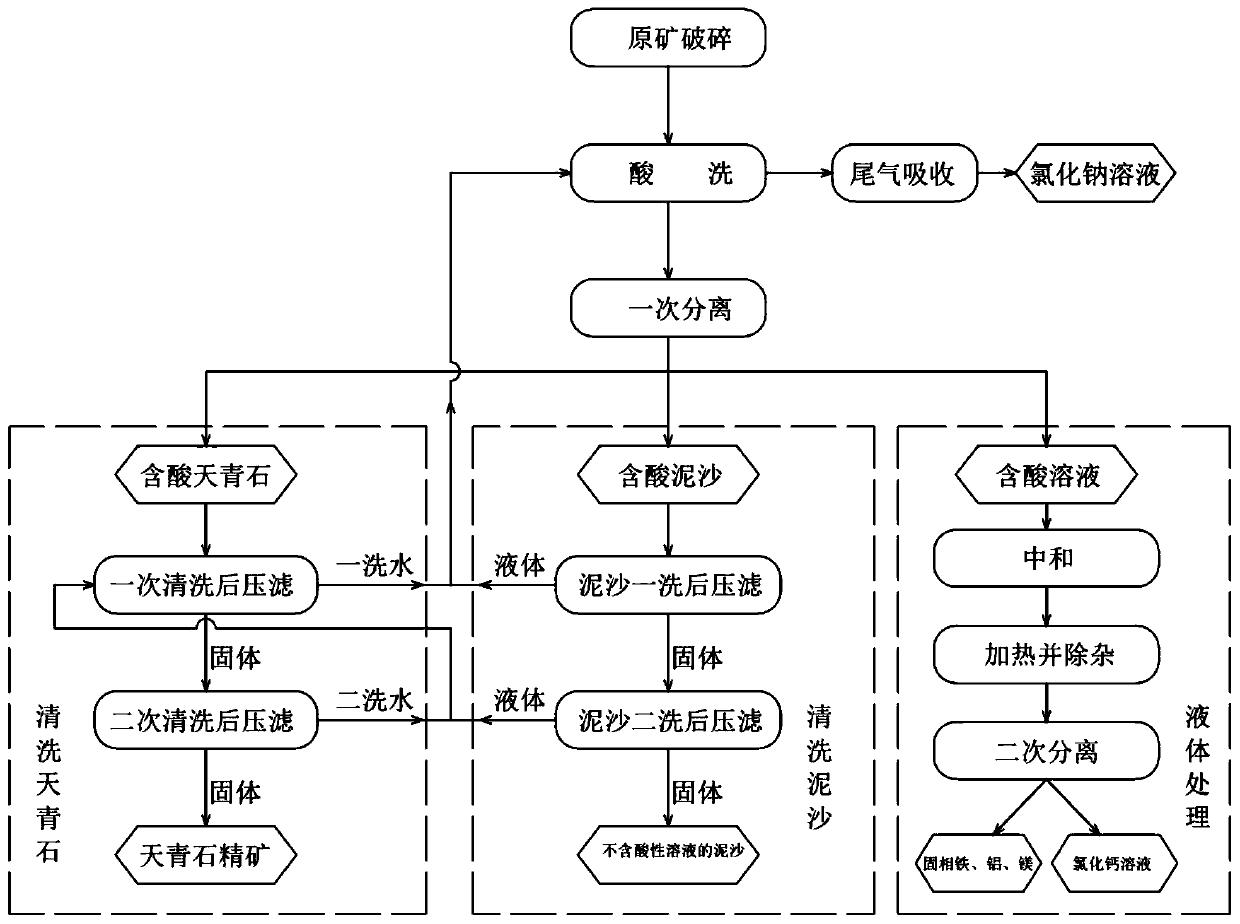

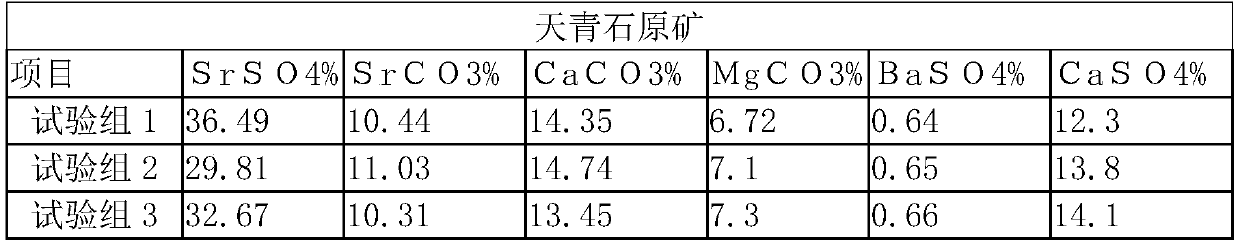

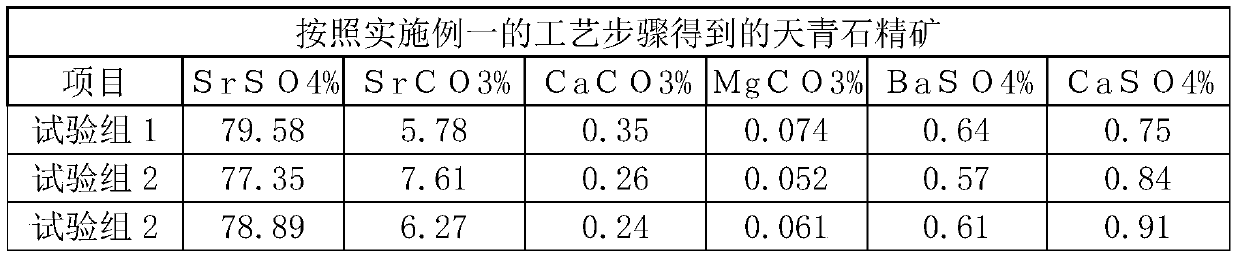

Beneficiation process for resource utilization of low-grade celestite

InactiveCN111017974AIncrease contentSatisfy the technological requirements for the production of industrial strontium carbonateStrontium carbonatesCalcium/strontium/barium chloridesCelestineExhaust fumes

The invention relates to the technical field of beneficiation processes, and particularly discloses a beneficiation process for resource utilization of low-grade celestite, which comprises the following steps: step 1, crushing raw ore: crushing the raw ore to obtain fine particles with the diameter of less than 4mm; step 2, acid pickling: carrying out acid pickling on the fine particles obtained in the step 1 by adopting hydrochloric acid; step 3, tail gas absorption: introducing gas generated in the pickling process into an alkaline solution for absorption; step 4, primary separation: separating solid and liquid generated after acid pickling; step 5, neutralizing; step 6, heating and removing impurities: heating the solution obtained in the step 5, and adding quick lime; step 7, secondaryseparation: separating the solid and the liquid obtained in the step 6; step 8, cleaning celestite; and 9, cleaning silt. According to the scheme, the problem that in the prior art, wastewater, wastegas and waste residues pollute the environment in the beneficiation process of low-grade celestite is solved.

Owner:王永范 +1

Drilling fluid weighting agent and preparation method thereof

ActiveCN104212417AImprove stabilityImprove structural performanceDrilling compositionCelestineEthyl group

The invention relates to a drilling fluid weighting agent and a preparation method thereof, and belongs to the technical field of oil extraction. The weighting agent comprises the following components by weight: 60-80 parts of bauxite, 0.5-2 parts of lapis lazuli, 1-1.5 parts of monazite, 10-15 parts of silicon micro powder, 0.08-0.2 part of cetyl ethyl hexanoate, 0.2-0.45 part of polyoxyethylene(20) sorbitan monolaurate, 0.5-2 parts of a dispersant, 0.5-1 part of modified attapulgite and 20 to 30 parts of water. The preparation method of the drilling fluid weighting agent is simple, the prepared drilling fluid weighting agent is can improve the stability of the structural properties of mud, has good suspension stability, and can avoid the precipitation problem of a common weighting agent, at the same time, the drilling fluid weighting agent solid product can be directly applied to oil base mud weighting, can maintain for 45 days at high temperature, is far more surpass the common weighting agent in the prior art which can only maintain for 7 days, and is easy in popularization and application.

