Refining cover for continuous casting tundish and manufacturing method of refining cover

The technology of continuous casting tundish and refining hood is applied in the field of refining hood and its preparation, and can solve the problems of affecting the service life of the tundish hood, low service life of the dipping hood, waste of argon gas resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

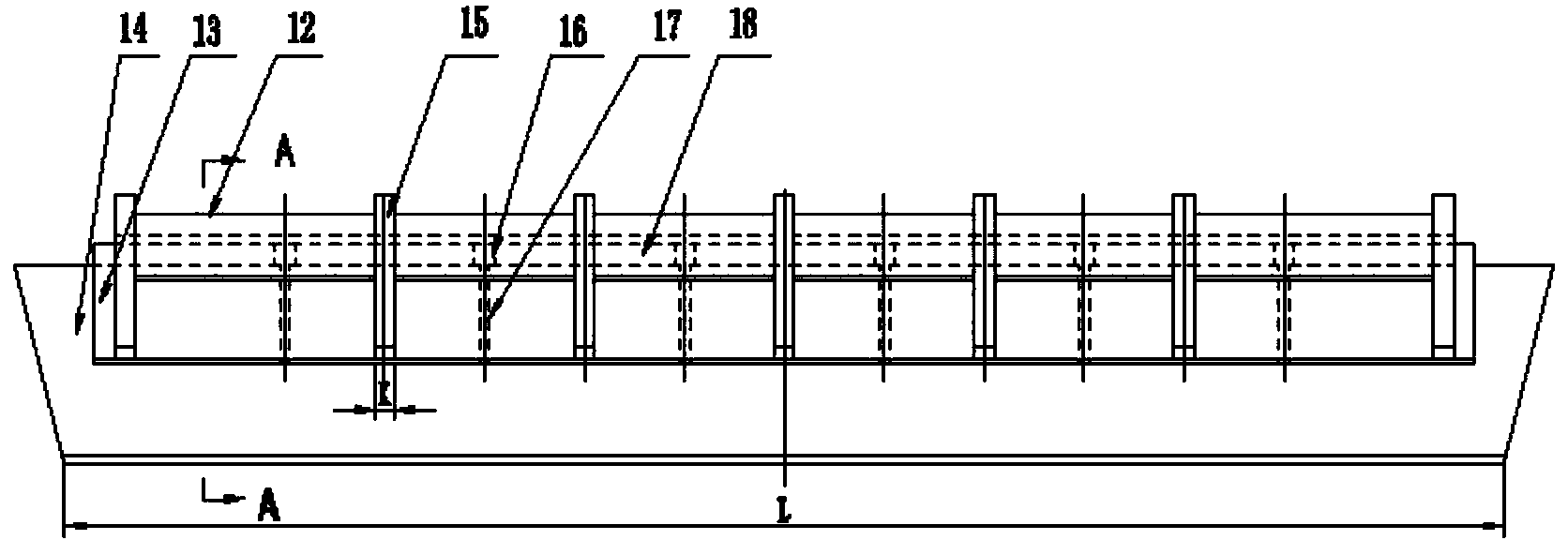

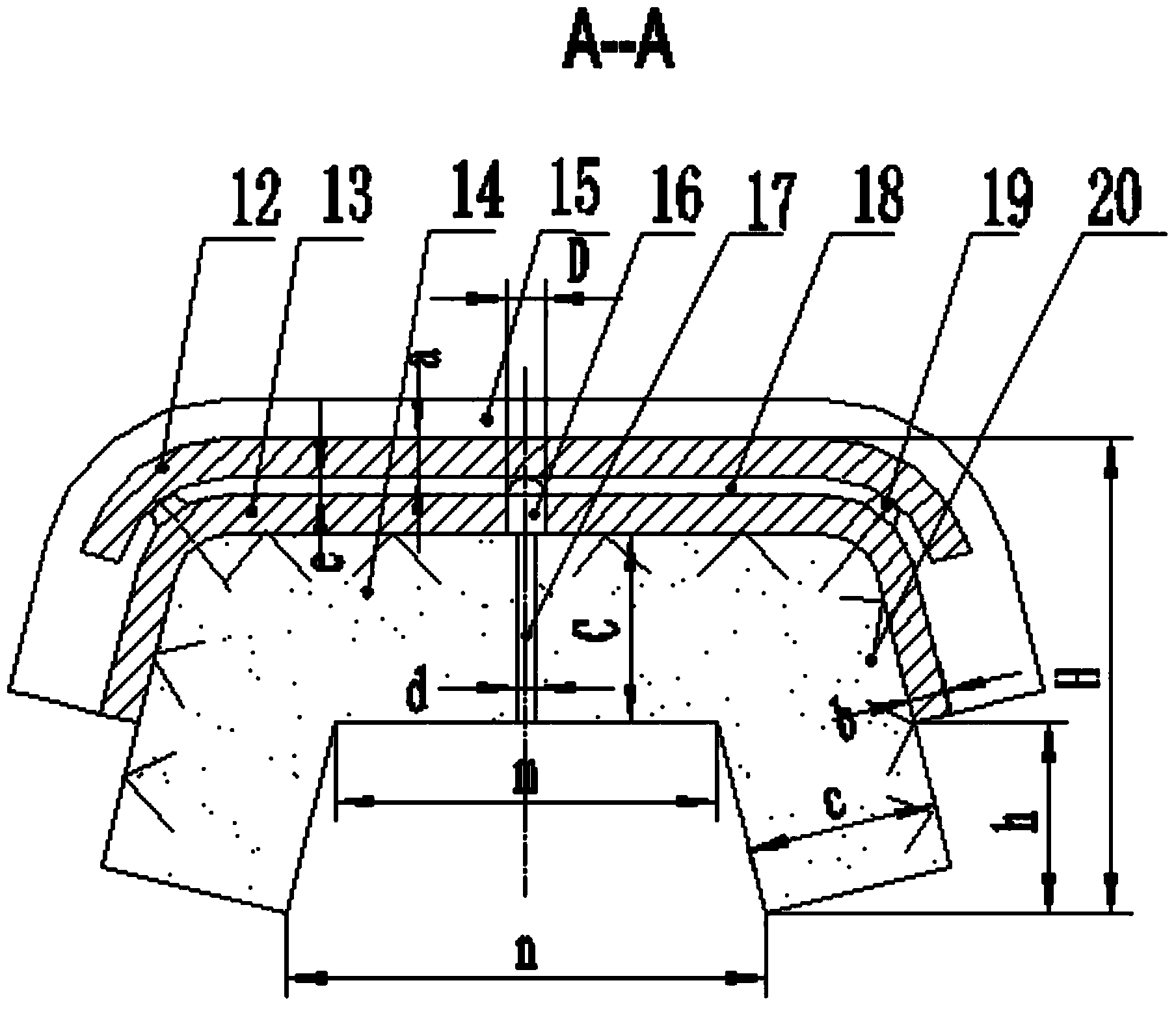

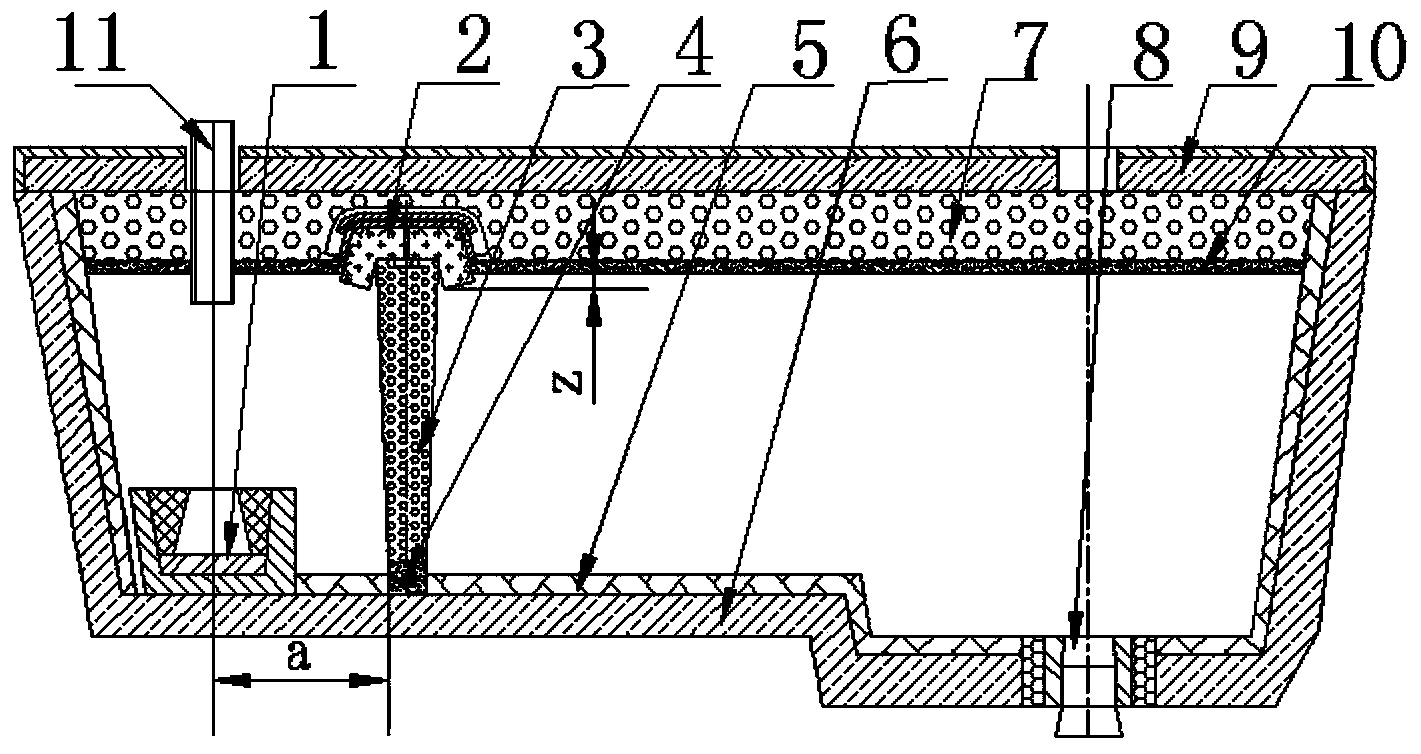

[0049] A refining cover for continuous casting tundish, the structure is as follows figure 1 , figure 2 As shown, it includes an outer arc plate 12, an inner arc plate 13 and an impregnation cover 14. The inner arc plate 12 is set on the impregnation cover 14, and anchor nails 20 are arranged on the inner wall of the inner arc plate 13. The inner arc plate 13 The anchor nail 20 is fixedly connected with the dipping cover 14, the outer arc plate 12 is set above the inner arc plate 13, and a connecting ball 19 is fixed on the outer wall of the inner arc plate 13, and the outer arc plate 12 is connected to the inner arc plate through the connecting ball 19. 