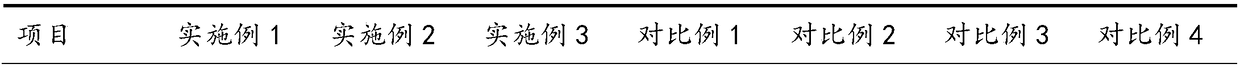

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

207results about How to "Reduce oxidation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous casting crystallizer protective scoria for weathering steel and manufacturing method thereof

InactiveCN101125357AReduce the formation of rare earth oxidesReduced enrichmentScoriaHeat transmission

The present invention relates to a continuous casting mold protecting powder and the manufacturing method of the mold protecting powder for a weathering steel. Adopting the making art of spraying particle, the mold protecting powder is made from the materials such as premelting material, quartz sand, fluorite, industrial calcined soda, magnesite, medium supper soot carbon, graphite, lithium carbonate and so on, chemical ingredients of the mold protection powder in weight percentage are as follows: SiO2 30.0 to 37.0 percent, CaO 30.0 to 37.0 percent, Al2O3 2.0 to 5.0 percent, MgO 3.0 to 6.0 percent, Li2O 1.5 to 2.5 percent, Na2O 5.5 to 8.5 percent, F 4.5 to 7.5 percent, TC(totally carbon) 4.5 to 6.5 percent, 0< Fe2O3 less than or eqal to 1.0%, binary alkalinity CaO / SiO2 is 0.95 to 1.05. The mold protecting powder regarding the invention melts evenly inside the mold and has weak reaction with the rare earth wire, excellent lubricating performance to the casting blank, even and proper heat transmission between the continuous casting mold and the casting blank, therefore reducing the ingot bleeding rate and the occurance rate of surface vertical flaws.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

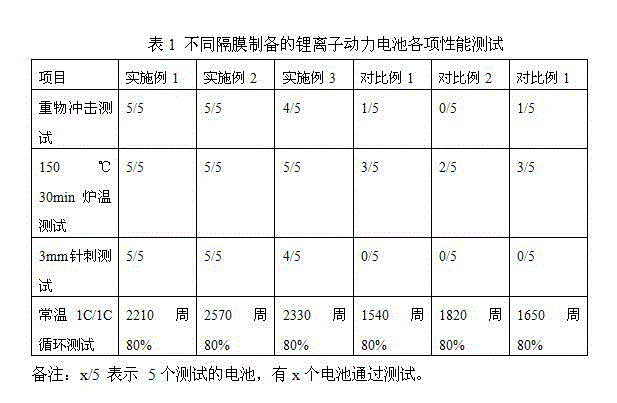

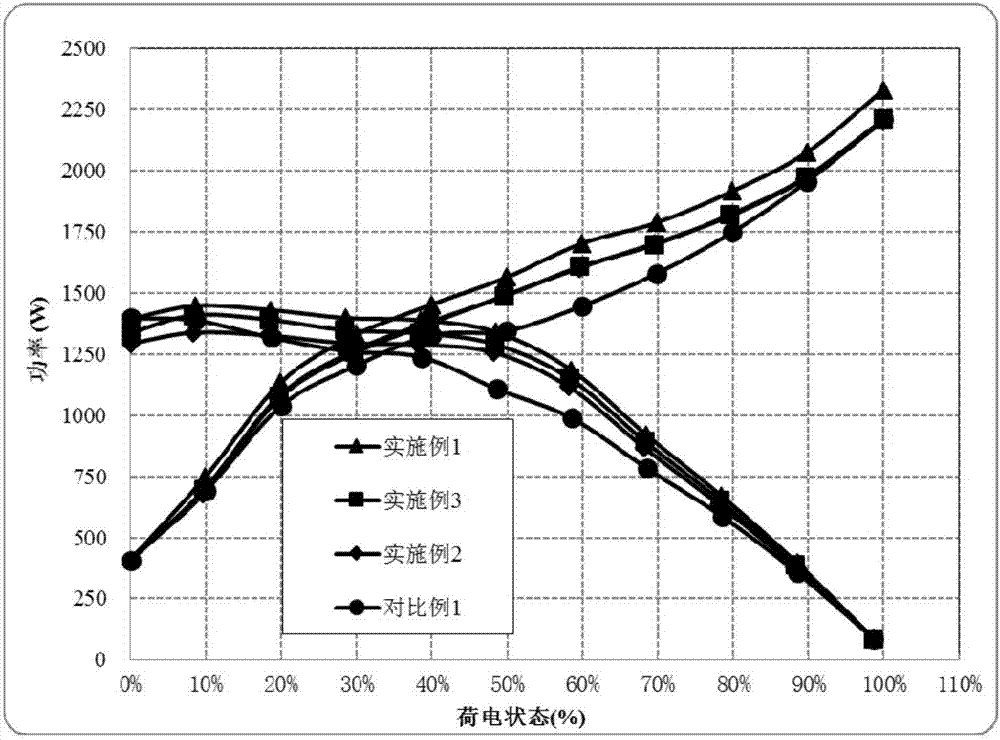

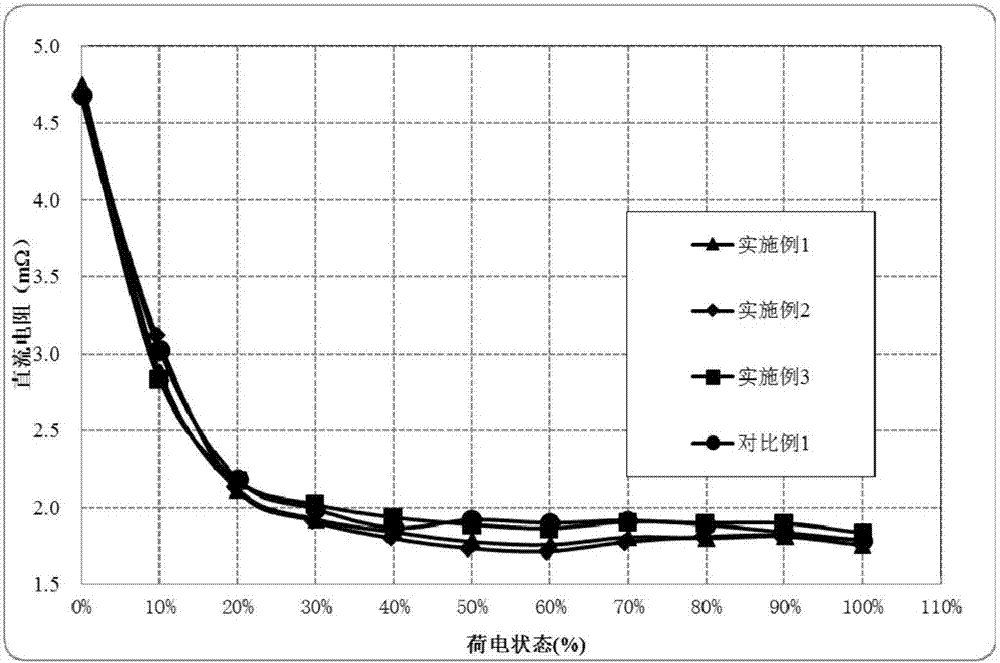

A preparing method of a lithium ion battery composite separating membrane

ActiveCN104681762AImprove mechanical propertiesImprove heat resistanceCell seperators/membranes/diaphragms/spacersPolyamide coatingsHeat resistanceResin coating

A preparing method of a lithium ion battery composite separating membrane is disclosed. A common PP or PE separating membrane is coated with an oxide coating, an aramid fiber resin coating and a PVDF-HFP copolymer layer to obtain the composite separating membrane. The composite separating membrane enhances mechanical performance and heat resistance of the separating membrane and enhances safety performance of batteries.

Owner:WANXIANG 123 CO LTD

Rolling method of titanium steel composite board

ActiveCN102794299AQuality assuranceReduce harmTemperature control deviceWork treatment devicesForeign matterWater flow

The invention provides a rolling method of a titanium steel composite board. The rolling method comprises the following steps of: 1, selecting the titanium steel composite board provided with a titanium plate as an upper layer and a steel plate as a lower layer; 2, pre-treating a surface; 3, heating and soaking in a heating furnace; and 4, rolling on a hot mill, and removing scale and cooling by utilizing high-pressure water. According to different physical characteristics of the titanium plate and the steel plate under the high-temperature state, through setting the proper heating and soaking processes, and adopting the high pressure water to remove the scale and cool in the rolling process, an oxide skin on the surface of the titanium steel composite board is greatly reduced, and sundries on the surface of the titanium steel composite board are eliminated, meanwhile, the titanium plate and the steel plate are cooled at different water flows, so that the deformation degree of the titanium plate corresponds to the deformation degree of the steel plate, head buckle or unwarp phenomenon of the titanium steel composite board in the rolling process can be effectively prevented, and damage about a roller is greatly reduced; and the titanium steel composite board, rolled by the invention, has the advantages of clean and tidy surface, no foreign matters to press and good plate cut.

Owner:WESTERN TITANIUM TECH

Surface coating for improving security performance of power lithium ion battery, surface coating application and power lithium ion battery

InactiveCN107394113AImprove cycle lifeImprove securityCell electrodesSecondary cells servicing/maintenancePower batteryElectrical battery

The invention discloses surface coating for improving the security performance of a power lithium ion battery, a surface coating application and the power lithium ion battery. The component of the surface coating slurry of the surface coating is alpha-Al<2>O<3> or AlOOH. The solid content of the surface coating slurry is 5%-50%. The surface coating is coated on the surface of a cathode plate, an anode plate or diaphragm of the battery. The thickness of the surface coating is about 1-15[mu]m. After a surface coating modification technology is applied to the power battery, the direct contact with the cathode plate and anode plate of the battery is avoided; the internal resistance of the battery in a thermal runaway state is clearly increased through adoption of an insulation characteristic of the surface coating; and the heat stability of the cathode plate and anode plate in the thermal runaway state of the battery is improved. Moreover, through application of the surface coating technology, the liquid preserving capability of the battery can be improved, the oxidation of electrolyte is inhibited, and the stability of SEI film is improved, so the service life of the battery is clearly improved. According to the application of the surface coating technology, the security performance of the power battery can be clearly improved, and the circulation capability of the power battery can be properly improved.

