Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Reduce secondary oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

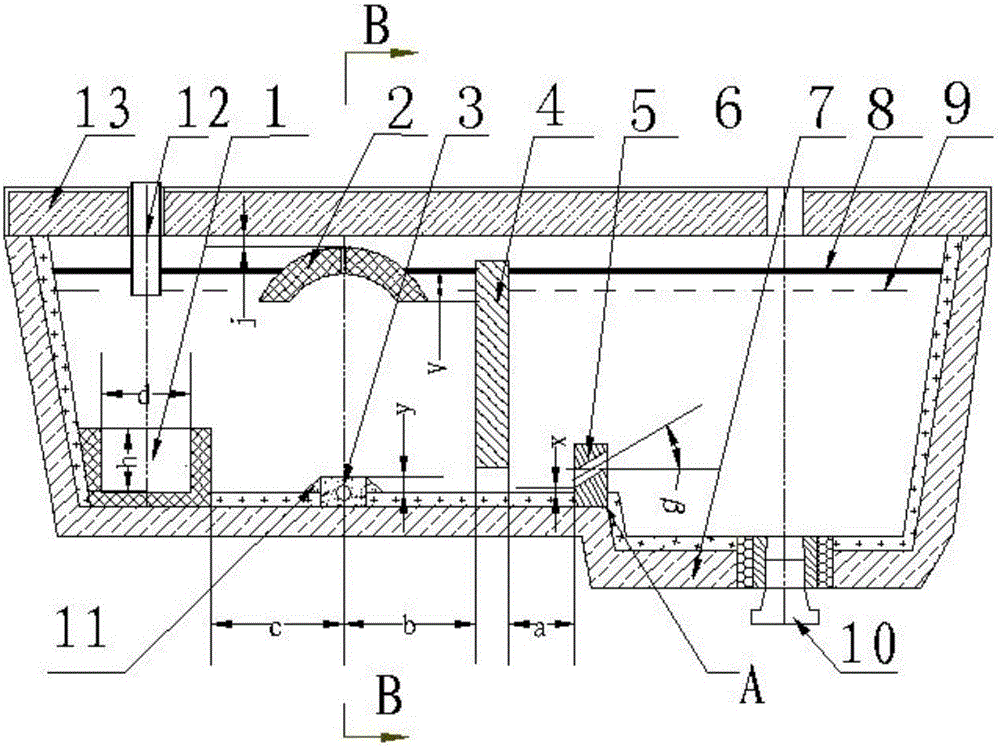

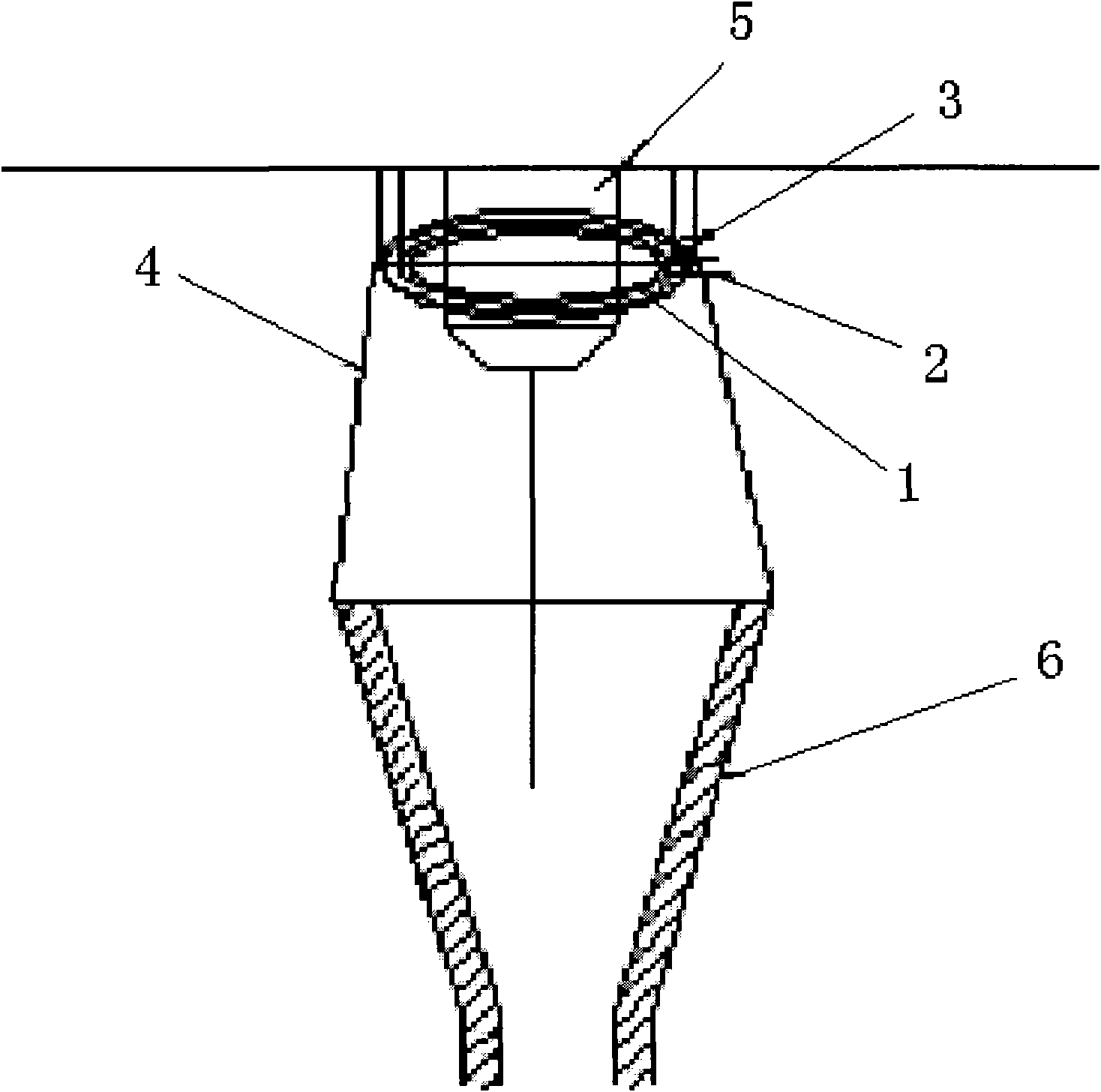

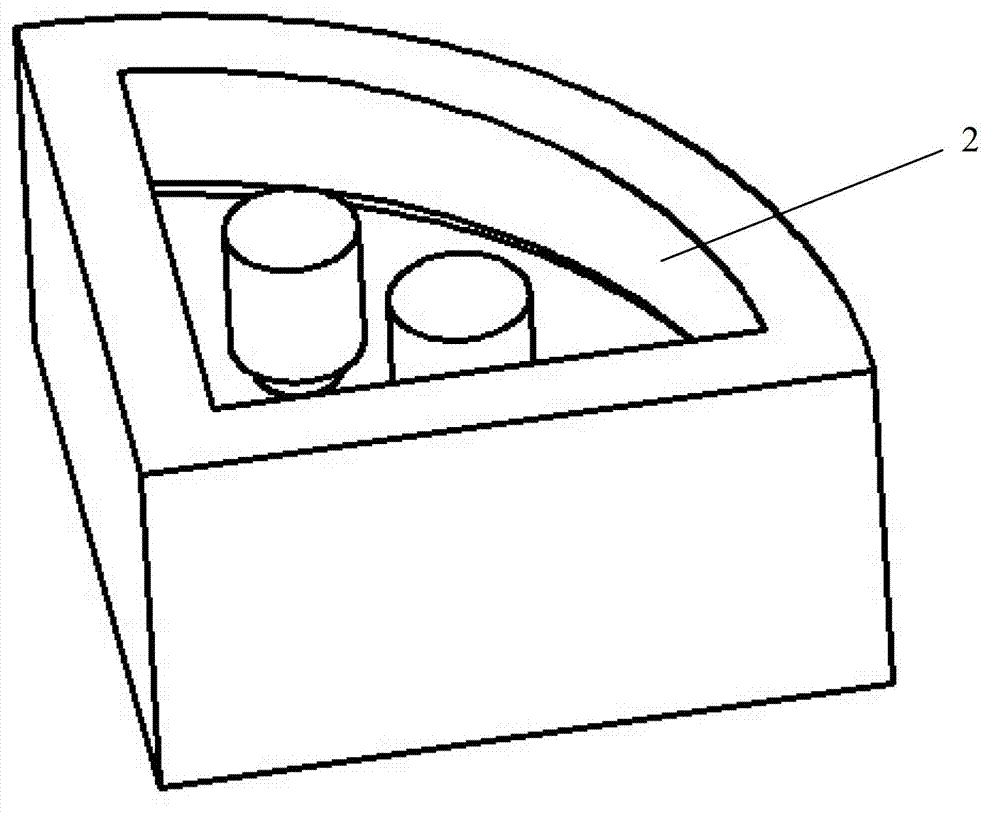

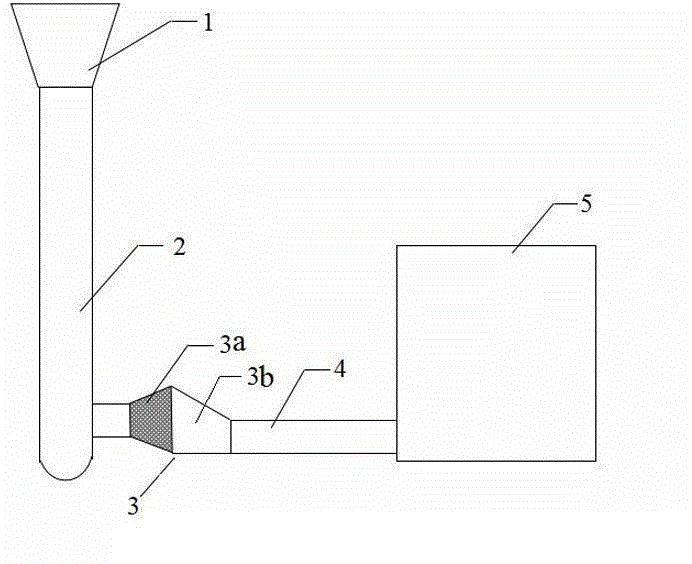

Covered argon blowing refining device for slab continuous casting tundish strip-shaped air brick and argon control method

The invention relates to a covered argon blowing refining device for a slab continuous casting tundish strip-shaped air brick and an argon control method. The device comprises a turbulent controller (1), a dipping cover (2), the strip-shaped air brick (3), a retainer wall (4) and an inclined hole stop dam (5); the dipping cover (2) is positioned rightly above the strip-shaped air brick (3); the lower end of the dipping cover (2) is dipped below a lowest pouring liquid level (9) of molten steel in a continuous-cast ladle exchange process tundish; an argon blowing control system PLC is adopted to collect and upload a pressure value of a first pressure gauge (22a), a flow value of a special metallurgy mass-flow controller (25) and a pressure value of a second pressure gauge (22b) into a continuous casting foundation automatic system database through ethernet communication; an argon flow automatic control instruction of the argon blowing control system PLC is performed; and the argon flow is automatically adjusted according to the net weight change of the molten steel in the tundish, so that the precise control is realized, and the effect of the tundish removing inclusions in the molten steel is improved.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

