Beneficiation process for resource utilization of low-grade celestite

A lapis lazuli and resource utilization technology, applied in inorganic chemistry, alkali metal chloride, chemical instruments and methods, etc., can solve the problems of waste water, waste gas and waste residue polluting the environment, and achieve easy promotion, avoiding environmental pollution, simple and feasible process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

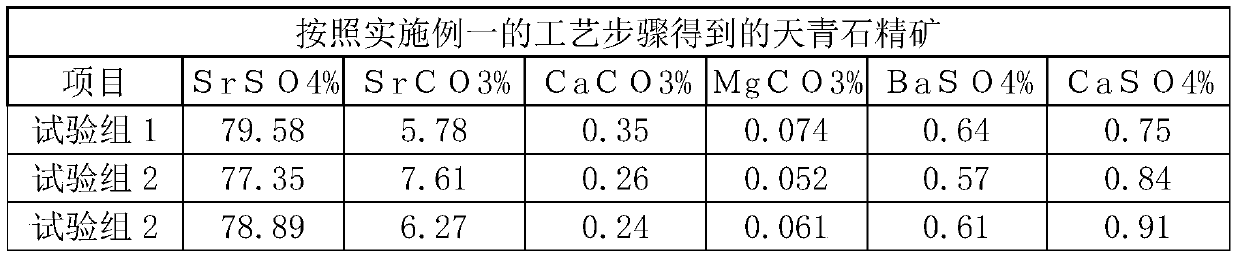

Embodiment 1

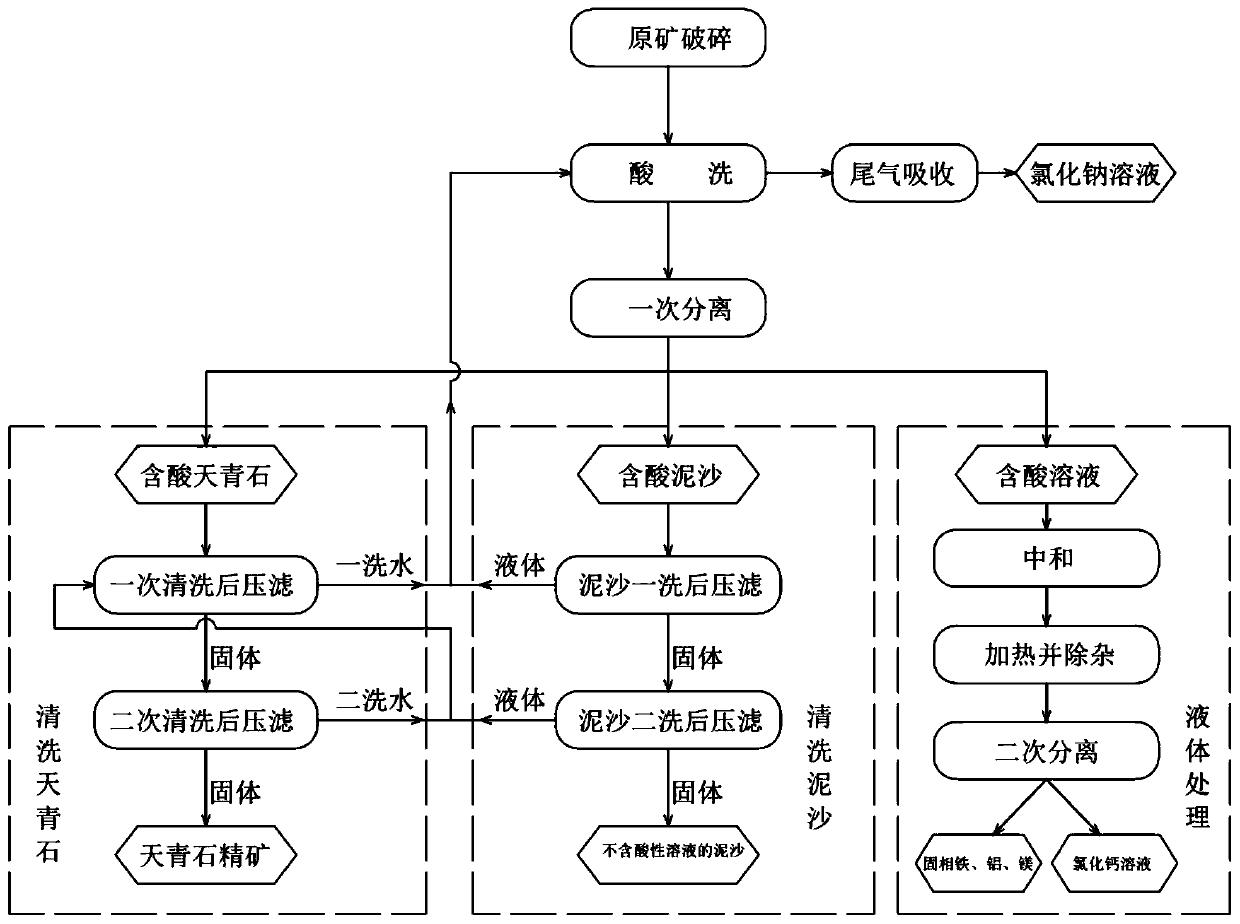

[0041] Embodiment one is basically as attached figure 1 Shown:

[0042] A beneficiation process for resource utilization of low-grade celestite, comprising the following steps:

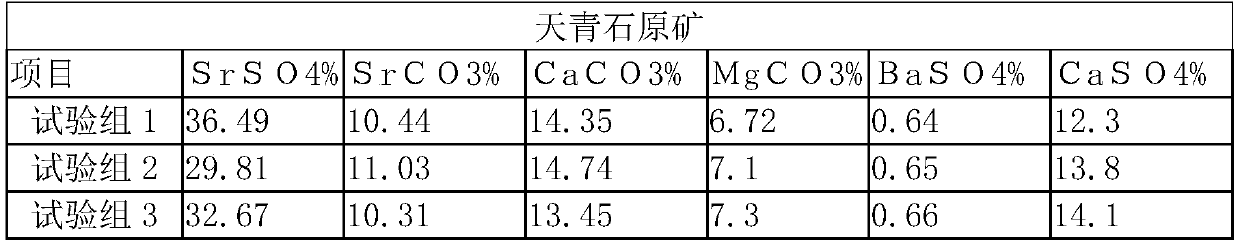

[0043] Step 1, raw ore crushing: take the raw ore, which mainly contains about 30% strontium sulfate, and other impurities such as calcite, dolomite, gypsum, silt and a small amount of iron, aluminum, etc., and use the jaw crusher to crush the raw ore Coarse particles with a diameter of 3-7 cm are obtained, and then a pulverizer is used to crush the coarse particles until fine particles with a diameter of less than 4 mm are obtained.

[0044] Step 2, pickling: add the fine particles obtained in step 1 into the acid tank, add hydrochloric acid with a mass concentration of 30% into the acid tank, and use stirring to make the hydrochloric acid fully contact and react with the fine particles, so as to realize the removal of fine particles The pickling process keeps the pH of the solution at 1; the gas a...

Embodiment 2

[0067] The difference between the second embodiment and the first embodiment is that in the second embodiment, the solution used for tail gas absorption is sodium carbonate solution, which can achieve the same effect as sodium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com