13 are connected together, and there is a gap between the outer arc plate 12 and the inner arc plate 13, the gap is a circulation joint 18, the height e of the circulation joint 18 is 10mm, and the circulation joint 18 is connected with the tundish cover 9 and the steel slag layer in the tundish The gaps between 10 are conne...

Embodiment 2

[0054] The preparation method of the refining cover for continuous casting tundish described in embodiment 1 comprises the following steps:

[0055] 1) Process the outer arc plate 12, the inner arc plate 13, and the rib plate 15 respectively, and weld the anchor nail 20 on the inner cavity wall of the inner arc plate 13;

[0056] 2) Place the inner arc plate 13 on the vibrating table of the prefabricated part, support the pouring tire mold with the dipping cover, and apply lubricating oil on the inner wall of the pouring tire mold with the dipping cover;

[0057] 3) After weighing the composition materials of the corundum-spinel castable used for the impregnation cover 14, add them to the mixer for dry mixing for 2 minutes, add 5.0% water of the total weight of the materials, and wet mix for 4 minutes, mix;

[0058] 4) Put the mixed pouring material into the tire mold, and vibrate with a vibrating rod while feeding until the surface is flooded and completely exhausted, then s...

Embodiment 3

[0062] The refining cover for continuous casting tundish as described in embodiment 1, the difference is:

[0063] The height e of the circulation slot 18 is 20 mm, the number of through holes 16 on the inner arc plate 13 is 9, the inner diameter D of the through holes 16 is 25 mm, the number of exhaust holes 17 on the dipping cover 14 is 9, and the inner diameter of the exhaust holes 17 is d 15mm.

[0064] The cross-section of the dipping hood is trapezoidal. Inside the trapezoid, there is an inner cavity with an open bottom. The inner cavity is a trapezoid with a narrow top and a wide bottom. The upper width m of the inner cavity is 250mm, and the bottom width n is 350mm. The thickness c of 14 is 100mm. The outer arc plate 12 and the inner arc plate 13 have the same thickness, and the thickness b of the outer arc plate 12 and the inner arc plate 13 is 25mm, both including the horizontal plate and the side plate, the horizontal plate is arranged horizontally and parallel to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Top width | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com