Owner:天津中科先进技术产业有限公司

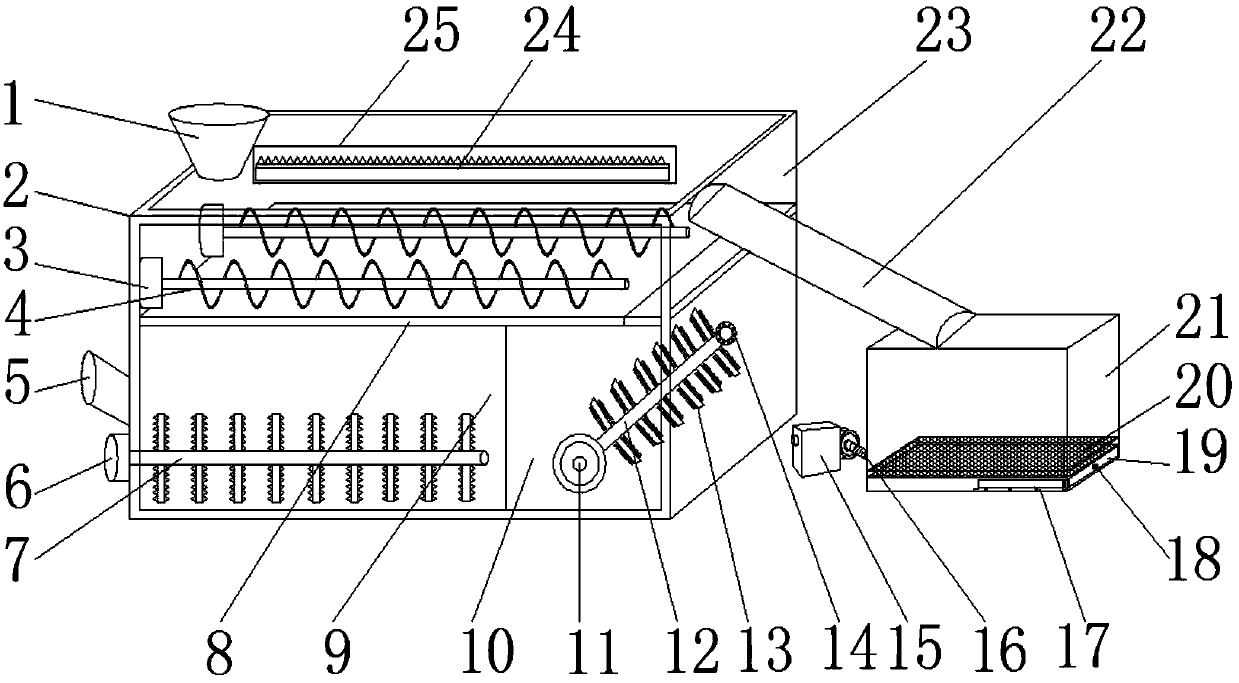

Garbage classified recycling treatment environmental-protection device

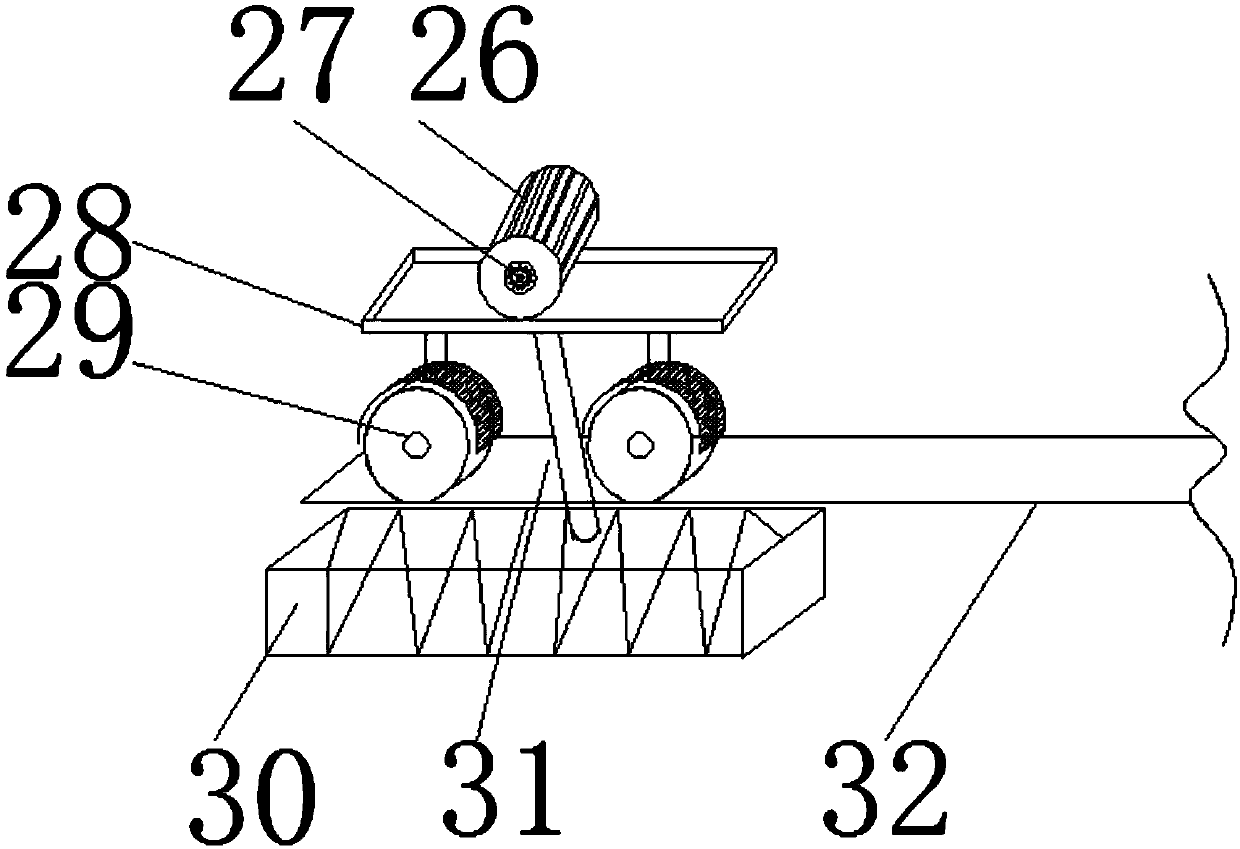

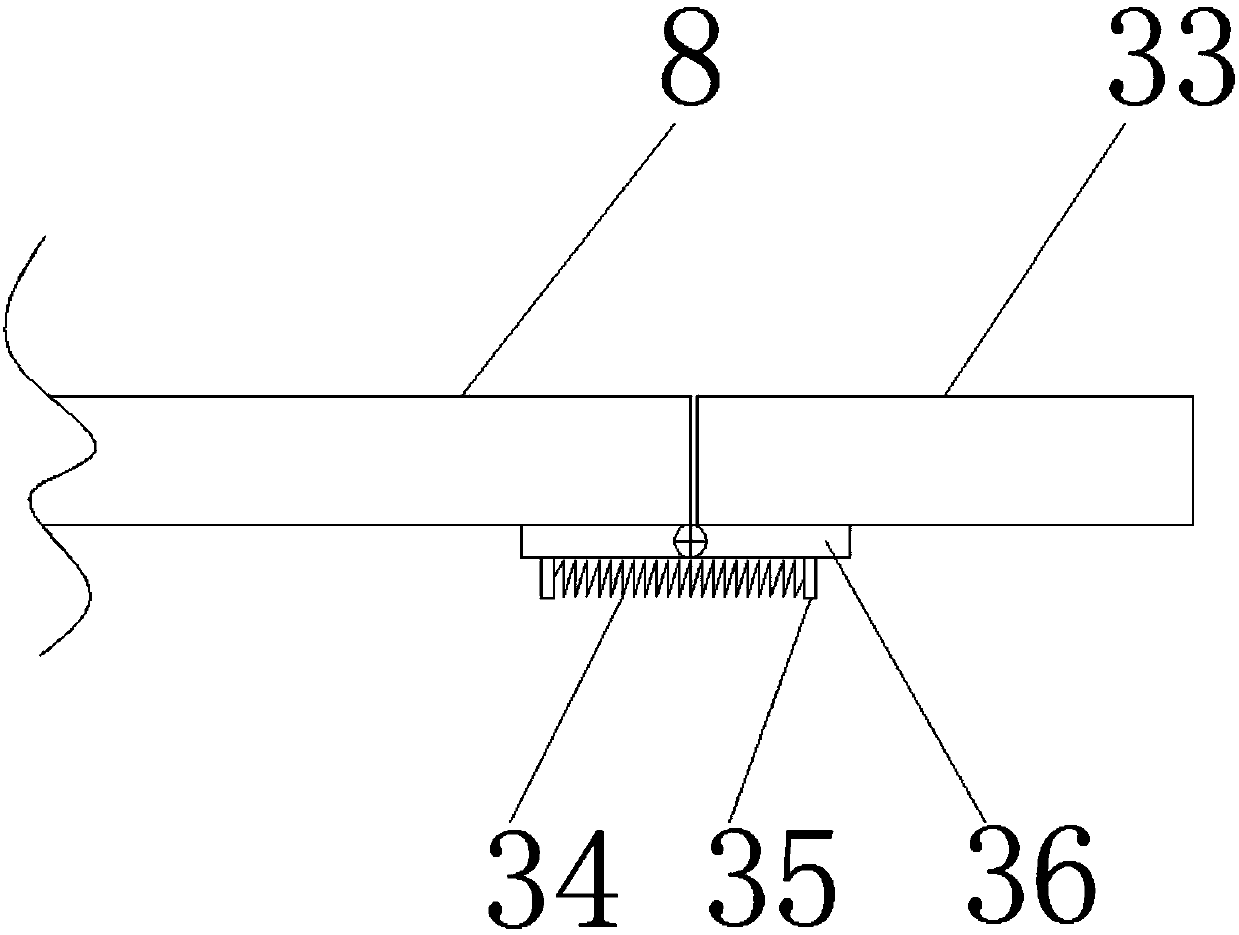

ActiveCN107617626AAchieve the purpose of separationFlipSolid waste disposalDrying gas arrangementsEngineeringMoisture

The invention discloses a garbage classified recycling treatment environmental-protection device. The garbage classified recycling treatment environmental-protection device comprises a second motor, astirring roller, a partition plate, a degradable garbage smashing area, a plastic smashing area, a third motor, a rotating rod, a smashing blade, a bearing, an air heater, an air pipe, sliding rails,a handle, a drawer, a partition net, a metal storage box, a leading-out sliding way, a separation area, a tooth guide rail, a protective shell, a forward and reverse rotating motor, a cylindrical gear, a mounting plate, rotating wheels, an electromagnet, a connecting rod, a rolling groove, a movable plate, a reset spring, a limiting plate and hinges. Through the partition net, the drawer can be mounted at the bottom of the metal storage box; drying agents are placed in the drawer so as to absorb moisture in air; the air heater blows hot air into the metal storage box through the air pipe so that moisture of metal can be conveniently evaporated for achieving dryness, the oxidizing reaction of the metal slows down, accordingly rust of the metal is relived, and the recycling rate of the metal is increased.