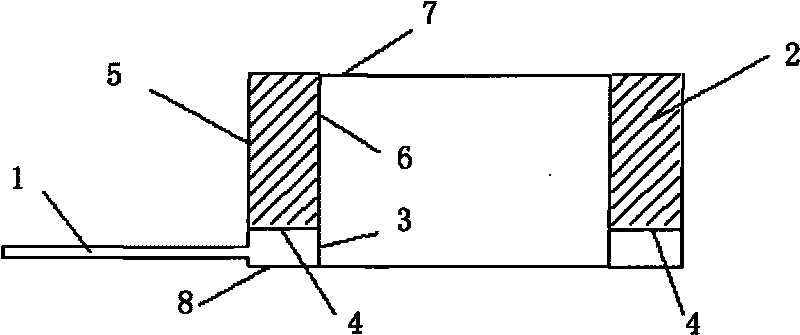

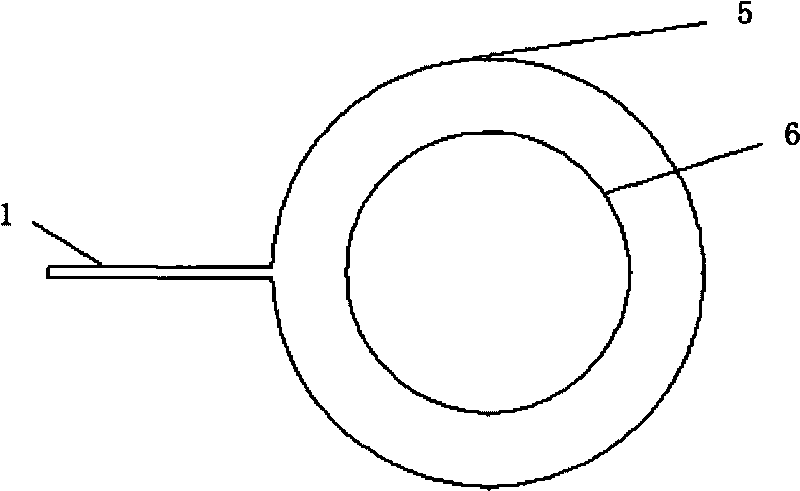

Automatic ladle drainage device

The present invention discloses an automatic ladle drainage device applied in a steel making system. The aim of the invention is to greatly reduce the dosage of draining sand, simplify the operating program and simultaneously obtain the purpose of automatic ladle drainage. The technical essential is that a circular barrel with a closed end is composed through inserting one circular cylinder into another circular cylinder with a larger diameter. The side surface of barrel body is provided with one or a plurality of side openings. Draining sand is filled in the barrel body. The side openings are closed by a sheet or a film with temperature of 40 DEG C to 1200 DEG C. In using, the automatic drainage device is inserted along the opening of ladle. Along with the erection of ladle, the draining sand in the barrel automatically fills the space in the filling pipe end and brick cup. The automatic ladle drainage device of the invention is suitable for the using of ladle in all technical conditions of steel making, and has the advantages of simple operation, dust pollution reduction, cost saving, shortened working procedure time, stable automatic drainage rate.

Owner:石宏帅 +1

Water-cooling die casting production process of plate blank used for medium plate

The invention discloses a water-cooling die casting production process of a plate blank used for a medium plate, which is characterized in that the production process adopts the protective pouring of argon gas in the overall process of the pouring so as to realize that the contact of molten steel with the air is isolated in the pouring process after the molten steel flows out from a water gap; the protective pouring of solid covering slag is adopted to ensure the surface quality of a casting blank; and an ascending hole of flow steel is regulated to enable the molten steel to stably ascend in water-cooling die casting, and the surface quality of the casting blank is ensured. The invention avoids the defects of skull patch, pits and the like of the surface and the defect of slag entrapment when the water-cooling die casting is adopted to produce the blank of the medium plate, and the adopted protective pouring reduces the secondary oxidation of the molten steel in the pouring process, has a certain adsorption function to inclusion and ensure the quality of the blank of the medium plate. The invention is suitable for the production process of the blank of a high-alloy steel medium plate of die steel with high requirement.

Owner:NANJING IRON & STEEL CO LTD

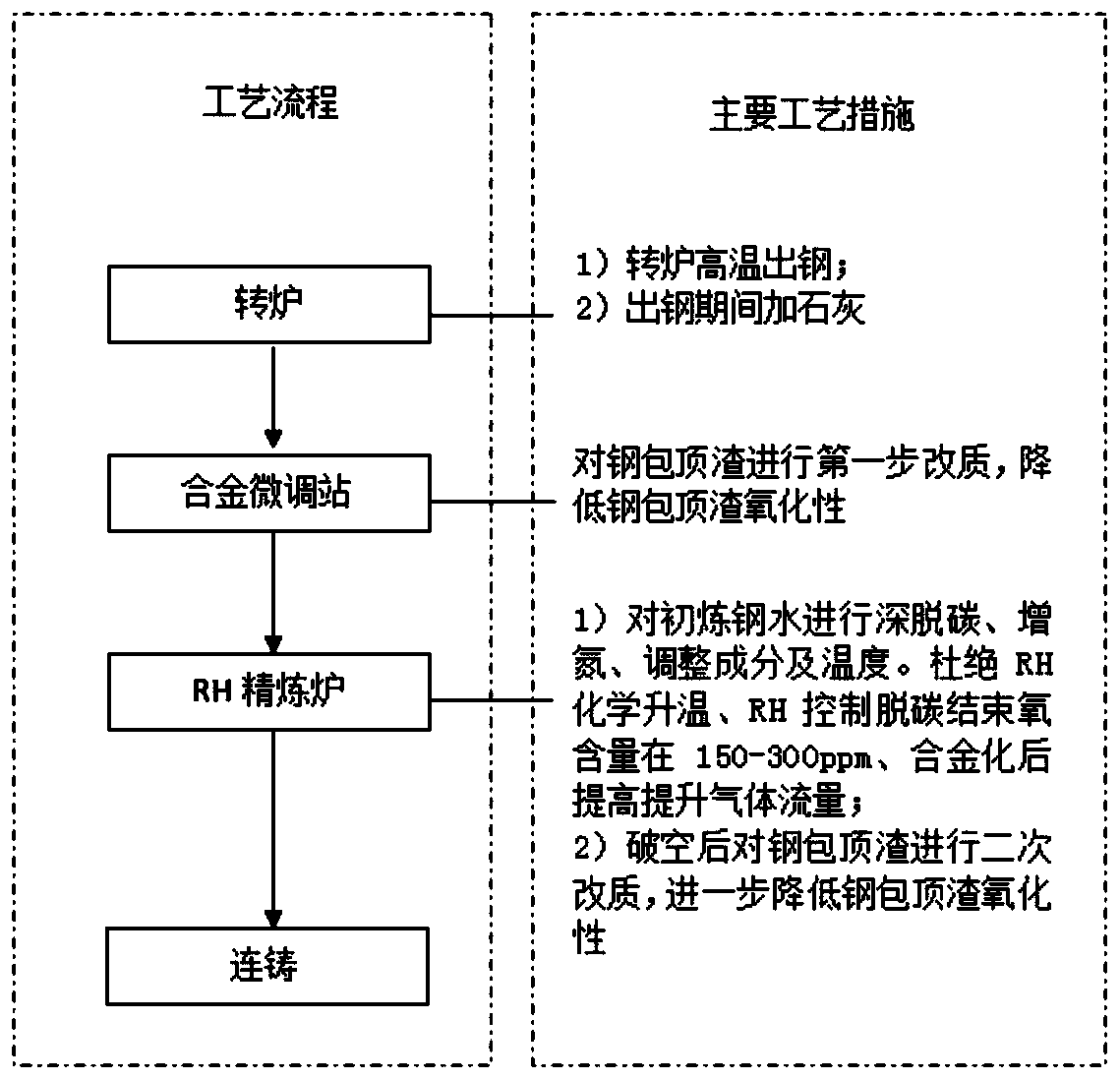

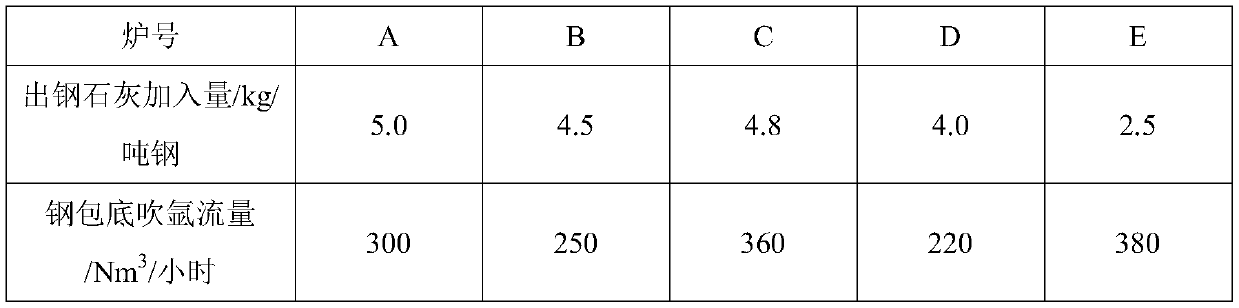

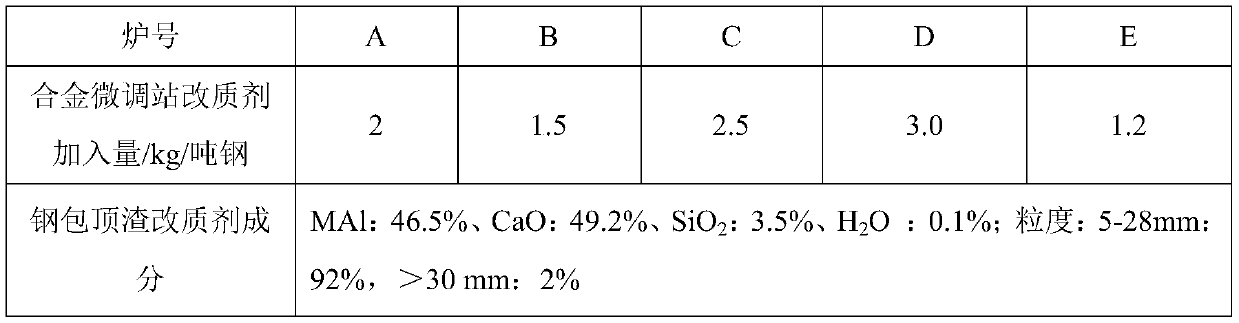

External refining method capable of increasing continuous casting heats of ultra-deep drawing cold-rolled enamel steel

The invention discloses an external refining method capable of increasing continuous casting heats of ultra-deep drawing cold-rolled enamel steel. The external refining method comprises the following steps: smelting molten iron and waste steel into primarily molten steel; performing first-step modifying on steel ladle slag in an alloy fine-tuning station process; performing decarburization and nitrogen pickup after RH molten steel is circulated, starting to measure oxygen before decarburization starts, adding aluminum particles to perform deoxidizing and alloying after decarburization is ended, and adding a steel ladle slag modifying agent to perform secondary modifying after performing RH vacuum-breaking. The external refining method disclosed by the invention increases continuous casting heats of ultra-deep drawing cold-rolled enamel steel to five-heat casting from three-heat casting with an increase rate of 66.7%, realizes batch, efficient and stable production of ultra-deep drawing cold-rolled enamel steel, and has remarkable economic benefits.

