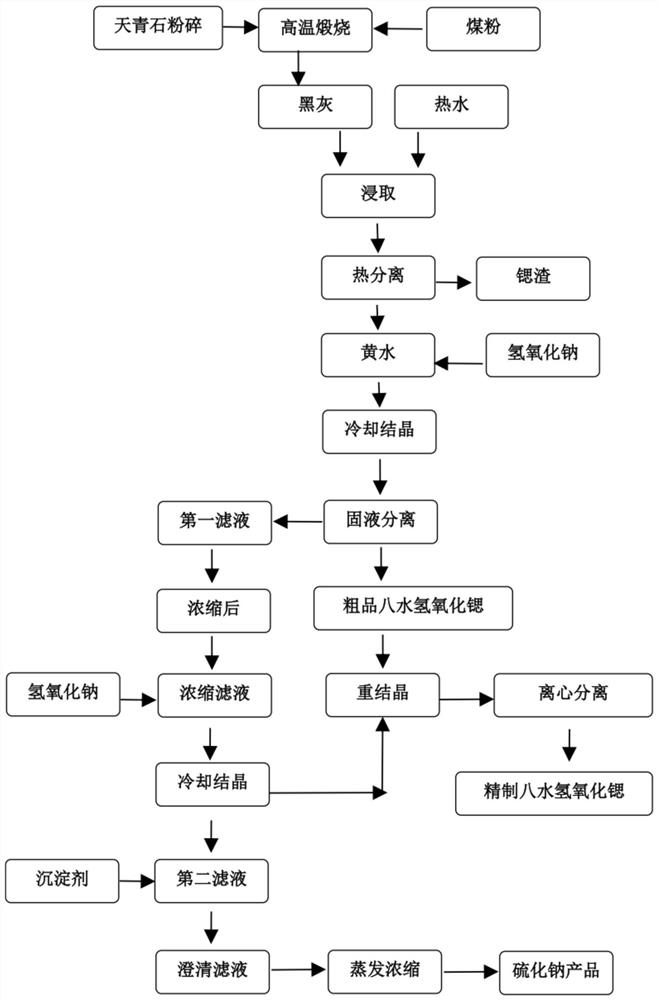

Method for producing strontium hydroxide and co-producing sodium sulfide

A technology of strontium hydroxide and sodium hydroxide, applied in the direction of alkali metal sulfide/polysulfide, etc., can solve the problems of long production process, many impurity ions, and high production cost, and achieves low production cost, short process flow, high production cost, etc. The effect of improving the final yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Weigh 500g of lapis lazuli (content 82%) and mix with 110g of coal powder evenly, roast in a high-temperature furnace at 1000°C for 1 hour, take it out after cooling slightly, place it in a constant temperature water bath at 90°C, measure 1.5L of hot water in a beaker, Pour all the obtained black ash into a beaker, start stirring at 500r / min, and soak for 1 hour. Take it off, heat filter to obtain 1.3L of leaching yellow water, the concentration of yellow water is 83.25g / L.

[0070] Measure 1L of yellow water (78°C) into a beaker, add 27.82g of NaOH at a ratio of 1:1, stir and mix evenly, seal, and naturally cool to room temperature at 33°C to precipitate crystals. Centrifuge the solid and liquid in the beaker to obtain 155 g of crude strontium hydroxide octahydrate.

Embodiment 2

[0072] Weigh 1000g of lapis lazuli (content 76%) and 200g of coal powder, mix evenly, roast in a high-temperature furnace at 1000°C for 1h, take it out after cooling slightly, place it in a constant temperature water bath at 90°C, measure 3L of hot water in a beaker, and put All the obtained black ash was poured into the beaker, and the stirring was started at 500r / min, and the leaching time was 1h. Take it off, heat filter to obtain 2.6L of leaching yellow water, the concentration of yellow water is 73.59g / L.

[0073] Measure 1L of yellow water (85°C) into a beaker, add 27.82g of NaOH at a ratio of 1:1, stir and mix evenly, seal, and naturally cool to room temperature at 34°C to precipitate crystals. Centrifuge the solid and liquid in the beaker to obtain 147g of crude strontium hydroxide octahydrate.

Embodiment 3

[0075] Weigh 50kg of lapis lazuli (content 78%) and mix it with 10.1kg of coal powder evenly, roast it in a rotary furnace at 1200°C for 2h, transport it to 150L of 90°C hot water for leaching, the leaching time is about 2.5h, after filtering, Get 142L of yellow water for leaching, and the concentration of yellow water is 84.63g / L.

[0076] Transfer the yellow water at 75°C to a tank, add 9.65kg of NaOH at a ratio of 1:1.2, stir and mix evenly, seal, and cool naturally to room temperature at 35°C for crystallization. Solid-liquid centrifugation was carried out through a filter cloth to obtain 21.7 kg of crude strontium hydroxide octahydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com