Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Excellent mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

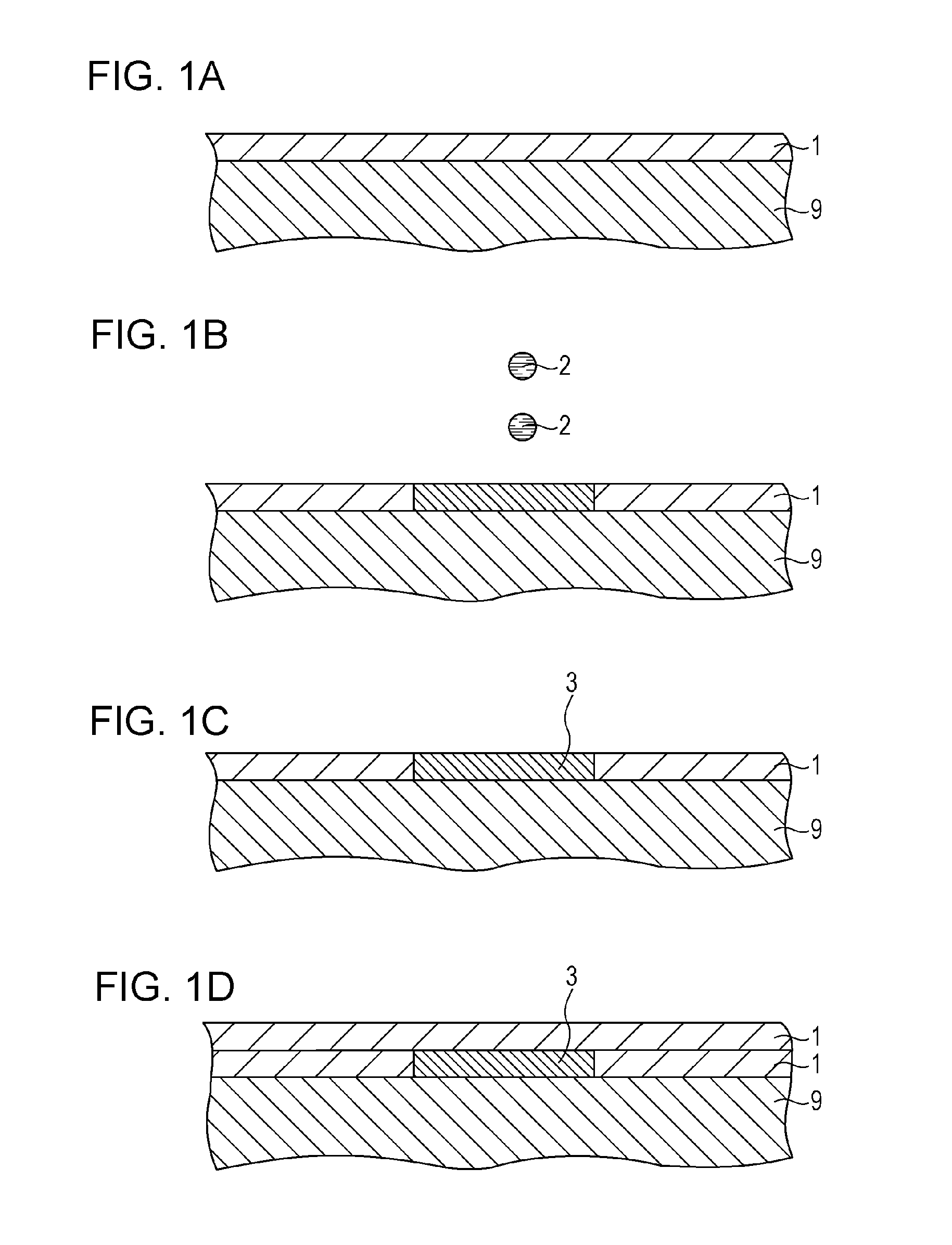

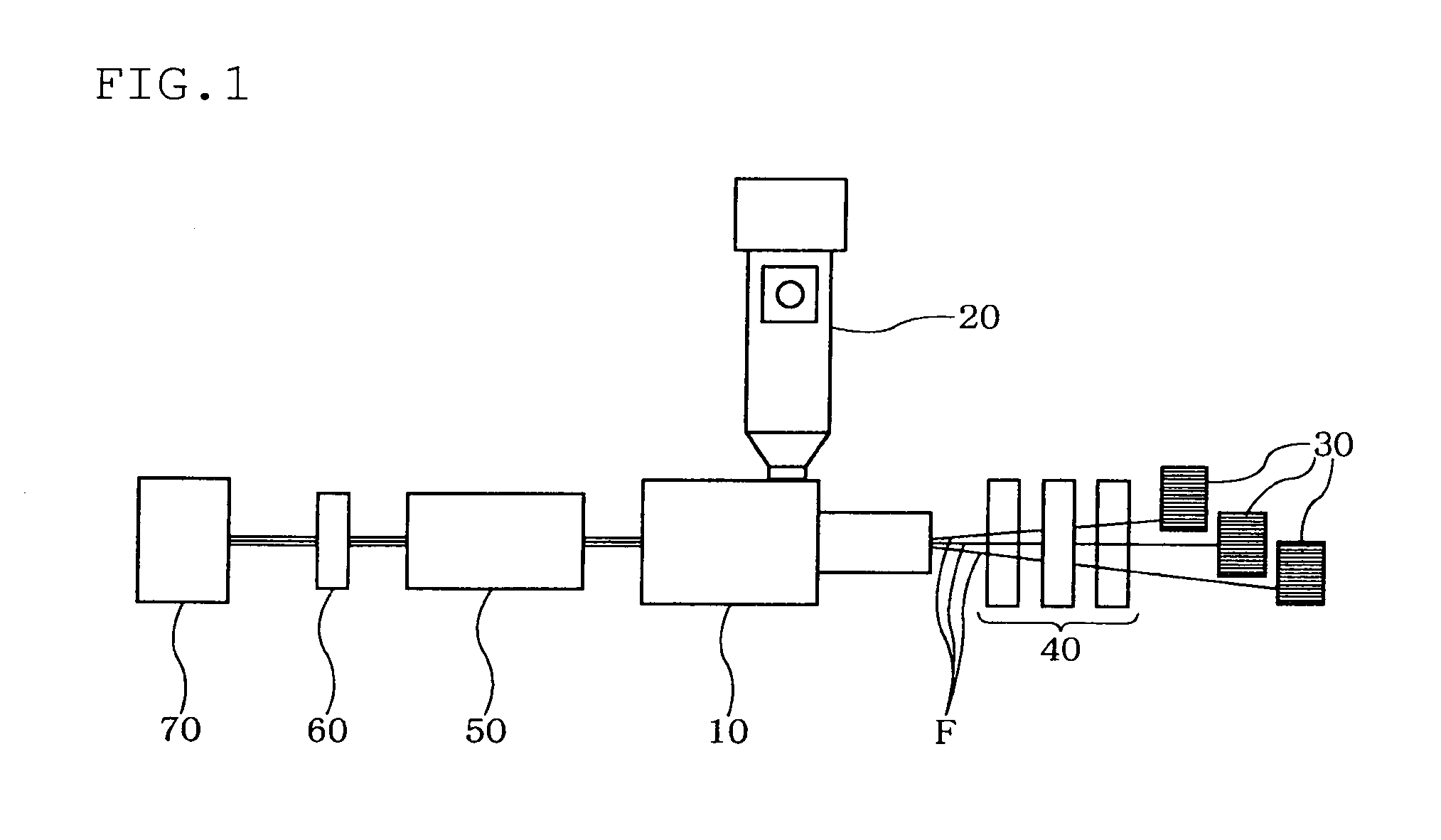

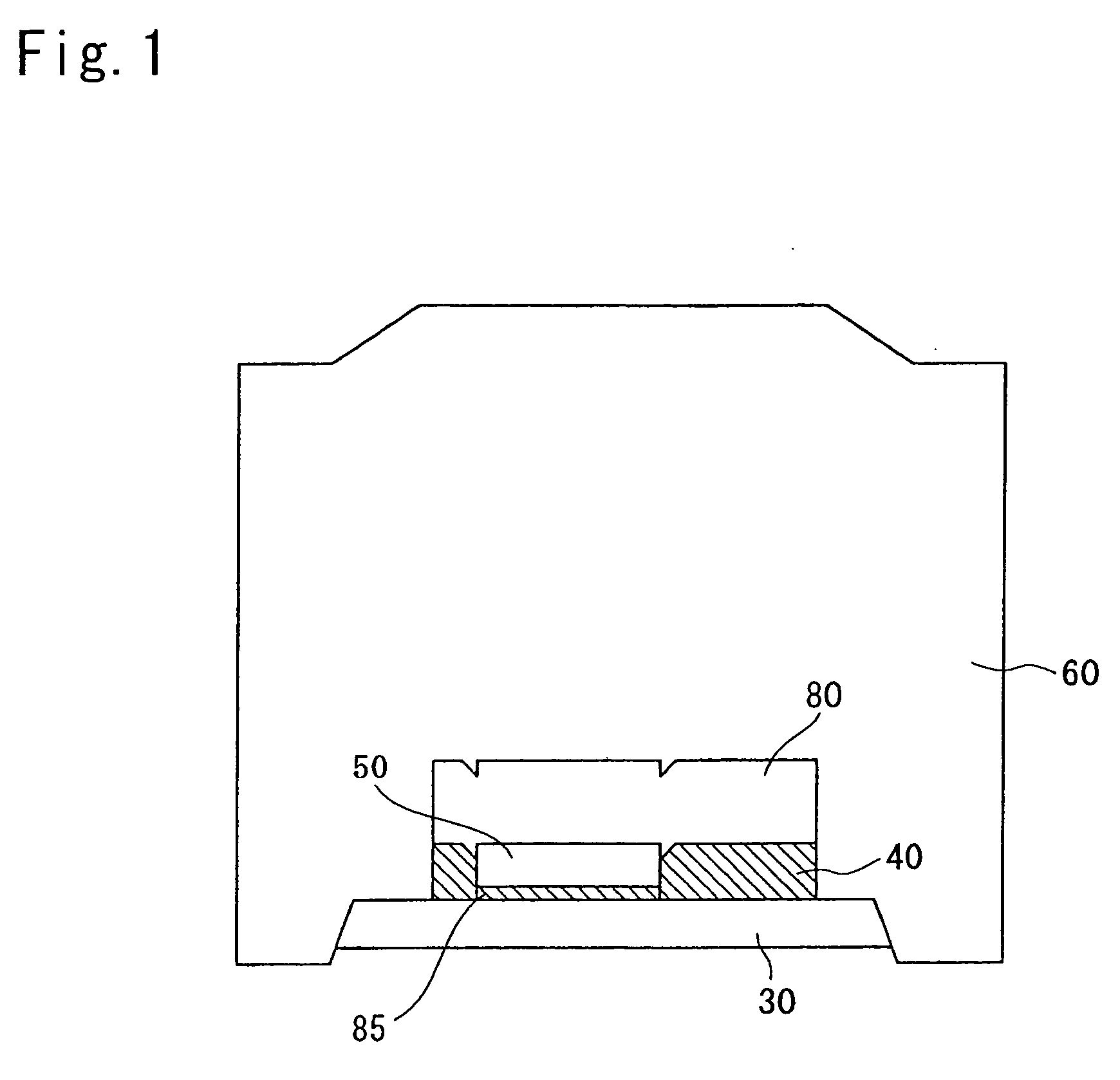

Separator for electronic component and method for producing the same

InactiveUS20050186479A1Excellent workability and productivityExcellent mechanical strengthElectrolytic capacitorsPretreated surfacesSolventPolymer chemistry

The present invention provides an electronic component separator that allows for easy thickness reduction and also has excellent mechanical strength, dimensional stability and heat resistance. This electronic component separator contains in a porous film made of a synthetic resin with a glass transition temperature of 180° C. or above, filler grains having a melting point of 180° C. or above or virtually no melting point, and the electronic component separator is produced by way of applying onto a base a coating material comprising (a) a synthetic resin with a glass transition temperature of 180° C. or above, (b) filler grains having a melting point of 180° C. or above or virtually no melting point, (c) at least one good solvent capable of dissolving the synthetic resin, and (d) at least one poor solvent incapable of dissolving the synthetic resin, and then drying the coated base to form a porous film.

