External refining method capable of increasing continuous casting heats of ultra-deep drawing cold-rolled enamel steel

A technology for refining and enamelling steel outside the furnace, applied in the field of steelmaking, can solve the problems of restricting the release of production capacity of steel mills, improving production efficiency, production interruption, poor pourability, etc., achieving significant economic benefits, accurately controlling nitrogen content, and improving continuous production. The effect of the number of continuous casting furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

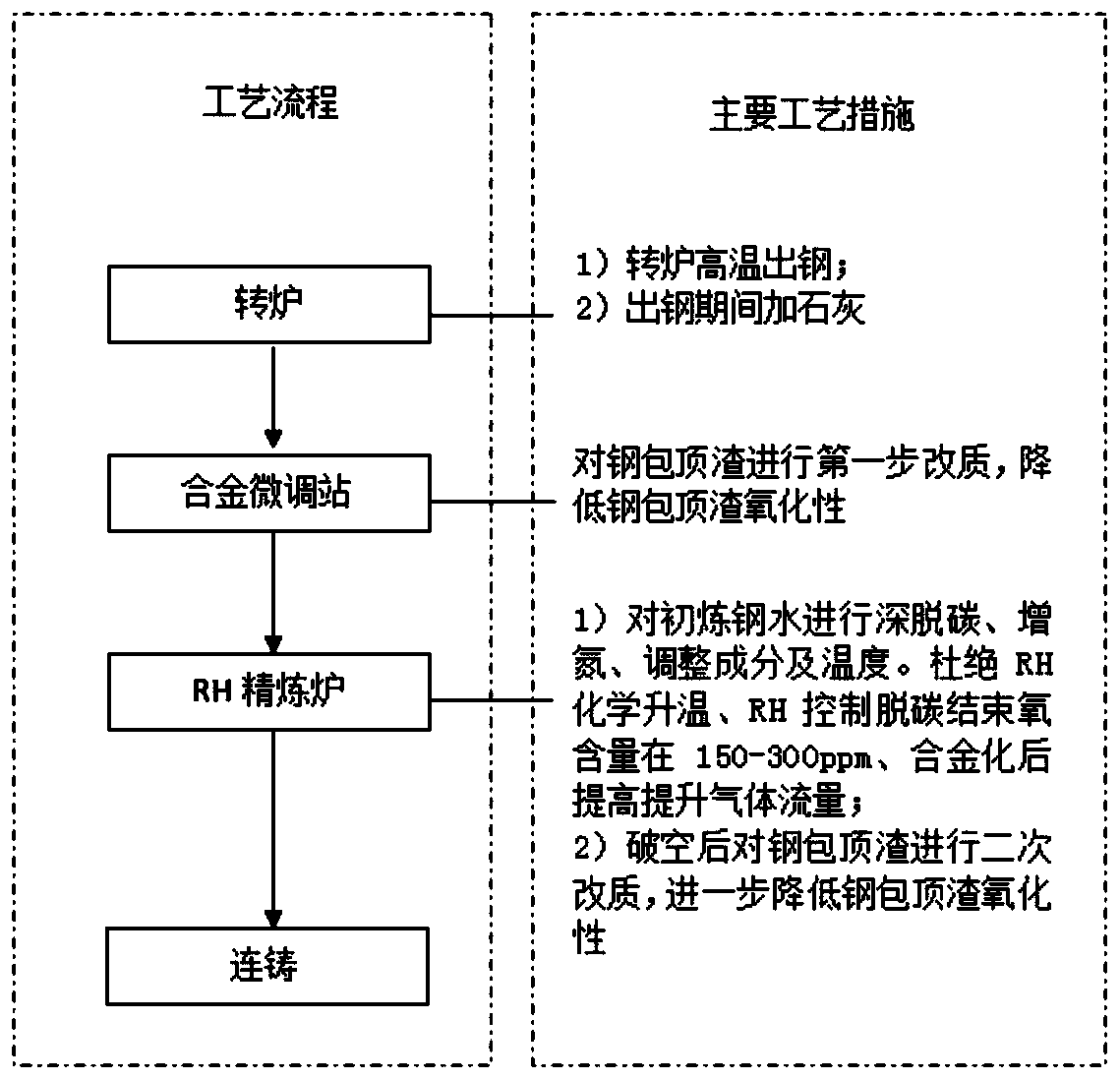

Method used

Image

Examples

Embodiment 1

[0027] An out-of-furnace refining method for increasing the number of continuous casting furnaces for ultra-deep-drawing cold-rolled enamel steel, including the following steps:

