Method of manufacturing solid aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and manufacturing methods, applied in solid electrolytic capacitors, drying/dipping machines, etc., can solve the problems of high energy consumption, long time, low efficiency, etc., and achieve high heat conduction efficiency, low oxygen content, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

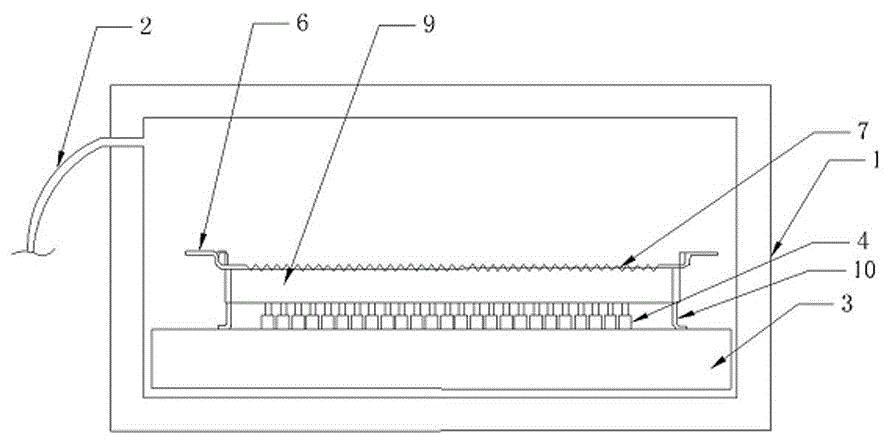

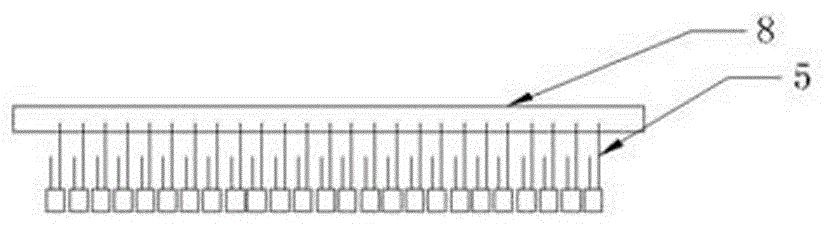

[0017] A method for manufacturing a solid aluminum electrolytic capacitor, comprising the following steps: 1) producing a core package, winding an anode foil, a cathode foil, and electrolytic paper into a core package; The guide pin is fixed on a fixed strip; 3) forming, immersing the core package in the electrolyte and repairing the oxide film with electricity; 4) forming and drying, putting the formed core package into a hollow drying box, and setting the vacuum drying temperature At 150-200 degrees Celsius, dry in a vacuum environment for 5-6 minutes; 5) impregnation, ① impregnate the pre-treatment agent, immerse the core bag in the pre-treatment agent; ② dry I, put the ① treated core bag into the vacuum In the drying oven, set the drying temperature at 60-80 degrees Celsius, and dry in a vacuum environment for 5-6 minutes; ③ impregnate the monomer, immerse the dried core bag in ② into the alcohol solution of 3-4 ethylenedioxythiophene Middle; ④ Drying II, put the ③ process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com