Owner:MAANSHAN IRON & STEEL CO LTD

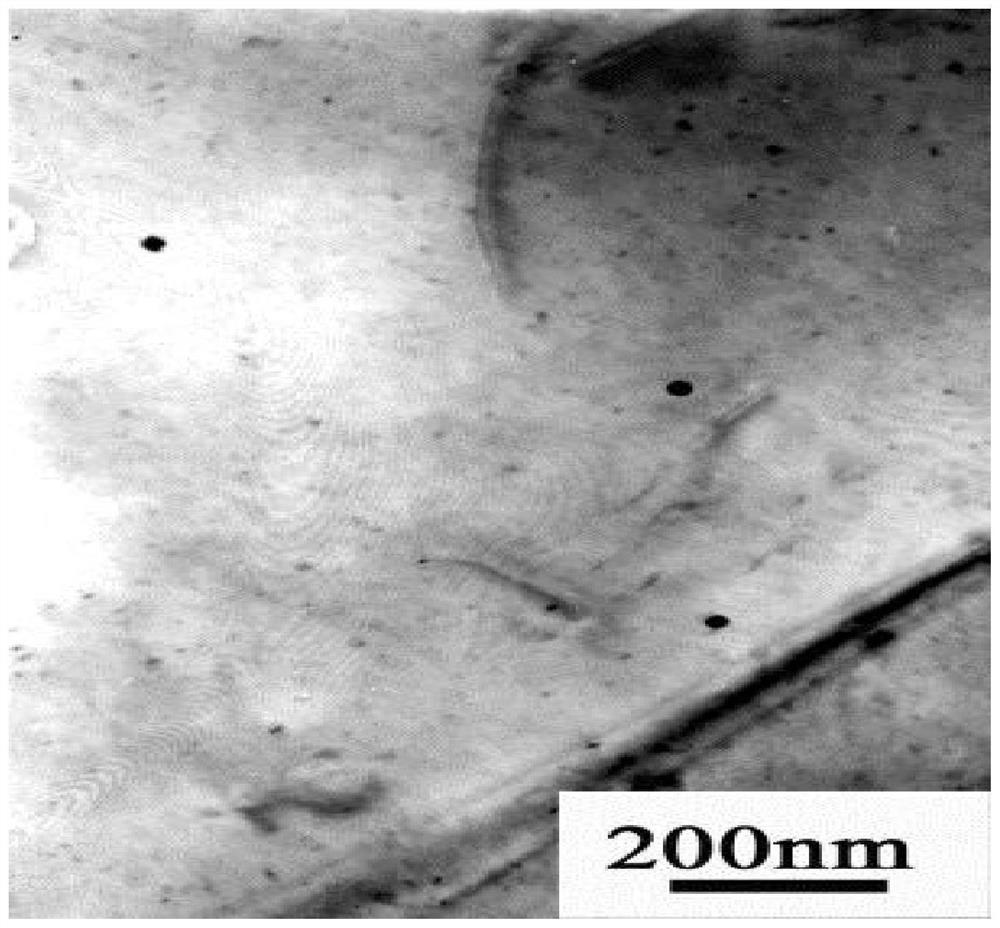

Refractory material for submersed nozzle inner hole body

The invention relates to a refractory material for a submersed nozzle inner hole body. The refractory material is used for an aluminum-killed steel continuous casting nozzle and particularly for casting of ultra-low-carbon automotive steel with high aluminum content. The refractory material for the submersed nozzle inner hole body is prepared from, by weight, 28%-58% of calcium hexaluminate, 20%-40% of calcium dialuminate, 20%-30% of alumina-magnesia spinel, 4%-6% of additionally added binding agent, namely, phenolic resin and the balance metallic silicon and boron carbide. The refractory material for the inner hole body has excellent alumina clogging resistance, molten steel erosion resistance and thermal shock resistance, can be used for aluminum-killed steel continuous casting and is relatively long in service life, and particularly, when the refractory material is used for casting of the ultra-low-carbon automotive steel with high aluminum content, secondary oxidation caused by the refractory material at the nozzle can be effectively reduced, and nozzle clogging caused by adhesion of alumina in molten steel can be effectively prevented.

Owner:BAOSHAN IRON & STEEL CO LTD

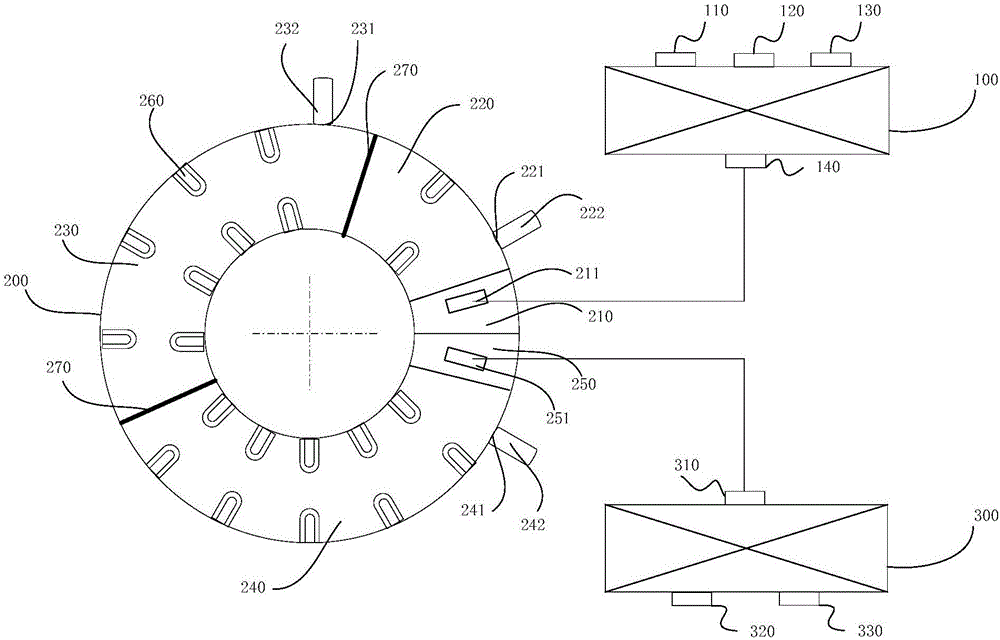

Totally-closed liquid-state cathode rare earth fused salt electrolytic cell

The invention discloses a totally-closed liquid-state cathode rare earth fused salt electrolytic cell which comprises a graphite cell body, wherein a liquid-state cathode is paved at the bottom of the graphite cell body; the graphite cell body is provided with an annular ring-shaped cell cover; a cylindrical anode is arranged in a ring of the annular cell cover, so as to realize the sealing of a cell mouth of the graphite cell body; a siphon port, a protection gas port and a feed port are formed in the annular cell cover; the anode is uniformly divided into four parts along the axial direction in a crossed manner; and the middle part of the upper part of each part of the anode is hollowed out and is provided with a steel claw fixing area. According to the totally-closed liquid-state cathode rare earth fused salt electrolytic cell, the solution loss and the secondary oxidation of metal can be reduced, the utilization rate of current is improved, and the distance between the cathode and the anode can be stably controlled, so that the normal operation of an electrolysis process can be facilitated; and the improved anode structure can improve the use efficiency of the anode, the anode consumption cost is reduced, introduced inertia protective gas can be used for prolonging the service lives of the anode and the cell body, the totally-closed cell-type design can enable the volatilization loss of a fluoride to be reduced, and the continuous and stable production can be facilitated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Smelting method for high-cleanliness chrome-molybdenum steel

ActiveCN109097525AReduce secondary oxidationHarm reductionElectric furnaceProcess efficiency improvementSteel platesSlag

The invention discloses a smelting method for high-cleanliness chrome-molybdenum steel. The smelting method comprises the working procedures of electric furnace primary smelting, refining and vacuum treatment. As for the working procedure of refining, calcium carbide is used in refining, foaming slag can be quickly formed at a low temperature, the temperature increasing speed is increased, refining power consumption is lowered, gas suction of molten steel is reduced, and secondary oxidation of the molten steel is relieved; and after vacuuming is finished, a certain quantity of pure calcium lines are fed, the deep deoxidation effect can be enhanced, meanwhile, inclusions in the steel can be modified, and thus harm of the inclusions to the steel is lowered. The cleanliness of the chrome-molybdenum steel is improved through brand-new various novel steel smelting technologies such as earlier compositing weak deoxidation, later aluminum feeding deep deoxidation, prolonging of the vacuum maintenance time and soft blowing time, and calcium treatment after vacuuming, the content of O in the obtained molten steel can reach 10 ppm or below, in analysis on the inclusions in a finished steel product, the thickness of the A, B, C and D types of inclusions is smaller than or equal to 0.5 grade, uniformity of a steel plate structure is improved remarkably, the mechanical property of a steel plate is improved, and thus the smelting method has high application value.