[0028] (1) Converter smelting. The composition of the molten steel in the converter is qualified, and when the end temperature of the molten steel reaches the target, the tapping temperature is shown in Table 1.

[0029] Table 1 Converter tapping temperature table

[0030] Furnace numberABCDE Steel tapping temperature / ℃16981695169716921690

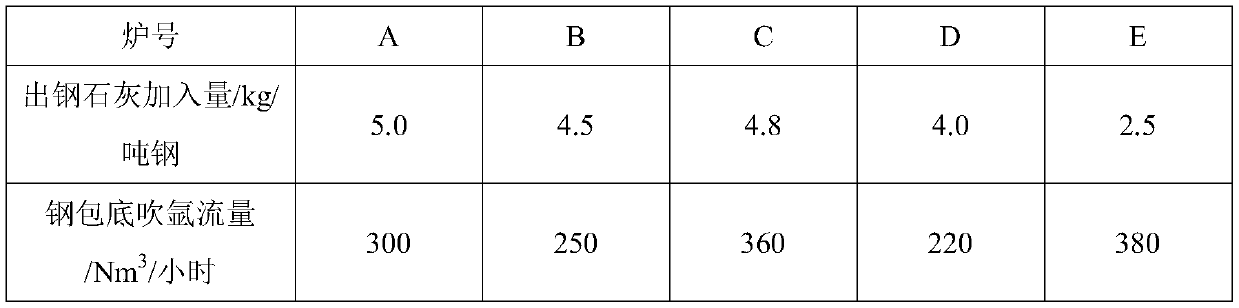

[0031] (2) Lime is added during the tapping of the converter. During the lime addition, the bottom of the ladle is opened and argon is blown. After the lime is melted, the bottom is closed. The amount of lime added and the flow rate of argon are shown in Table 2.

[0032] Table 2 The amount of lime added and the argon flow rate during the tapping period of the converter

[0033]

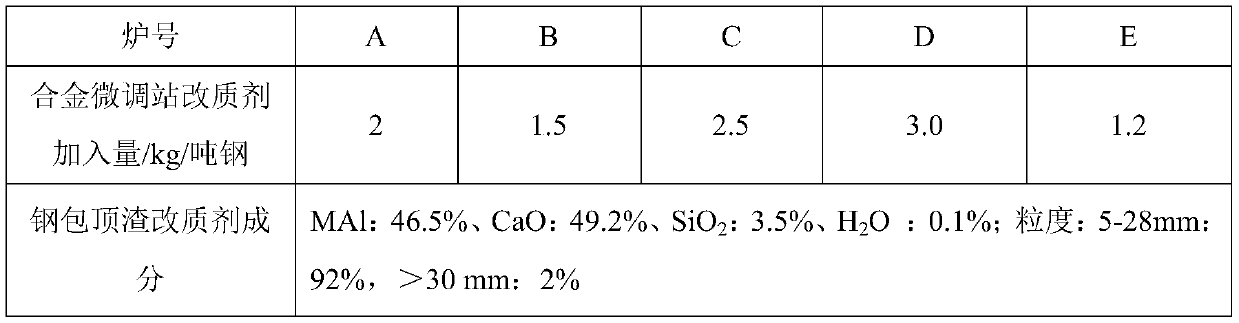

[0034] (3) The amount of slag under the control of the converter is shown in Table 3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com