Owner:TOMOEGAWA PAPER CO LTD

Foamed polyolefin resin beads

InactiveUS20090169895A1Good surface conditionExcellent mechanical strengthSynthetic resin layered productsCellulosic plastic layered productsChemistryAntistatic agent

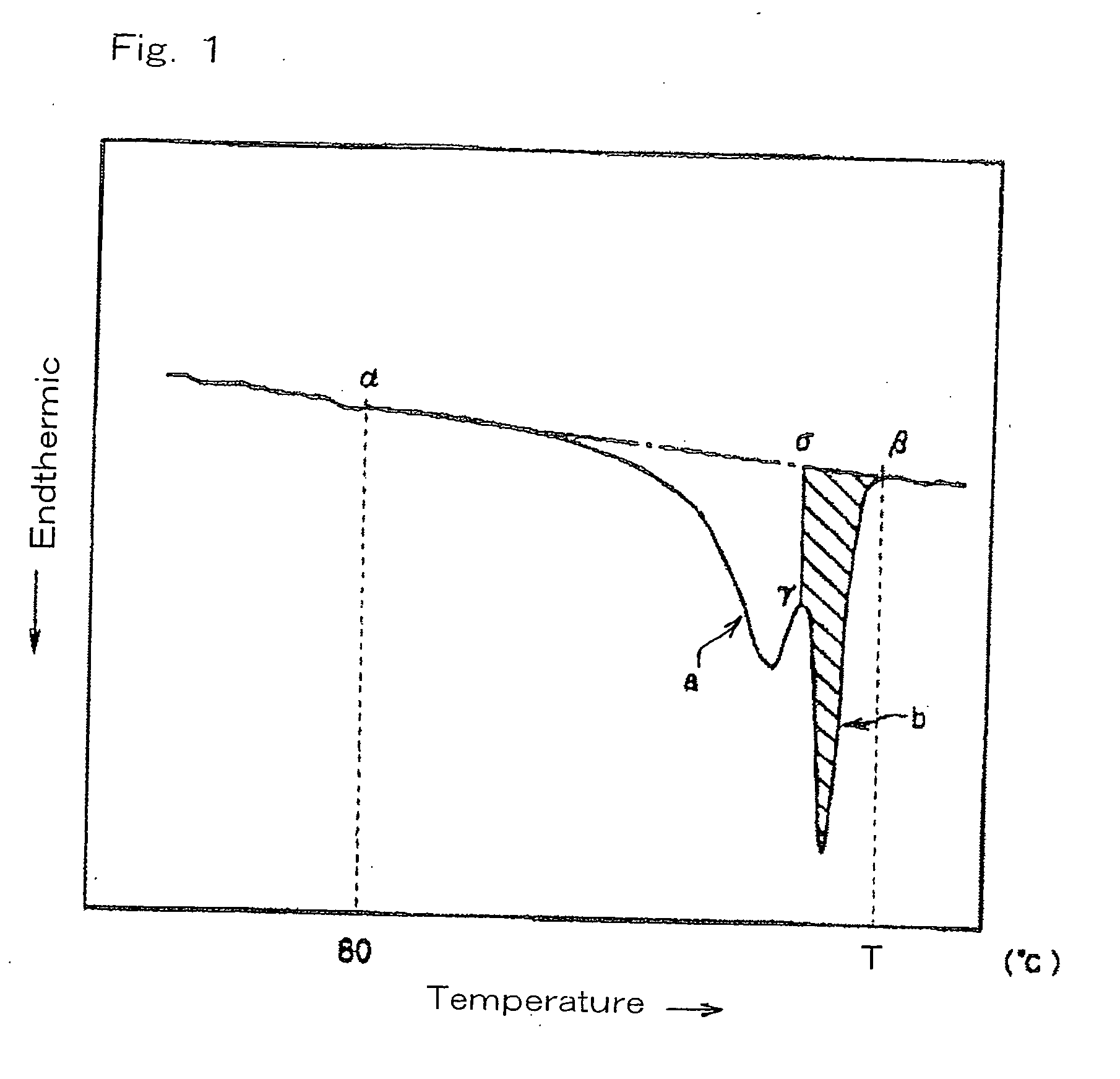

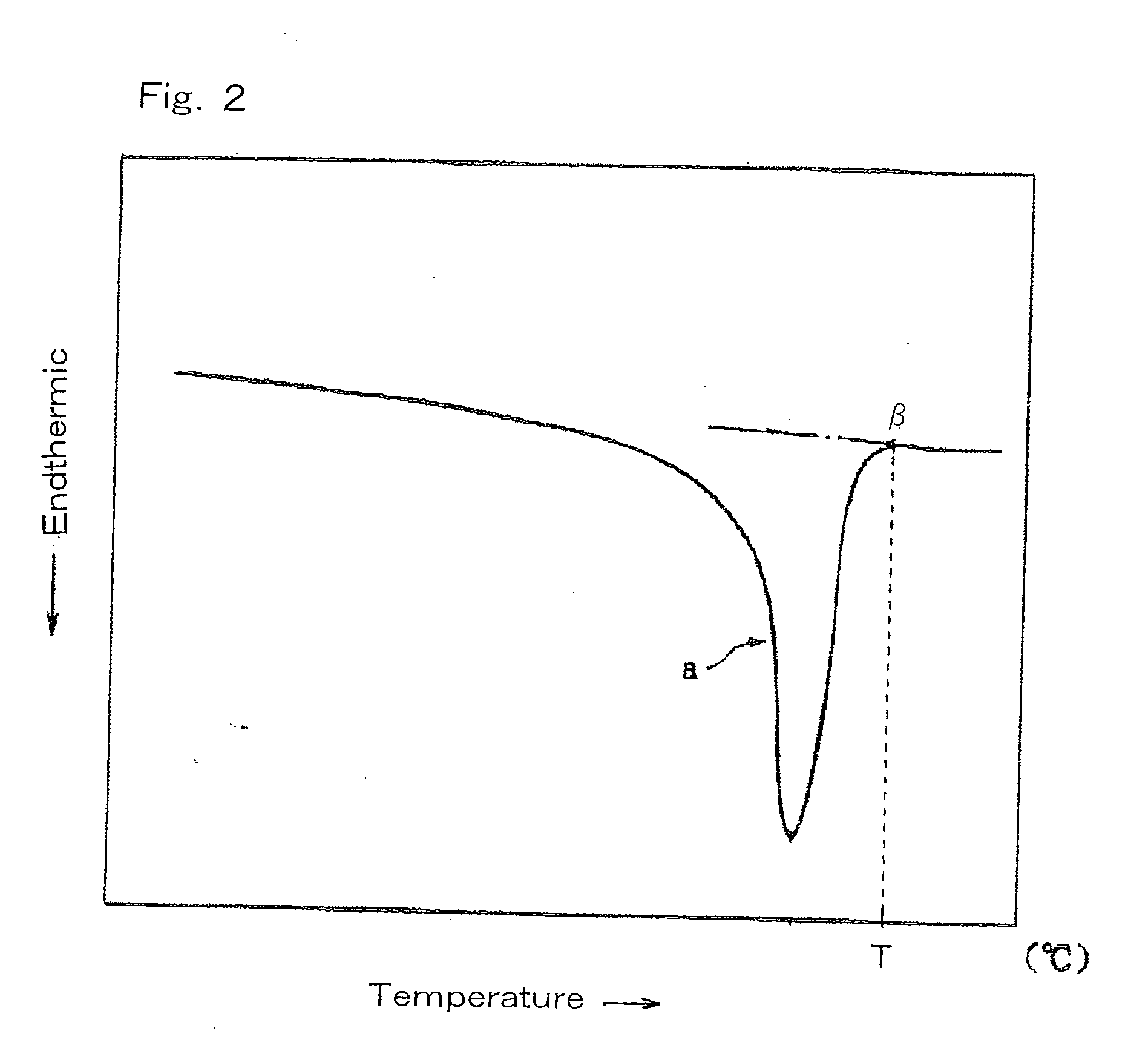

The present invention relates to foamed polyolefin resin beads. Further, the present invention provides foamed resin beads obtained by foaming and expanding composite resin beads which include a core layer constituted by a polyolefin resin and a covering layer which covers the core layer constituted by a polyolefin resin, wherein (a) the polyolefin resin constituting the core layer is a crystalline polyolefin resin, (b) the polyolefin resin constituting the covering layer is a crystalline polyolefin resin which has a lower melting point (B) than a melting point (A) of the polyolefin resin constituting the core layer, wherein a temperature difference [(A)−(B)] between the melting point (B) and the melting point (A) is more than 0° C. and 80° C. or less, or a noncrystalline polyolefin resin which has a softening point (C) lower than the melting point (A) of the polyolefin resin constituting the core layer, wherein a temperature difference [(A)−(C)] between the softening point (C) and the melting point (A) is more than 0° C. and 100° C. or less, and 10% by weight or more and less than 50% by weight of polymer type antistatic agent is contained in the covering layer. The foamed polyolefin resin beads of the present invention provide foamed polyolefin resin beads are excellent in fusion properties between beads at the time of molding in a mold, capable of providing a molded foamed article which is excellent antistatic performance, has no deterioration of the antistatic performance with age, whose antistatic performance is not humidity dependent, does not contaminate packaging products, has a good molded foamed article surface, and has excellent mechanical properties.

Owner:JSP CORP

Composition containing proton-conductive copolymer, polymer electrolyte membrane, method of producing the membrane , and fuel cell using the membrane

InactiveUS20080157422A1Low degreeExcellent mechanical strengthSolid electrolytesFinal product manufacturePolymer electrolytesUnsaturated bonds

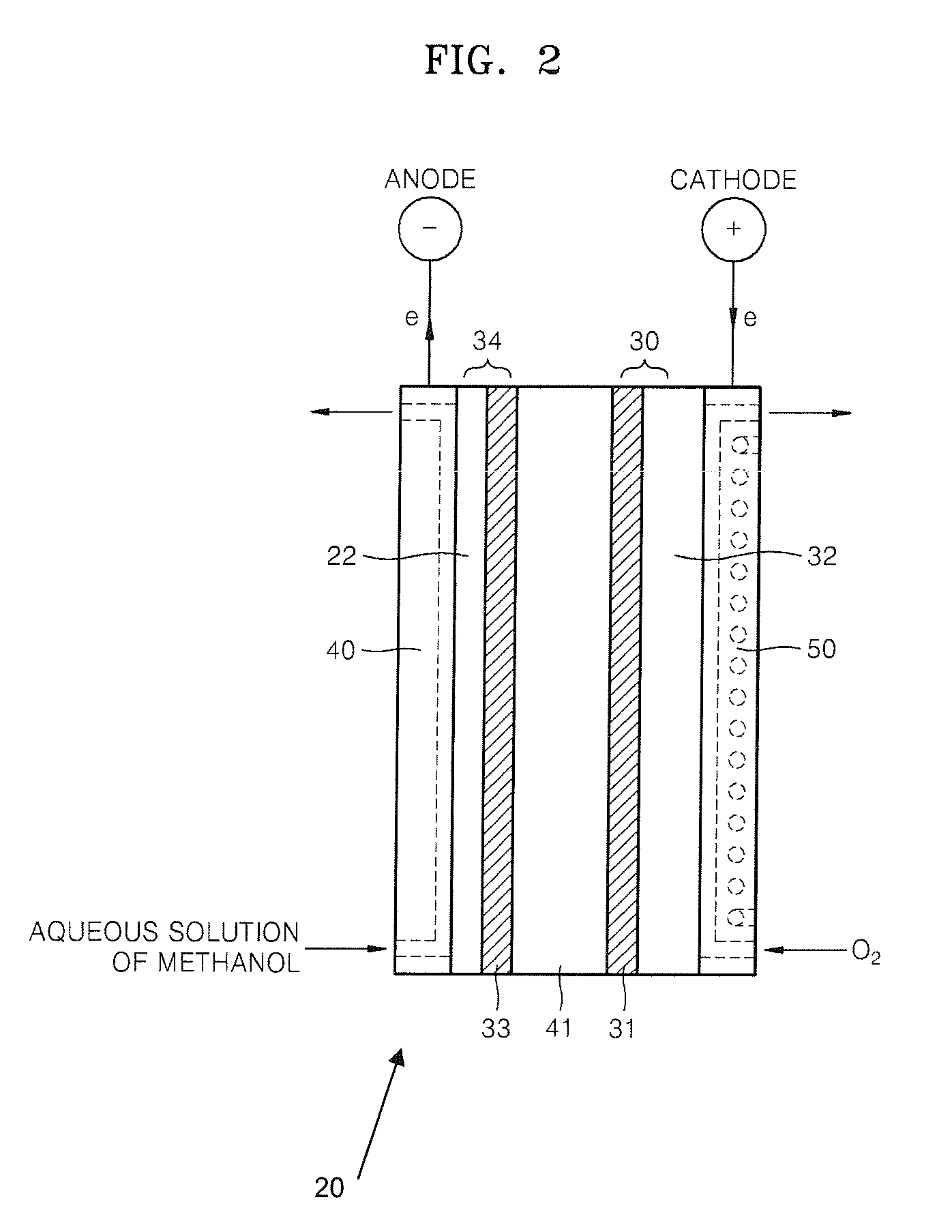

A composition containing a proton-conductive copolymer, a polymer electrolyte membrane containing the composition; a method of producing the membrane; and a fuel cell employing the membrane. The composition includes: a proton-conductive copolymer comprising a first styrene repeating unit, a second styrene repeating unit, and a dimethylsiloxane repeating unit; and a cross-linked polymer obtained from a cross-linking reaction between a siloxane oligomer having an unsaturated bond and a cross-linking agent. The cross-linked polymer has the same properties as the dimethylsiloxane repeating unit of the proton-conductive copolymer.

Owner:SAMSUNG SDI CO LTD

Resin composition for hollow blow-molded article, hollow blow-molded article, and method of producing the hollow blow-molded article

ActiveUS20130059976A1Excellent mechanical strengthExcellent moldabilitySynthetic resin layered productsOrganic dyesIndustrial scaleChemistry

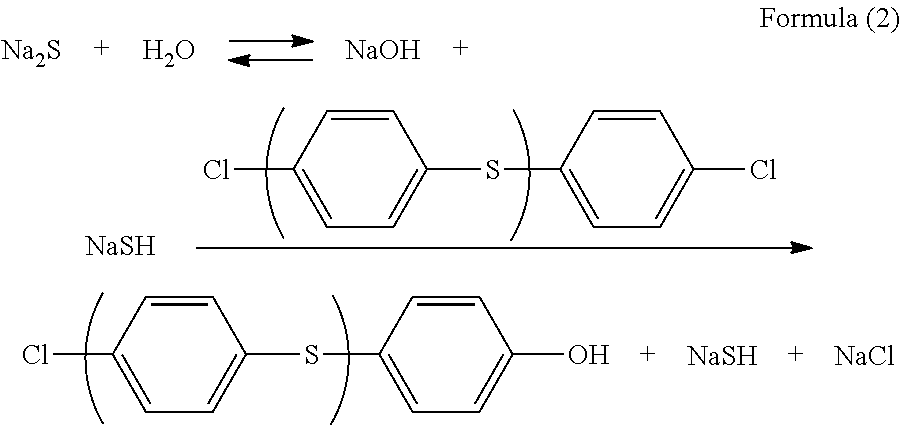

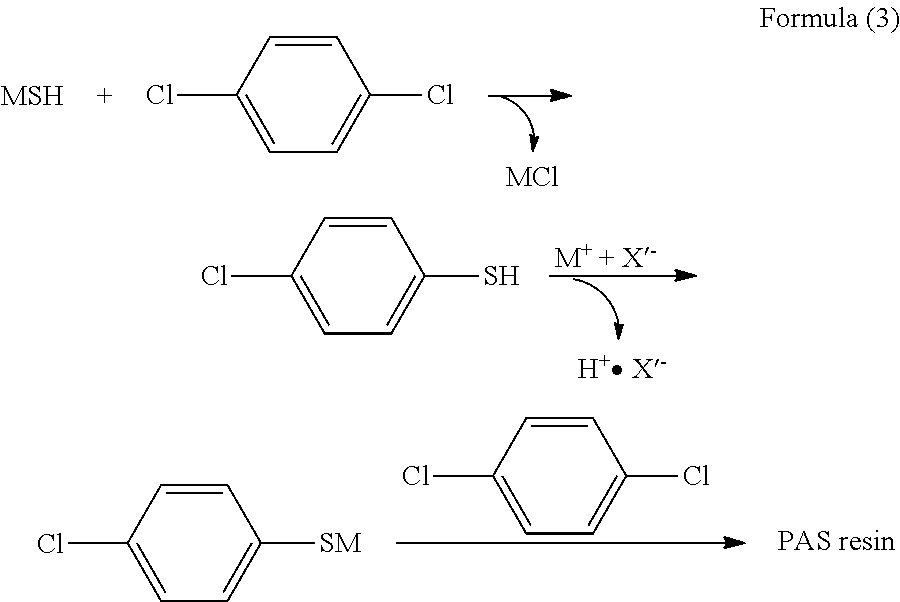

There are provided, according to the present invention, a resin composition for hollow blow-molded article which is obtained in a high productivity on an industrial scale with excellent moldability and drawdown resistance, and the production method thereof, by melting and mixing a polyarylene sulfide resin including a terminal carboxyl group within the resin in an amount of 25 to 45 (μmol / g), and having a non-Newtonian index of 0.90 to 1.15 and also a melt viscosity as measured at 300° C. within the range of 1,000 poise to 3,000 poise and an epoxy group-containing polyolefin so that the proportion of the epoxy group-containing polyolefin is 5 to 30 parts by mass with respect to 100 parts by mass of the polyarylene sulfide resin; and a hollow blow-molded article with excellent mechanical strength, such as the heat resistance and impact resistance, and surface appearance, and the production method thereof.