Owner:WUYANG IRON & STEEL

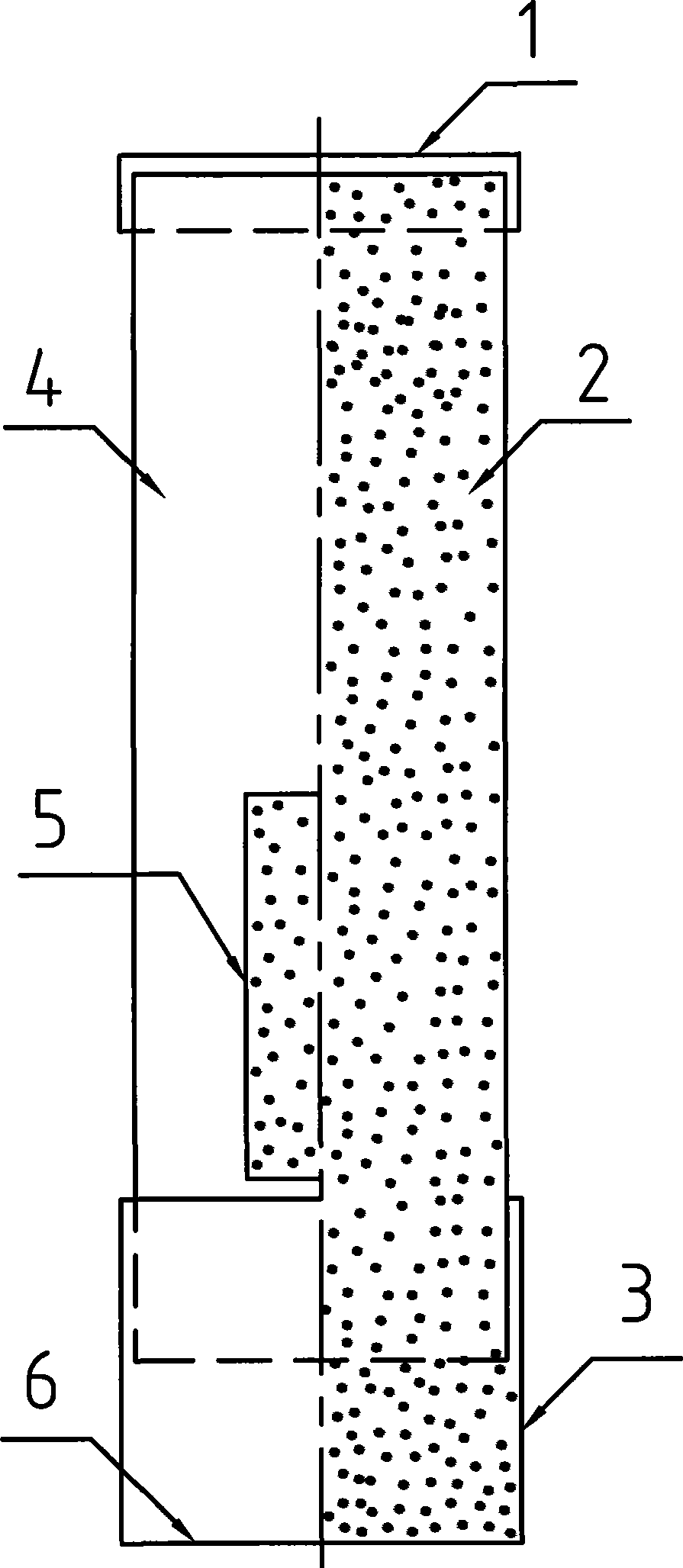

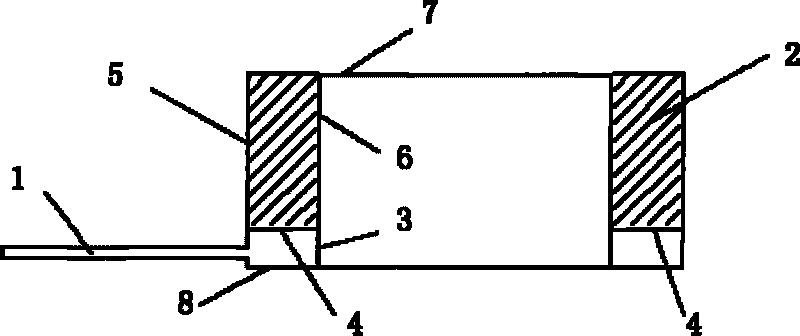

Argon protective device for ingot steel casting

The invention discloses an argon protective device for ingot steel casting, which is composed of an inner barrel and an outer barrel; a connecting plate for connecting the inner barrel and the outer barrel is arranged at the lower end of the inner barrel and the outer barrel, ceramic fiber sealing sleeve is filled between the inner barrel and the outer barrel at the upper end of the connecting plate, and the ceramic fiber sealing sleeve is higher than the upper end surface of the inner barrel and the outer barrel; an argon lead-in pipe which is extended outwards is arranged on the outer barrel wall at the lower end of the connecting plate, and a plurality of through holes which lead argon out are arranged on the inner barrel wall corresponding to the argon lead-in pipe, and the height between the upper end surface of the connecting plate and the upper end surface of the inner barrel and the outer barrel is more than the height between the lower end surface of the connecting plate and the lower end surface between the inner barrel and the outer barrel. The argon protective device can reduce secondary oxidization in the casting process of molten steel, reduce the mixed sundries in the molten steel and improve the molten steel purity degree.

Owner:SHANGHAI HEAVY MACHINERY PLANT +1

Refining process for producing spring steel through electric furnace

InactiveCN110592313ASmooth changeAvoid enteringProcess efficiency improvementElectric furnaceElectric arc furnaceSlag

The invention discloses a refining process for producing spring steel through an electric furnace, and belongs to the technical field of steel smelting. The refining process comprises the steps of firstly, electric furnace smelting, wherein (a) steel scraps and molten iron are adopted as raw materials, (b) eccentric bottom tapping is adopted for preventing slag discharging, the refining rephosphorization quantity is smaller than or equal to 0.005%, the tapping temperature is 1620 DEG C or above, and (c) argon bottom blowing and stirring are carried out in the whole electric furnace tapping process; secondly, LF furnace smelting, wherein (a) lime, calcium carbide and silicon calcium barium are used for deoxidization and slagging in the early stage, and silicon carbide and calcium carbide are used for slag maintaining in the later stage, (b) components of refining slag are required to comprise 48%-55% of CaO, 23%-28% of SiO, smaller than 15% of Al2O3, 5%-8% of MgO and not larger than 0.8% of TFe+MnO; and thirdly, RH smelting. By means of the refining process, the components of the refining slag can be precisely controlled, and quartz sand does not need to be added for slag adjusting;meanwhile, stable control over the molten steel temperature and the components of the refining slag can be guaranteed through the manners of slag quantity control, stirring control, process slag maintaining and the like, and secondary oxidation of molten steel is reduced; and the deoxidization capacity of the refining slag is high, and the aims of deep deoxidization and deep desulfuration are achieved effectively.

Owner:MAANSHAN IRON & STEEL CO LTD

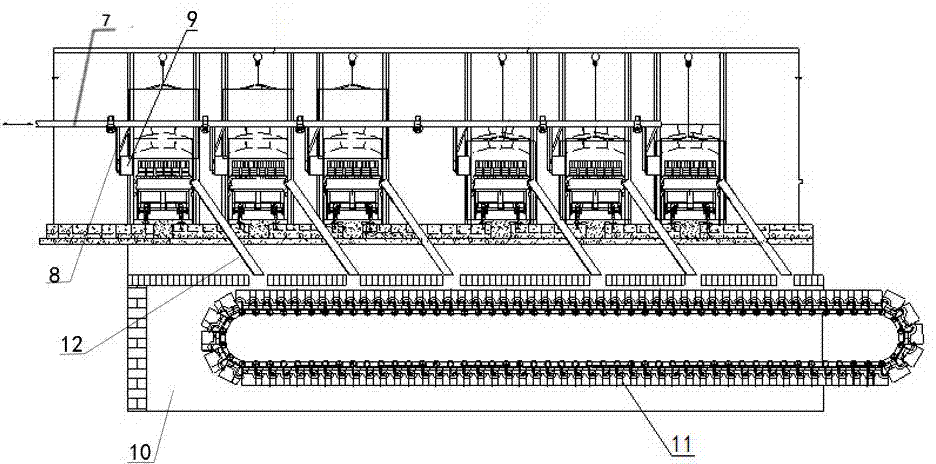

Iron-making method with low grade refractory iron ore and equipment thereof

The invention relates to an iron-making method with low grade refractory iron ore, particularly to an iron-making method for low grade refractory iron core and equipment thereof to solve the problems of long procedures and high energy consumption in an existing iron-making method with low grade refractory iron ore. The iron-making method with the low grade refractory iron ore comprises the steps of mixing the low grade refractory iron ore with reduction coal and crushing the iron core and the reduction coal, adding flux, catalyst and water and performing stirring, molding the materials into cuboid blocks, conveying the dried cuboid blocks into a tunnel reduction furnace for solid-state initial reduction; and then conveying the cuboid blocks into a three-phase arc furnace. The low grade refractory iron core and the reduction coal are mixed on the base of calculating coal blending according to C / O=1.2 and further 2-4% carbon is blended in an excess mode; the catalyst is dolomite powder or limestone powder, and the addition amount of the flux is calculated according to the formula of CaO+MgO / SiO2=0.8; the catalyst is salt materials containing sodion and the utilization amount is 3-5% of that of the coal blending amount. The iron-making equipment is additionally provided with a loading section based on an original tunnel reduction furnace and further provided with a conveyer belt and a three-phase arc furnace.

Owner:NANJING YOU RONG ENERGY SAVING TECH CO LTD

Performance-improved novel steel pouring equipment

PendingCN109332658AReduce secondary oxidationImprove surface qualityEngineeringMechanical engineering

The invention discloses performance-improved novel steel pouring equipment. The novel steel pouring equipment comprises a base; a mould shell is placed at the top side of the base; the two sides of the mould shell are each provided with a squeezing board; a holding cavity is formed in the base; the inner walls of the top side and the bottom side of the holding cavity are rotatably provided with asame rotating shaft; the rotating shaft is fixedly connected with a turnplate in a sleeved manner; the top side of the turnplate is fixedly provided with two circular columns; the two circular columnsare each rotatably connected with a connecting rod in a sleeved manner; and two movable holes are formed in the inner wall of the top side of the holding cavity. The novel steel pouring equipment disclosed by the invention is reasonable in structure; secondary oxidation of a material during pouring is greatly reduced, surface quality of a Monel material steel casting is increased, production costis reduced, and production can go smoothly; a pull rod is moved to drive a rack to move, and the rack moves to drive each rotating rod to rotate to squeeze the corresponding squeezing board, so thatthe mould shell can be squeezed more simply by the squeezing boards, and meanwhile, is stressed more uniformly; meanwhile, the squeezing board can be conveniently replaced to coordinate with differentmoulds; and use is convenient.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

Method for deflection bottom tapping of revolving furnace

InactiveCN101368223ASolve the problem of slagReduce back phosphorusManufacturing convertersSlagEngineering

The invention discloses a method used for tapping through deflecting the bottom of a convertor, which is characterized in that the tapping opening of the converter is designed at the lower part of the converter; the position at the upper end of the tapping opening is arranged below a molten liquid surface; the lower end is higher than the slag surface after tapping in the convertor only with the slag left by 10 to 20cm; the diameter of the tapping opening is between 10 and 20cm; when the smelting reaches the end point, the converter is deflected by 20 to 60 degrees; the rotated angle leads the position of the tapping opening to be arranged at the lowest side of the converter; then the tapping opening is opened, the molten steel flows into a ladle arranged below the tapping opening; after the molten steel flows out, the converter is resumed to the normal vertical position and the ladle is removed, then the liquid surface of slag is lower than the lowest position of the tapping opening of the converter; then the ladle is arranged below the converter and the converter is deflected to lead the opening of the converter to face the lower side; and then the slag is spilled out from the opening of the converter. The method used for tapping through deflecting the bottom of a convertor solves the problem of slag during the tapping of the converter, ensures the slag amount of the converter to be lower than 0.5kg / t. Not only the rephosphorization of the molten steel can be reduced and the alloy recycling rate is improved, but also the occluded foreignsubstance in the steel can be reduced and the cleanness of the molten steel can be improved. Besides, the refining time can be shortened and the desulfurization degree can be improved.

Owner:UNIV OF SCI & TECH BEIJING

Process for performing casting under negative pressure condition

InactiveCN102179497AQuality improvementReduce secondary oxidationInvestment castingLost-foam casting

The invention discloses a process for performing casting under a negative pressure condition. In the method, the advantages of investment casting and lost foam casting are combined, the high-quality casting mould of investment casting is used, and pouring is performed under a thermal condition; by using a negative pressure technology of a lost foam, the negative pressure environment is formed around the investment casting mould, and the secondary oxidation of metal is reduced; and metal filling is promoted and the feeding capacity of molten metal is improved by using the pressure difference between the casting mould and a pouring gate, so that a high-quality casting is obtained, and a large-sized casting can be cast.