Owner:新沂市绅奥环保用品有限公司

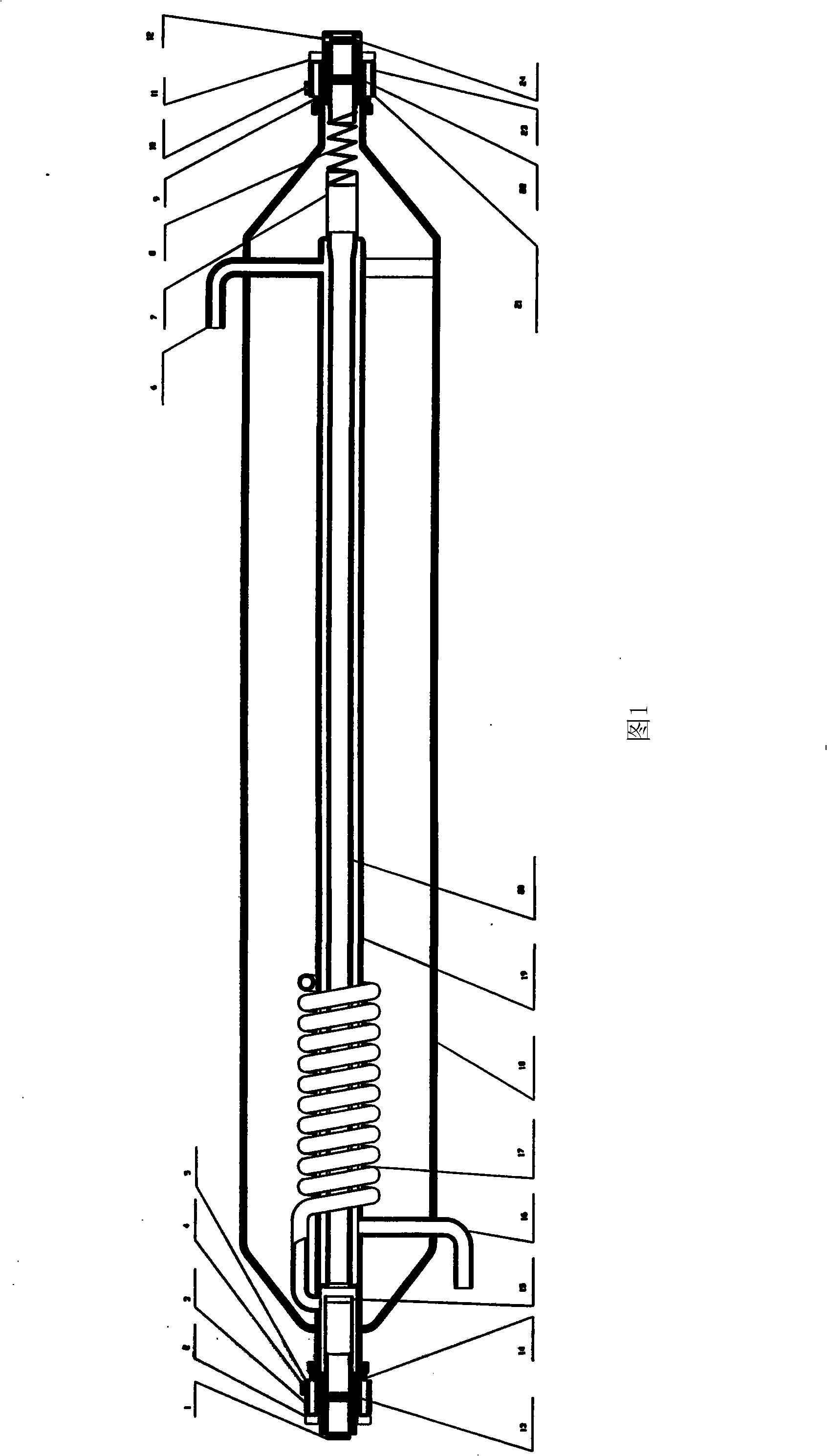

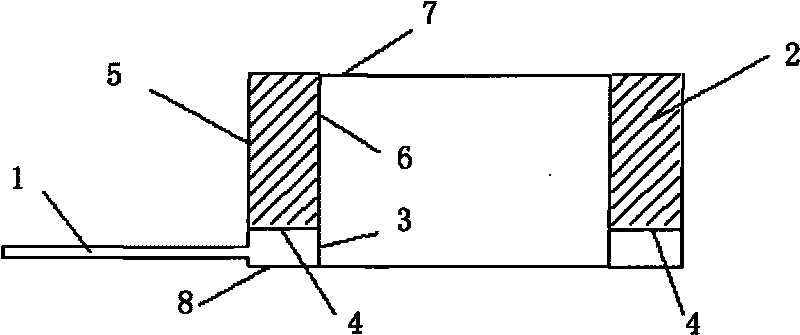

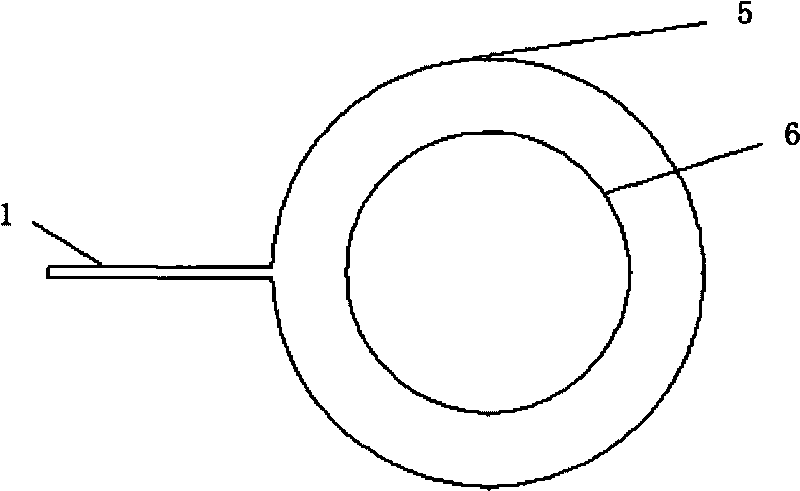

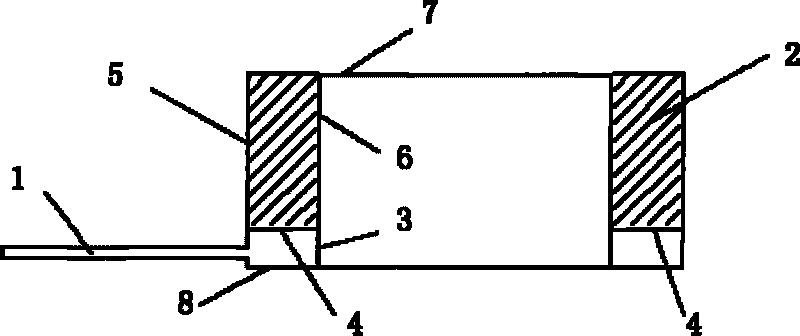

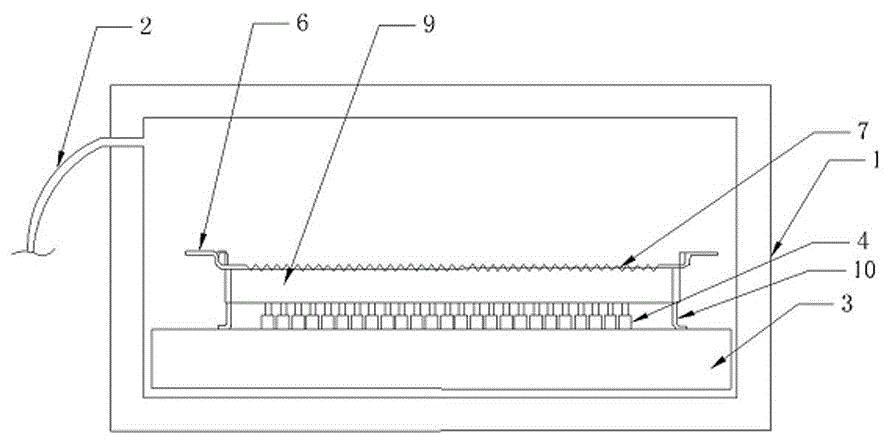

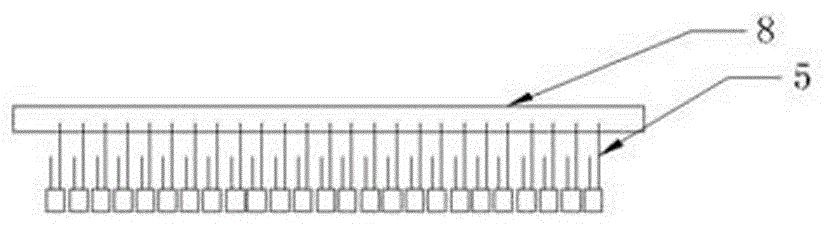

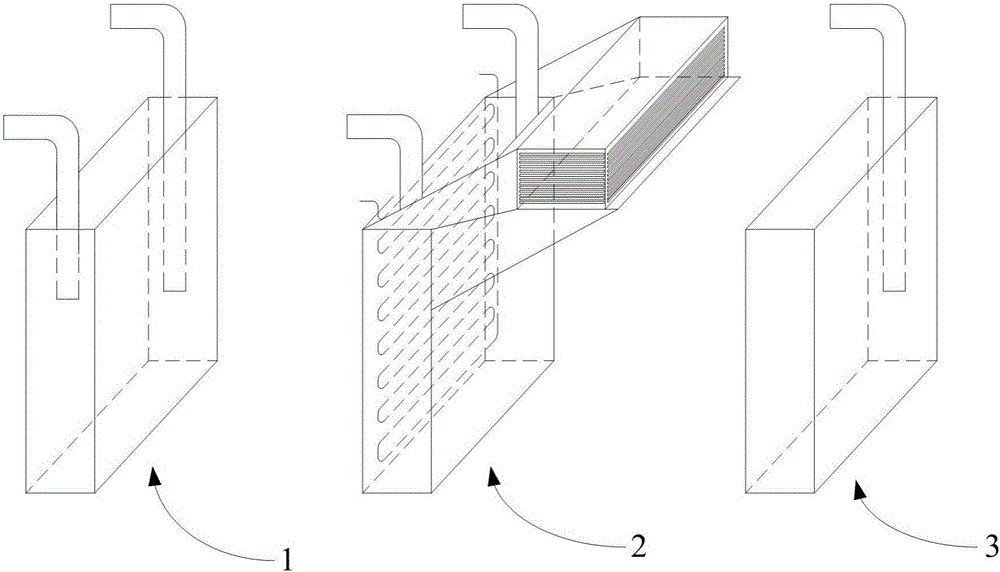

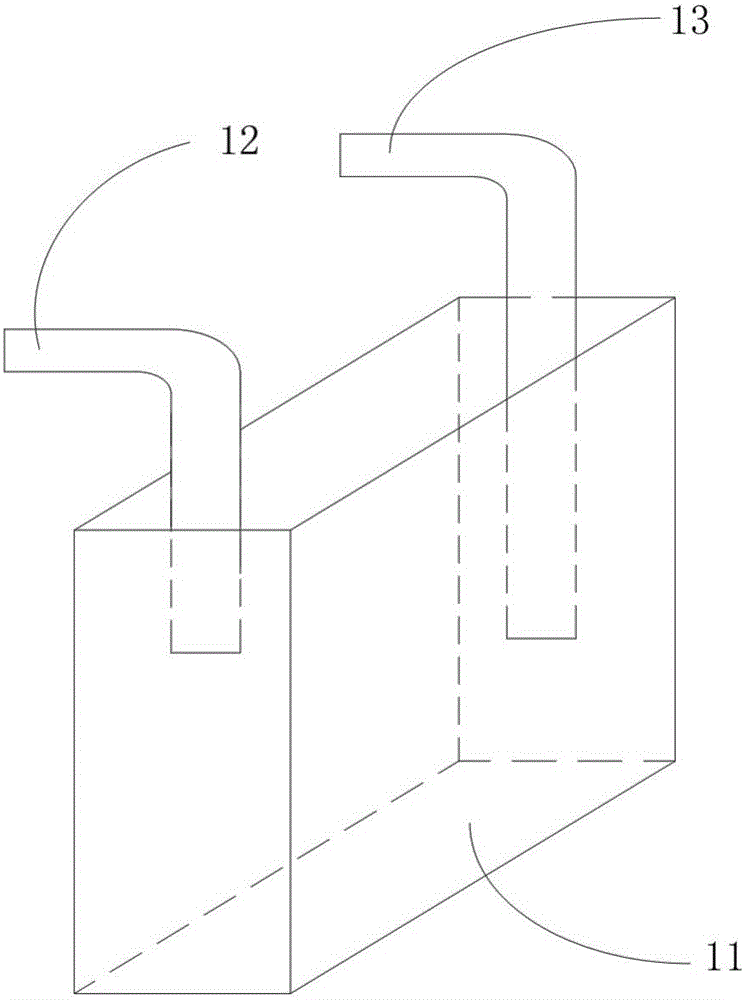

A CO2 laser with new structure

ActiveCN101262112AIncrease output powerHigh beam qualityGas laser constructional detailsOptoelectronicsLaser cutting

The invention relates to a carbon dioxide laser with new structure. Sealing and connecting metal structures at two sides can adjust the angle of a lens (1) and a lens (12); the major structure of the laser pipe shaft comprises a glass material discharge tube (20), a jacket pipe (19), an air-storing pipe (18), an air-returning pipe (17), a water inlet (16) and a water outlet (6); a resonant cavityis composed of a total reflective mirror (1) and an output mirror (23); an angle adjusting system for the total reflective mirror comprises a fixed flange (5), an adjustable flange (3), a soft metal gasket (13) and an adjusting screw (2); the metal structure of the angle adjusting system is sealed and connected with the glass structure of the laser pipe shaft by spacer flange chips (14)(9); a high pressure protective sleeve (24) plays a role in protecting the laser metal structure part with a high pressure; an output mirror protective sleeve (23) plays a role in protecting the output mirror (12) and releasing heat. The carbon dioxide laser is mainly applicable to the laser cutting and the carving machine tool with medium and small power and material processing.

Owner:ZHEJIANG RECI LASER TECH CO LTD

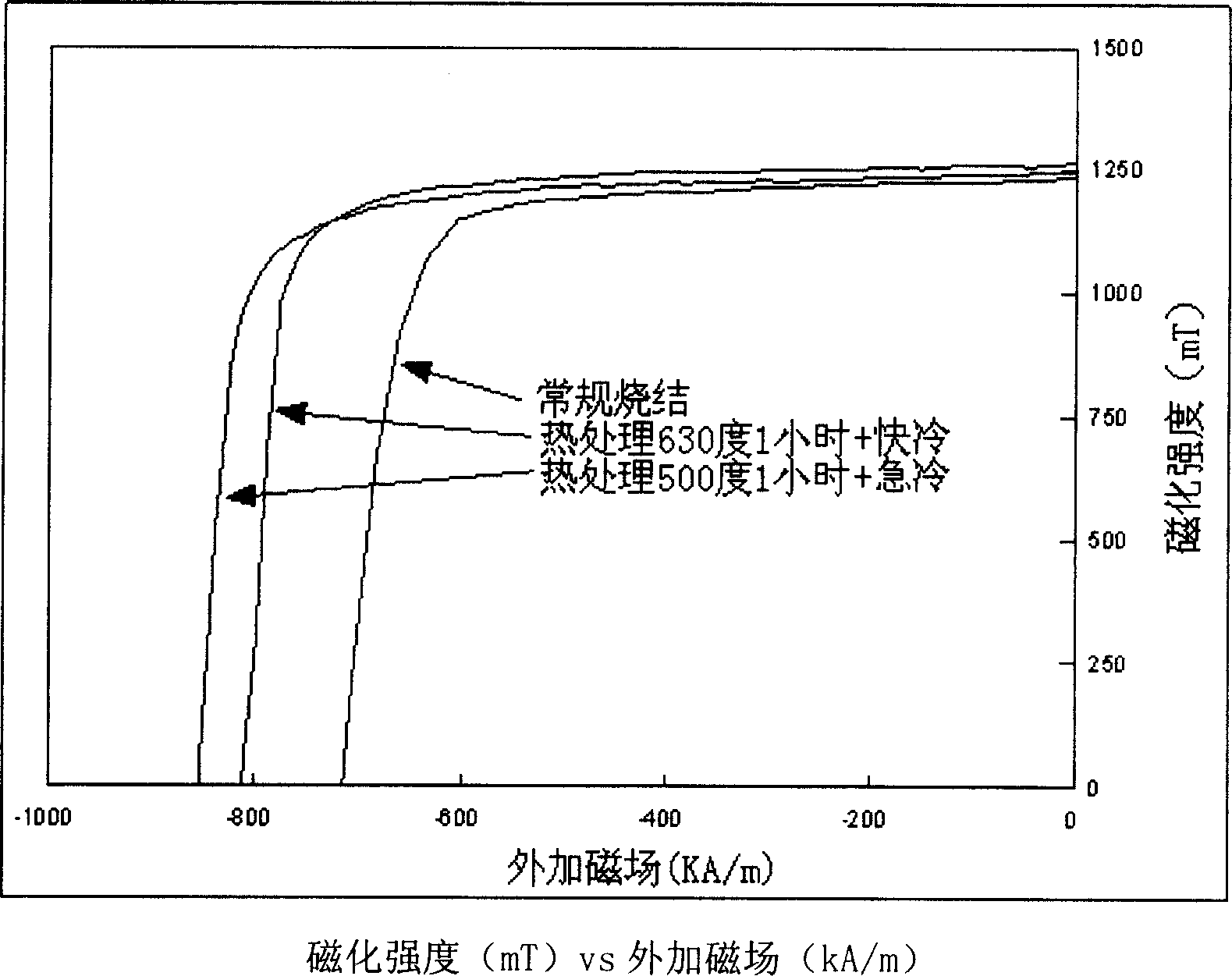

Method for regenerating high-performance permanent magnet by degenerated rare earth permanent magnet material

The invention discloses a permanent magnet regenerating method of degenerated rare earth permanent magnet material, which comprises the following steps: grinding mechanically; removing impurity; dewetting in the vacuum; proceeding hydrogen disposal or hydrogen disproportionating reaction; adding high-magnetocrystalline anisotropic element and auxiliary texture forming element or alloy; moulding through sintering or adhering to produce anisotropic regenerated permanent magnet. The technology is reasonable with little oxide reaction, which can explore new path for degenerated rare earth permanent magnet.

Owner:严高林

Oxygen reduction and humidity control curing agent for tobacco leaf storage

The invention provides an oxygen reduction and humidity control curing agent for tobacco leaf storage, comprising a controlled-atmosphere curing agent and a humidity controlled curing agent which are in coordinated use with a use ratio range of (2-10):1. The controlled-atmosphere curing agent comprises the following components: 40-80% of reduced iron powder or pyrite powder, 1-8% of calcium oxide, 0.1-2% of mould proof assistant, 10-21% of activated carbon, 0-12% of sodium chloride, 1-15% of water absorbent, 3-15% of pearlite, 0.1-5% of first water retaining agent, 2-10% of diatomite and 0-10% of water. The humidity controlled curing agent comprises the following components: 30-60% of drier, 2-30% of second water retaining agent and 5-30% of pearlite. The curing agent for tobacco leaf storage can enable the oxygen reduction process to be mild and simultaneously improve dehumidification speed. The invention also provides a manufacturing method of the oxygen reduction and humidity control curing agent for tobacco leaf storage.