Owner:DAINIPPON INK & CHEM INC

Proton exchange membrane and preparation method thereof

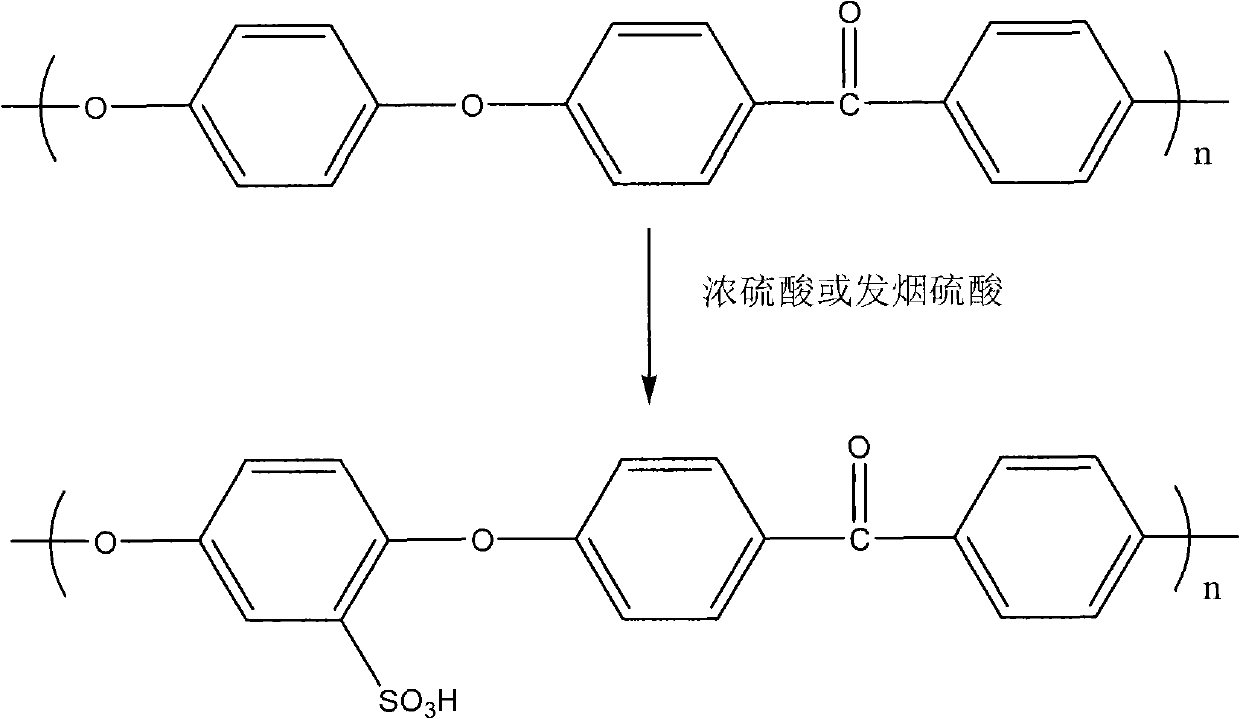

ActiveCN101771159AHigh mechanical strengthExcellent thermal stability at high temperatureCell component detailsFuel cell detailsProtonPolyether ether ketone

The invention provides a proton exchange membrane with excellent proton conductivity, high mechanical strength, high stability and low cost and a preparation method thereof. The proton exchange membrane is prepared from a blend of sulfonated polyether ether ketone with more than 60 percent and less than 100 percent of sulfonation degree and SPES with more than 0 percent and less than 60 percent of sulfonation degree, wherein the the proportion of sulfonated polyether ether ketone in the blend is between 30 and 50 weight percent; and the proportion of SPES in the blend is between 50 and 70 weight percent.

Owner:ENN SCI & TECH DEV

Peptide type tree-shaped macromolecule self-assembly body as well as preparation method and application thereof

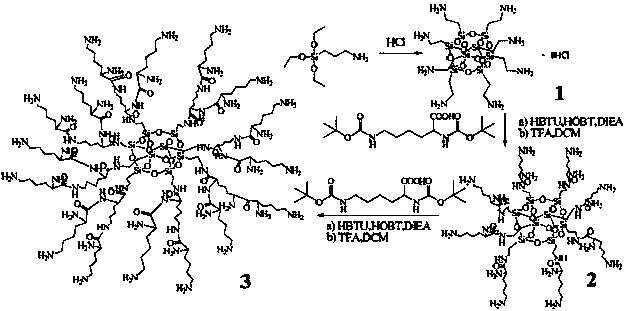

InactiveCN103554923AExcellent mechanical strengthExcellent functionalityFlow propertiesOther foreign material introduction processesCovalent bindingPeptide

The invention discloses a peptide type tree-shaped macromolecule self-assembly body, provides a policy of driving peptide type tree-shaped macromolecules to self assemble and constructs a type of new peptide type tree-shaped macromolecule self-assembly bodies. By utilizing the weak interaction, one movable hydrophilic-lyophobic segment is guided into the periphery of a peptide type tree-shaped macromolecule, the hydrophilic-lyophobic segment and the peptide type tree-shaped macromolecule form a two-hydrophily assembly unit without covalent binding in a cosolvent, and the formation of a self-assembly system of the peptide type tree-shaped macromolecule can be further guided. The peptide type tree-shaped macromolecule self-assembly body disclosed by the invention has excellent stability, mechanical strength and functionality, exact molecular structure and abundant surface functional groups, further has the biological characteristics of excellent biocompatibility, a proteoid structure, easiness in endocytosis of cells and the like, and has the wide application prospect in the biological material field.