Owner:天津大港油田海诚泥浆技术服务股份合作公司

Wood-plastic composite section

The invention discloses a wood-plastic composite section which comprises the following raw materials in percentage by weight: 40-50% of PVC (Polyvinyl Chloride), 0.1-1% of a foaming agent, 0.1-3% of acoupling agent, 0.1-3% of an antistatic agent, 0.1-3% of celestite and 40-60% of wood flour. The wood-plastic composite section disclosed by the invention has the characteristics of being mildew-proof, weather-resistant and antistatic.

Owner:佛山萃智新材料科技有限公司

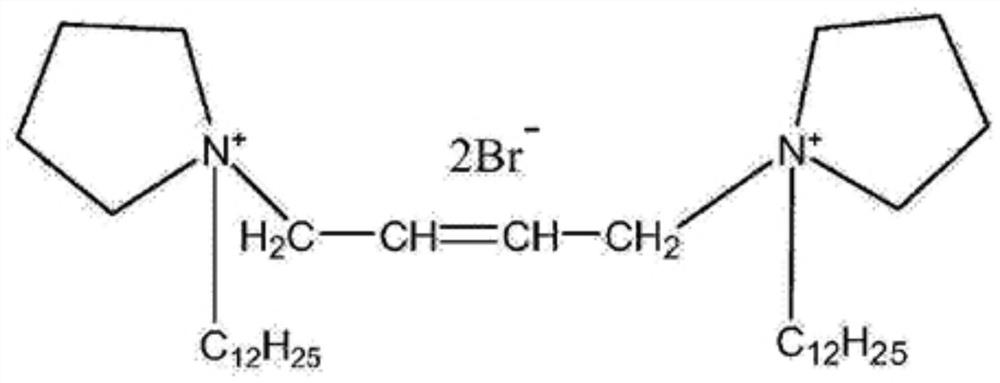

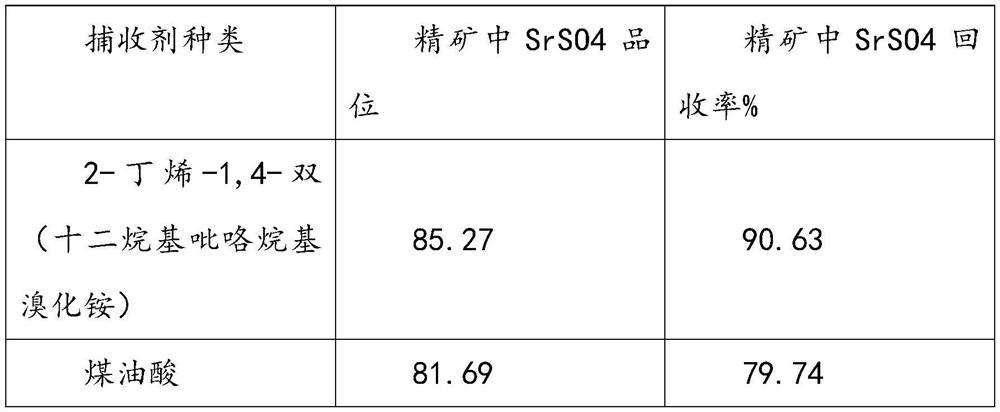

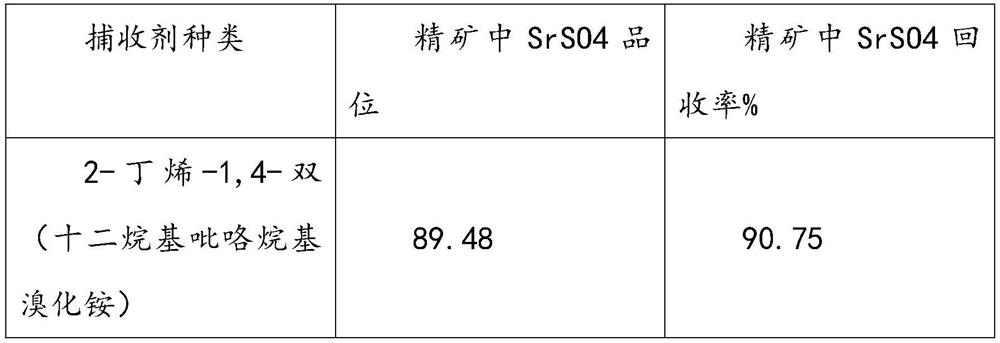

Application of metallurgical surfactant

The invention provides application of a metallurgical surfactant, belonging to the field of metallurgical surfactants. The application based on the metallurgical surfactant comprises the metallurgical surfactant, water glass, terpenic oil and an application method. The application method comprises the following steps: after celestite ore is smashed, adding water for size mixing to form flotation pulp; adding the metallurgical surfactant and the terpenic oil into the flotation pulp for foaming, and performing primary roughing through a flotation process; after primary roughing is carried out, adding the metallurgical surfactant into the flotation pulp again, and conducting primary scavenging through a flotation process; and after primary scavenging, subjecting beneficiation pulp to concentration twice to three times through a flotation process, wherein during each time of concentration, different amounts of water glass are sequentially added into the flotation pulp to serve as inhibitors. When the metallurgical surfactant is used as a celestite ore flotation collecting agent, the celestite ore collecting capacity of the metallurgical surfactant at a low temperature is high, selectivity is good, the grade and the recovery rate of the celestite ore are improved, and good application and popularization value is achieved.

Owner:震赛(嘉兴)智能科技有限公司

High-adhesion ceramic grinding wheel

A high-adhesion ceramic grinding wheel comprises, by weight, 6-10 parts of high-temperature-resistant adhesives, 8-14 parts of ammonium ferrous sulfate, 6-11 parts of glycerol trioleate, 3-5 parts of boric acid, 6-10 parts of silicon carbide, 7-9 parts of steel powder, 1-4 parts of ferric chloride, 9-16 parts of microcrystal ceramic abrasive, 2-5 parts of wetting agent, 6-11 parts of celestite, 