Owner:湖南华望熏蒸消毒有限公司

Environmental protection tea composite board material and its processing method

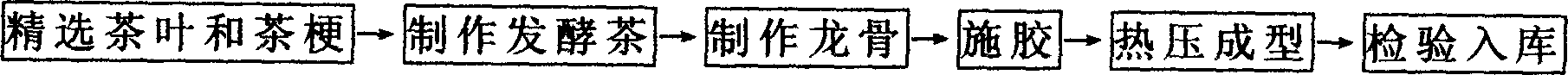

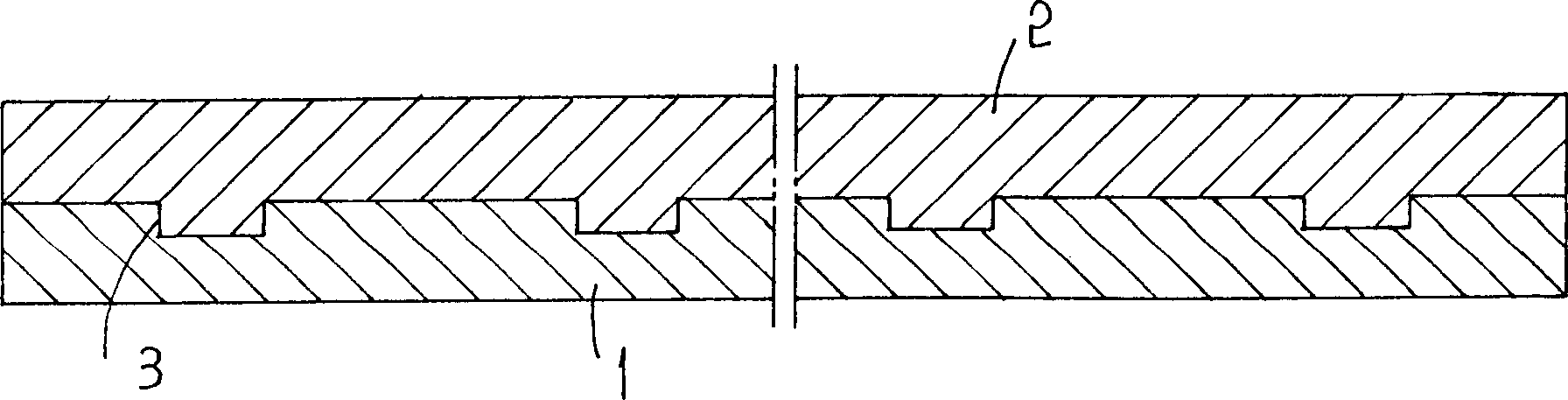

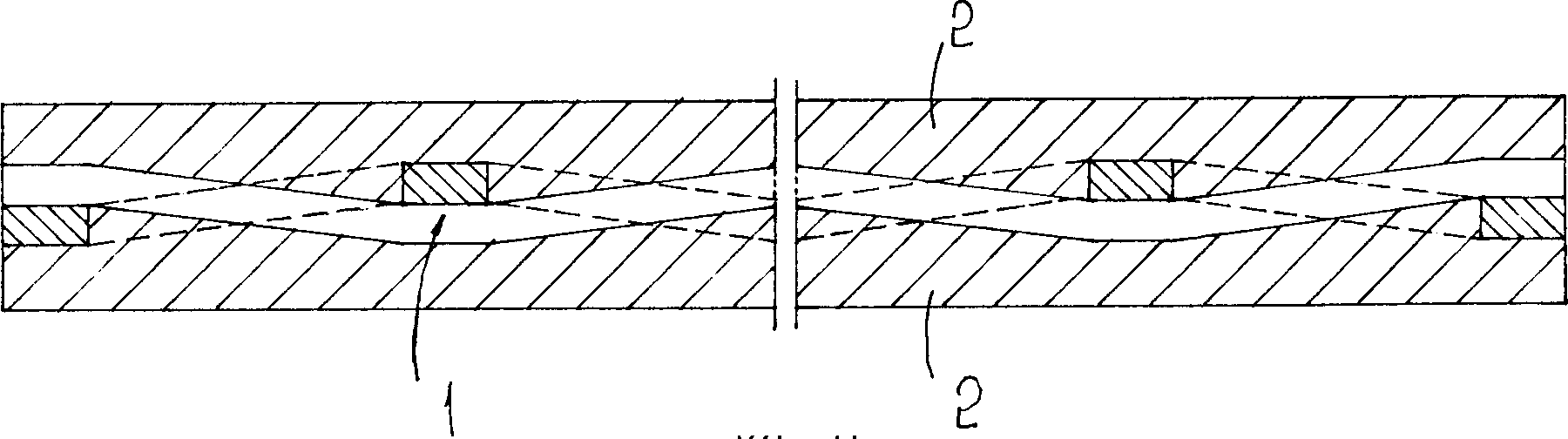

InactiveCN1785615AFully activated extracellular enzymesHas the function of refreshingWood veneer joiningFlat articlesEngineeringHot pressing

An environmental protection type composite board is composed of a joist layer and 1-2 layers of tea leaves and tea stems. Its preparing process includes such steps as choosing tea leaves and tea stems, fermenting, preparing joist, mixing tea leaves and tea stems with resin, and hot pressing.

Owner:王文毓

Freezing method of Luchuan pork

InactiveCN106879715APrevent the loss of pork nutrientsImprove water resistanceMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingChemistryCentral layer

The invention belongs to the field of fresh keeping of foods, and particularly relates to a freezing method of Luchuan pork. The freezing method comprises the following steps of (1) preparing a film coating agent; (2) performing micro-freezing treatment on pork; (3) performing film coating packaging treatment on the micro-frozen pork; and (4) performing ultrasonic assisted freezing preservation on the packaged pork: conveying the packaged pork into a freezing room, performing freezing until the temperature of the central layer of the pork is reduced to 2-4 DEG C, performing ultrasonic-assisted freezing for 3-6h, when the temperature of the central layer of the pork is reduced to minus 6 to minus 8 DEG C, stopping performing ultrasonic-assisted freezing, and continuing freezing the pork to minus 18 to minus 23 DEG C so as to obtain the frozen pork. The freezing method disclosed by the invention is simple to operate and stable in technology conditions, ice crystals generated during freezing of the pork can be reduced, the pork freezing speed can also be increased, the preservative effect is achieved, bacteria are restrained, the freezing storage time of the pork can be prolonged, the cell activity of frozen fresh meat can be guaranteed, and the phenomenon that juice flows outwards after the frozen pork is unfrozen is reduced.

Owner:广西神龙王农牧食品集团有限公司

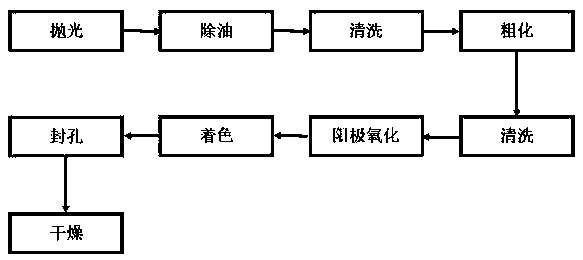

Aluminum alloy anodizing treatment method

The invention belongs to the technical field of metal surface treatment and particularly relates to an aluminum alloy anodizing treatment method. The aluminum alloy anodizing treatment method comprises the following steps of 1, polishing; 2, deoiling; 3, cleaning; 4, coarsening; 5, cleaning; 6, anodizing; 7, coloring; 8, hole sealing; and 9, drying. According to the aluminum alloy anodizing treatment method, the binding force formed between an oxidation film and the surface of aluminum alloy is increased through coarsening; an alternating current and a direct current are introduced into electrolyte in a mixed and superposed manner, and generation efficiency of the oxidation film is improved; and thus, the oxidation film large in binding force with the aluminum alloy and high in generationefficiency is obtained.

Owner:东莞市史雷帝三维数控科技有限公司

High-strength Al-Zn-Mg-Cu-Ce-Y-Er-La-Sc wrought aluminum alloy and manufacturing method thereof

The invention provides a high-strength Al-Zn-Mg-Cu-Ce-Y-Er-La-Sc wrought aluminum alloy. The alloy is composed of, by mass, 7% of Zn, 2% of Mg, 2.3% of Cu, 0.1% of Ce, 0.5% of Y, 0.1% of Er, 0.01% of La, 0.2% of Sc and the balance Al, wherein Al, Zn, Mg and Cu are added in a form of industrial pure Al, Zn, Mg and Cu with purity larger than 99.99wt.%, and Ce, Er, Y, Sc and La are added respectively in a form of powdery rare earth alloy with Al and 30wt.% of Ce, Mg and 30wt.% of Er, Mg and 20wt.% of Y, Al and 30wt.% of La, Al and 2wt.% of Sc. The invention further provides a manufacturing method of the alloy. Good composition homogenization effect is realized by adding rare earth elements and utilizing helium to blow rare earth alloy powder in, and a protecting atmosphere is formed through helium in the process of manufacturing, so that oxidizing reaction in the process of smelting is reduced as much as possible, the formed alloy is more accurate in composition, and the problem that conventional Al-Zn-Mg-Cu alloys are insufficient in performance and have product defects is solved effectively.

Owner:SHENYANG POLYTECHNIC UNIV

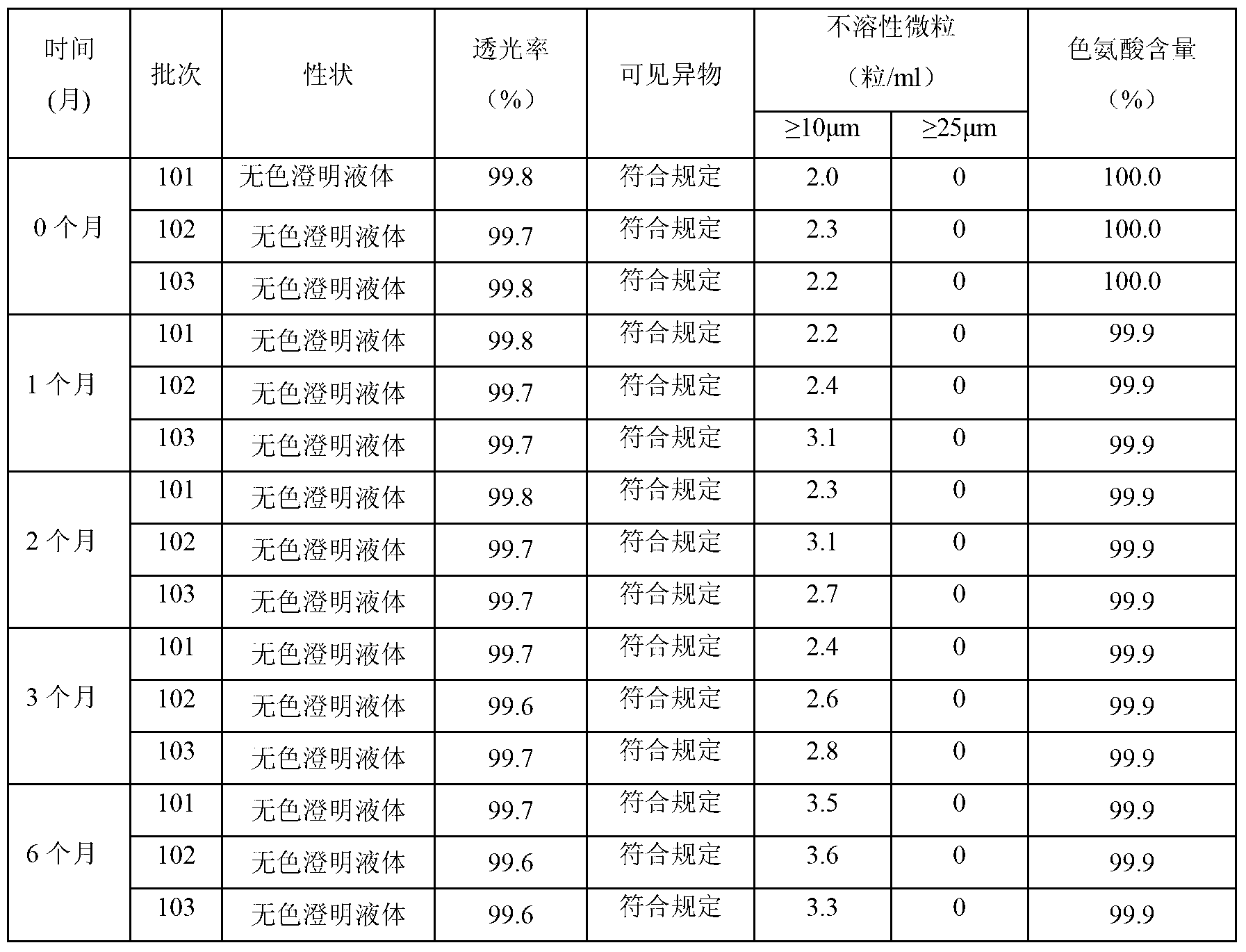

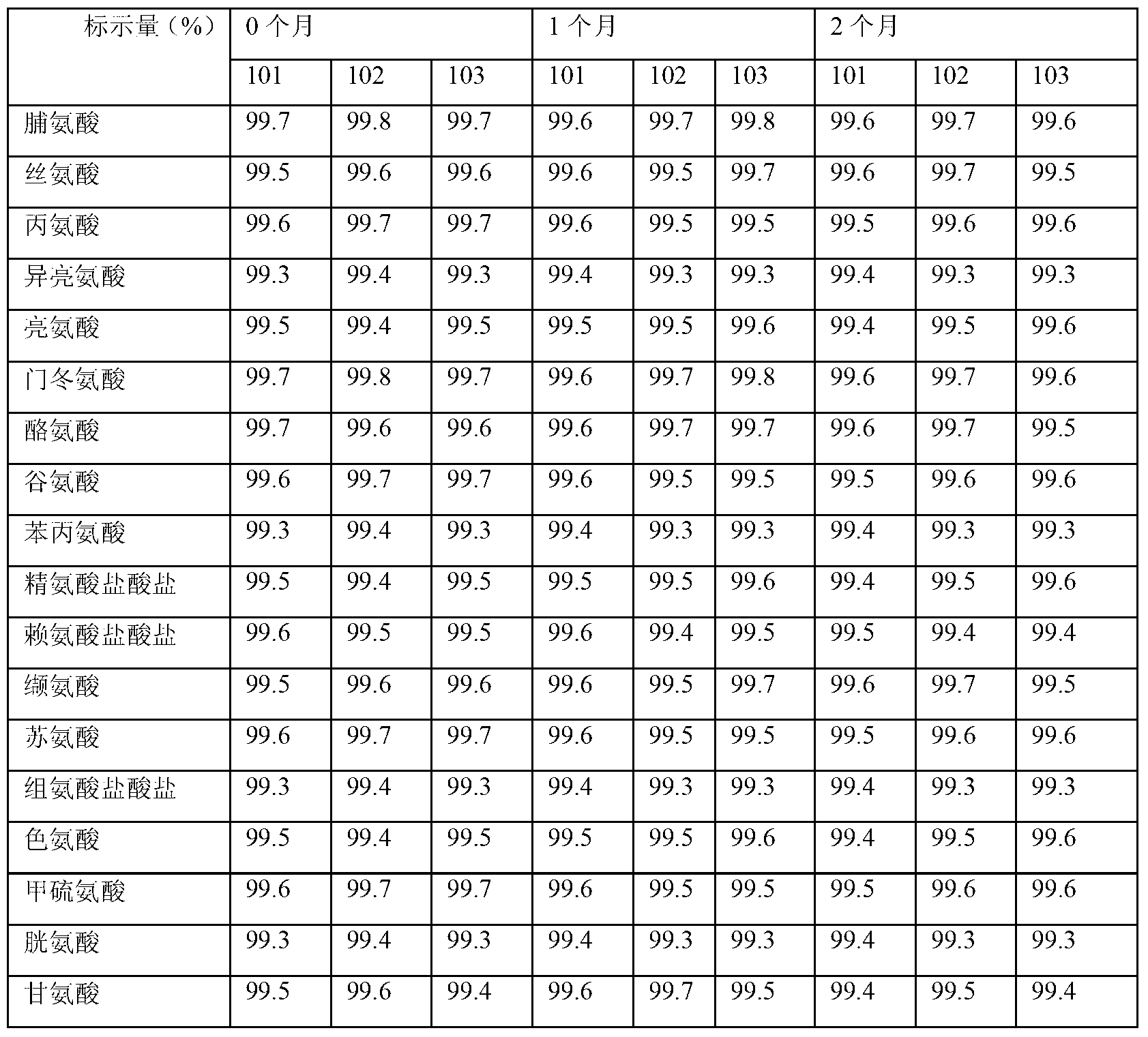

Compound amino acid composition and preparation method thereof

InactiveCN103315999AEasy to manufactureThe prepared L-tryptophan is convenient to prepareOrganic active ingredientsOrganic chemistryTryptophanCombinatorial chemistry

