Catalyst for coal-to-natural gas methanation reactor and preparation method thereof

A methanation reactor and coal-to-natural gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems that are not suitable for coal-to-natural gas projects, Lack of operating experience, small number of developments, etc., to reduce the risk of cracking carbon deposits, easy to clean and remove, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

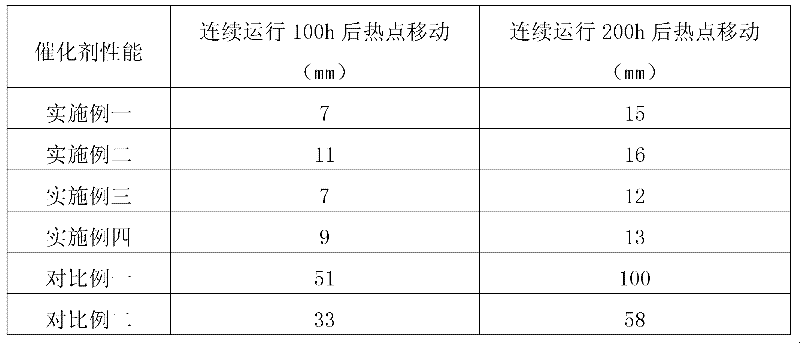

Examples

Embodiment 1

[0032] In this embodiment, a catalyst for a coal-to-natural gas methanation reactor mainly includes an active component, a carrier, a first auxiliary agent, a second auxiliary agent and graphite, wherein the mass percent content of each component is: NiO: 10% 、Al 2 o 3 : 75%, CeO 2 : 5%, CuO: 8%, graphite 2%.

[0033] In this embodiment, a catalyst for a coal-to-natural gas methanation reactor is prepared by a method comprising the following main steps:

[0034] Step 1: take by weighing 19.46 grams of hydrated nickel nitrate Ni (NO 3 ) 2 ·6H 2 O, 7.96 grams of ammonium cerium nitrate (NH 4 ) 2 Ce(NO 3 ) 6 , 12.15 grams of hydrated copper nitrate Cu(NO 3 ) 2 ·3H 2 O, 275.94 grams of hydrated aluminum nitrate Al(NO 3 ) 3 9H 2 0 and 78.73 grams of urea, then each material taken by weighing is dissolved in deionized water and diluted to 2500ml to form a mixed solution, calculated according to all metal ions in the precipitation solution, and the precipitation agent ...

Embodiment 2

[0041] In this embodiment, a catalyst for a coal-to-natural gas methanation reactor mainly includes an active component, a carrier, a first auxiliary agent, a second auxiliary agent and graphite, wherein the mass percent content of each component is: NiO: 40% 、Al 2 o 3 : 40%, Sm 2 o 3 : 8%, CuO: 10%, graphite 2%.

[0042] In this embodiment, a catalyst for a coal-to-natural gas methanation reactor is prepared by a method comprising the following main steps:

[0043] Step 1: take by weighing 77.86 grams of hydrated nickel nitrate Ni (NO 3 ) 2 ·6H 2 O, 10.19 grams of hydrated samarium nitrate Sm (NO 3 ) 2 ·6H 2 O, 15.19 grams of hydrated copper nitrate Cu (NO 3 ) 2 ·3H 2 O, 147.17 grams of hydrated aluminum nitrate Al(NO 3 ) 3 9H 20 and 71.51 grams of urea, then each material taken by weighing is dissolved in deionized water and diluted to 2500ml to form a mixed solution, calculated according to all metal ions in the precipitation solution, and the precipitation a...

Embodiment 3

[0050] In this embodiment, a catalyst for a coal-to-natural gas methanation reactor mainly includes an active component, a carrier, a first auxiliary agent, a second auxiliary agent and graphite, wherein the mass percent content of each component is: NiO: 23% 、Al 2 o 3 : 60%, La 2 o 3 : 10%, CuO: 5%, graphite 2%.

[0051] In this embodiment, a catalyst for a coal-to-natural gas methanation reactor is prepared by a method comprising the following main steps:

[0052] Step 1: take by weighing 44.77 grams of hydrated nickel nitrate Ni(NO 3 ) 2 ·6H 2 O, 10.52 grams of hydrated lanthanum nitrate La(NO 3 ) 3 ·6H 2 O, 7.59 grams of hydrated copper nitrate Cu (NO 3 ) 2 ·3H 2 O, 220.75 grams of hydrated aluminum nitrate Al(NO 3 ) 3 9H 2 0 and 73.48 grams of urea, then each material taken by weighing is dissolved in deionized water and diluted to 2500ml to form a mixed solution, calculated according to all metal ions in the precipitation solution, and the precipitation ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com