3-11 parts of oxidized polyethylene wax, 2.5-6 parts of chisel tool steel powder, 6-9 parts of calcium carbonate, 1-4 parts of calcium oxide, 9-12 parts of titanium dioxide and 2.3-5 parts of copper oxide. The high-adhesion ceramic grinding wheel has the advantages that the ceramic grinding wheel is good in adhesion, particles are less prone to falling, and grinded workpieces are high in quality and glossiness.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Mineral crystal composition capable of regulating uric acid

InactiveCN111419873ALower uric acid levelsNo side effectsHeavy metal active ingredientsSkeletal disorderCelestinePhysical chemistry

Aiming at the technical problems in the prior art, the invention provides a mineral crystal composition capable of adjusting uric acid. The composition is composed of the following components in partsby weight: 15 to 20 parts of red marble; 20 to 30 parts of Longjiang stone; 10 to 15 parts of celestite; 10 to 15 parts of dolomite; and 10 to 15 parts of potassium feldspar. The composition can reduce the uric acid content in a human body, has no side effects, and can further improve the treatment speed.

Owner:邓兴龙

A kind of powder metallurgy helical gear and preparation method thereof

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Underglaze kiln-changing glaze pigment and method for preparing underglaze kiln-changing glaze ceramic products using it

Owner:福建省德化云水窑陶瓷有限公司

Nano aluminum oxide water-purifying agent and preparation method thereof

InactiveCN105923692AImprove adsorption capacityReduce contentAccessory food factorsWater/sewage treatment by sorptionCelestineHazardous substance

The invention discloses a nano aluminum oxide water-purifying agent and a preparation method thereof. The nano aluminum oxide water-purifying agent is made from the following materials according to parts by weight: 2-6 parts of nano aluminum oxide, 20-40 parts of medical stone, 5-15 parts of celestite, 25-40 parts of zeolite, 10-25 parts of perlite, and 20-40 parts of wood charcoal. The nano aluminum oxide water-purifying agent has high adsorbing capacity, can adsorb toxic harmful substances in water, such as heavy metal, remove peculiar odor in water and reduce the content of harmful substances in water, and can release various minerals and trace elements good for the growth of fry while purifying water since the materials are rich in minerals, thus helping the fry to grow healthily and quickly.