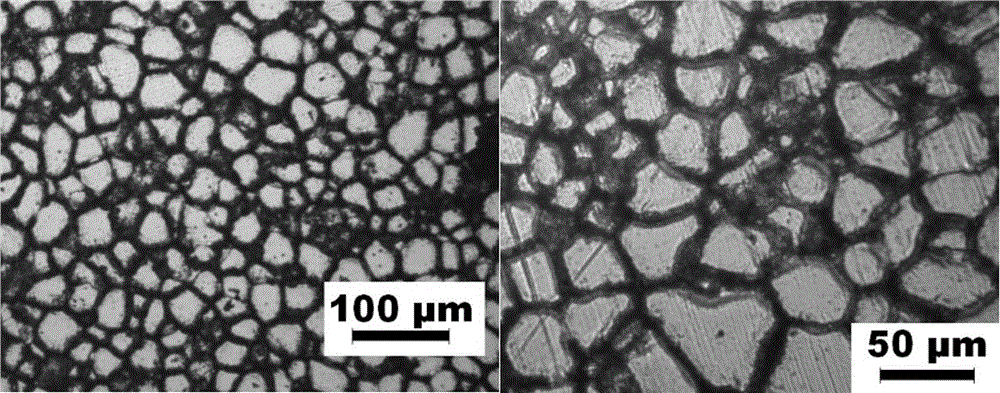

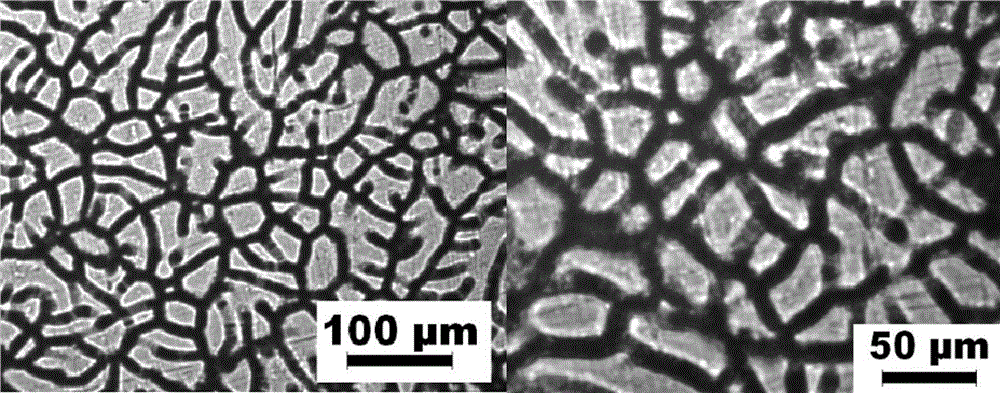

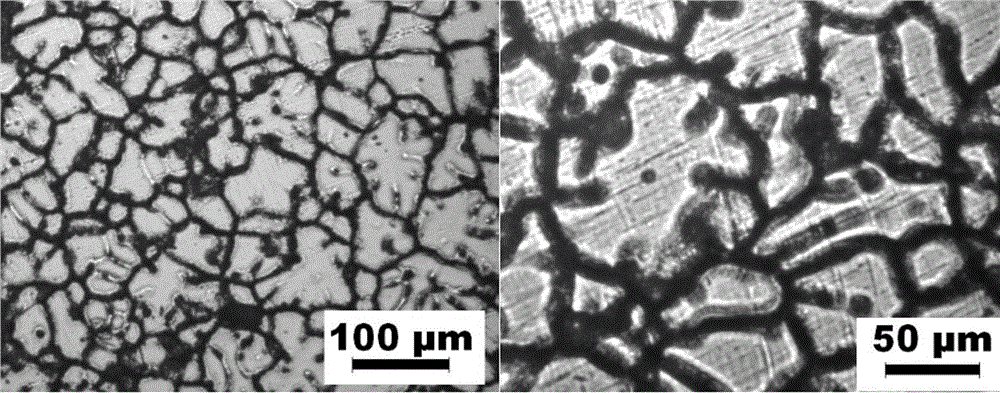

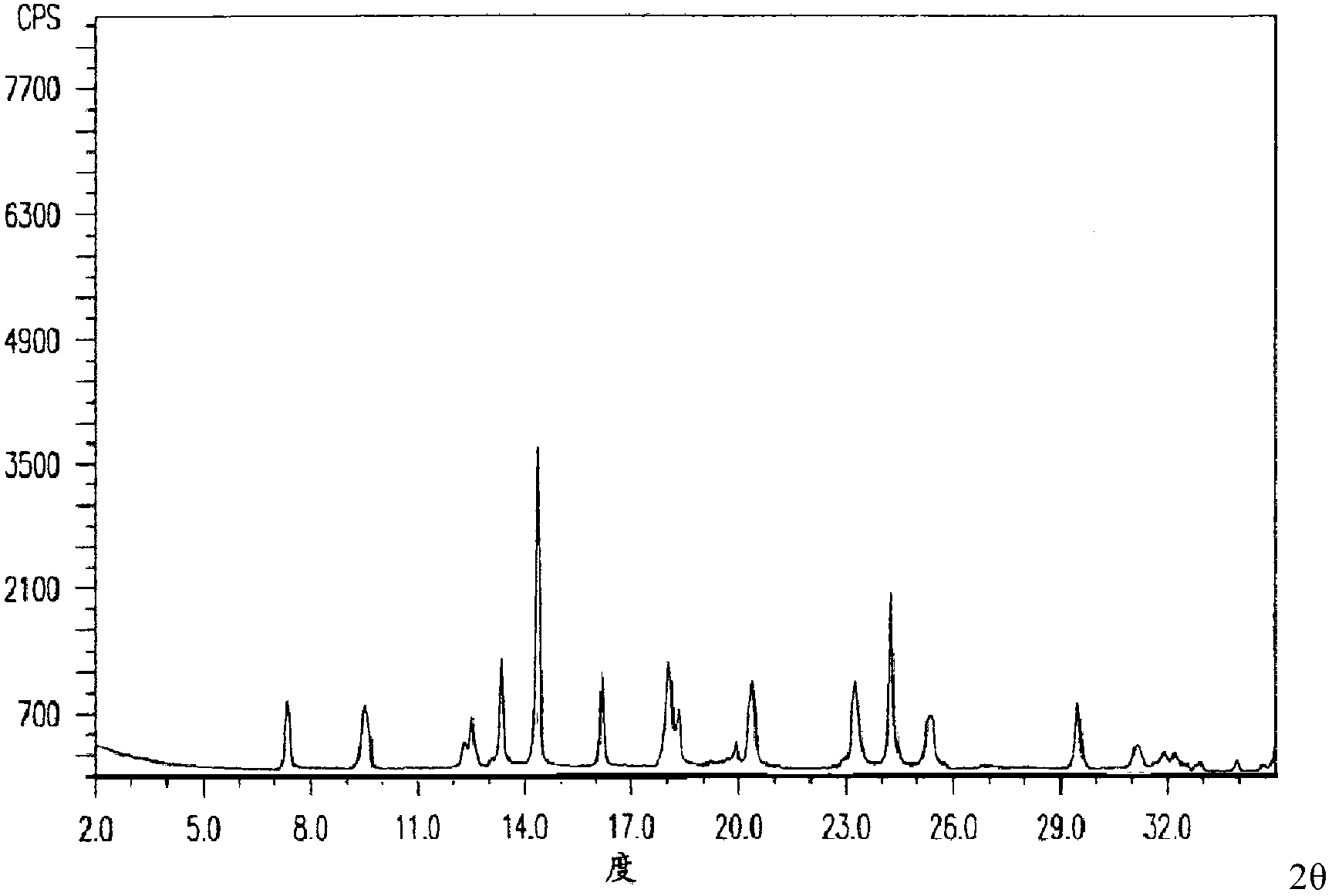

The invention relates to a pharmaceutical composition, and particularly relates to a compound amino acid composition and a preparation method thereof. The compound amino acid composition contains 18 amino acids and pharmaceutical adjuvants; tryptophan is a compound as shown in an X-ray powder diffraction figure I, which is obtained by measurement with a Cu-Kalpha ray. The preparation of the compound amino acid composition, which is prepared from the tryptophan, has good stability and is very suitable for clinical application. The compound amino acid composition has very good mobility and is convenient for preparing the preparation in the medicine preparation process.

Owner:四川省惠达药业有限公司

Dry type transformer

InactiveCN108831679APlay the role of heat dissipationReduce oxidation reactionTransformers/inductances coolingTransformers/inductances casingsTransformerNitrogen

The invention discloses a dry type transformer, and relates to electrical equipment. The dry type transformer comprises a transformer, wherein a shell is arranged outside the transformer; the transformer is arranged in the shell in a sealed mode; the shell is provided with a vacuum interlayer, and a cable channel is formed in the vacuum interlayer; a gas circulating device is further arranged on the shell; the gas circulating device comprises an air pump and a gas storage tank; compressed nitrogen is stored in the gas storage tank; the shell is further provided with an air inlet and an air outlet which are matched with the gas circulating device; and a heat exchange device is further arranged on the gas circulation device. Compared with the prior art, the dry type transformer is sealed ina shell full of nitrogen, so that external dust and impurities are isolated, and the constant-temperature and constant-humidity in the shell can be kept; and due to the fact that no oxygen exists, oxidation reaction is completely eradicated, so that the service life of the dry type transformer is greatly prolonged, and the occurrence rate of faults is reduced. Moreover, after the dry type transformer is exploded, the occurrence of fire disasters can be reduced under the inhibition of nitrogen.

Owner:浙江城电电气有限公司

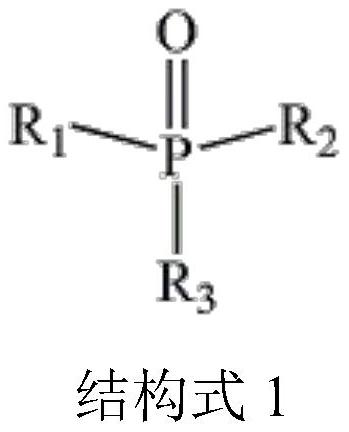

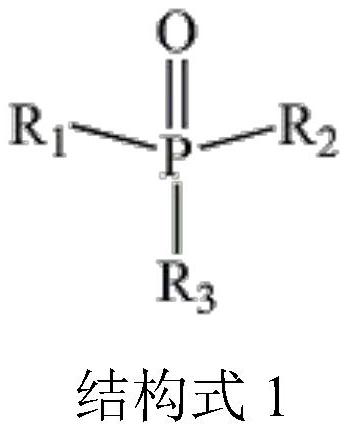

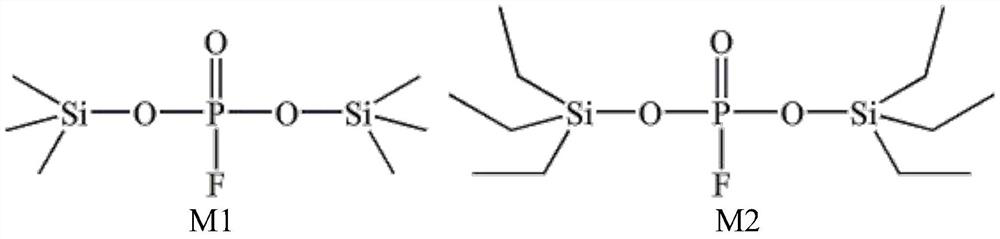

Non-aqueous electrolyte for high-voltage lithium ion battery and lithium ion battery

InactiveCN112448034AReduce oxidation reactionRich chemical compositionSecondary cells servicing/maintenanceElectrolytic agentOrganosolv

The invention belongs to the technical field of batteries, and discloses a non-aqueous electrolyte for a high-voltage lithium ion battery and the lithium ion battery. The non-aqueous electrolyte for the high-voltage lithium ion battery comprises a non-aqueous organic solvent, an electrolyte and a film-forming additive, wherein the film-forming additive contains a negative electrode film-forming additive and a fluorine-containing phosphate additive as shown in a structural formula 1. In the electrolyte, the HOMO energy of the fluorine-containing phosphate compound shown in the structural formula 1 is higher than that of ethylene carbonate, and the fluorine-containing phosphate compound preferentially undergoes an oxidation reaction on the surface of a ternary material to form a stable and compact CEI film, so the oxidation reaction of the electrolyte on the surface of an electrode is reduced; meanwhile, the interface film with low impedance is formed on the surface of the negative electrode, so the dynamic characteristics inside the battery can be improved, and the cycle life is prolonged; the negative electrode film-forming additive such as ethylene sulfate is preferentially reduced and decomposed on the surface of the negative electrode to form an excellent solid electrolyte membrane, so that the chemical composition of the SEI membrane is enriched, the impedance is adjusted,and the high-low temperature performance, the rate capability and the storage performance of the battery are improved.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Argon protective device for ingot steel casting

The invention discloses an argon protective device for ingot steel casting, which is composed of an inner barrel and an outer barrel; a connecting plate for connecting the inner barrel and the outer barrel is arranged at the lower end of the inner barrel and the outer barrel, ceramic fiber sealing sleeve is filled between the inner barrel and the outer barrel at the upper end of the connecting plate, and the ceramic fiber sealing sleeve is higher than the upper end surface of the inner barrel and the outer barrel; an argon lead-in pipe which is extended outwards is arranged on the outer barrel wall at the lower end of the connecting plate, and a plurality of through holes which lead argon out are arranged on the inner barrel wall corresponding to the argon lead-in pipe, and the height between the upper end surface of the connecting plate and the upper end surface of the inner barrel and the outer barrel is more than the height between the lower end surface of the connecting plate and the lower end surface between the inner barrel and the outer barrel. The argon protective device can reduce secondary oxidization in the casting process of molten steel, reduce the mixed sundries in the molten steel and improve the molten steel purity degree.