Owner:SICHUAN UNIV

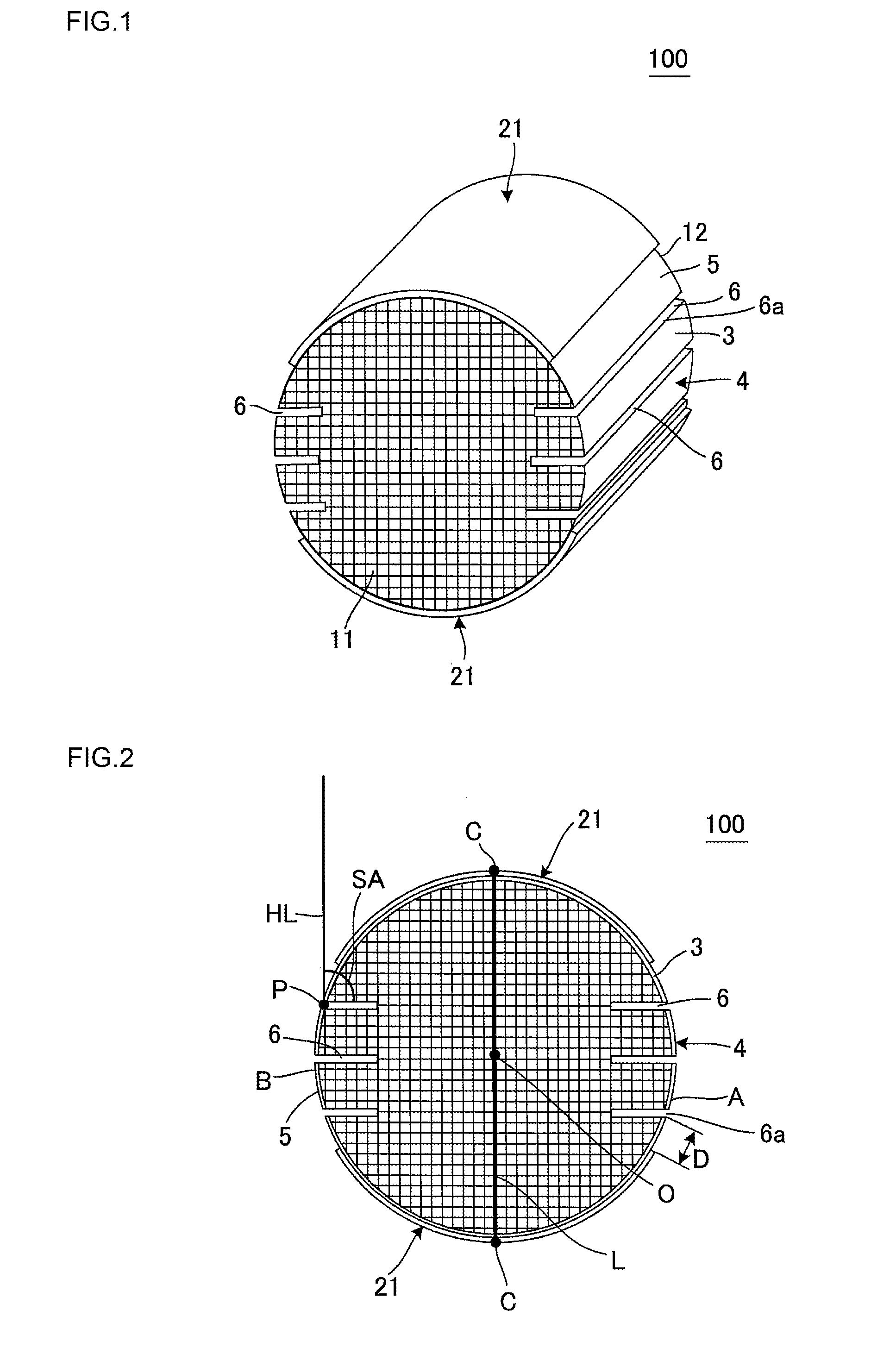

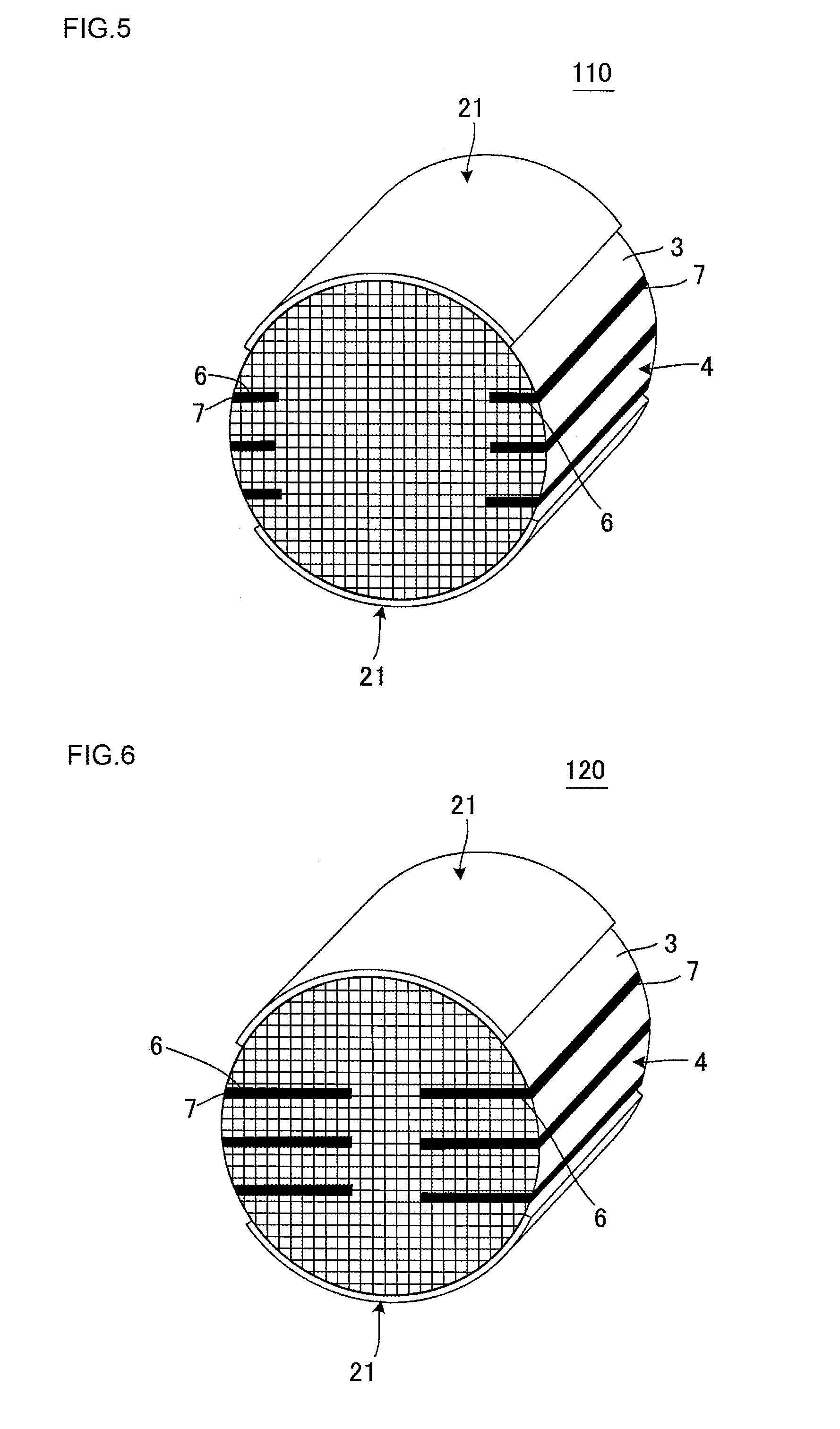

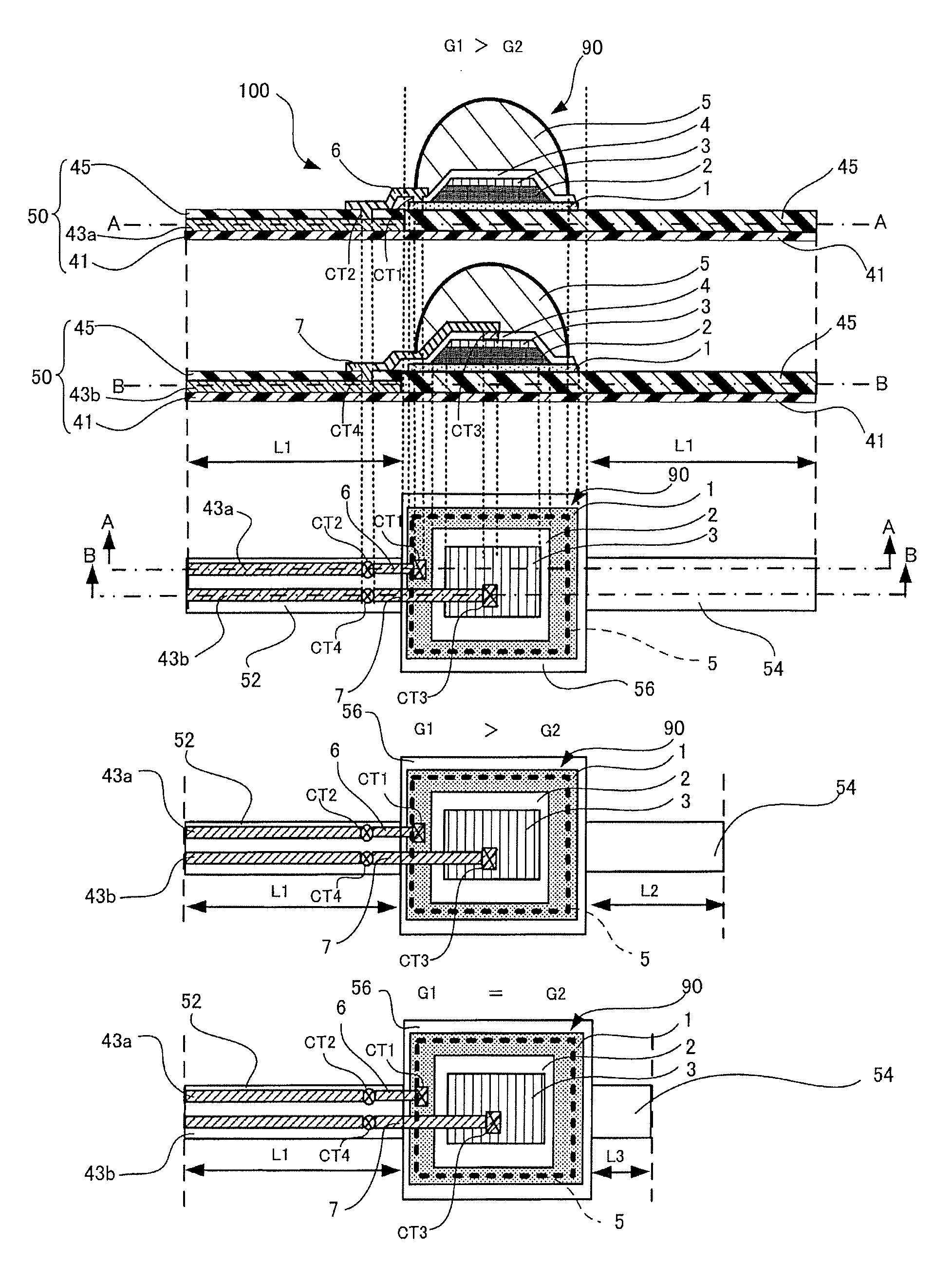

Honeycomb structure

ActiveUS20150030510A1Excellent thermal shock resistanceExcellent mechanical strengthCombination devicesPhysical/chemical process catalystsHoneycomb structureEngineering

A honeycomb structure of the present invention includes a honeycomb structure body and a pair of electrode member arranged at a side surface of the honeycomb structure body. The honeycomb structure body has an electrical resistivity of 1 to 200 Ωcm, and the respective pair of electrode members is formed into a band-like shape extending in a direction in which the cells extend. In a cross section perpendicular to the cell extending direction, one of the electrode members is arranged opposite to another of the electrode members sandwiching a center of the honeycomb structure body. One or more of slits, which being open to a side surface, are formed at the honeycomb structure body. At least the one slit is formed so as not to intersect with a straight line connecting center portions of the respective pair of electrode members in the cross section perpendicular to the cell extending direction.

Owner:NGK INSULATORS LTD

Scaffold

InactiveUS20090076530A1Excellent mechanical strengthSuitable for cell growthMonocomponent polyethers artificial filamentDiagnosticsProsthesisCell culture media

To provide a scaffold having excellent mechanical strength and cell growth capability and is suitable for use as a cell culture medium or a prosthetic material.The present invention relates to a scaffold composed of an assembly of fibers and having a 3-D structure consisting of two end faces and a side face, wherein(1) the fibers are aligned in a plane direction;(2) the fibers have a diameter of 0.05 to 50 μm;(3) the fibers are essentially composed of a biocompatible polymer; and(4) the scaffold has an apparent density of 95 to 350 kg / m3.

Owner:TEIJIN LTD

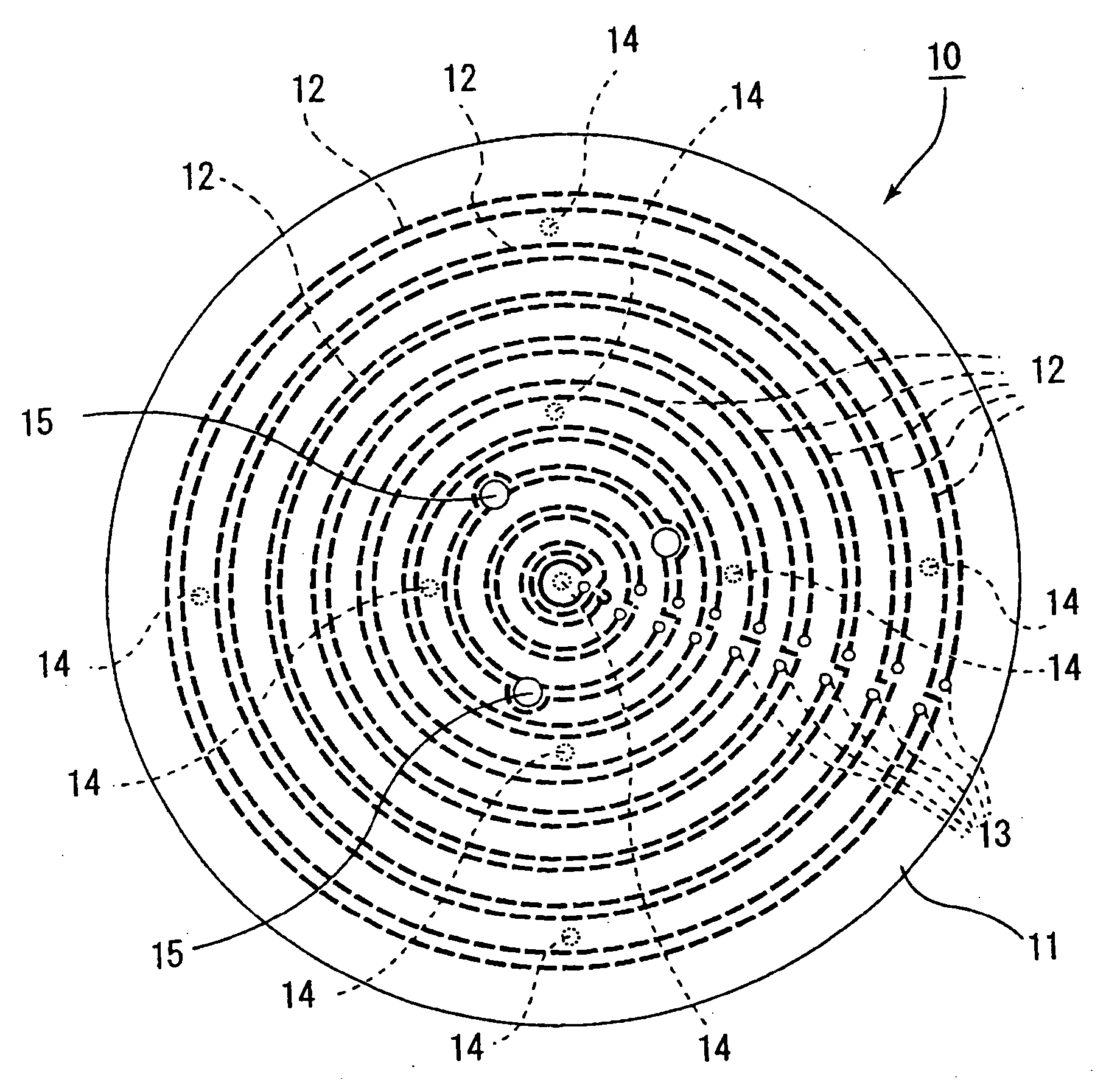

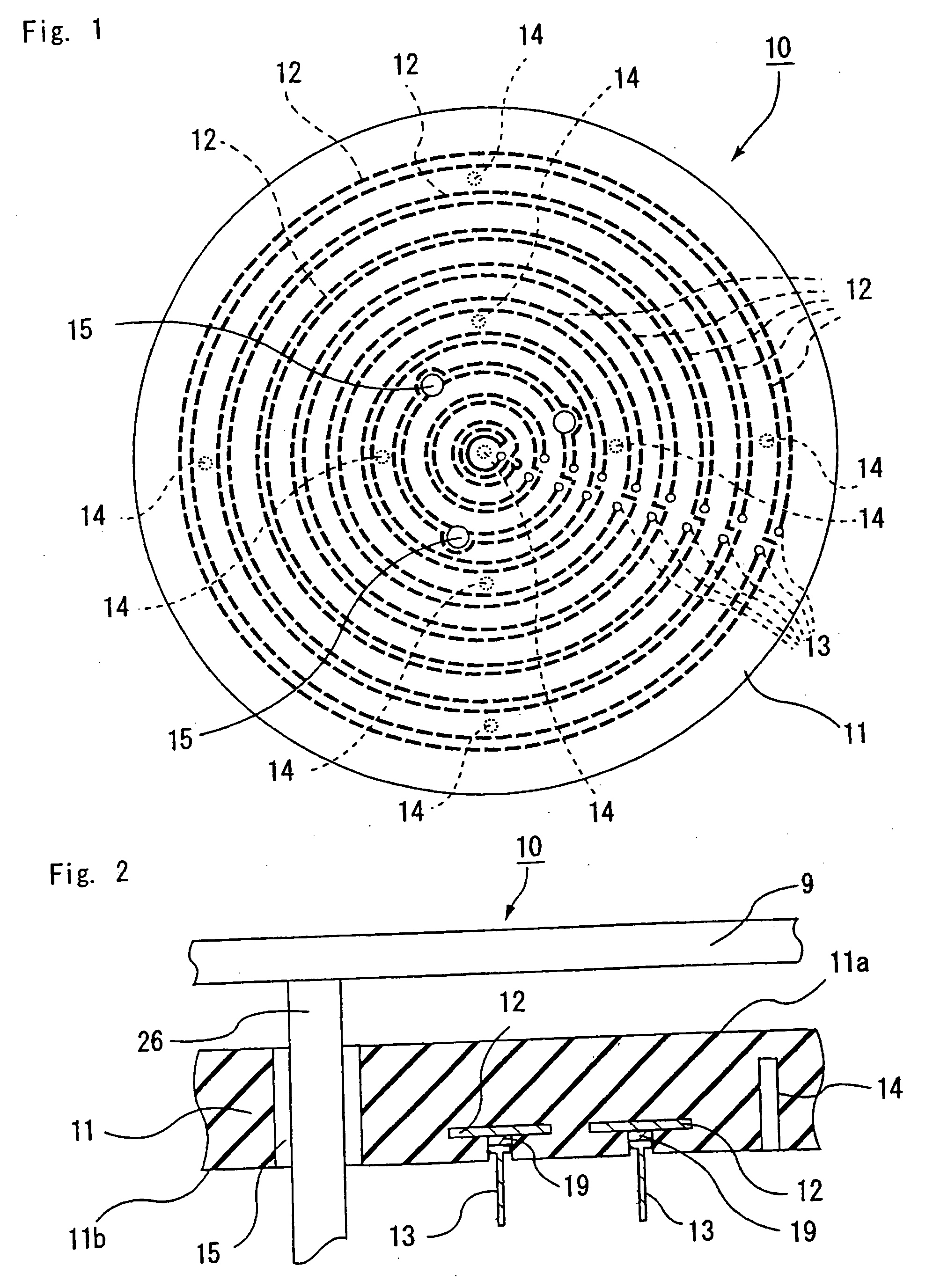

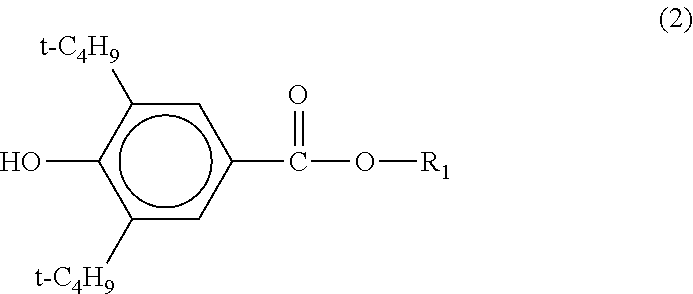

Aluminum nitride sintered body, ceramic substrate, ceramic heater and electrostatic chuck

InactiveUS20050014031A1Excellent mechanical strengthPrevent short-circuitingLamination ancillary operationsSolid-state devicesCeramic particleCeramic heater

The object of the present invention is to provide an aluminum nitride sintered body which has excellent mechanical strength and in which ceramic particles is prevented from coming off from the surface and / or side thereof and generation of free particles is suppressed. The aluminum nitride sintered body of the present invention is wherein it contains sulfur.

