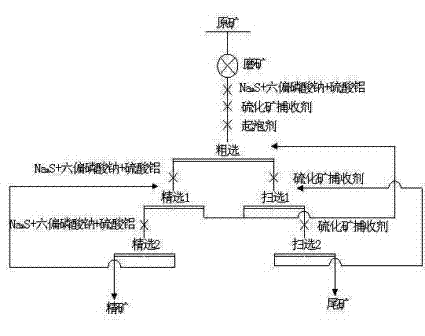

Method for beneficiating high-peat copper sulphide ore

A technology of copper sulfide ore and ore dressing method, which is applied in flotation, solid separation, etc., can solve the problems of mineral flotation difficulties, etc., and achieve the effects of efficient flotation recovery, high flotation index, and low chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are intended to further illustrate the present invention, but not to limit the present invention. The g / t mentioned in this application refers to the mass of the agent added per ton of raw ore. Said percentages are all mass percentages.

[0022] Copper-cobalt-nickel polymetallic deposits in a certain place in Australia are produced from sedimentary carbonaceous shale deposits. Due to long-term weathering, the mineral species and ore structure of the raw ore tend to be complicated. The ore hardness is 1~2, which can be depicted and stained with fingernails. The content of carbonaceous matter in the raw ore is as high as 4.41%; the content of clay minerals reaches 55.26%, which are mainly silicate minerals with layered structure such as hydrokaolinite and hydromuscovite, and the interlayers are combined by residual bonds, which can not only Adsorbs a large number of free metal ions, and also adsorbs many flotation reagents, which makes the flotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com