Owner:TSINGHUA UNIV

Production method of low-carbon low-silicon cold heading steel

InactiveCN112251661AImprove purityReduce secondary oxidationProcess efficiency improvementSlagCastability

The invention discloses a production method of low-carbon low-silicon cold heading steel. The steel comprises the following chemical components including, by weight, 0.02%-0.20% of C, less than or equal to 0.06% of Si, 0.25%-0.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.005% of S, more than or equal to 0.020% of Al and the balance Fe and inevitable impurities. A smeltingprocess includes converter-LF furnace-VD furnace-square billet continuous casting. In the converter working procedure, the Si in molten steel is less than 0.01%, and the Al is equal to 0.015%-0.040%;in the LF working procedure, the Al is equal to 0.015%-0.040%, in final slag components, CaO is equal to 54%-62%, Al2O3 is equal to 31%-38%, SiO2 is less than or equal to 2.0%, MgO is equal to 3%-7%,and TFe is less than or equal to 0.8%; the Al is increased to 0.055%-0.070% before leaving a station, and the Si in the molten steel leaving the station is smaller than 0.04%; the VD is kept in vacuumfor 5-7 min, soft blowing is carried out for more than or equal to 18 min after vacuum breaking for coming to the station, and the Ca in the molten steel leaving the station is equal to 0.0015%-0.0030%; in the continuous casting working procedure, tundish gas driving is conducted after a tundish car is in place before large ladle casting, and gas driving operation continues to be conducted afterlarge ladle casting; when the liquid level of the molten steel in a tundish reaches 280-320 mm, a covering agent starts to be rapidly put into the tundish till the molten steel surface is completely covered; and after the liquid level of the molten steel in the tundish reaches 650 mm, tundish casting is organized. According to the production method, the castability of the molten steel of a castingfurnace for producing the low-carbon low-silicon cold heading steel by a billet caster can be greatly improved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Control method for vortex slag entrapment during converter tapping

A control method for vortex slag entrainment in converter tapping. When the molten steel in the furnace reaches two-half and the slag on the liquid surface rotates, the electromagnetic stirrer around the tapping hole is started, and continuous and pulsed slag are adopted respectively according to specific conditions. Type and alternate stirring mode, the power adjustment range of the agitator is 30-200kW, the power frequency adjustment range is 5-10Hz, when the molten steel is about to be discharged, the taphole is blocked with a slag stopper. The invention can reduce the amount of slag in the converter, increase the alloy yield, reduce the burning loss of deoxidized aluminum, reduce the secondary oxidation of molten steel, improve the cleanliness and refining effect of molten steel, reduce the amount of modifier used, and shorten the treatment cycle , and reduce the amount of residual steel in the furnace, effectively prevent the occurrence of steel sticking when the oxygen lance is splashing slag to protect the furnace, and improve the service life of the oxygen lance.

Owner:ANGANG STEEL CO LTD

Submerged arc refining slag and preparation method thereof

InactiveCN102220456AImprove ingredient stabilityHigh yieldProcess efficiency improvementSlagHigh carbon

The invention discloses submerged arc refining slag, which is prepared from the following raw materials in part by weight: 35 to 40 parts of sintered bauxite, 1 to 2 parts of metal aluminum powder, 8 to 12 parts of silicon carbide, 2 to 4 parts of high carbon powder, 40 to 45 parts of limestone, 1 to 3 parts of blast furnace grain slag and 2 to 4 parts of lignin. In the invention, deoxygenation, submerged arc foaming and refining are integrated, production process is simplified, working environment is improved, the stability of ingredients of molten steel is improved, smelting cost is lowered, refining time is reduced, yield of expensive metal is increased, secondary oxidization of molten steel is relieved, the recovery rate of molten steel is increased, arc and noise pollution are reduced and the service life of refractory materials is prolonged.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

Preparation method of narrow-hardenability pinion steel

ActiveCN102400052BImprove hardenabilityHardenability improved and stabilizedManufacturing convertersProcess efficiency improvementWear resistanceImpurity

The invention provides a narrow-hardenability pinion steel which comprises the following components in percentage by weight: 0.18%-0.22% of C, 0.20%-0.30% of Si, 0.90%-1.15% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 1.00%-1.35% of Cr, 0.04%-0.08% of Ti, 0.004%-0.005% of B, 0.025%-0.038% of W, less than or equal to 11.5*10<-6> of [O], less than or equal to 1.5*10<-6> of [H], 35*10<-6>-45*10<-6> of [N] and the balance of Fe and inevitable impurities. The invention provides a preparation method of the narrow-hardenability pinion steel. The preparation method comprises the following steps: 1) primary smelting based on a top-bottom blowing converter; 2) ladle deoxidizing and alloying; 3) LF (ladle furnace) refining; 4) RH refining; and 5) continuous casting. Compared with the prior art, the narrow-hardenability pinion steel provided by the invention has the characteristics of better wear resistance and high temperature resistance, higher hardenability andnarrower jominy hardenability.

Owner:WANGUAN SMELTING MOLD CASTING

Method and system for treating iron vitriol slag

PendingCN106544460ARaise the gradeReduce collectionProcess efficiency improvementHearth type furnacesReduction treatmentSlag

The invention discloses a method and system for treating iron vitriol slag. The method for treating the iron vitriol slag comprises the steps that the iron vitriol slag containing water, reducing agents and additives are mixed so that wet mixed materials can be obtained; the wet mixed materials are treated in an annular furnace, specifically, the wet mixed materials are subjected to drying treatment in a drying area to obtain dried materials, vapor produced through drying treatment is discharged through a first flue and is recycled; the dried materials are subjected to decomposition treatment in a decomposition area to obtain decomposition products, flue gas which contains sulfur oxide and is produced through decomposition treatment is discharged through a second flue and collected; and the decomposition products are subjected to reduction treatment in a reduction area to obtain reduced products, flue gas which contains lead and zinc and is produced through reduction treatment is discharged through a third flue and collected, and the reduced products are subjected to ball milling and magnetic separation treatment so that metal iron powder and tailings can be obtained. By means of the method, the flue gas containing the sulfur oxide and the flue gas containing the lead and the zinc can be collected correspondingly, and high-grade fine iron powder is obtained.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Argon blowing device capable of improving metallurgical ability of tundish and reducing flocculant flow of nozzle and use method thereof

The invention discloses an argon blowing device capable of improving the metallurgical ability of a tundish and reducing the flocculant flow of a nozzle and a method. The argon blowing device comprises a hollow closed ring, a plurality of gas outlets for argon gas to flow out are uniformly formed in the closed ring at equal intervals, the closed ring is made of an oxygen burning tube and is provided with a gas inlet, the gas inlet is connected with one section of a ventilation pipeline approximate to a right angle, the ventilation pipeline is connected with an external argon gas pipeline, and a protective sleeve is arranged on the ventilation pipeline at a ladle tapping hole and is closely connected with the ladle tapping hole on a central axis. The method comprises the following steps: cleaning impurities inside the tundish before the tundish is online; putting the argon blowing device into the tundish in advance, arranging the argon blowing device at the bottom of the tundish and putting one argon blowing device at each of a steel hole and a temperature measuring hole; connecting the argon blowing device and the argon gas pipeline together after the argon gas pipeline is online; lifting the argon blowing device onto the lower surface of a tundish cover before ladle pouring, and continuous blowing the argon gas; pouring.

Owner:SHANDONG IRON & STEEL CO LTD

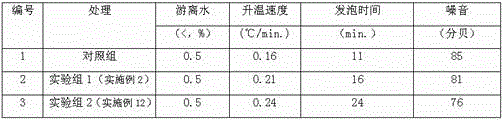

Environment-friendly submerged arc heat accumulation agent and preparing method thereof

The invention relates to an auxiliary steelmaking material, in particular to an environment-friendly material and a preparing method thereof. The environment-friendly material is characterized in that a submerged arc heat accumulation agent comprises, by weight, 63-71 parts of limestone, 8-16 parts of magnesite, 7-9 parts of light calcined magnesia, 1-5 parts of barium carbonate, 1-5 parts of metallic aluminum, 1-3 parts of silicon carbide, 0.5-1.5 parts of metallic silicon and 3.5-4.5 parts of water. Material decomposition is achieved at the high temperature, gas is continuously generated under the condition that 0.7-1.0 Kg / ton of steel is added, slag liquid is foamed, the slag liquid is emulsified in the gas-slag mixing state, the slag liquid level rises, and electrode arc light is continuously and more effectively embedded. In the steel refining process, the purposes that the extremely high noise generated by electrode arcing in an LF furnace is lowered, the noise in an operation room of the LF furnace is reduced to 74-85 decibels from 87-97 decibels, and the environment-friendly steel making is achieved are achieved.

Owner:鞍山天祥冶金材料有限公司 +1

Cold charging production process of high-compactness and high-purity fine-grain grinding ball steel

ActiveCN112281061AImprove the ability to adsorb inclusionsImprove purityManufacturing convertersProcess efficiency improvementTemperature controlAustenite grain

The invention discloses a cold charging production process of high-compactness and high-purity fine-grain grinding ball steel. The cold charging production process comprises the following processes ofpre-desulfurizing molten iron, smelting in a converter, refining in an LF furnace, carrying out RH vacuum treatment, continuously casting, slowly cooling a large round billet casting blank, heating,rolling, cooling, high-temperature pit entering slow cooling, pit exiting finishing, packaging and warehousing. According to the production process, a grinding ball steel round billet cold charging temperature control system is adopted for heating, and a mode of combining differential temperature rolling and single-pass high-pressure rolling is adopted, so that the deformation of the center of thebillet is increased, and the internal compactness and the grain size of the steel are improved. The grinding ball steel produced by the production process has the advantages of excellent macrostructure (central porosity is less than or equal to 1.0 grade and general porosity is less than or equal to 0.5 grade), high purity (A-type inclusions are less than or equal to 1.0 grade, B-type inclusionsare less than or equal to 0.5 grade, C-type inclusions are less than or equal to 0.5 grade and D-type inclusions are less than or equal to 1.0 grade) and fine austenite grains (austenite grain size isgreater than or equal to 6.5 grade). The grinding ball obtained by carrying out a conventional rolling process on the produced grinding ball steel is good in impact toughness and long in fatigue life.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

LF composite deoxidization reducer

The invention discloses an LF compound deoxidation reducing agent, which is made by compounding aluminium grain (AL), silicon-aluminum-barium alloy (SiCaBa), carborundum (SiC) and graphite. The compound contains Ca, Ba, C, Al and Si which have the weight proportions in the compound of: 1-5 percent of Ca, 2-7 percent of Ba, 15-45 percent of C, 5-30 percent of Al, 20-55 percent of Si. The LF compound deoxidation reducing agent can be used for LF refining molten steel and the beneficial effects can be brought out: 1. the average content of out-station molten steel (O) is 20-30 ppm, and reoxidation is lowered; 2. the average desulfurization rate is above 50 percent; 3. the content of inclusion is lowered greatly; 4. submerged-arc time is greatly shortened; 5. electric consumption of 1.5 DEG C is shortened to produce one-ton steel; 6. qualified rate of defects detection is above 95 percent. The invention has higher economic and social benefits and has good application prospect.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