Owner:SHANGHAI HEAVY MACHINERY PLANT +1

Natural fruit and vegetable powder and preparation method thereof

InactiveCN106579110AImprove health benefitsImprove antioxidant capacityFood ingredient as antioxidantDermatological disorderWater ChestnutsSucrose

The invention discloses a natural fruit and vegetable powder and a preparation method thereof, and belongs to the field of food processing. The natural fruit and vegetable powder comprises the raw materials: a citrus powder, a water chestnut powder, a grape powder, a zizania aquatica powder, a lemon powder, a carrot powder, a bitter gourd powder, a pumpkin powder, a tomato powder, sucrose, and auxiliary materials; the auxiliary materials comprise maltodextrin, lecithin, isolated soy protein and glucomannan. The natural fruit and vegetable powder is prepared through the steps of preparing a fine powder, batching, cooking thoroughly, drying, crushing and the like. The natural fruit and vegetable powder has the following advantages: the preparation process is simple, the added auxiliary materials promote fusion of various raw materials, all the components are allowed to be mixed and emulsified completely and uniformly, and the reconstituability of the natural fruit and vegetable powder is improved; at the same time, all the raw materials are interacted with each other, and the nutrition and health-care functions of the natural fruit and vegetable powder are strengthened.

Owner:钟山县洲星食品有限公司

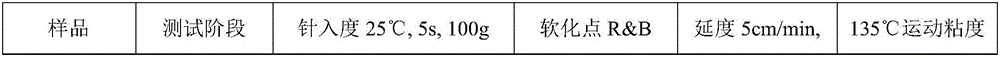

High-aging-resistance modified asphalt and preparation method thereof

InactiveCN106433164AImprove thermal stabilityImprove photostabilityBuilding insulationsMethyl isobutyl ketoneAging resistance

The invention discloses a high-aging-resistance modified asphalt and a preparation method thereof. The high-aging-resistance modified asphalt comprises the following components in percentage by mass: 72-80% of substrate asphalt, 1.3-2.7% of hindered amine light stabilizer, 0.5-1.2% of trilauryl phosphite, 0.5-2% of barium stearate, 6-8% of diatomite, 5-10% of epoxy soybean oil and 5-8% of methyl isobutyl ketone. The preparation method comprises the following steps: adding the hindered amine light stabilizer, trilauryl phosphite and barium stearate into the substrate asphalt at appropriate temperature, uniformly mixing with the asphalt, and adding the diatomite, epoxy soybean oil and methyl isobutyl ketone to obtain the high-aging-resistance modified asphalt. The asphalt has very high heat stability and light stability, is capable of greatly enhancing the pavement performance and durability and prolonging the maintenance period and service life of the high-grade asphalt pavement when being applied to the asphalt pavement, and thus, has very high cost performance and wide application prospects.

Owner:CHANGAN UNIV

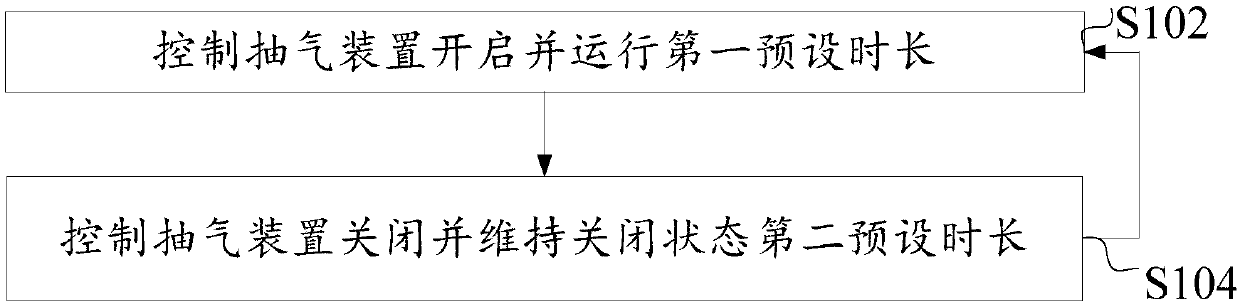

Cooking utensil, control method of cooking utensil, control device of cooking utensil and computer readable storage medium

ActiveCN110507172AReduce oxidation reactionReduce reproduction ratePressure-cookersVacuum pumpingProcess engineering

The invention provides a cooking utensil, a control method of the cooking utensil, a control device of the cooking utensil and a computer readable storage medium. The control method comprises a heat insulation stage in which an air extraction device is controlled to be started, and the air extraction device is controlled to intermittently work. According to the control method provided by the invention, at the heat insulation stage, the air extraction device is controlled to be started, and the air extraction device extracts air in a cooking cavity; the cooking cavity is subjected to vacuum pumping, so that the inside of the cooking cavity is in a negative pressure state; the oxygen content in the cooking cavity can be reduced; the food oxidization reaction speed and the bacterium breedingspeed are decelerated; the food storage time of the cooking utensil is prolonged; and the food freshness is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Aluminum coil annealing process

InactiveCN108179367ALow oxygenReduce oxidation reactionFurnace typesHeat treatment furnacesWater coolingOxide

The invention discloses an aluminum coil annealing process. The aluminum coil annealing process comprises the following steps that S1, an aluminum coil is fed into an annealing furnace, and the annealing furnace is sealed; S2, a check air outlet of the annealing furnace is sealed, the annealing furnace is vacuumized through vacuum equipment, and vacuumizing is stopped after the absolute vacuum degree in the annealing furnace reaches 0.2 pa; S3, nitrogen is pumped into the annealing furnace continuously so that the relative vacuum degree in the annealing furnace can be greater than or equal to0; S4, the temperature in the annealing is increased to 300-390 DEG C and is held; S5, when the annealing time requirements are met, an annealing furnace water cooling system is started, and the temperature in the annealing is decreased to 150 DEG C or lower; S6, nitrogen with the temperature being no higher than 50 DEG C is pumped into the annealing furnace; and S7, after the temperature in the annealing furnace is lower than the temperature of the pumped nitrogen, the aluminum coil is taken out. Through the process, the effect that the thickness of an oxide film of the annealed aluminum coilis smaller than 50 A can be ensured.