Owner:IBIDEN CO LTD

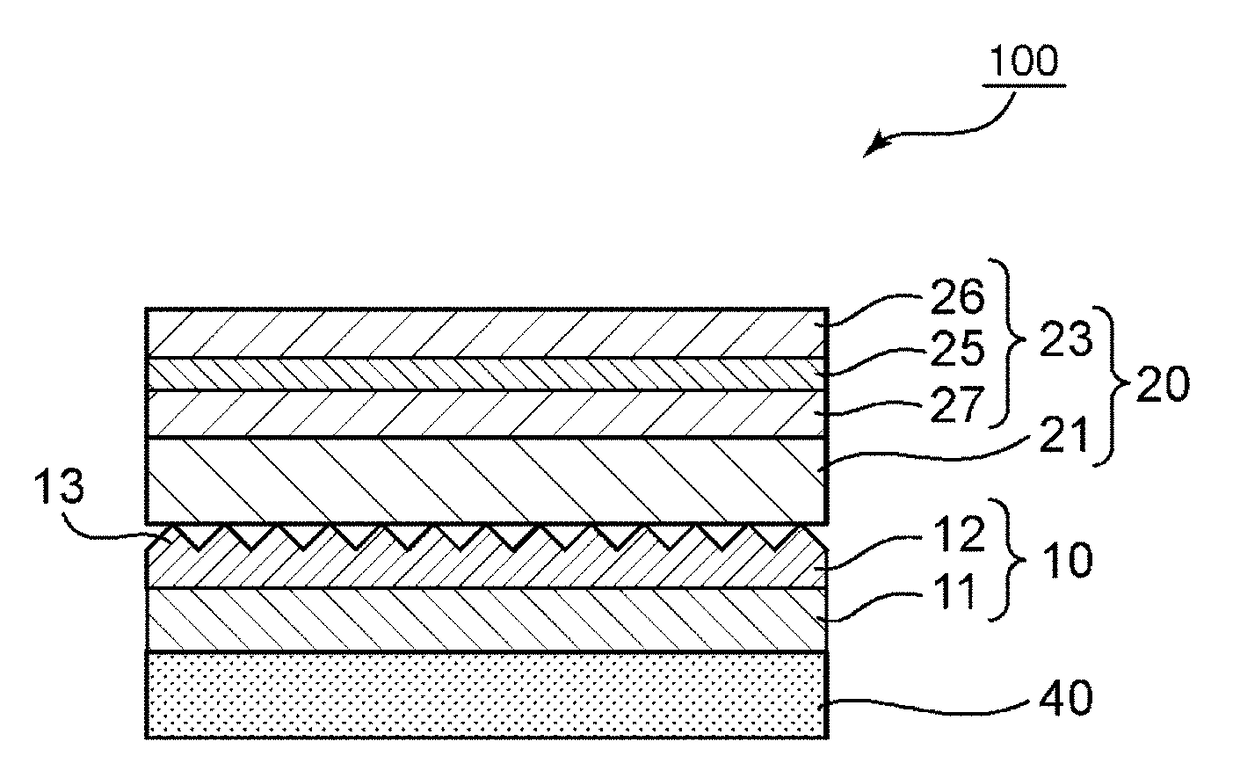

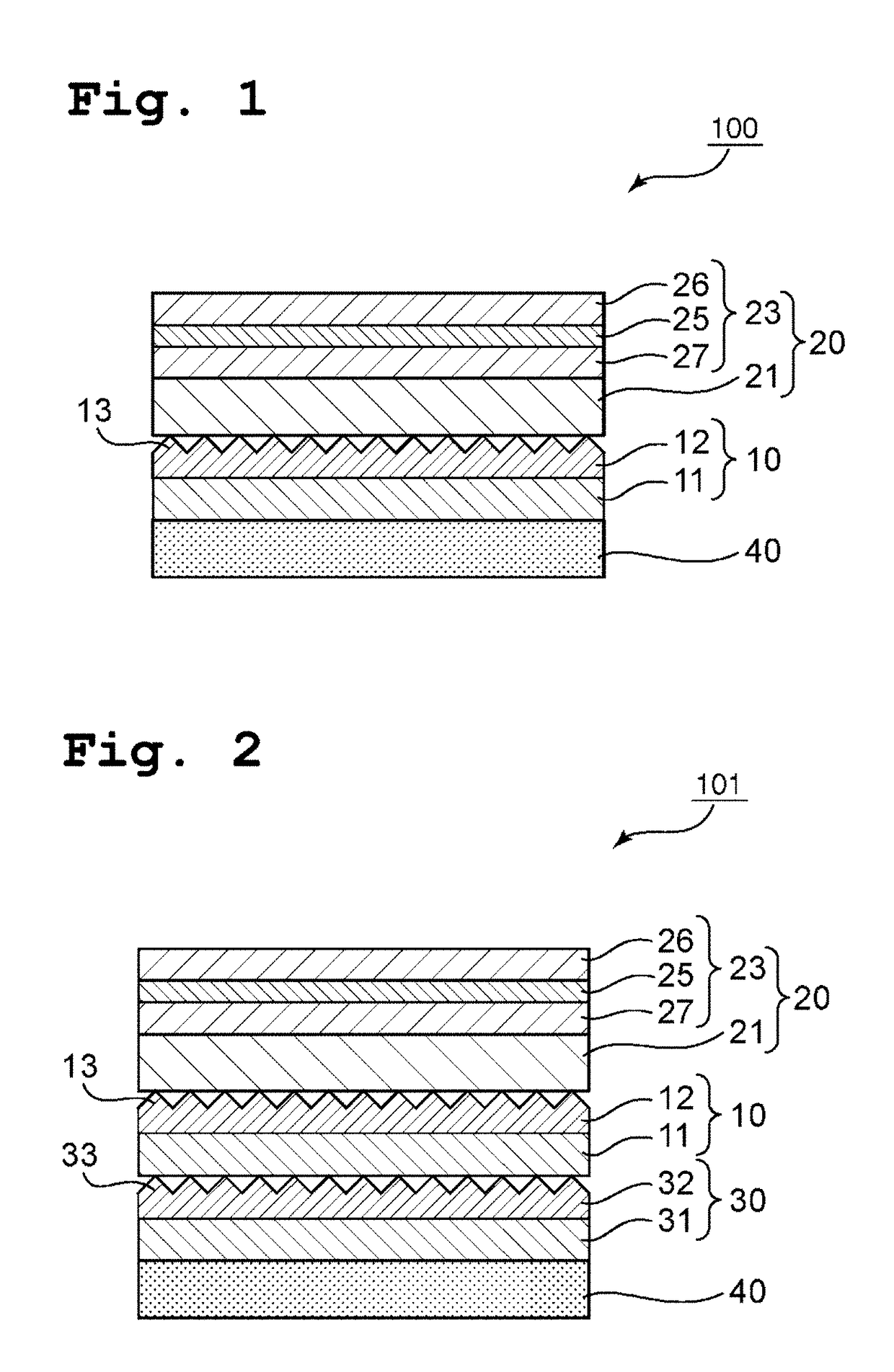

Optical member, and polarizing plate set and liquid crystal display device that use said optical member

ActiveUS20180252968A1Excellent mechanical strengthGood hueMechanical apparatusOptical filtersPolarizerLiquid-crystal display

Provided is an optical member that can achieve a liquid crystal display apparatus that is excellent in mechanical strength, has an excellent hue, and shows little change in hue dependent on a viewing angle. The optical member includes a prism sheet and an optically functional element that are integrated with each other. The prism sheet has: a first main surface, which is flat; and a second main surface, on which a plurality of unit prisms each having a columnar shape convex toward an opposite side to the first main surface are arrayed. Convex portions formed by the plurality of unit prisms on the second main surface of the prism sheet are bonded to one main surface of the optically functional element.

Owner:NITTO DENKO CORP

Method of manufacturing three-dimensional structure, three-dimension formation composition, and three-dimensional structure

InactiveUS20160067917A1Excellent mechanical strengthEfficient preparationAdditive manufacturing apparatusLayered productsSolventIsocyanate

There is provided a method of manufacturing a three-dimensional structure, in which the three-dimensional structure is manufactured by laminating a layer, the method including: forming the layer using a three-dimension formation composition containing particles having an isocyanate group on a surface thereof, a water-soluble resin having a hydroxyl group, and a water-based solvent; and discharging a curable ink onto the layer.

Owner:SEIKO EPSON CORP

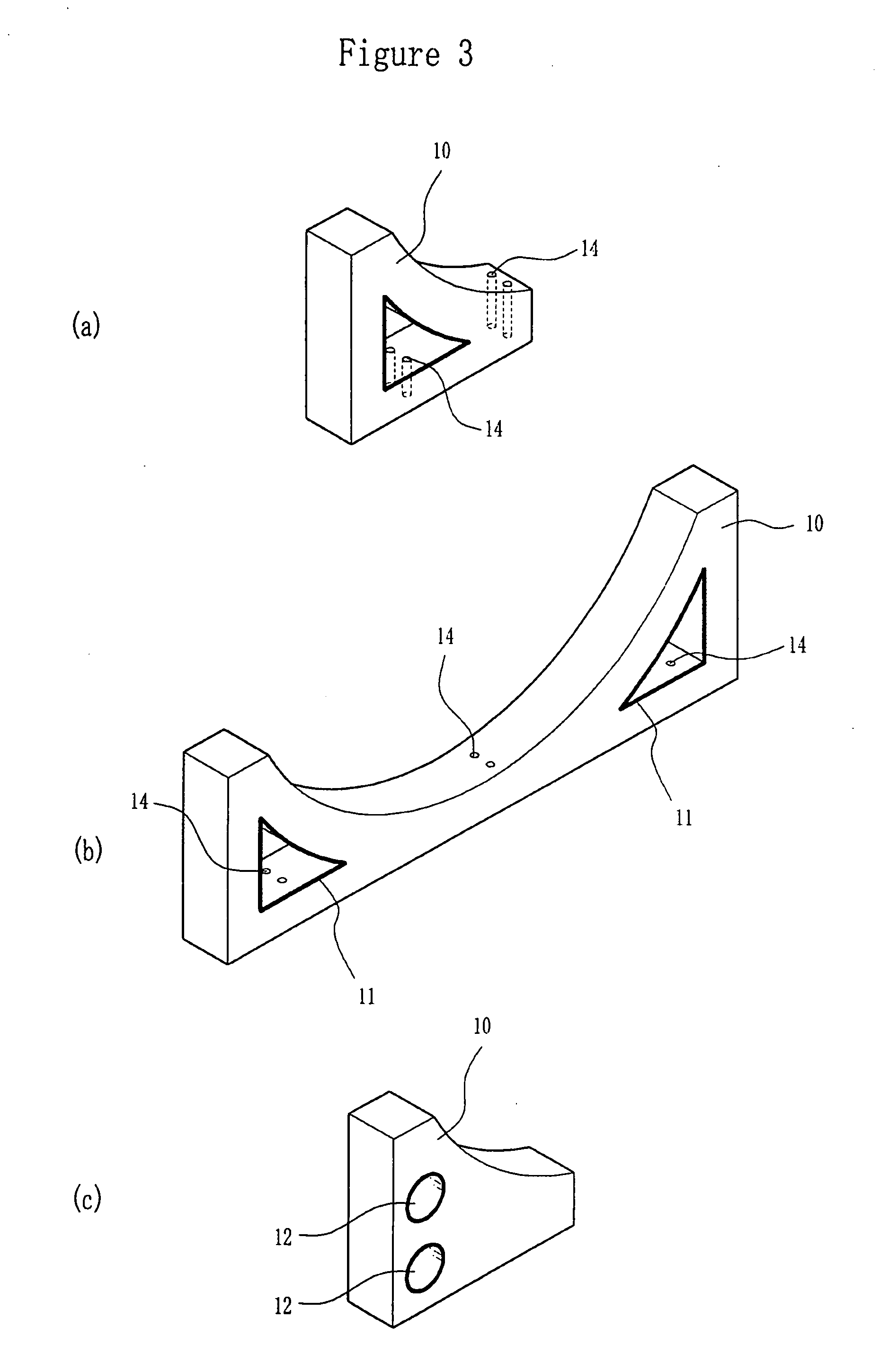

Thermal detector, thermal detector device, and electronic instrument

InactiveUS20110272581A1Small structureExcellent mechanical strengthPhotometryMaterial analysis by optical meansElectricityEngineering

A thermal detector has a substrate, a thermal detector element having a light-absorbing film, and a support member. The support member has a mounting part mounting the thermal detector element, a first arm part having one end that is linked to one end of the mounting part and another end that is supported on the substrate, and a second arm part having one end that is linked to the other end of the mounting part and another end that is supported on the other end of the substrate. A plurality of wirings electrically connected with the thermal detector element are provided on the first arm part, and the length of the second arm part is shorter than the length of the first arm part.

Owner:SEIKO EPSON CORP

A curing composition comprising a polymer having two or more thiol groups per molecule, a compound having two or more isocyanate groups per molecule, carbon black and silicic acid or silicate filler, and/or a pulverized coal filler.

InactiveUS20060167167A1Excellent mechanical strengthOther chemical processesSpecial tyresCarbon blackCompound (substance)

A curing composition contains a polymer having two or more thiol groups per molecule, a compound having two or more isocyanate groups per molecule, and carbon black, and further contains a filler of which main ingredient is silicic acid or a silicate, or contains an organic filler of which main ingredient is pulverized coal. The curing composition has satisfactory storage stability of base compound and satisfactory curability event after storage of the base compound and, furthermore, gives a cured compound having sufficient strength at break, hardness, and gas-barrier properties. The curing composition is hence suitable for use as a sealant for insulating glass manufacture, vehicle window frames, etc.