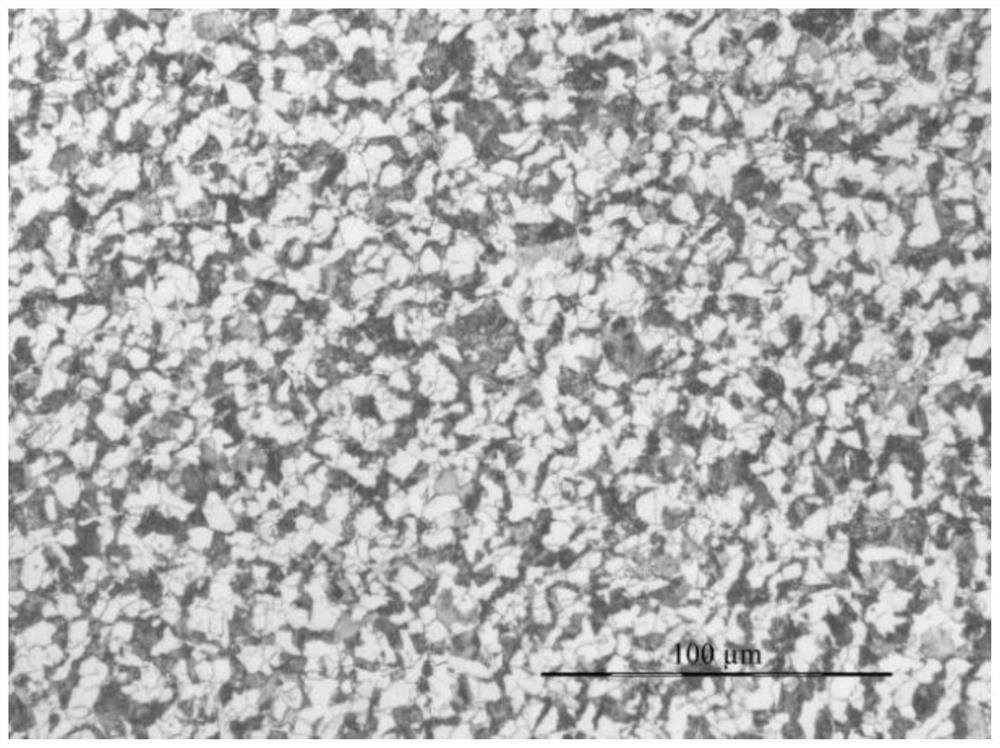

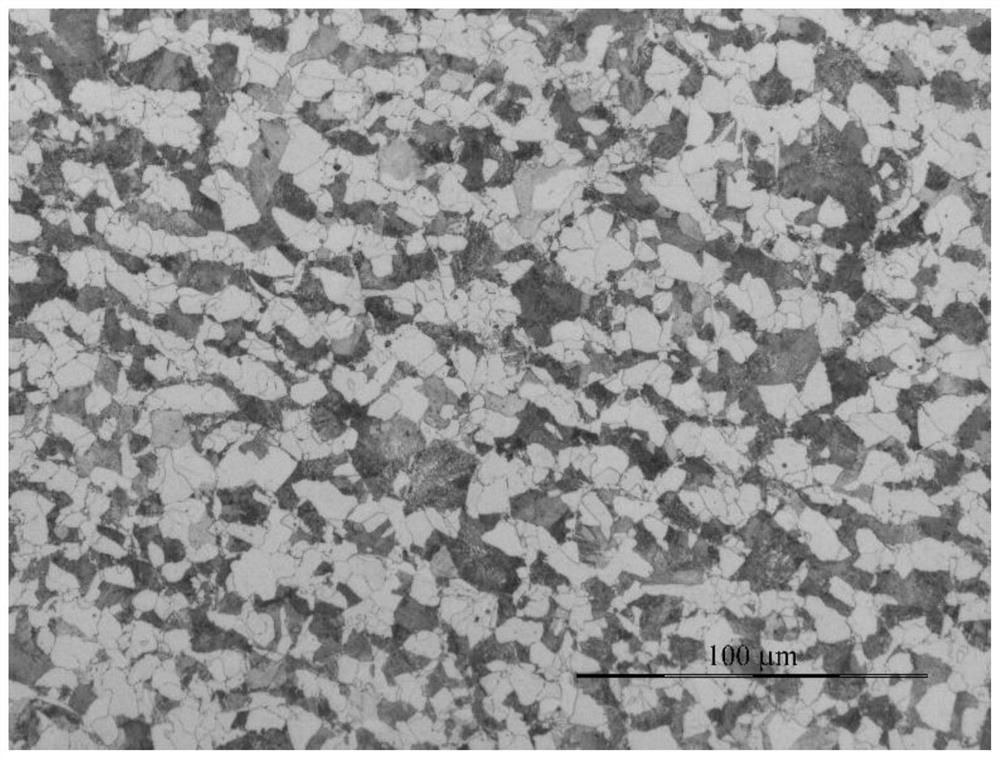

Technology for producing peritectic steel by ultra-wide slab continuous casting machine

The invention discloses a technology for producing peritectic steel by an ultra-wide slab continuous casting machine, and relates to the technical field of metallurgy. Filling of argon is more favorable to inclusion removing, and protective casing argon seal protection and immersion protection further improve purity of molten steel; casting powder is high in alkalinity, so that heat transfer of the casting powder is more uniform, and non-uniformity of a solidification initial stage of a solidified shell is reduced; a cobalt 60 radiation method and a liquid level feedforward control technologygreatly reduce liquid level fluctuation on the basis of realizing automatic detection and control of a liquid level; and aerosol cooling of a secondary cooling zone and a drawing speed are set at a suitable level, fluctuation of the liquid level of a crystallizer can be reduced, and the bonding phenomenon is not prone to generate due to improper control over the drawing speed. By means of the above steps and parameter setting, an initial solidified shell can be more uniform, the grain size can be kept consistent everywhere, during a molten steel solidification process, the solidified shell canbe evenly solidified, and therefore the probability of occurrence of cracks on the surface of a cast blank is greatly reduced.

Owner:NANJING IRON & STEEL CO LTD

Double steelmaking tundish continuous casting heat number in-depth study method

The invention relates to the technical field of double steelmaking tundish continuous casting heat number study, and discloses a double steelmaking tundish continuous casting heat number in-depth study method. The method comprises the following steps that 1) firstly, a reasonable and effective tundish baking system is formulated, the tundish baking time is controlled to be 2 h to 3 h, a capping production mode is adopted on a tundish, and therefore when baking is needed, the casting waiting time is effectively shortened through capping, a cover plate can be pulled to be open when the tundish needs to be stopped, the tundish cooling waiting time and the temperature drop are shortened, and the tundish baking temperature during casting is ensured to be higher than or equal 900 DEG C. By meansof the double steelmaking tundish continuous casting heat number in-depth study method, the double steelmaking tundish continuous casting heat number is wholly and effectively improved, the overall double steelmaking tundish continuous casting heat number in-depth study method is clear and explicit in step, operation is simple, the service life of the tundish can be effectively prolonged, meanwhile, the double steelmaking tundish continuous casting heat number is greater than or equal to 90 furnaces, the production cost of steelmaking is reduced, and implementation by a user is facilitated.

Owner:成渝钒钛科技有限公司

Method for reducing nitrogen increment of molten steel in refining process

The invention provides a method for reducing nitrogen increment of molten steel in a refining process. The scheme is mainly realized by the following technical measures: (1) after molten steel reaches the refining step, lifting the furnace cover of a finery and starting a buggy ladle to underface of the furnace cover of the finery; (2) reducing the furnace cover of the finery to a lower limit position; (3) meanwhile, inserting argon blowing conduits the original accidental argon gun hole, the original wire feeding hole and a new argon blowing hole, wherein the distance from the argon blowing conduits to the molten steel level is 200-1000mm; and (4) blowing argon to the refinery along the argon blowing conduits, wherein the pressure range of argon is 0.5-1.0Mpa. An argon protective layer is formed on the molten steel surface to increase the reducing atmosphere in the furnace cover, so that the probability of contact of molten steel and air is reduced, and nitrogen increment caused by high temperature ionized air during heating is avoided, therefore, secondary oxidation of the molten steel during stirring is greatly reduced, and the degree of purity of the molten steel is improved.

Owner:JIGANG GRP

Ti microalloyed 635MPa-grade hot-rolled ribbed steel bar and preparation method thereof

ActiveCN112111687AImprove plasticityImprove strong plasticityTemperature control deviceFurnace typesSteelmakingRebar

The invention discloses a Ti microalloyed 635MPa-grade hot-rolled ribbed steel bar and a preparation method thereof, and belongs to the technical field of hot-rolled ribbed steel bars for reinforced concrete structures. The steel in the steel bar comprises, by weight, 0.22-0.28% of C, 0.60-0.80% of Si, 1.40-1.60% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.020-0.040 of Ti, and the balance Fe and inevitable impurity elements. The Ti microalloyed components are combined with steel making and steel rolling processes; the preparation process comprises the steps of carrying out converter smelting, carrying out LF ladle refining, carrying out continuous casting to obtain 150mm<2> steel blanks, carrying out heating by a heating furnace and carrying out rolling on the steel blanks by a rolling mill to form the steel bar; the mechanical performance of the steel is improved by using the principle of precipitation strengthening and fine grain strengthening of titanium in the steel; the 635MPa-grade high-strength steel bar with high strength and high plasticity is produced under the premise of not reducing the ductility index; and the yield strength of the prepared steel bar is greater than or equal to 635MPa, the tensile strength of the prepared steel bar is greater than or equal to 795MPa, and the elongation after fracture of the prepared steel bar is greater than or equal to 15%, and the Ti microalloyed 635MPa-grade hot-rolled ribbed steel bar satisfies the demands of markets and high-rise and long-span building structures on the 635MPa-grade steelbar.