Owner:JIANGMEN JIANGHAI WEI CLEAN WATER MATERIALS CO LTD

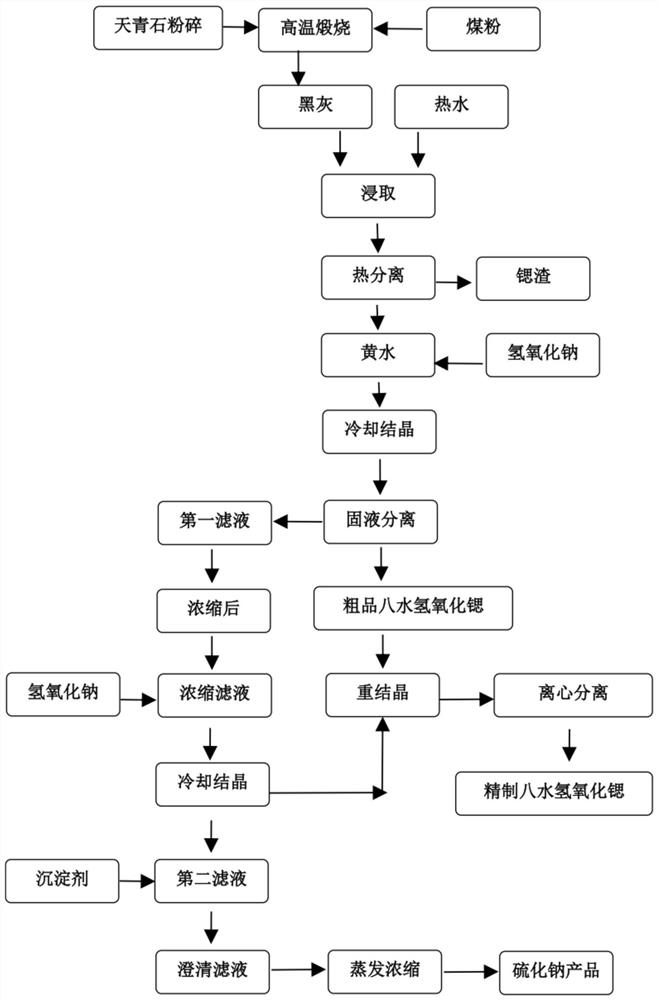

Method for producing strontium hydroxide and co-producing sodium sulfide

PendingCN113896215AShort processReduce manufacturing costAlkali metal sulfides/polysulfidesCelestinePhysical chemistry

The invention belongs to the field of strontium hydroxide preparation, and particularly relates to a method for producing strontium hydroxide and co-producing sodium sulfide, which comprises the following steps: (1) mixing celestite powder and pulverized coal, conducting roasting at high temperature, conducting leaching with hot water, and conducting filtering to obtain yellow water; (2) adding sodium hydroxide into the yellow water, and after the reaction is finished, carrying out solid-liquid separation to obtain strontium hydroxide octahydrate and first filtrate; (3) concentrating the first filtrate, conducting filtering, adding sodium hydroxide into the concentrated filtrate, and after the reaction is finished, carrying out solid-liquid separation to obtain strontium hydroxide octahydrate and second filtrate; and (4) adding a precipitant into the second filtrate, filtering out a precipitate, and conducting heating, evaporating and concentrating to obtain a sodium sulfide product. Compared with a conventional preparation method of strontium hydroxide octahydrate, the preparation method disclosed by the invention has the advantages of short process flow and low production cost.

Owner:GUIZHOU REDSTAR DEVING

Steelmaking deoxidizer and preparation method, application and use method thereof