Owner:TORAY FINE CHEMICALS CO LTD

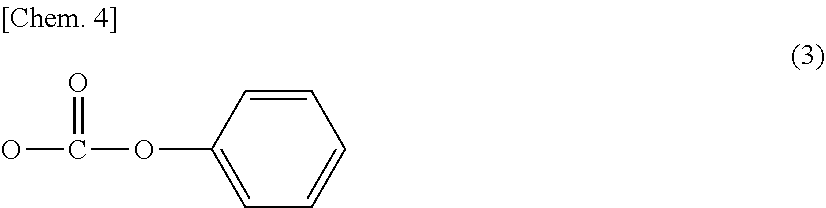

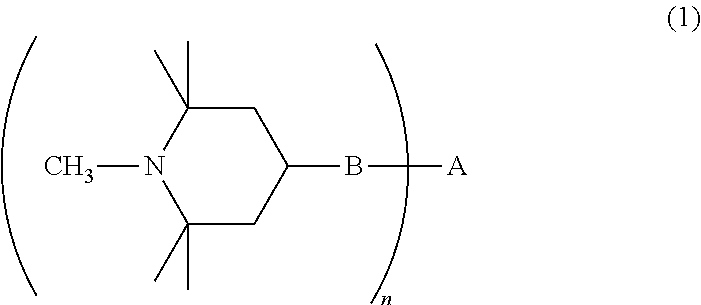

Polycarbonate resin composition and molded article

ActiveUS20130012628A1Excellent mechanical strengthGood light fastnessAluminium compoundsConstruction materialPolycarbonateStructural unit

The invention is to provide a polycarbonate resin composition having excellent light resistance, transparency, hue, heat resistance, thermal stability, and mechanical strength. The invention relates to a polycarbonate resin composition which includes a polycarbonate resin at least containing structural units derived from a dihydroxy compound having the portion represented by the following general formula (1) as part of the structure thereof, the polycarbonate resin composition giving a molded object which has a haze of 12 or less as measured in accordance with a specific manner. (The case where the portion represented by the general formula (1) is part of —CH2—O—H is excluded).[Chem. 1]CH2—O (1)

Owner:MITSUBISHI CHEM CORP

Binder for Separator of Non-Aqueous Electrolyte Battery Comprising 2-Cyanoethyl Group-Containing Polymer and Separator and Battery Using the Same

ActiveUS20120258349A1Sufficient adhesionExcellent mechanical strengthFinal product manufactureSecondary cellsWeight distributionPolymer chemistry

An object of the invention is to provide a binder for a separator which can be comprised by a non-aqueous electrolyte battery with improved heat resistance, a separator comprising the binder, and a non-aqueous electrolyte battery comprising the separator. More specifically, provided are a binder for a separator of a non-aqueous electrolyte battery comprising at least a 2-cyanoethyl group-containing polymer having a molecular weight distribution (Mw / Mn), which is a ratio of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn), of 6 or less, the weight-average molecular weight (Mw) of 50,000 to 1,000,000, and 30% by weight or less of a low molecular weight portion having a molecular weight of 30,000 or less.

Owner:MATSUGAKI CHEM IND +1

Metal conduit inserted monomer cast nylon support block producing method and monomer cast nylon support block producing thereof

PendingUS20090226275A1Excellent mechanical strengthLarge sizeLoad securingWagons/vansEngineeringMechanical engineering

A detachable nylon elastomer support block is disclosed, which can be easily attached to a transportation vehicle like a transportation trailer, and in particular to a metal conduit-inserted nylon elastomer support block and its manufacturing method which are able to tolerate a large impact and a low temperature.

Owner:SNM +1

Long-fiber reinforced resin composition and molded object thereof

InactiveUS20120065306A1Excellent dispersibilityExcellent mechanical strengthPlastic/resin/waxes insulatorsPolymer chemistryFiber

A long fiber-reinforced resin composition including components (A), (B), and (C), the composition including 50 to 90 wt % of the component (A) and 10 to 50 wt % of the component (B) based on the total content of the components (A) and (B), the component (A) having a content of reinforcing fibers of 20 to 60 wt % based on the total content of the components (A) and (B).

Owner:PRIME POLYMER CO LTD

Room-temperature-cured epoxy resin cast cushion block and preparation method thereof

InactiveCN102372464ASolve the problem of inconvenient constructionSolve sticky surfaceEpoxyToughening

The invention belongs to a filling material used for fixing equipments, and especially relates to a room-temperature-cured epoxy resin cast cushion block and a preparation method thereof. According to existing technologies, the fixation of machineries with relatively large weights requires a large amount of bolts, such that the operation is difficult; in an environment with severe corrosion, fixing bolts are likely to be corroded, and the strengths of the bolts are reduced. The a room-temperature-cured epoxy resin cast cushion block provided by the invention is composed of, by weight: 100 parts of epoxy resin, 0 to 20 parts of a toughening agent, 0 to 3 parts of a diluent, 50 to 100 parts of active silicon micro-powder, 5 to 25 parts of an active crystal whisker material, 0 to 3 parts of titanium dioxide, 0 to 3 parts of a pigment, 0 to 1 part of an antifoaming agent, and 5 to 15 parts of a curing agent. The invention is advantaged in that: the surface properties of the product provided by the invention are stable, the product is not easy to contract, and the service life of the product is long. The cushion block can be cured under room temperature, such that the preparation method is simple. With the cushion block, the equipment can be firmly fixed, and requirements under vessel rocking and corrosion conditions can be satisfied.

Owner:SHANGHAI TITANOS IND

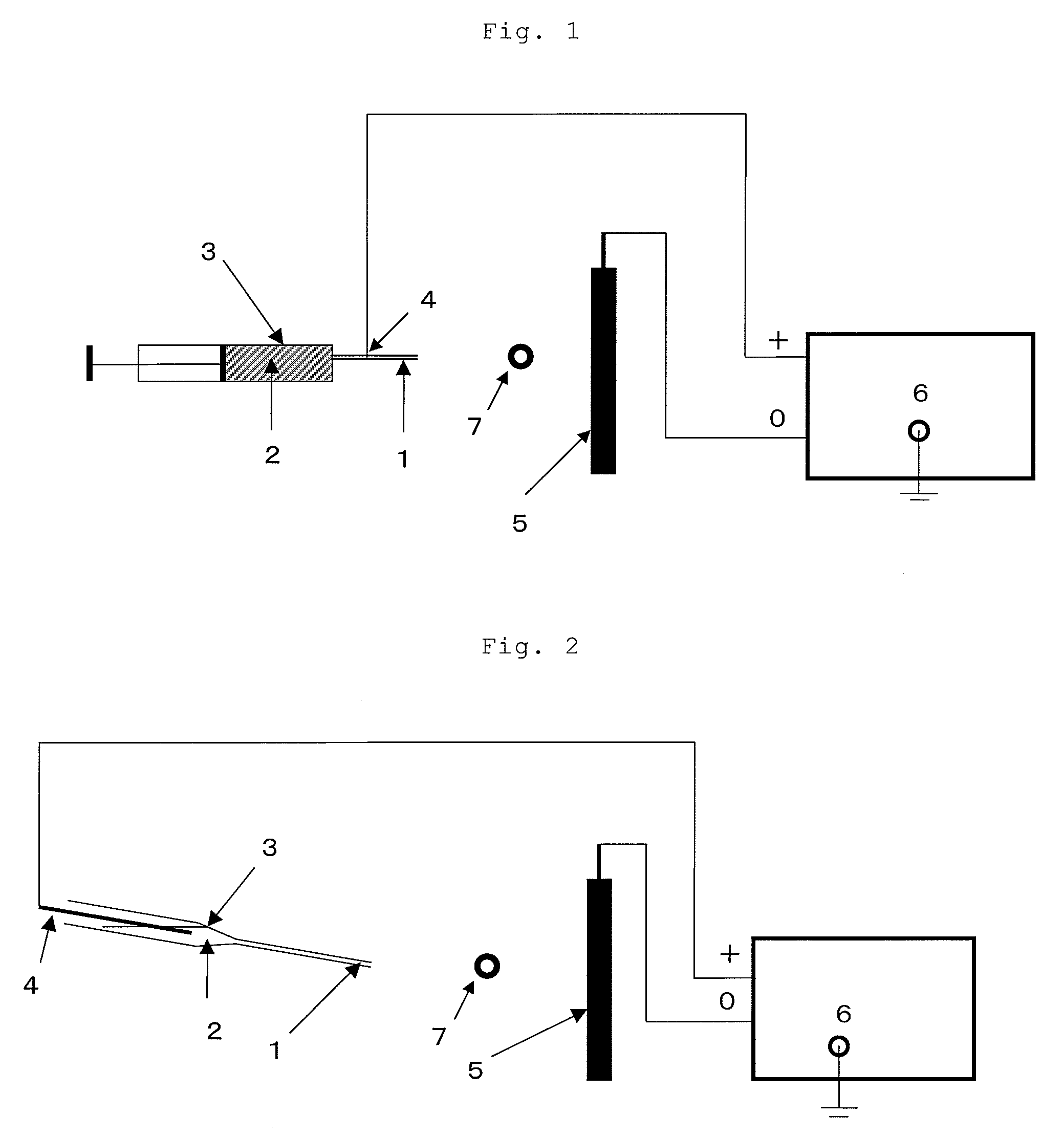

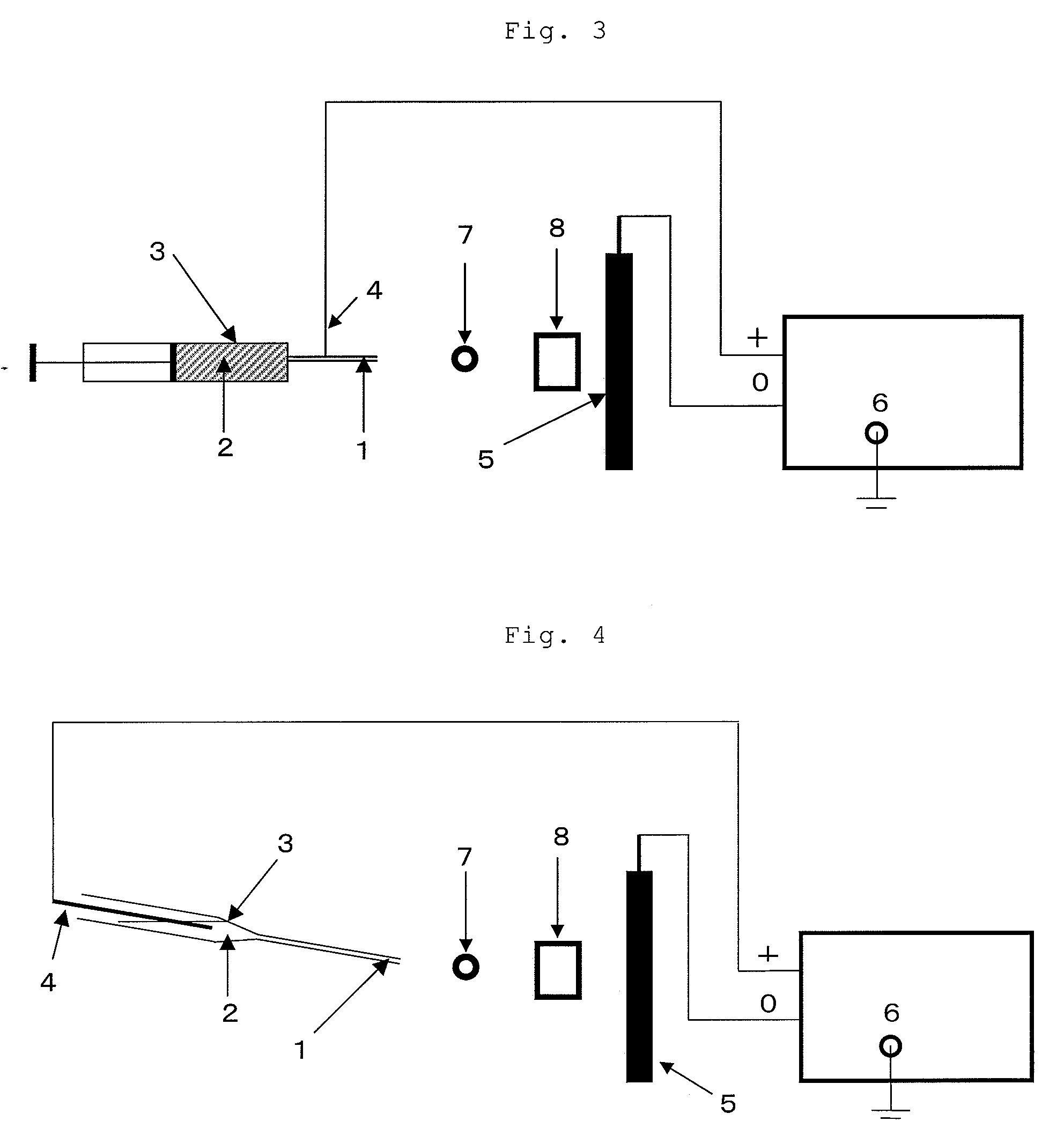

Method for fabricating thin layer device

InactiveUS20070128829A1Excellent mechanical strengthMaterial efficiencySemiconductor/solid-state device manufacturingSuperconductor devicesThin layerWaveguide

A method for producing a thin layer device such as a superconductive device excellent in mechanical strength and useful as a submillimeter band receiver is provided. The thin layer device is produced by forming a multilayer structure substance comprising an NbN / MgO / NbN-SIS junction on an MgO temporary substrate, then forming SiO2, as a substrate, on said multilayer structure substance, and subsequently removing the MgO temporary substrate by etching. A superconductive device (a thin layer device) produced by a method of the present invention has excellent performance and high mechanical strength, and therefore introduction to a waveguide for a submillimeter band is also easy.

Owner:NAT INST OF INFORMATION & COMM TECH

Method adopting temperature inductivity characteristic of phase-change high polymer material to prepare biodegradable particles

InactiveCN103073733AExcellent mechanical strengthSolvent volume minimizedSurgeryOrganosolvHigh polymer

The invention discloses a method adopting the temperature inductivity characteristic of phase-change high polymer material to prepare biodegradable particles, which includes the following steps: S1, dissolving biodegradable high polymer material in an organic solvent, dissolving a second copolymer in PBS, and forming emulsifying solution through ultrasonic emulsification after the solutions are mixed; S2, dissolving a first copolymer in water, and adding the emulsifying solution; S3, transferring the mixed liquid to a thermostatic bath, stirring, and vacuumizing at the arranged temperature of 30-40 DEG C; S4, adding ultrapure water at the set temperature of 4-15 DEG C; S5, cleaning particles, and performing freeze drying; and S6, sterilizing. The invention has the benefits that the solvent quantity is minimum, the product stability and safety can be further guaranteed; the operation is simple, and particle volume production can be realized more easily; and the prepared product has the characteristics of biocompatibility, biodegradability, porosity and the like, the mechanical strength of particles is excellent, and the sizes of particles are adjustable.