Owner:重庆市铜梁区华亿来铝材加工厂

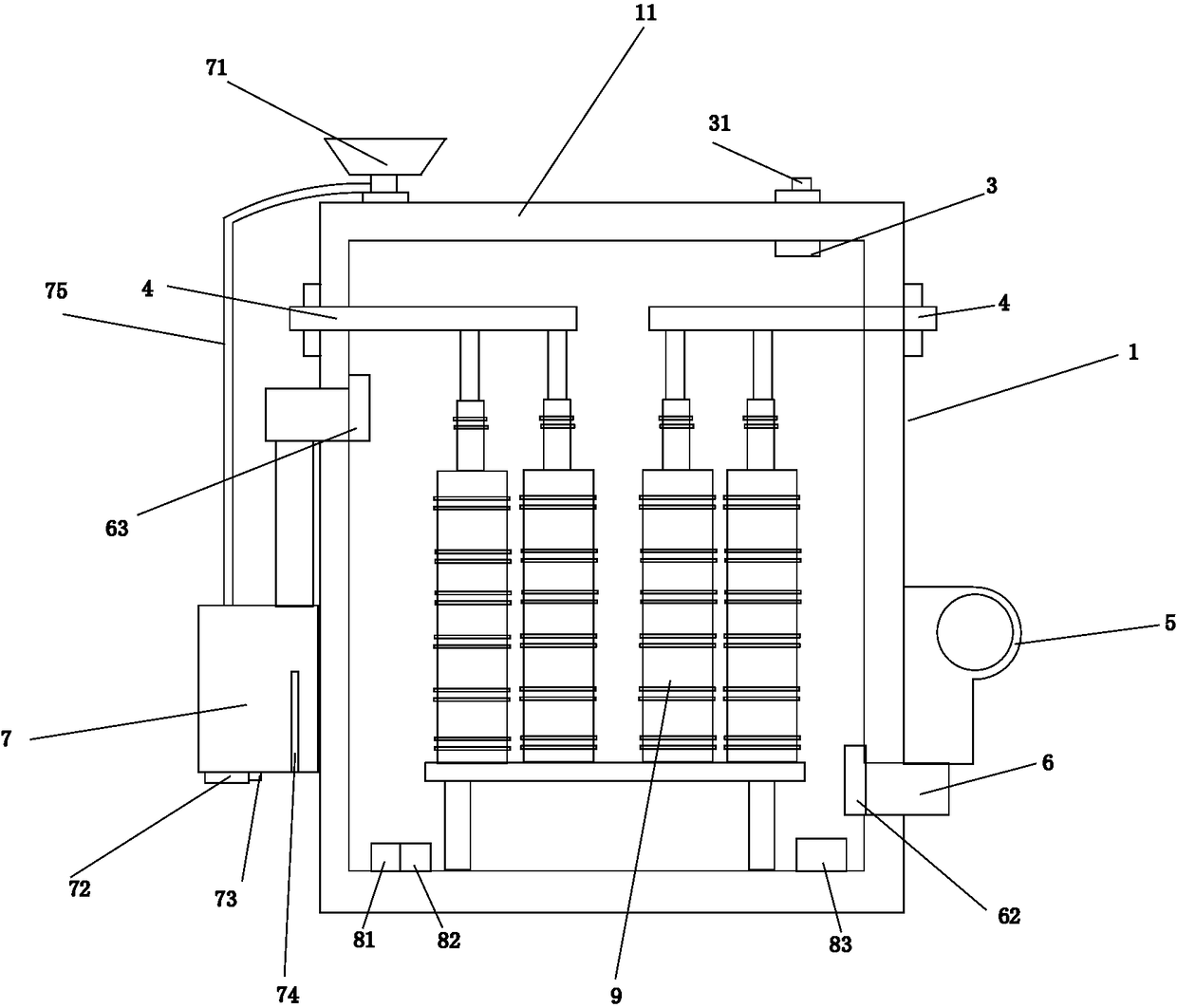

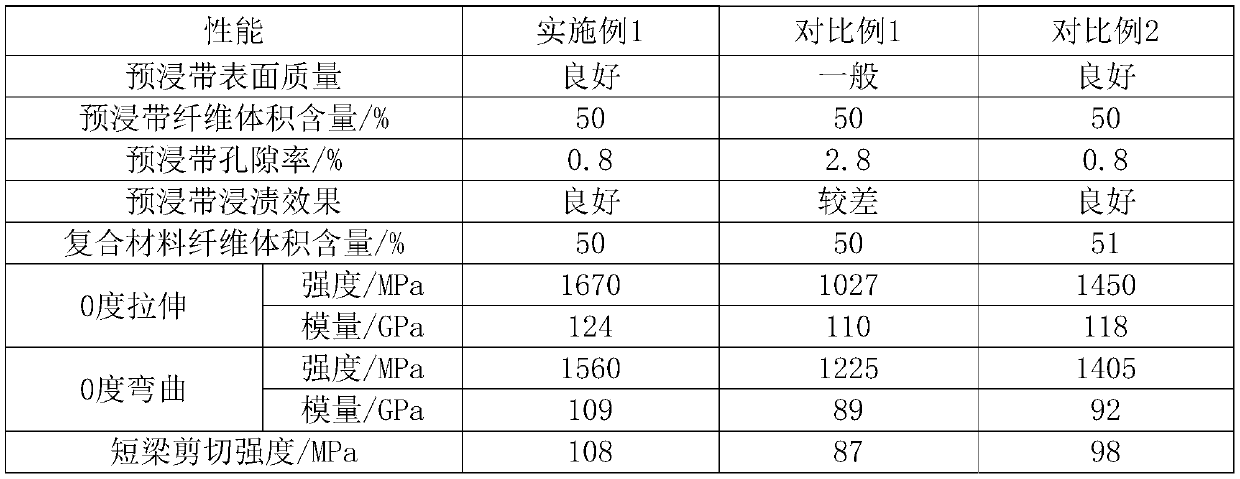

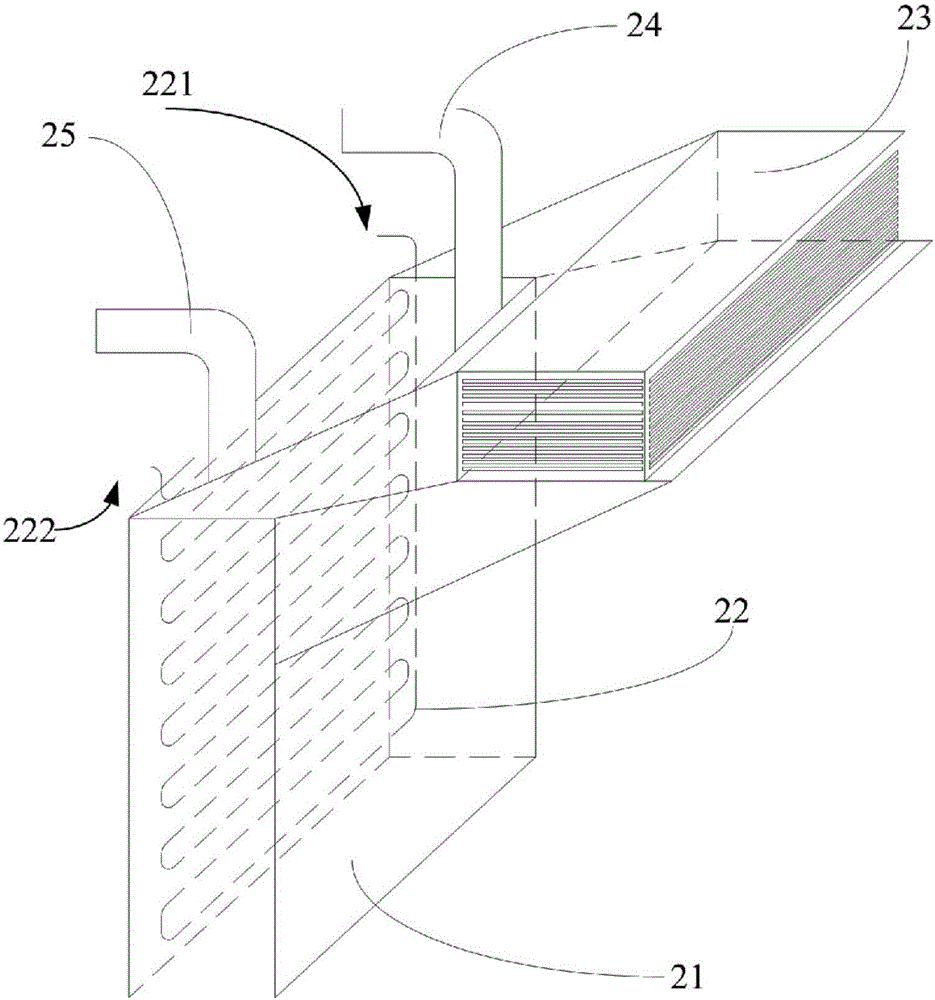

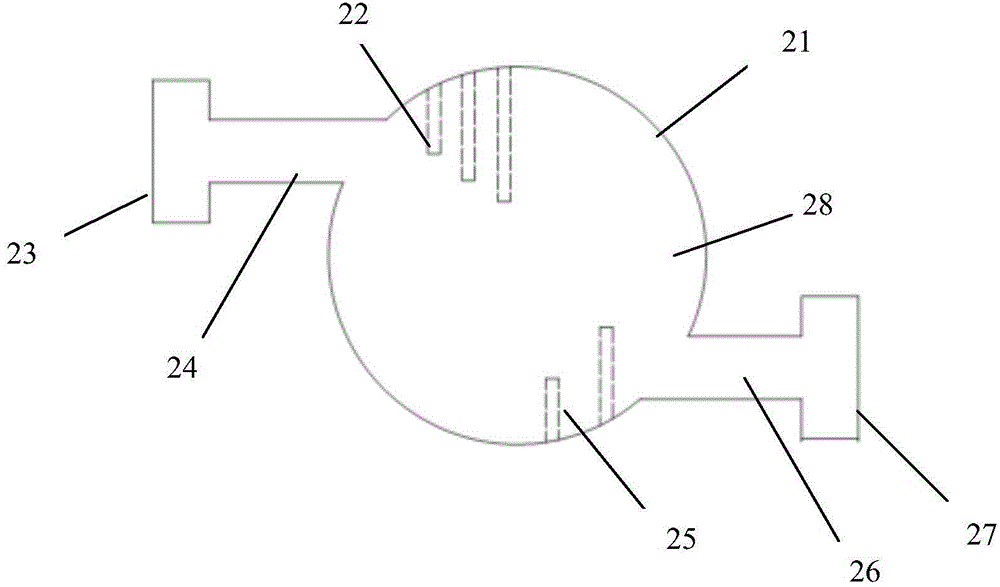

Equipment and method for preparing continuous carbon fiber reinforcement PEEK thermoplastic preimpregnating belt

The invention discloses equipment and method for preparing a continuous carbon fiber reinforcement PEEK thermoplastic preimpregnating belt. The equipment for realizing the method adopts 4 stagger heatrollers and an infrared drying tunnel which are arranged in an S shape. The method comprises the following steps that after preliminary impregnating is performed on used PEEK resin particle materialsor used PEEK resin powder and two sides of continuous carbon fiber yarn, the used PEEK resin particle materials or the used PEEK resin powder and two sides of the continuous carbon fiber yarn jointlyenter front high-temperature heating rollers for heating, and extruded impregnating; then the preimpregnating belt enters the four stagger heat rollers to perform S-shaped propelling, and in the propelling process, impregnating is realized for four times, so that resin molten mass on two sides of the preimpregnating belt and carbon fibers are sufficiently impregnated, and the situation that a resin rich layer is generated on two sides of the preimpregnating belt is avoided; after being processed by guide rollers, the propelling direction of the impregnated preimpregnating belt is parallel tothe infrared drying tunnel; the impregnated preimpregnating belt is slowly cooled in the infrared drying tunnel to eliminate residual stress, so that the resin molten mass on two sides of the carbon fiber can be repeatedly extruded and impregnated, the impregnating effect is greatly increased, and the porosity of the preimpregnating belt is reduced; and the preimpregnating belt slowly passes through the infrared drying tunnel, so that slow temperature lowering is realized, and the residual stress produced in the S-shaped propelling process is released to a great extent.

Owner:基准宇航(北京)有限公司

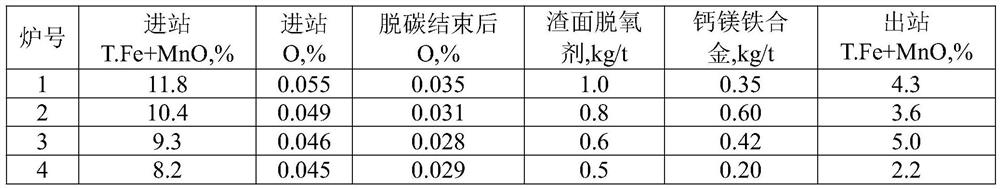

Production method for improving pouring property of silicon-manganese killed silicon steel

ActiveCN113249639AReduce oxygen contentImprove corrosion resistanceMelt-holding vesselsManganeseFerrosilicon

The invention provides a production method for improving a pouring property of silicon-manganese killed silicon steel, and belongs to the technical field of steel smelting. The production method comprises the steps of converter smelting, RH vacuum refining and continuous casting, wherein a slag amount is strictly controlled during converter tapping, and lime and a slag surface deoxidizer are added to adjust slag; after RH vacuum refining decarburization is finished, low-carbon low-sulfur ferrosilicon is added for deoxidation, then manganese metal, ferrophosphorus and the like are added for alloying, meanwhile, a low-carbon steel slag surface deoxidizer is added to a slag surface of a steel ladle to modify the slag, calcium-magnesium-iron alloy is added after molten steel components reach the standard, after circulation is conducted for 3 min to 5 min, circulation treatment is conducted for 6 min to 10 min, and breaking and tapping are conducted; and continuous casting adopts protective pouring, a stopper rod with a stopper rod head containing more than or equal to 80% of Al2O3, less than or equal to 10% of C, and 8% to 15% of SiC, and having a porosity of less than or equal to 12% and a mass density of more than or equal to 2.9 g / cm<3> is selected for flow control in a pouring process, and the number of continuous pouring furnaces is more than or equal to 15 per tundish. According to the method, a corrosion problem of the stopper rod head in the pouring process can be remarkably solved, the number of continuous pouring furnaces is increased, and the production cost is reduced.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Method of manufacturing solid aluminum electrolytic capacitor

InactiveCN106449116AReduce oxygen contentReduce oxidation reactionSolid electrolytic capacitorsDrying/impregnating machinesAluminiumAluminum electrolytic capacitor

A method of manufacturing a solid aluminum electrolytic capacitor comprises the following steps: (1) core package winding; (2) core package fixing: fixing a positive or negative guide pin of a core package to a fixed bar and placing the core package on a material rack; (3) formation; (4) formation drying: setting the vacuum drying temperature at 150-200 DEG C, and drying the core package for 5-6 minutes in a vacuum environment; (5) impregnation; and (6) polymerization. The step of impregnation includes the following sub-steps: [1] pretreatment agent impregnating; [2] drying I: setting the drying temperature at 60-80 DEG C, and performing drying for 5-6 minutes in a vacuum environment; [3] monomer impregnating; [4] drying II: putting the core package treated in step (3) in a vacuum drying oven, setting the drying temperature at 60-80 DEG C, and drying the core package for 5-6 minutes in a vacuum environment; and [5] oxidant impregnating. The efficiency of capacitor production is high, and produced capacitors are of good quality.

Owner:HUNAN AIHUA GRP

Polishing bath of aluminium material and production technology of aluminium material

InactiveCN105780007AReduce oxidation reactionAvoid affecting the washing effectPhosphoric acidFresh water

The invention discloses a polishing bath of an aluminium material. The polishing bath of the aluminium material comprises a two-acid main bath and a rinsing bath, and further comprises a two-acid sub bath, wherein the two-acid sub bath accommodates a bath solution, and is equipped with a cooling device used for dissipating heat of the bath solution. The invention further discloses an aluminium material polishing production technology utilizing the polishing bath of the aluminium material. During aluminium material polishing production, after polishing of the two-acid main bath, the two-acid sub bath is newly added for temperature decreasing treatment, the temperature of the bath solution is controlled between 10 DEG C and 40 DEG C through temperature decreasing of the cooling device, the high-temperature aluminium material is quickly cooled, and the bath solution is enabled to drip for a long time till the bath solution is empty, so that the bath solution in the two-acid main bath is recycled during aluminium material polishing, and the unnecessary waste of raw materials such as phosphoric acid and sulfuric acid, and the fresh water resource is avoided.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

Direct-mixing type multi-purpose automatic accurate fertilizer irrigation system

InactiveCN104584757AShorten mixing timeReduce oxidation reactionPressurised distribution of liquid fertiliserAgriculture gas emission reductionFertilizerAutomatic control

The invention relates to a direct-mixing type multi-purpose automatic accurate fertilizer irrigation system which comprises a clean water tank, a raw fertilizer tank, a venturi tube, a fast fertilizer suction electromagnetic valve, an irrigation pump, an automatic control system, an electro connecting pressure gauge and a spherical fertilizer mixer, wherein the venturi tube sucks a raw fertilizer or an acid solution into a pipeline; the fast fertilizer suction electromagnetic valve controls a fertilizer suction amount; the output end of the irrigation pump is connected with the input end of the spherical fertilizer mixer through the pipeline, the pipeline positioned between the irrigation pump and the spherical fertilizer mixer is provided with the electro connecting pressure gauge; the output end of the spherical fertilizer mixer is respectively connected with an irrigation delivery pipeline and a fertilizer suction feedback pipeline; and the irrigation delivery pipeline is provided with an irrigation electromagnetic valve and a pipeline pressure detection device. The direct-mixing type multi-purpose automatic accurate fertilizer irrigation system disclosed by the invention realizes the immediate usage of a water fertilizer after mixing by adopting the independently developed spherical fertilizer mixer, can be used for furthest shortening the mixing time of a fertilizer and water and reducing the oxidation reaction generated because the fertilize contacts with air and can prevent the fertilizer waste generated in a fertilizer mixing process, provide higher output pressure through a direct-mixing type and cover more irrigated area.

Owner:上海璞研电子科技有限公司

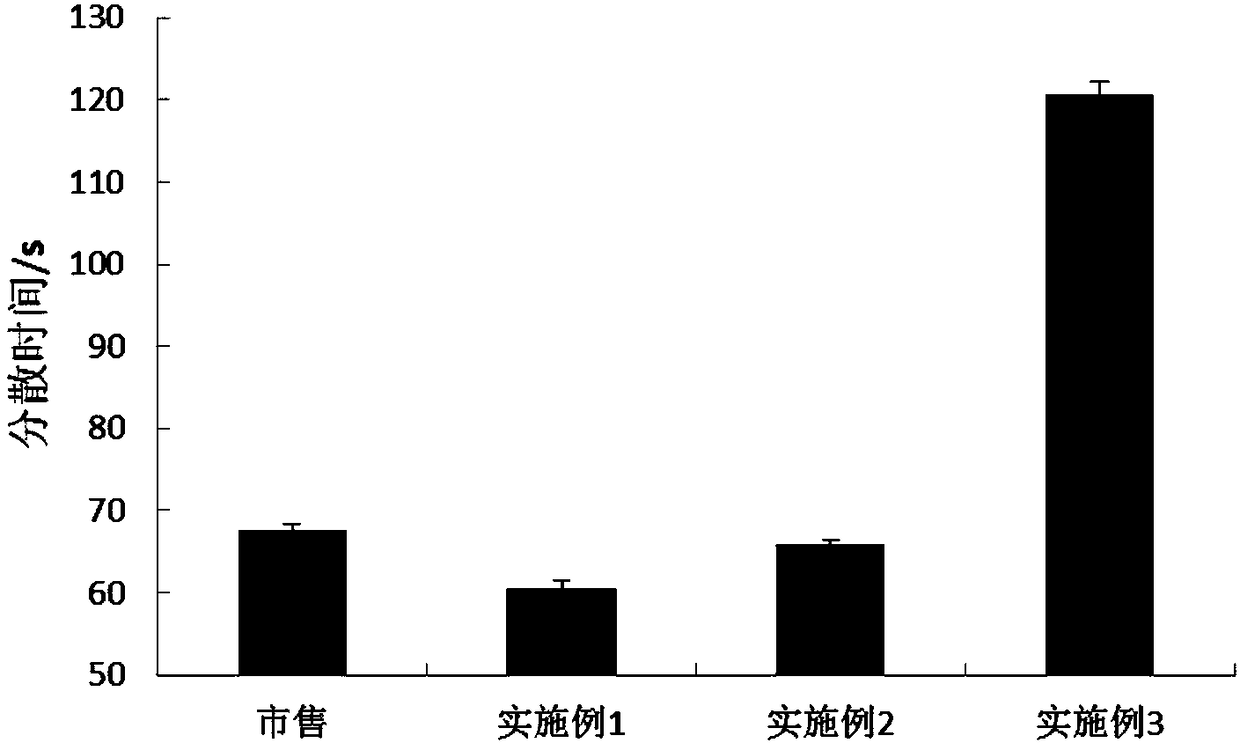

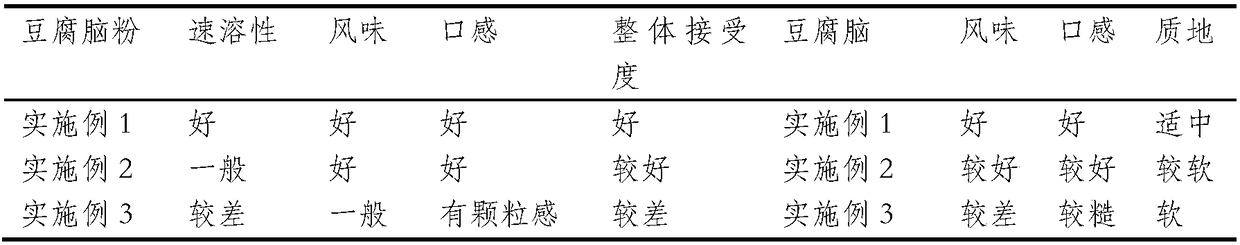

Instant tofu jelly powder and preparation method thereof

ActiveCN108056178AGood instant solubilityGood dispersionCheese manufactureFood scienceBiotechnologySoybean product

The invention discloses instant tofu jelly powder and a preparation method thereof. The preparation method is characterized by comprising the following steps: soaking, and grinding; separating a slurry, deactivating enzymes; preparing a mixed solution; sterilizing and concentrating; performing spray drying; performing fluidized granulation. The invention provides the preparation method of the instant tofu jelly powder with a good flavor, a fine texture and very good elasticity. A bad flavor of a soybean product is fundamentally solved; the prepared tofu jelly has bean fragrance and mellow fragrance; after spray drying, the solubility of soybean protein is greatly improved; meanwhile, a compounded emulsifying and bonding agent is used as spray coating liquid for spray coating, so that the instant solubility and the dispersion of the powder are improved; the enzymes such as lipoxygenase in soybean milk prepared by the preparation method provided by the invention can be inhibited to a large extent, so that an oxidation reaction in the soybean milk is greatly reduced, the texture and the elasticity of the tofu jelly are improved, and thus the texture and the elasticity of the instant tofu jelly are closer to those of commercially available tofu jelly.