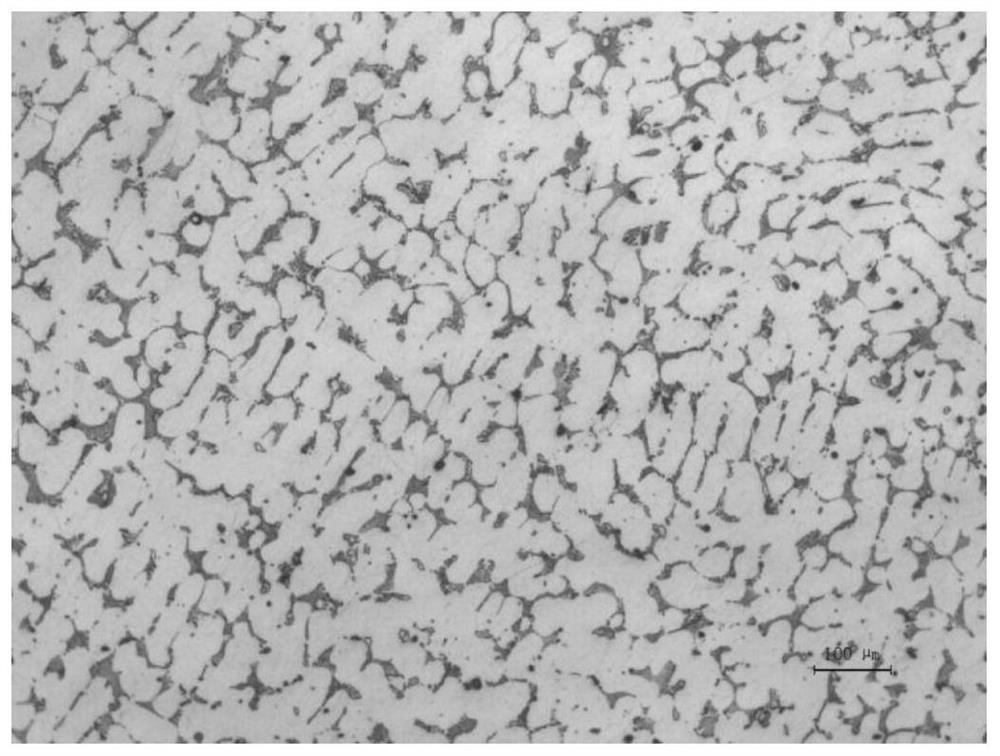

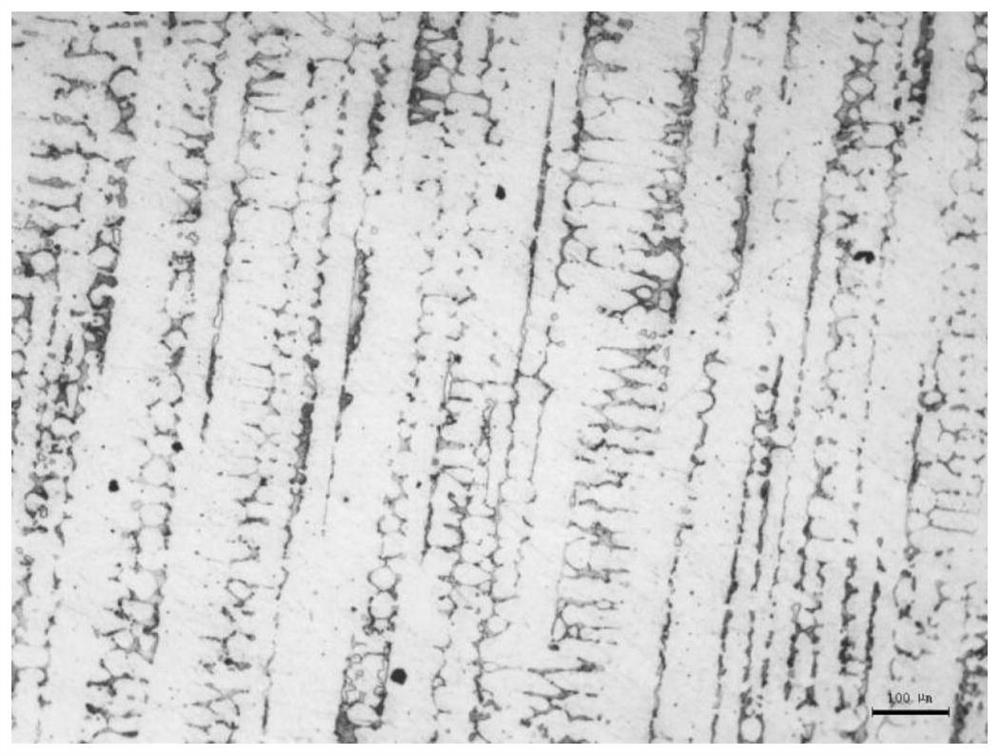

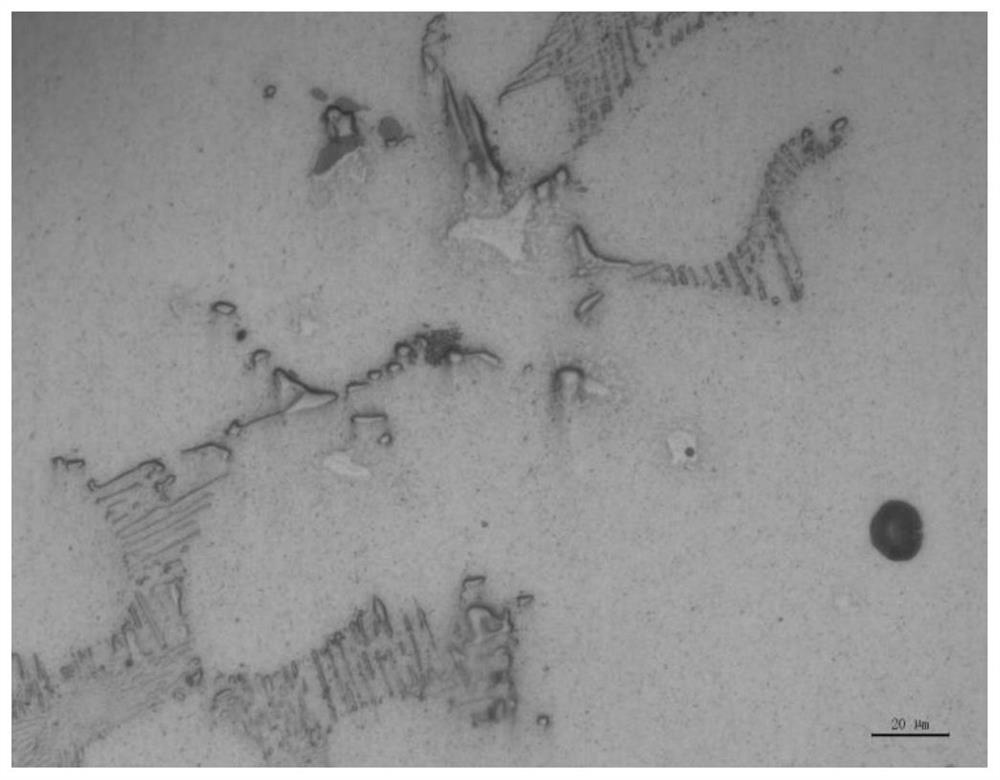

PendingCN112063799AImprove mechanical propertiesSlow growth rateProcess efficiency improvementSteelmakingCelestine

The invention discloses a steelmaking deoxidizer. The steelmaking deoxidizer comprises the following raw materials of, by weight, 35%-45% of silicon, 4%-6% of strontium and the balance iron. A preparation method of the steelmaking deoxidizer comprises the following steps of (1), weighing quartz stone, celestite and iron filings by weight; and (2), feeding the iron filings, the quartz stone and thecelestite in sequence, heating to completely melt, cooling, discharging and crushing to obtain the steelmaking deoxidizer. A use method of the steelmaking deoxidizer comprises the steps of (1), smelting molten steel to 1500-1700 DEG C, and standing at constant temperature for 3-5 minutes; (2), adding a deslagging agent to remove scums, and then adding the steelmaking deoxidizer to stand for 3-5 minutes; and (3), adding the deslagging agent again to remove the scums. The steelmaking deoxidizer is thorough in deoxidation, carbides can be formed into equiaxed crystals by simple one-time precipitation deoxidation, inclusions are spheroidized, and crystal grains of steel are refined, so that the thermal fatigue performance of a material is greatly improved, meanwhile, the smoke dust is less, and thus the steelmaking deoxidizer is environmentally friendly.

Owner:西峡县众德汽车部件有限公司

Multi-effect biofertilizer

The invention discloses a multi-effect biofertilizer, which comprises the following raw materials in parts by weight: 6-11 parts of potassium chloride, 4-9 parts of diammonium phosphate, 1-3 parts of copper sulfate, 2.5-6 parts of celestite powder, 3-5 parts of earthworm cast, 1.2-3 parts of potato straws, 2.3-4.8 parts of gypsum powder, 3.5-8 parts of pig manure, 1.3-3.2 parts of wheat bran, 0.6-1.3 parts of egg shell meal, 1.3-2.8 parts of ferrous sulfate, 1.5-4 parts of EM microbial inoculant, 1.1-2.4 parts of zinc oxide, and 1.5-3.4 parts of lactobacillus. The multi-effect biofertilizer has the beneficial effects of providing nutrients for crops, also improving the soil to restore the soil, and being incapable of causing pollution to soil, water and the like.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com