Owner:嘉兴天源药业有限公司

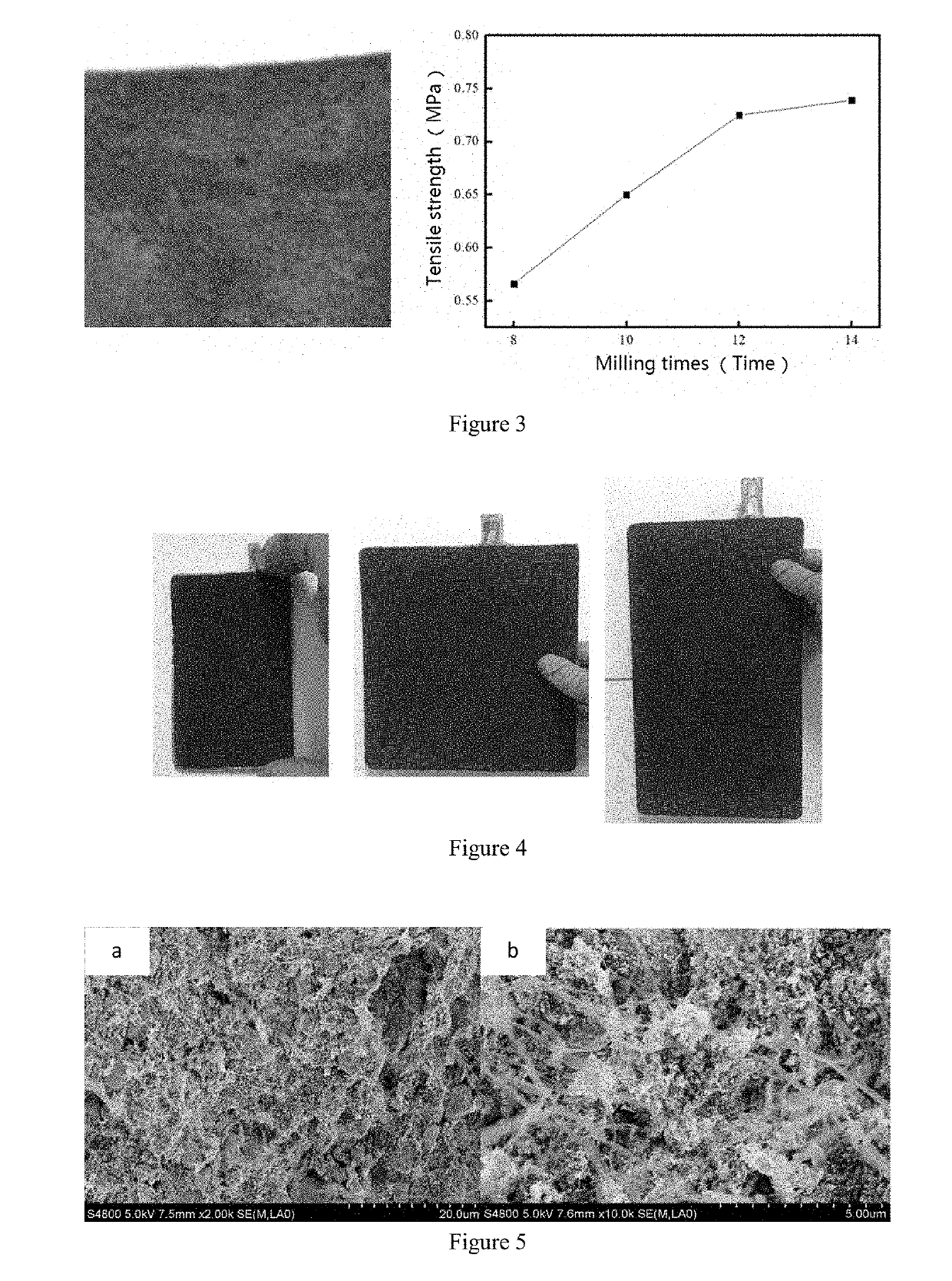

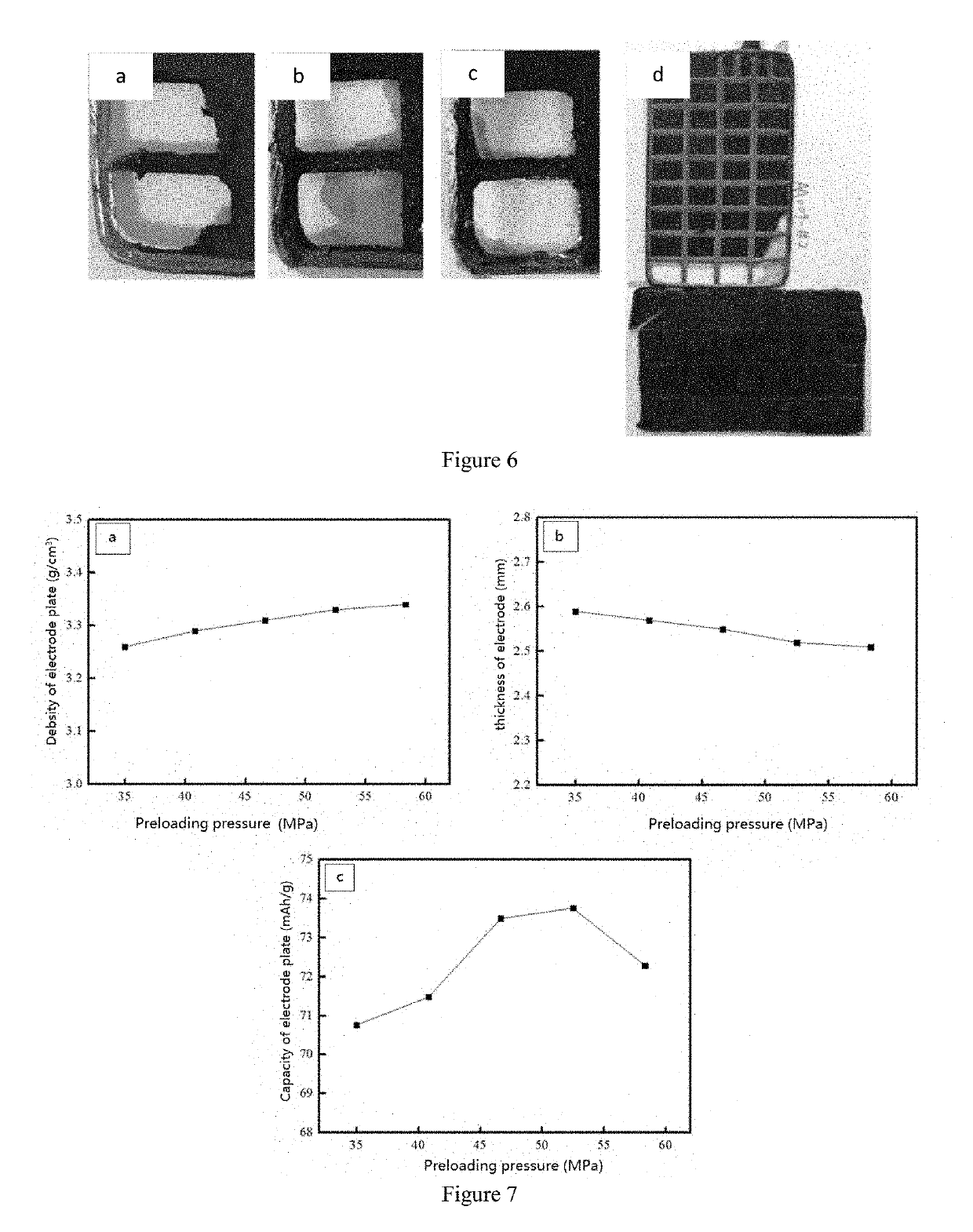

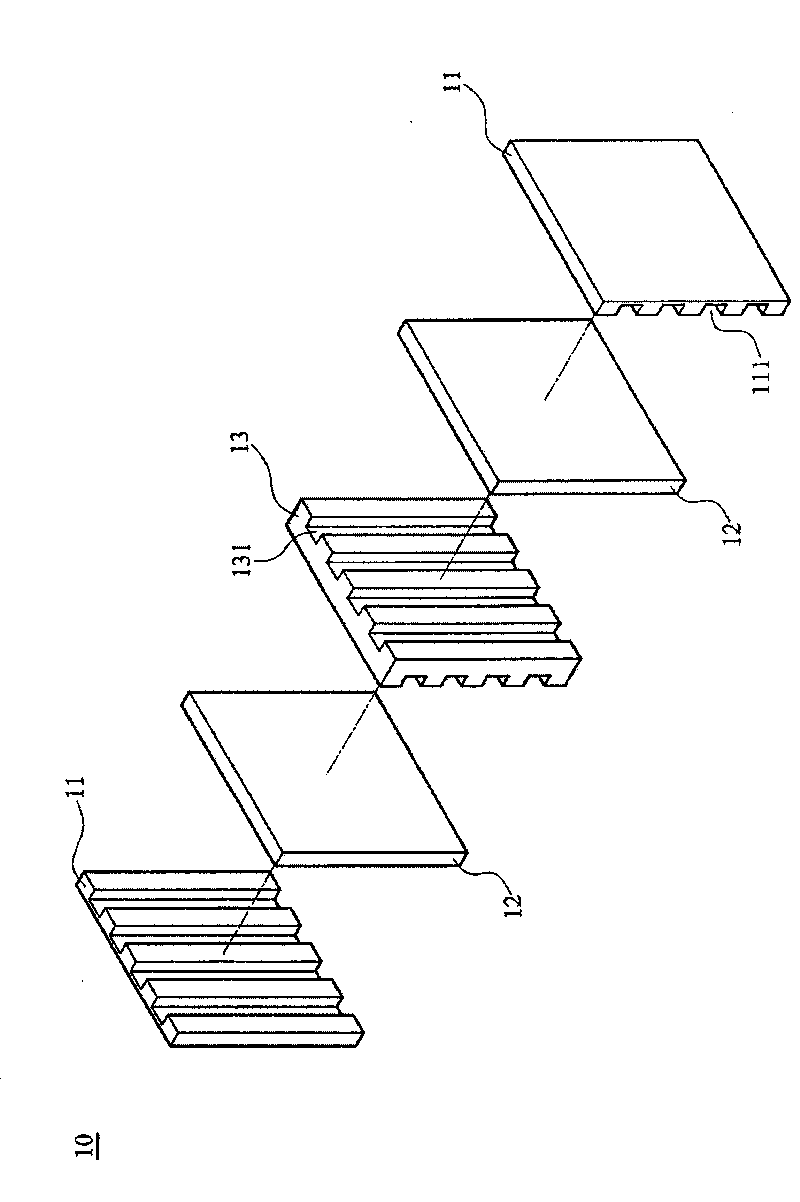

Battery electrode plate preparation method

ActiveUS20190326583A1High conductivity and capacity and active material loadingExcellent mechanical strengthElectrode thermal treatmentHybrid capacitor electrodesLithium electrodeBattery electrode

A new type of battery electrode plate preparation method is described. The method can include the following steps: a) a mixing process; b) a milling and polishing process; c) an extrusion shearing and extending process; d) cutting to obtain an electrode membrane; and e) pressing at a high temperature and a high pressure to obtain a battery electrode plate. The method can adopt the active material of different electrochemical batteries as the main body to prepare a thick type battery electrode plate with a high conductivity, a high capacity and a high active material loading, which has a viscoelastic body. The electrode plate can have a flexible organic network structure and an excellent mechanical strength, and can still exist in a variety of electrolytes after hundreds of times or even thousands of times of deep charge and discharge cycles. The thick electrode plate prepared by using the method can be applied to a variety of batteries such as lead-acid battery positive and negative electrode plates, a lead carbon battery electrode plate, a lithium ion battery electrode plate, a supercapacitor electrode plate, a Ni-MH battery electrode plate, and others.

Owner:NANTONG VOLTA MATERIALS LTD

Bonding agent and membrane electrode group thereof

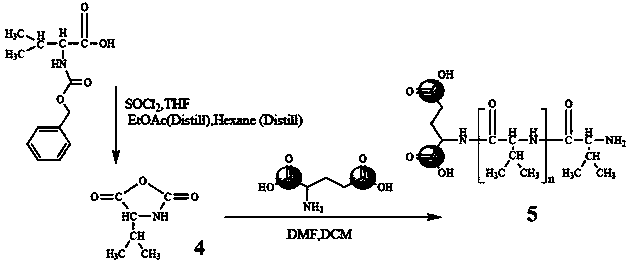

ActiveCN101752566AHigh tensile strengthExcellent water fixation coefficientCell electrodesBiochemical fuel cellsPolymer substratePolymer chemistry

The present invention provides a bonding agent used by a membrane electrode group. The bonding agent comprises a solvent system, a hyperbranched polymer and an organic polymer capable of conducting ions, wherein the branching degree of the hyperbranched polymer is bigger than 0.5, and the hyperbranched polymer and the organic polymer capable of conducting ions are dispersed in the solvent system.

Owner:IND TECH RES INST

Porous film, separator including the same, electrochemical device including the porous film, and method of preparing the porous film

InactiveUS20180145299A1Excellent mechanical strengthHigh mechanical strengthHybrid capacitor separatorsLi-accumulatorsNanometreCellulose

Provided are a porous film, a separator including the porous film, an electrochemical device including the porous film, and a method of preparing the porous film. The porous film includes an aqueous resin of a single film having an elongation at break of about 50% or greater; and cellulose nanofibers, wherein an elongation at break of the porous film is about 3% or greater.