Owner:JIANGNAN UNIV

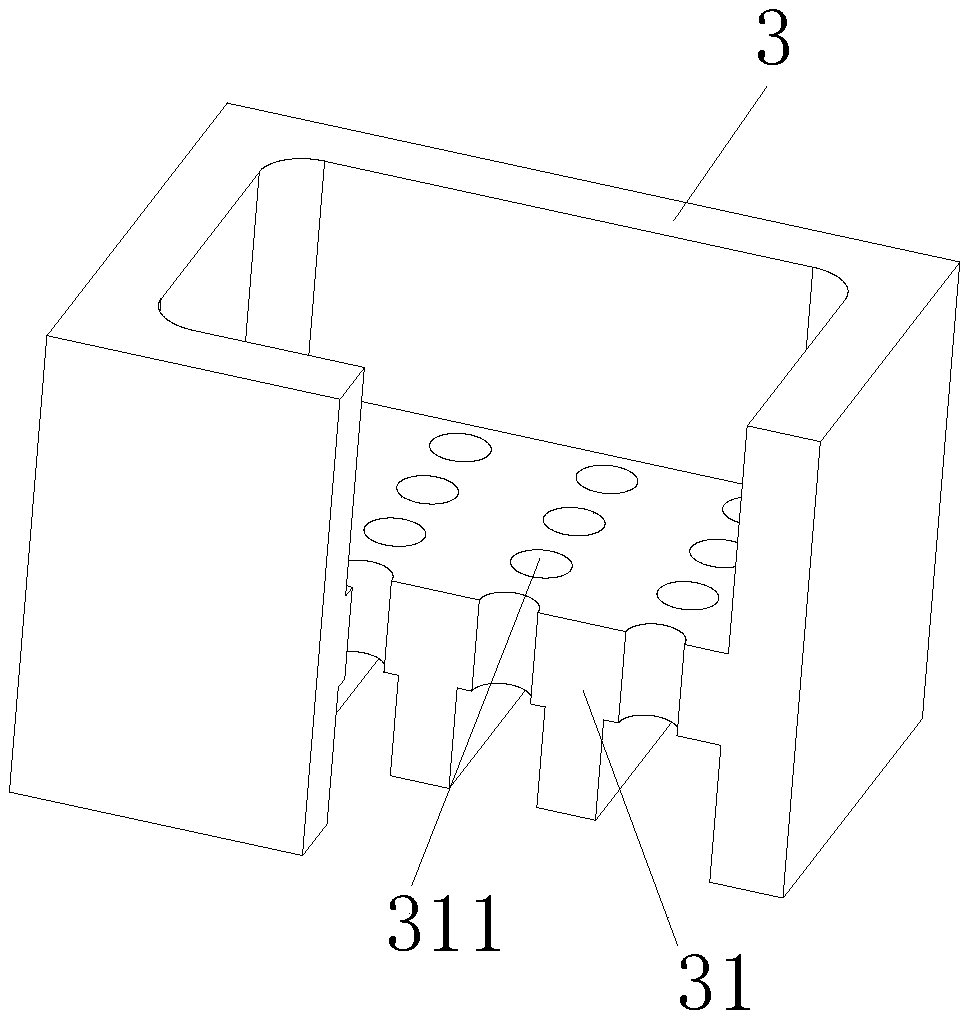

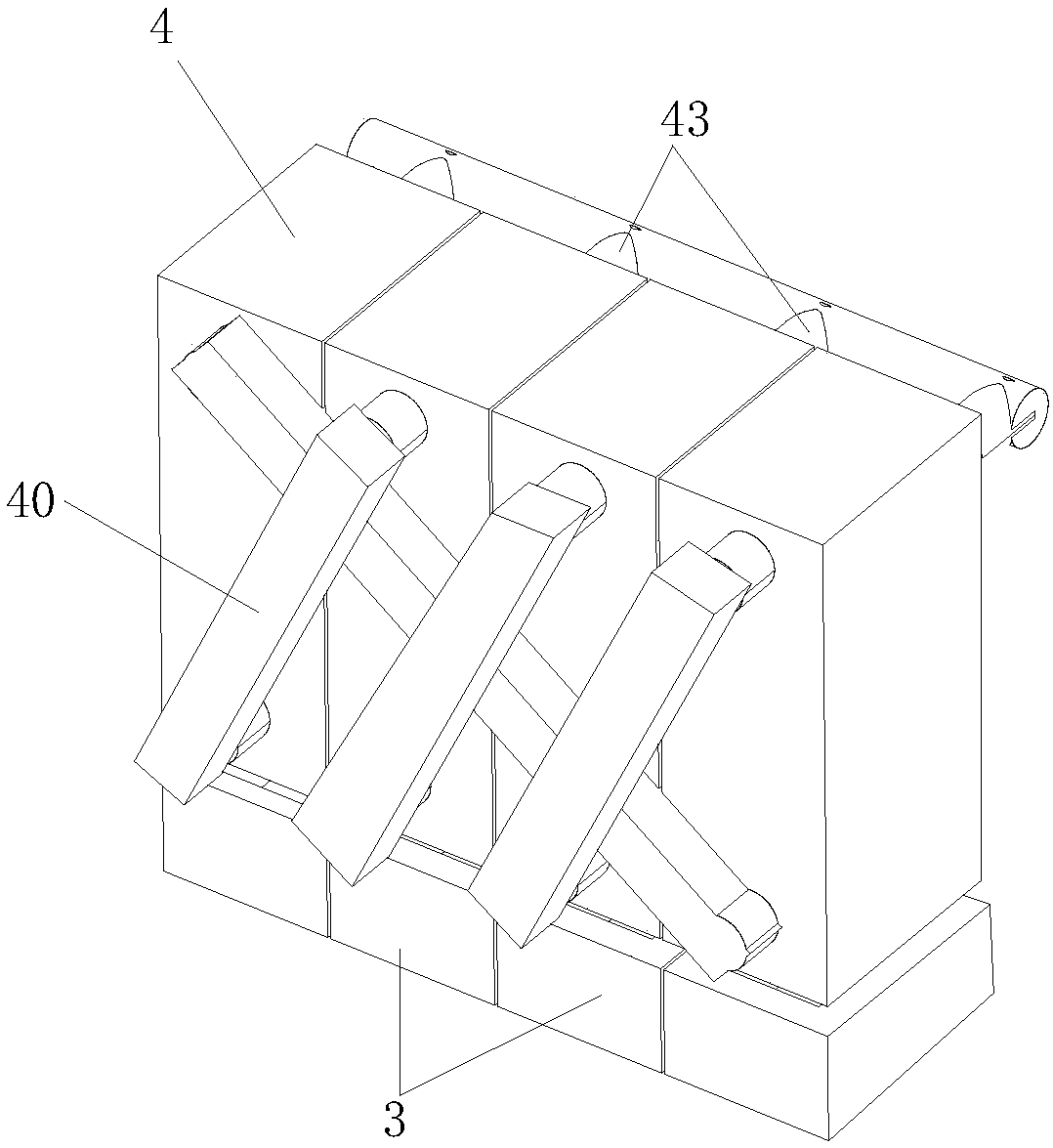

Novel energy-saving melting furnace with low burn out rate

PendingCN108826971AEfficient use ofAchieve energy saving effectPreheating chargesCrucible furnacesCombustion chamberGuide tube

The invention discloses a melting furnace. By means of the melting furnace, heat of gas in a combustion chamber is kept at the temperature of a molten metal crucible holding chamber, resources are utilized more effectively, and meanwhile, an energy saving effect is achieved. Fire grates are arranged in melting chambers correspondingly, traditional reflection-type heat transfer is changed, fuel gaspenetrates through holes of the fire grates and melts metal, and the heat efficiency is improved; draft guide tubes are connected between preheating chambers, gas is exhausted through exhaust outletsafter circulating to and fro in sequence between the preheating chambers through the draft guide tubes, the temperatures of tail gas of the melting chambers can be greatly decreased, and the heat efficiency is improved; and part of the tail gas exhausted out of the preheating chambers flows back to the combustion chamber, the other part of the tail gas is exhausted out through a counterflow heatexchanger, meanwhile, fresh air enters a combustion engine through the counterflow heat exchanger, and accordingly, the air can be preheated in the counterflow heat exchanger. According to the novel energy-saving melting furnace with the low burn out rate, the heat efficiency is increased to 85% or above, the aluminum oxidation rate is dropped to 0.3% or below, and the melting furnace has the advantages of energy saving and lowering of production cost and is suitable for application and popularization.

Owner:易平

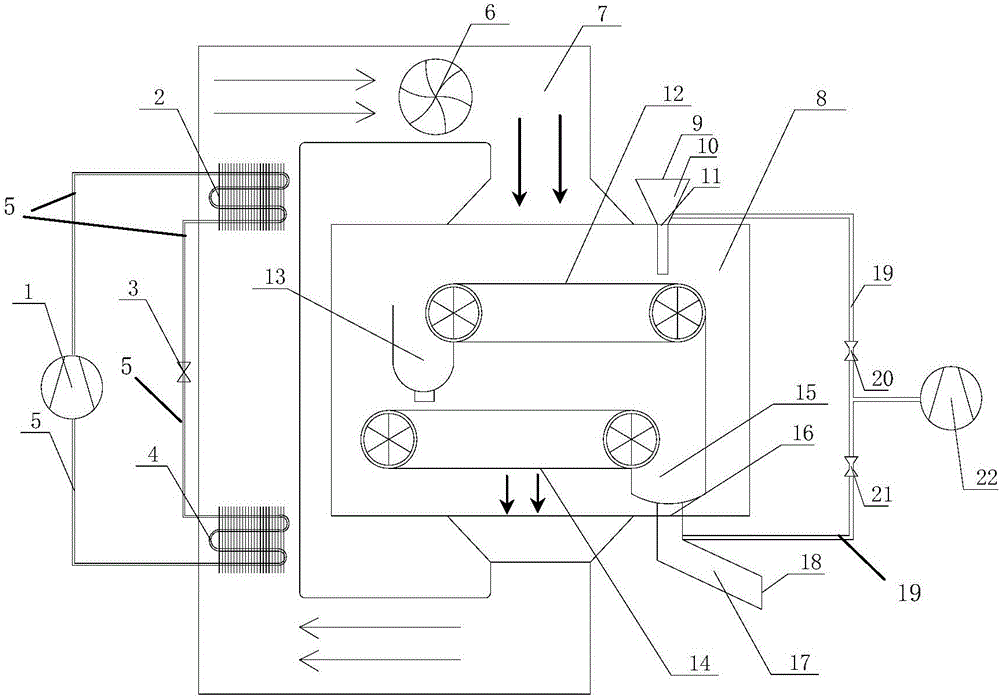

Heat pump vacuum drying machine capable of working continuously

InactiveCN106482453AGuaranteed nutrient contentAvoid consumptionHeat pumpsDrying solid materials without heatAdditive ingredientProcess engineering

The invention discloses a heat pump vacuum drying machine capable of working continuously. The heat pump vacuum drying machine capable of working continuously comprises a heat pump drying system and a vacuum system; the heat pump drying system is used for promoting circulating flowing of dry air and heating the dry air flowing in a circulating manner, and therefore to-be-dried materials placed in the heat pump drying system can be subjected to drying treatment, and dried materials are obtained; and the vacuum system is connected with the heat pump drying system and is used for placing the to-be-dried materials into the heat pump drying system and isolating the interior of the heat pump drying system from the outside air in the process when the dried materials are taken out of the heat pump drying system, and the vacuum degree in the heat pump drying system is maintained. The heat pump vacuum drying machine capable of working continuously can achieve continuous drying treatment on materials in various batches, unnecessary energy consumption and heat losses caused when the materials are replaced are avoided, it is avoided that oxygen rich in the outside air makes direct contact with the to-be-dried materials in a drying box, the generated oxidization reaction is reduced, and the content of nutritional ingredients in the materials is guaranteed.

Owner:TIANJIN UNIV OF COMMERCE

Winged prickly ash-flavored seasoned bamboo shoot slices and preparation method thereof

The present invention relates to the technical field of bamboo shoot product processing, and especially relates to winged prickly ash-flavored seasoned bamboo shoot slices and a preparation method thereof. The winged prickly ash-flavored seasoned bamboo shoot slices in the invention are prepared from the following raw materials in parts by weight: 100 parts of bamboo shoot slices, 10-13 parts of thick broad-bean sauce, 2-2.5 parts of winged prickly ash oil, 0.3-0.4 part of beef powder, 0.15-0.2 part of yeast powder, 0.15-0.2 part of flavor peptide, 0.3-0.4 part of I+G (disodium inosine 5'-monophosphate and disodium guanosine 5'-monophosphate), 1-1.5 parts of sodium glutamate, 0.3-0.4 part of white granulated sugar, 0.03-0.05 part of potassium sorbate, 0.03-0.05 part of sodium dehydroacetate and 0.01-0.02 part of disodium ethylenediamine tetraacetate. With the above components, the winged prickly ash-flavored seasoned bamboo shoot slices which are prepared by the steps of raw material pretreatment, first-time color-protection and brittleness-keeping treatment, second-time color-protection and brittleness-keeping treatment, stirring and packaging and sterilization treatment have thecharacteristics of a unique flavor, good taste and luster, high nutrient component content and high safety quality.

Owner:成都吉食道食品有限公司

Cosmetic brush for skin care and its making method

InactiveCN1480124AImprove antioxidant capacityPrevent moisture loss by evaporationMedical preparations

A skin-protecting face pen for shielding sunshine, preventing wrinkles, delaying sanility and moistening skin is prepared from 13 raw materials including refined paraffin wax No.60, natural white beeswax candle, Uninual MC-80, superfine TiO2, animal fat, etc through mixing, fusing at 100-110 deg.c, grinding 6-8 times, heating to 70 deg.C, stirring while adding VE and VE, heating to 120-130 deg.c, and extruding out.

Owner:EAST CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com