Owner:安徽吾兴新材料有限公司

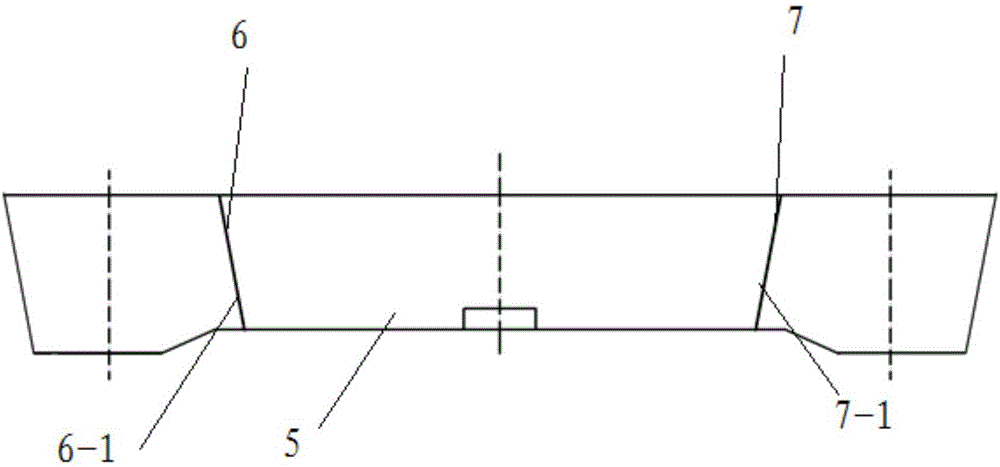

Filtering device for magnesium alloy casting and pouring

InactiveCN105522139AReduce secondary oxidationIncrease the effective filter areaCasting cleaning apparatusFilter mediaRight trapezoid

The invention relates to a filtering device for magnesium alloy casting and pouring. The lower portion of a sprue is communicated with a casting die through a cross gate, a metal liquid filtering pool is arranged in the cross gate and comprises a left filtering pool box and a right filtering pool box which are buckled, the left filtering pool box is in a shape of a circular truncated cone, a metal liquid inlet is formed in the smaller bottom face of the left filtering pool box, the right filtering pool box is in a shape of a right trapezoid, and a magnesium alloy metal liquid outlet is formed in the smaller bottom face of the right filtering pool box; and a conic foamed ceramic filtering block is arranged in the left filtering pool box, the outer conic face of the conic foamed ceramic filtering block is matched with the conic face of the left filtering pool box, and the ceramic filtering block is made of magnesium oxide foamed ceramic. The foamed ceramic filtering block in the shape of the circular truncated cone is arranged in the filtering pool, influences on casting of an overall structure are avoided, the effective filtering area is large, and blockage can be avoided; and as the foamed ceramic is an efficient and stable alloy melt filtering medium, various impurities in the metal liquid in the pouring process can be effectively removed, the impurity content is obviously reduced, and the quality of a cast magnesium alloy is improved.

Owner:HENAN UNIV OF SCI & TECH

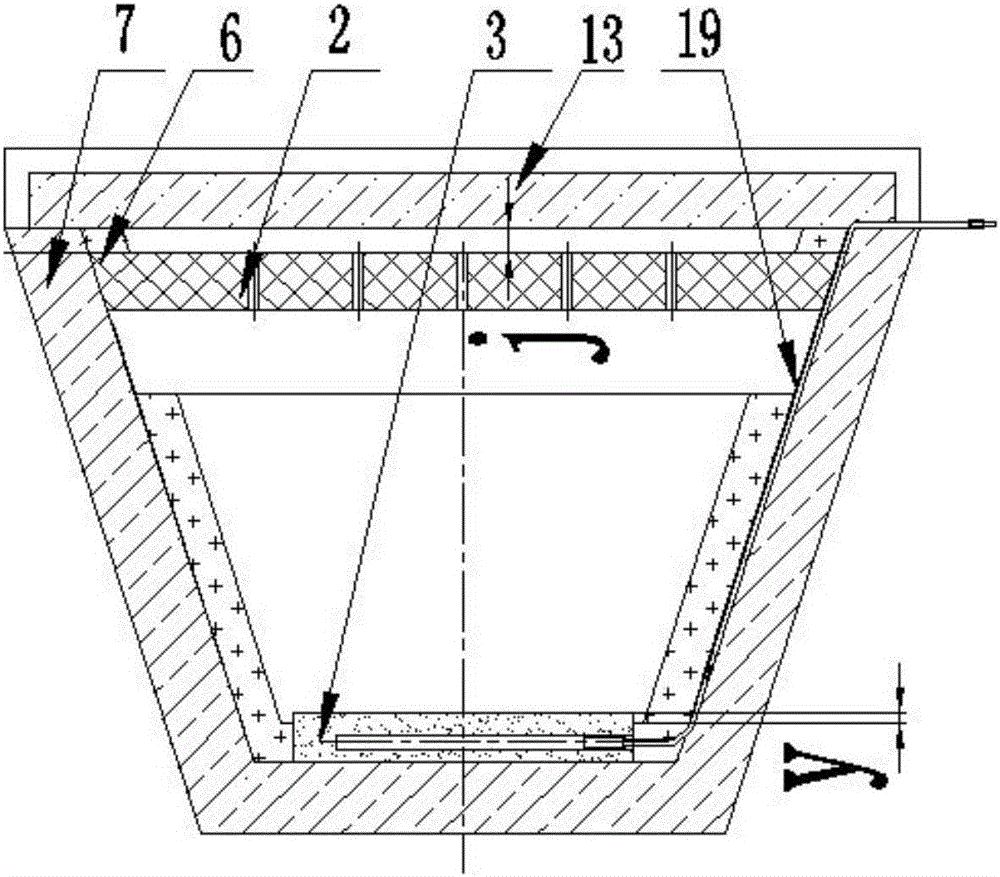

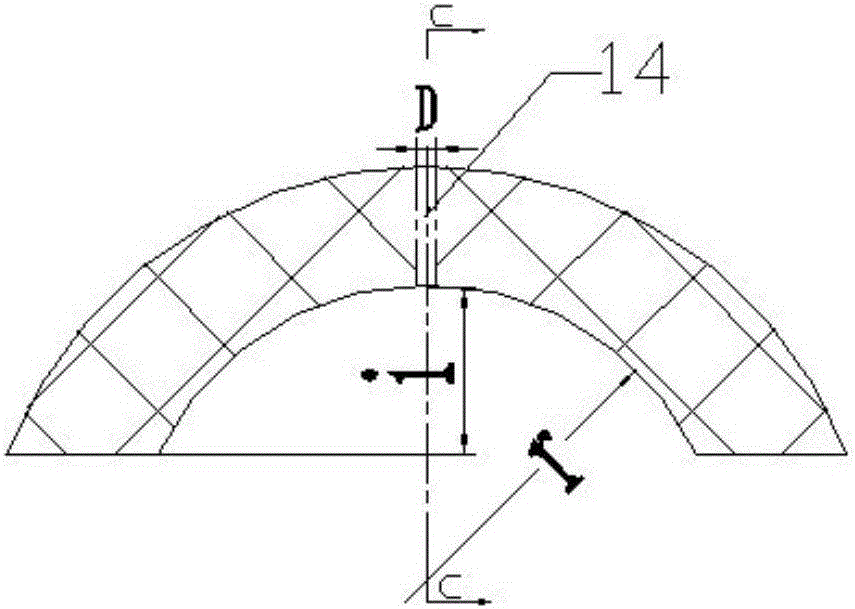

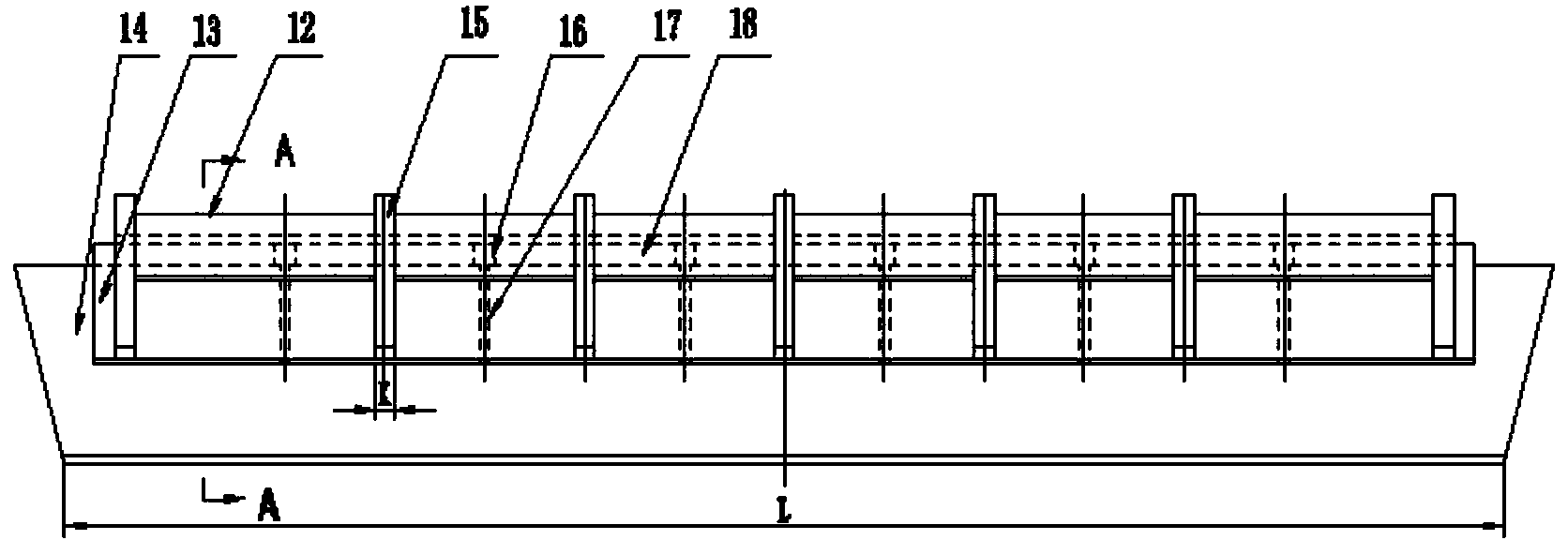

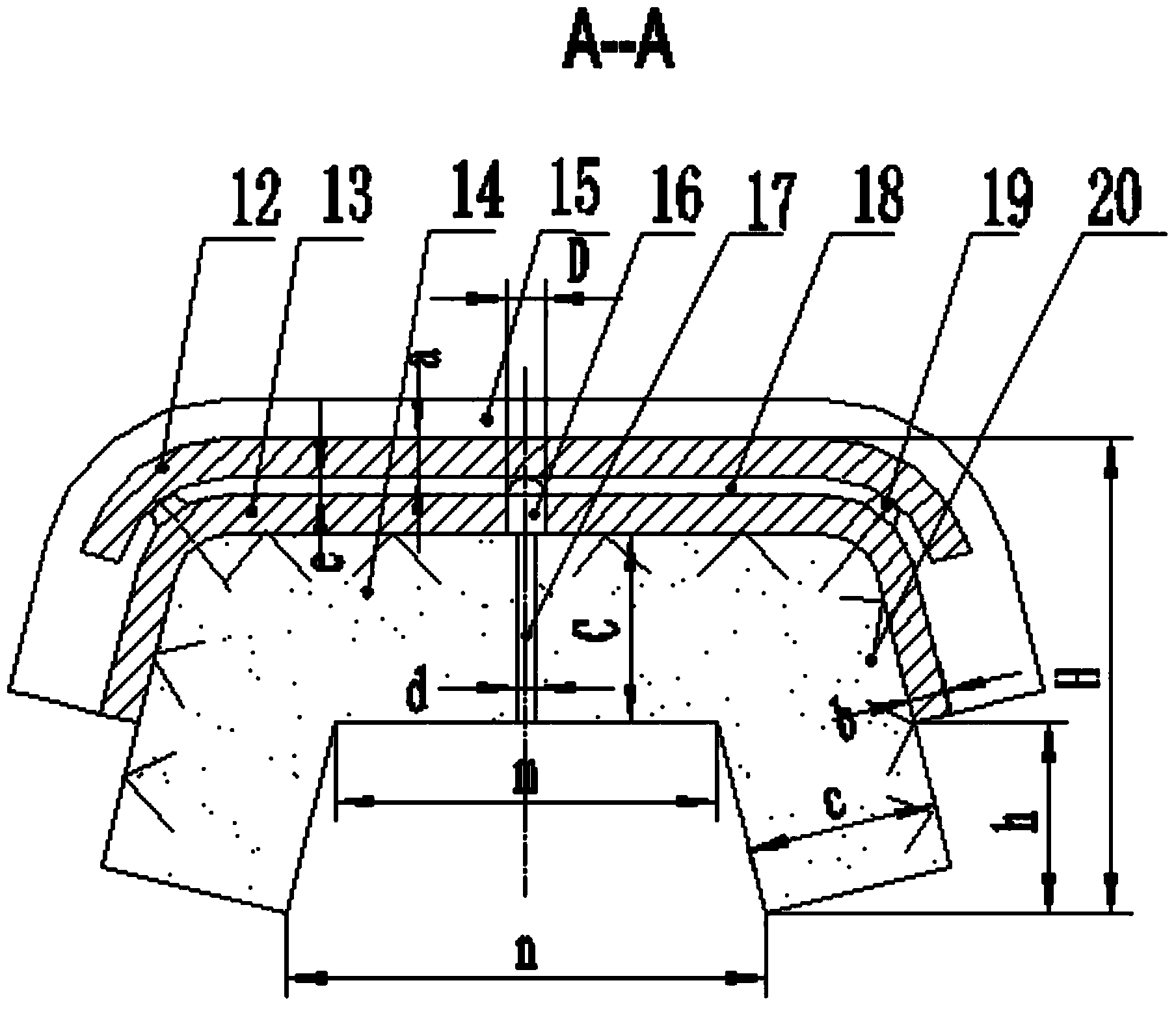

Refining cover for continuous casting tundish and manufacturing method of refining cover

