A CO2 laser with new structure

A carbon dioxide and laser technology, which is applied in lasers, laser parts, laser parts, etc., can solve problems that affect the stable use of products, the grinding accuracy of nozzles is difficult to meet the expected requirements, and damage to the lens film layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

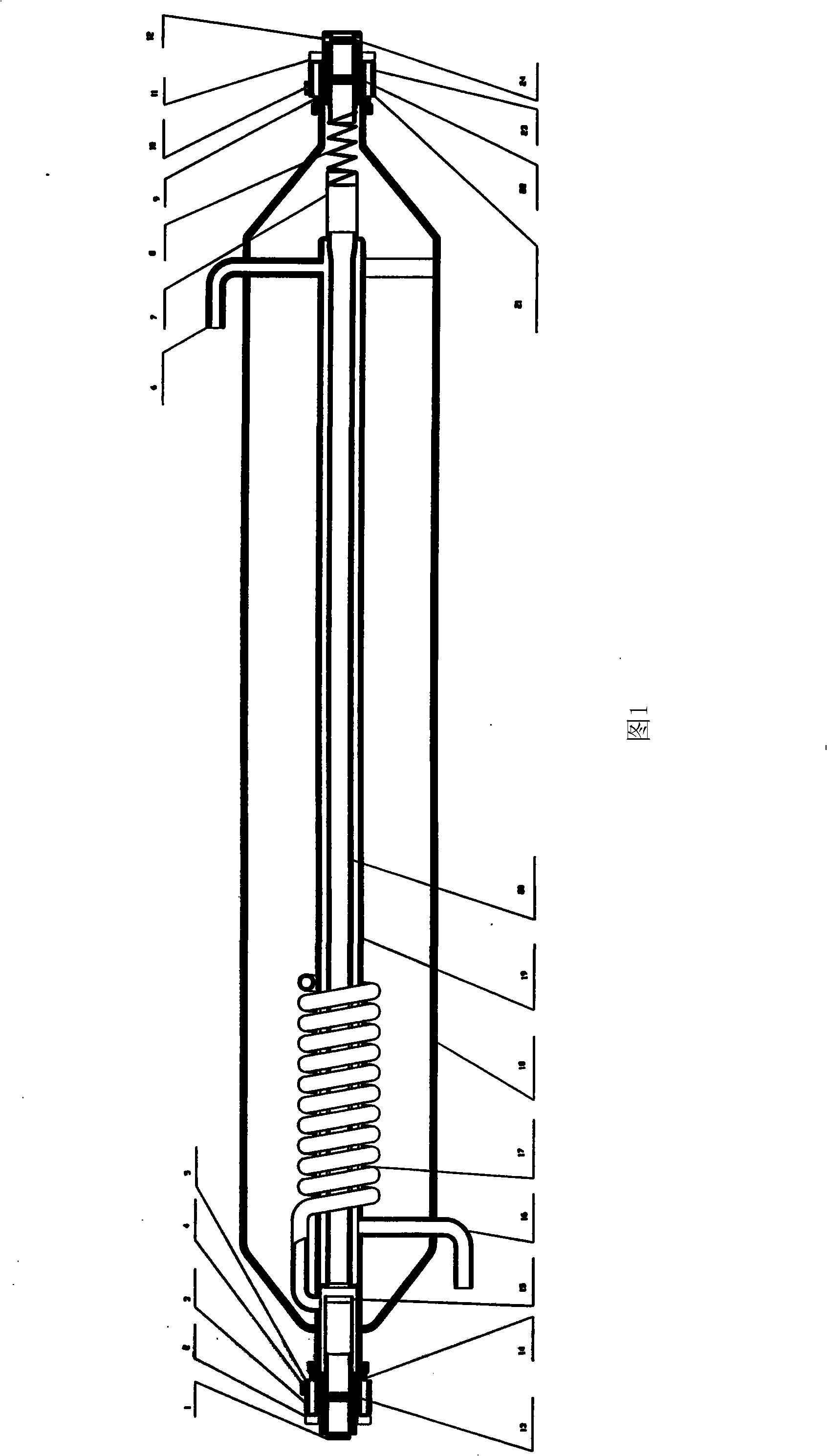

[0006] The accompanying drawings show the structure of the present invention and its embodiments, and the detailed description and principles will be described below in conjunction with the accompanying drawings. The invention discloses a carbon dioxide laser with a new structure. Its glass tube part is made up of discharge tube (20), water jacket pipe (19), air return pipe (17), gas storage pipe (18), water inlet (16), and water outlet (6). First put the glass tube on the dimmer table, use the inner focusing telescope to align the discharge tube (20) coaxially, weld the fixed flange (5) to the transition flange (14), and connect the positive electrode (15) The mounting ring (26) of the fixed flange (5) is set on the cylinder extending inward, and the transition flange (14) is bonded to the glass nozzle near the end of the return air pipe with epoxy resin, and the fixing method The inner hole of the blue (5) and the discharge tube (20) remain coaxial. Seal the total reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com