High-strength Al-Zn-Mg-Cu-Ce-Y-Er-La-Sc wrought aluminum alloy and manufacturing method thereof

A technology of deformed aluminum alloy, mg-30wt.%er, applied in the field of metal materials, can solve problems such as insufficient alloy performance and product defects, achieve good composition uniformity, improve strength and toughness, and meet application requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

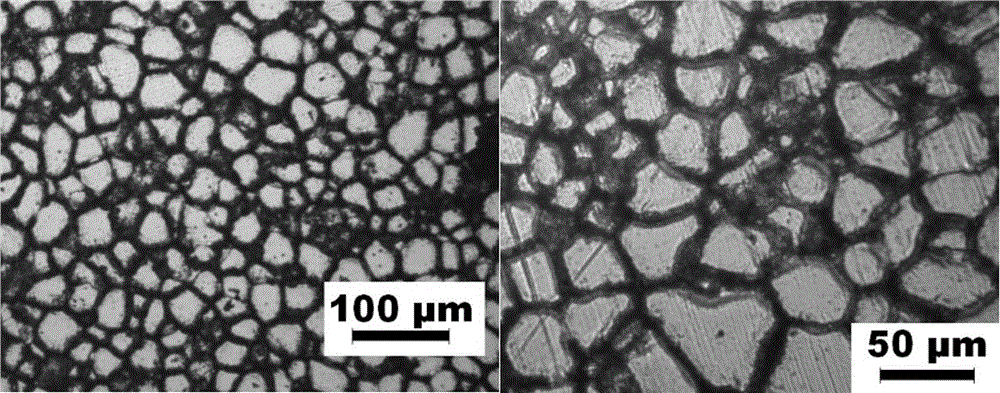

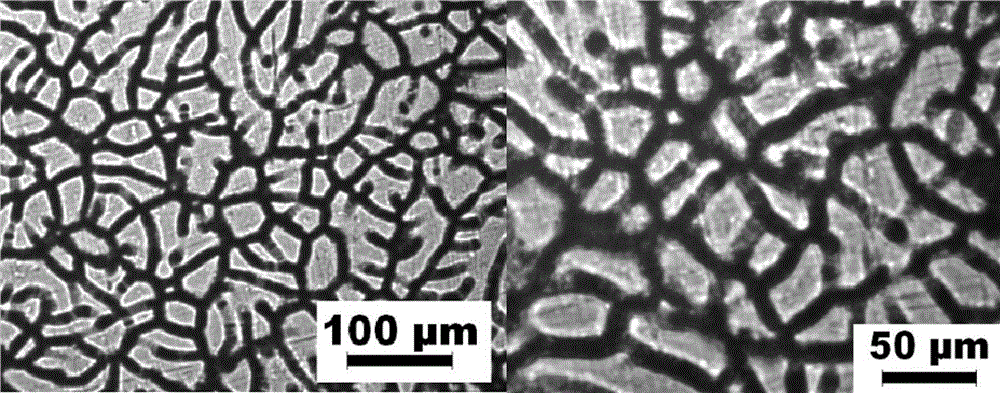

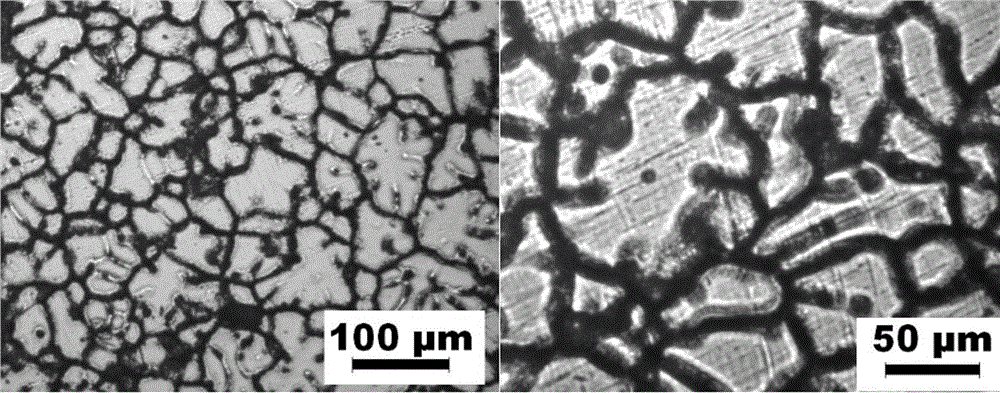

Image

Examples

Embodiment 1

[0022] This example provides a high-strength Al-Zn-Mg-Cu-Ce-Y-Er-La-Sc deformed aluminum alloy, which consists of the following components in mass percentage: Zn (zinc) 7%, Mg (magnesium) 2%, Cu (copper) 2.3%, Ce (cerium) 0.1%, Y (yttrium) 0.2%, Er (erbium) 0.1%, La (lanthanum) 0.01%, Sc (scandium) 0.2%, Al (aluminum) balance.

[0023] This embodiment also provides a method for preparing a high-strength Al-Zn-Mg-Cu-Ce-Y-Er-La-Sc deformed aluminum alloy, which includes the following steps.

[0024] Step 1. Prepare Al, Zn, Mg, Cu, Ce, Y, Er, La and Sc according to the mass percentage of the formula for smelting. Among them, Al, Zn, Mg, and Cu are added in the form of industrially pure Al, pure Zn, pure Mg, and pure Cu with a purity >99.99wt.%, and Ce, Er, Y, La, and Sc are added in the form of Al-30wt.%Ce , Mg-30wt.%Er, Mg-20wt.%Y, Al-30wt.%La, Al-2wt.%Sc powdered rare earth alloys are added. Raw materials do not require preheating.

[0025] Magnesium exists in the form of sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com