The invention relates to a refining cover for a continuous casting tundish and a manufacturing method of the refining cover. The refining cover comprises an outer arc plate, an inner arc plate and a dipping cover. A circulation seam is reserved between the outer arc plate and the inner arc plate, and communicated with a gap between a tundish cover and a steel slag layer inside the tundish. Air exhaust holes penetrating through the dipping cover are formed in the dipping cover, through holes opposite to the air exhaust holes are formed in the inner arc plate, the air exhaust holes are communicated with the circulation seam through the through holes, argon is blown in through air curtain ventilation bricks, an air curtain barrier with the large continuous intensity is formed between the air curtain ventilation bricks and the dipping cover, the inclusions are captured and are adsorbed and removed by the steel slag layer, the argon breaks through the steel slag layer below the dipping cover to move upwards continuously and enters the circulation seam through the air exhaust holes and the through holes, the argon enters the position above the steel slag layer of the tundish through the circulation seam, and argon seal is formed in the space between the steel slag layer inside the tundish and the tundish cover. The steel slag face is protected, secondary oxidation of liquid steel is avoided, the 0.5 level of the four kinds of inclusions in LHG2 steel reaches more than 90%, and the cleanliness of the liquid steel is greatly improved.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Method for solving blockage of pouring nozzle of billet caster producing high carbon chromium bearing steel

The invention discloses a method for solving blockage of a pouring nozzle of a billet caster producing high carbon chromium bearing steel. The method includes LF refining, RH refining and a casting process. According to the method, calcium treatment operation is carried out in the middle of the LF refining. Calcium line addition is 0.10-0.35 kg / t steel. The content of molten steel Ca is controlledwithin 0.0010-0.0025 wt %. The sulfur content of the molten steel is less than or equal to 0.010 wt % before calcium treatment, otherwise the calcium treatment is delayed. Aluminum products are not added into the molten steel in the later period of the LF refining and the RH process. A slab section of the billet caster is less than or equal to 260mm*260mm. A tundish nozzle is an immersion nozzle,and an argon blowing stopper with holes is not needed to be used. The method solves the technical problems troubling the billet caster producing high carbon chromium bearing steel for a long time that the immersion nozzle is likely to be plugged, causing the billet caster to have accidents to stop pouring, the molten steel to return to a furnace or falls to the ground. The method reduces the production cost, improves the benefit of an enterprise and has excellent promotion and application value.

Owner:HANDAN IRON & STEEL GROUP +1

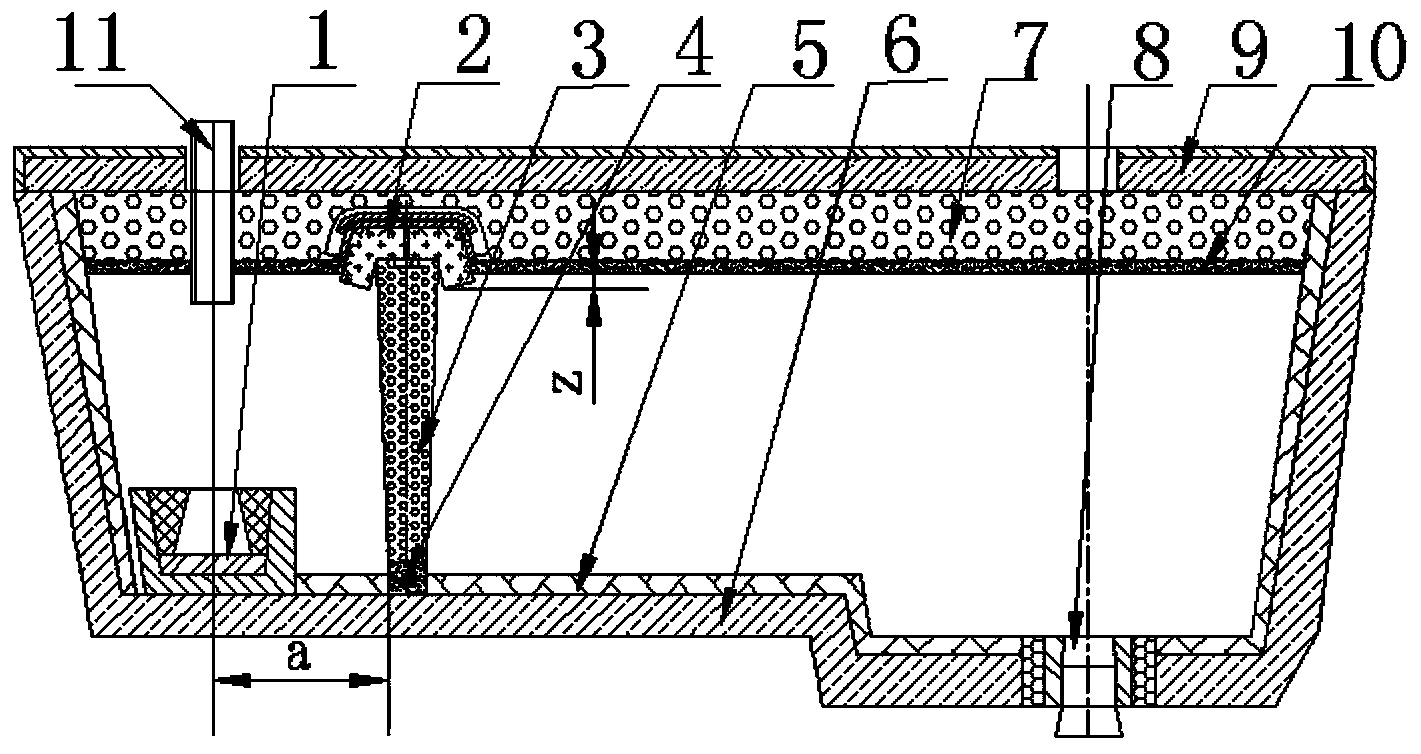

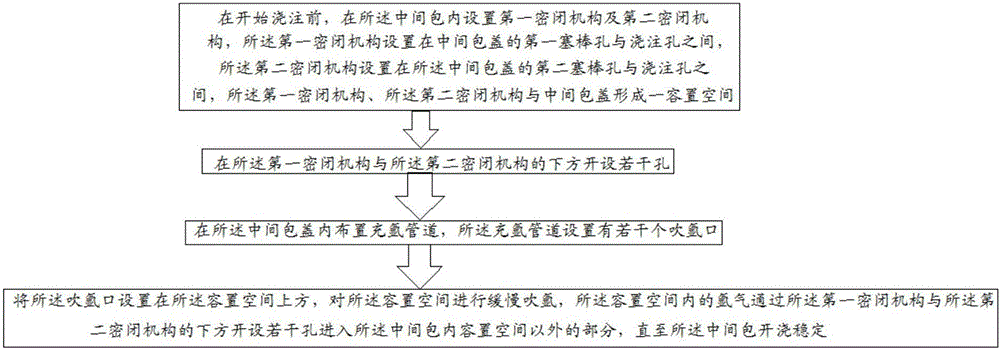

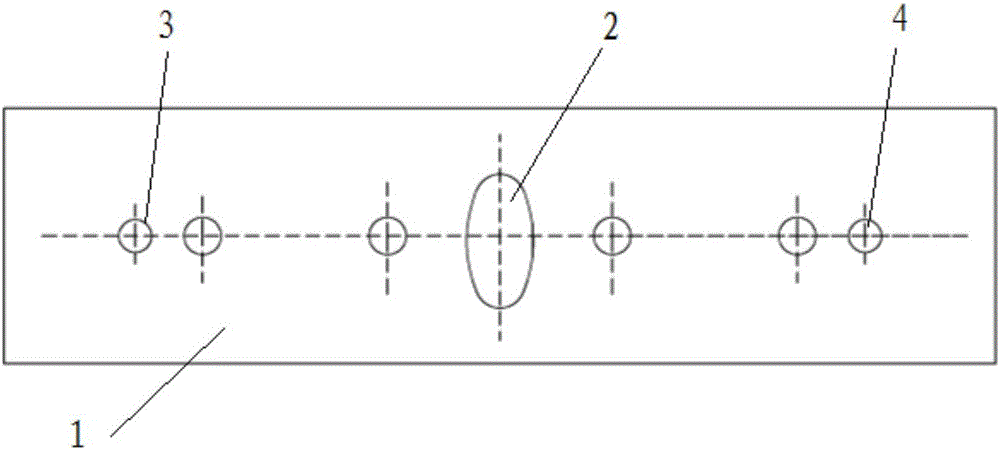

Method and device for filling continuous casting tundish with argon

ActiveCN105964998AGuaranteed tightnessReduce blowing volumeMelt-holding vesselsSteelmaking continuous castingArgon gas

The invention discloses a method and a device for filling a continuous casting tundish with argon, and belongs to the technical field of steelmaking and continuous casting. The device for filling the continuous casting tundish with the argon comprises a first closed mechanism, a second closed mechanism and an argon filling pipeline, wherein the first closed mechanism is arranged in the tundish and positioned between a first stick plug hole and a pouring hole of a tundish cover; a plurality of holes are formed in the lower part of the first closed mechanism; the second closed mechanism is arranged in the tundish and positioned between a second stick plug hole and the pouring hole of the tundish cover; a plurality of holes are formed in the lower part of the second closed mechanism; the argon filling pipeline is arranged in the tundish cover; and a plurality of argon blowing openings are formed in the argon filling pipeline. According to the method and the device for filling the continuous casting tundish with the argon, the blowing-in amount of the argon is reduced, the argon filling efficiency is improved, and the intake amount of external air is reduced; and furthermore, the rated aim of reducing secondary oxidization of molten steel is fulfilled, so that the comprehensive control effect for the first slab quality is better.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com