Owner:SAMSUNG ELECTRONICS CO LTD

Film, film forming composition and electronic device having the film

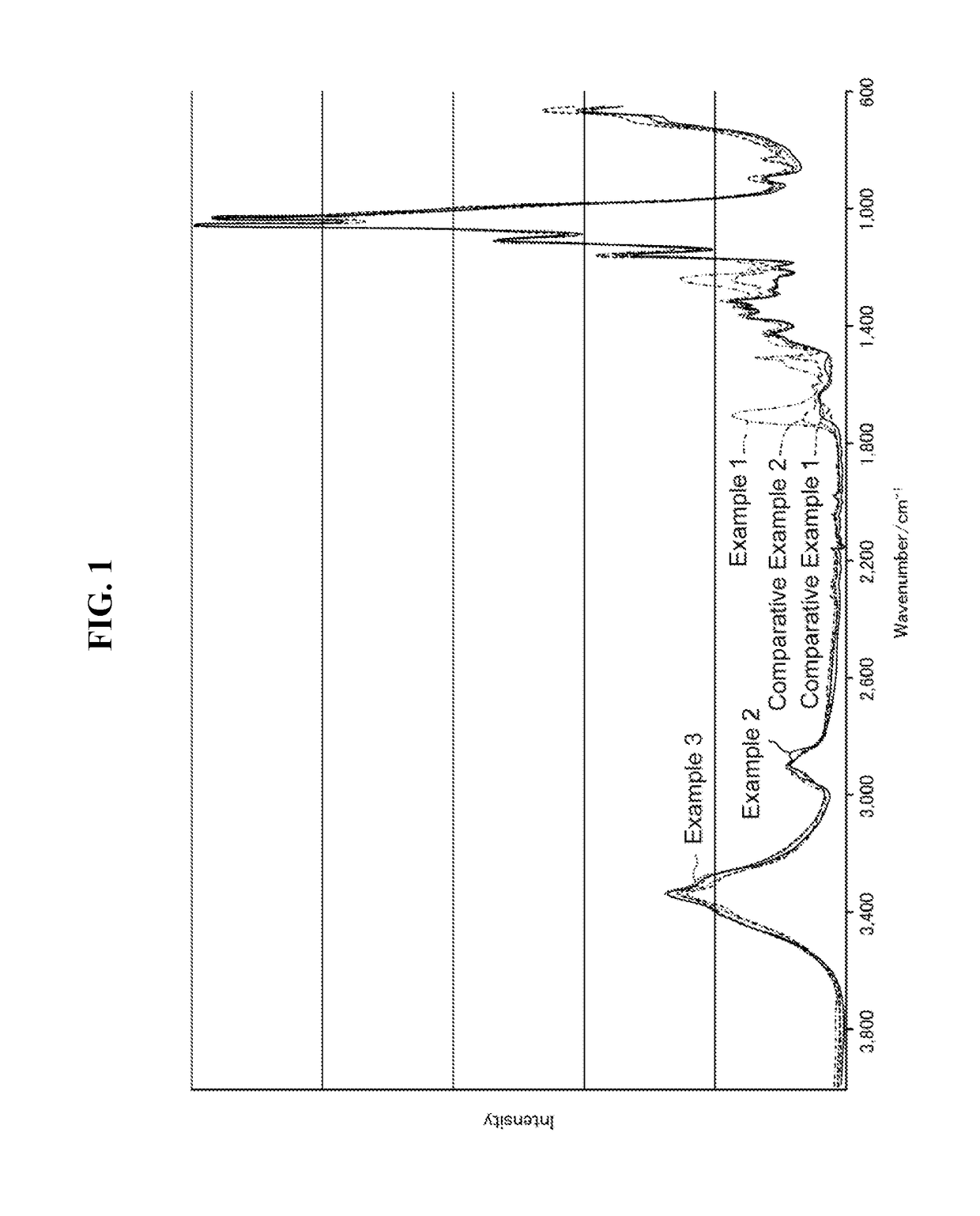

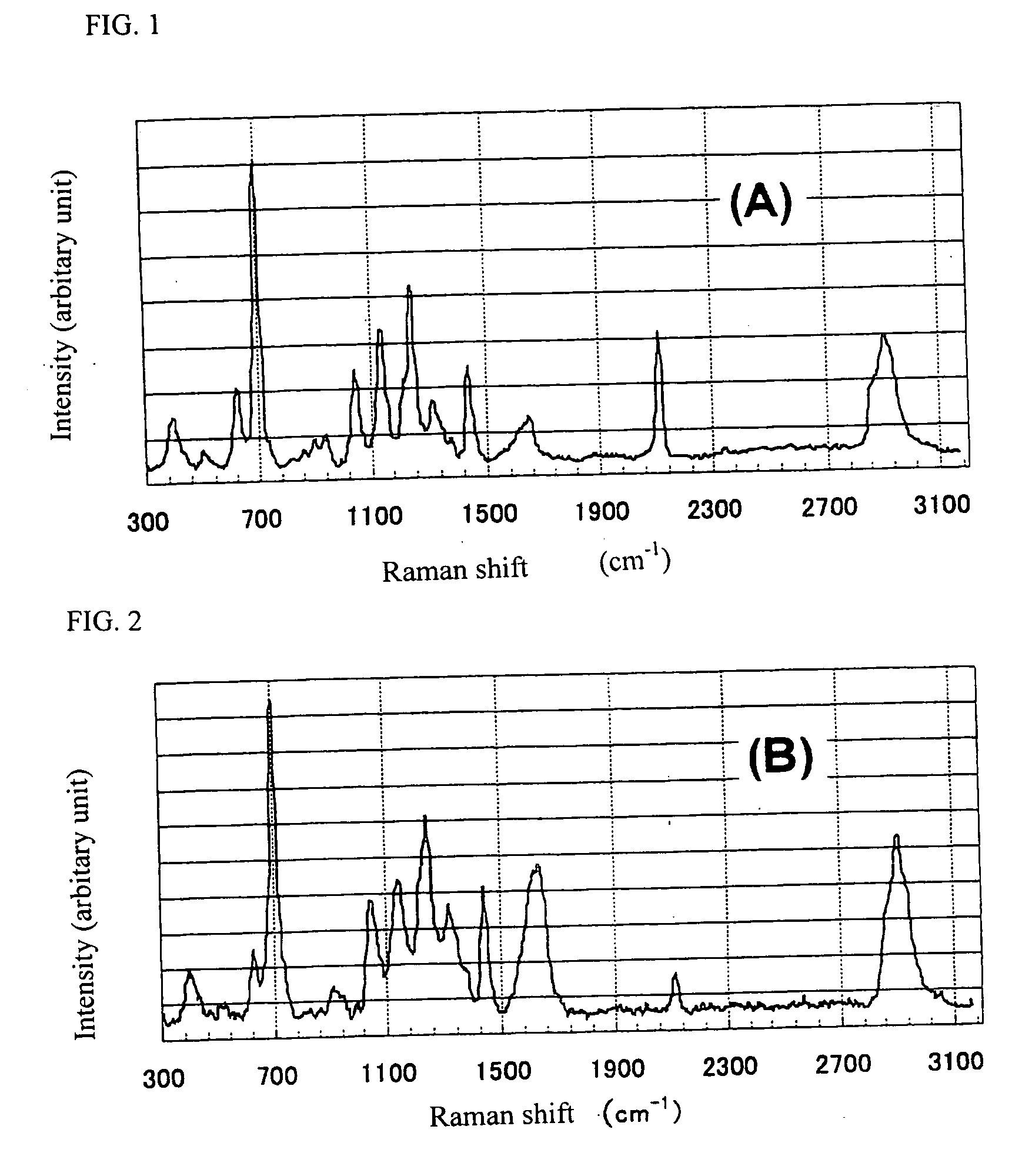

InactiveUS20070135603A1Excellent heat resistanceExcellent mechanical strengthRaman spectroscopyEngineering

A film having, as a result of raman spectroscopy, the highest intensity peak within from 690 to 800 cm−1 in a Raman shift range of from 300 to 3100 cm−1; a film forming composition capable of forming, the film; and an electronic device having the film.

Owner:FUJIFILM CORP

Impact hardening material and preparation method thereof

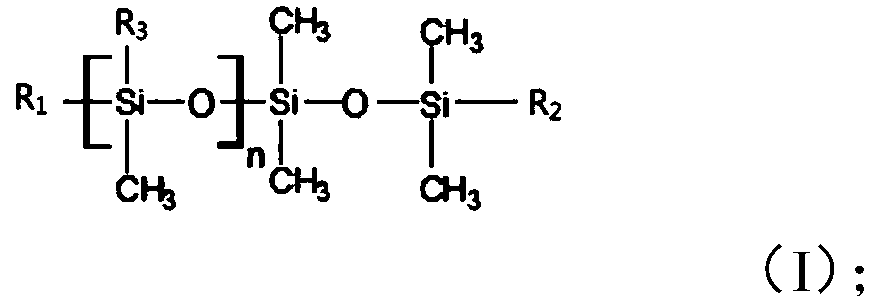

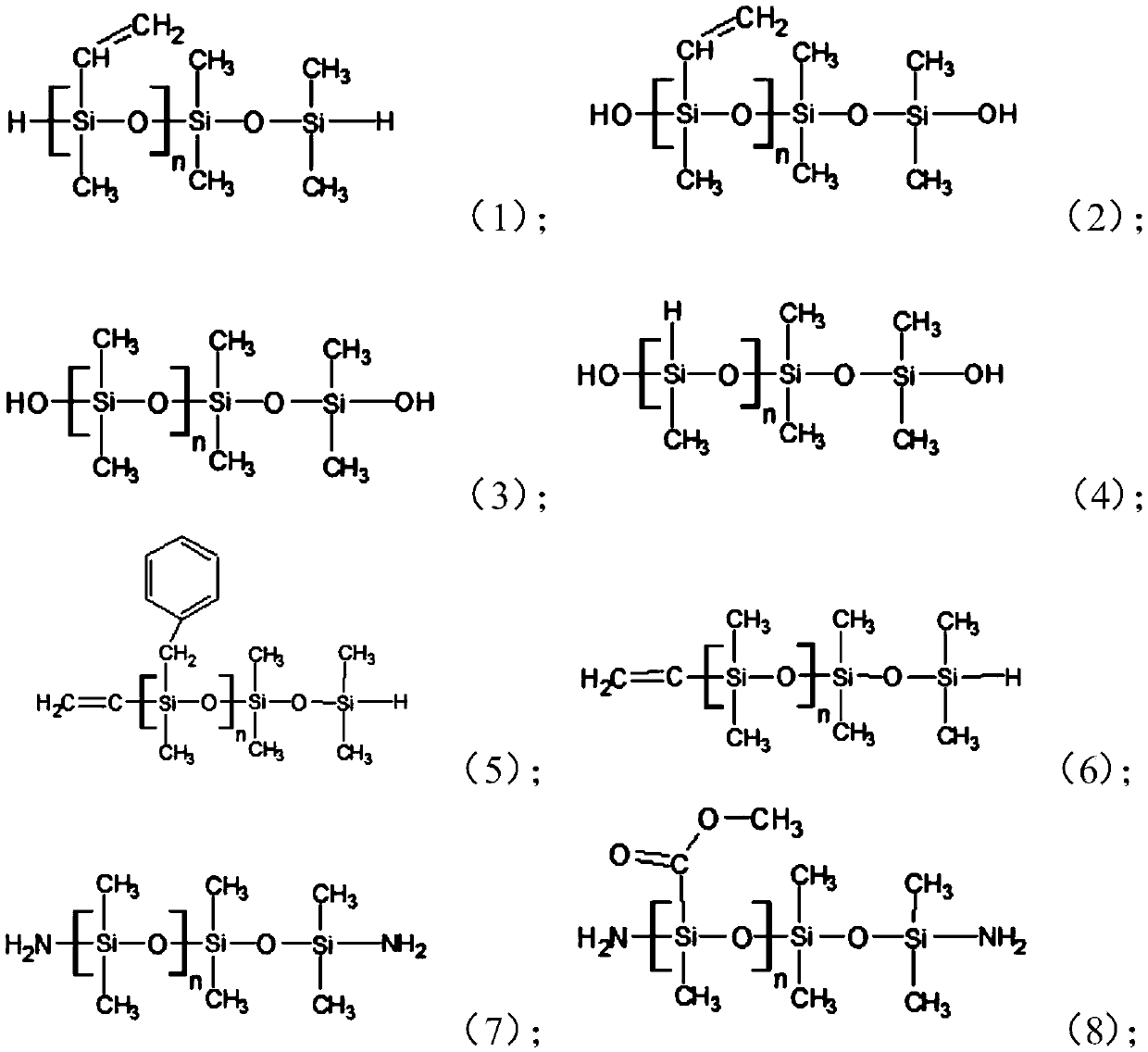

The invention takes main chain oligomer with a structure shown by formula (I), a chain extender and a boron-containing compound for mixing and reacting to obtain a first heavy polymer system. The invention also takes a branch chain oligomer with a structure shown by formula (II); the branch chain oligomer reacts with a chemical cross-linking agent to obtain a branched and cross-linked structure, forming a second heavy network. According to the impact hardening material and the preparation method thereof disclosed by the invention, the first heavy polymer system provides a stress response characteristic; then the second heavy cross-linked network is introduced to give the material dimensional stability and relatively good mechanical property. A catalyst plays a role of enabling a group reaction between the branched polymer chain added in the second step of reaction and the cross-linking agent, so as to obtain a constant cross-linked structure. The interpenetrating structure can improvethe elasticity modulus and dimensional stability of the material. Therefore, the prepared impact hardening material has relatively high self-stability and mechanical strength as well as relatively good impact hardening performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Rubber plate used for table facet of lifting machine

InactiveCN103360649AExcellent mechanical strengthIncrease frictionButadiene-styrene rubberPolymer chemistry

The invention discloses a rubber plate used for a table facet of a lifting machine. The rubber plate comprises the following ingredients, by weight, 70-90 parts of styrene butadiene rubber, 30-50 parts of cis-polybutadiene rubber, 2-4 parts of zinc oxide, 1-2 parts of sulphur, 1-2 parts of stearic acid, 0.5-1.5 parts of accelerants, 50-60 parts of carbon black, 0.15-0.25 part of anti-aging agents, 2.5-3.5 parts of paraffin and 5-8 parts of aromatic oil. The preparation method is as follows: the weighed ingredients are blended to form a mixing rubber at the temperature of 140-160 DEG C; then the mixing rubber is subjected to milling; after milling, the mixing rubber is subjected to piece cutting and forming; the cut rubber pieces are subjected to mold clamping and vulcanization in molds, the mold vulcanization temperature is 145 DEG C, and the mold vulcanization time is 25 min; after vulcanization, the molds are opened, the products are taken out, and the rubber plates are obtained. The obtained rubber plate has excellent wear resistance, shock resistance and mechanical strength.

Owner:太仓成铭液压机械有限公司

Preparation method and application of degradable mulching film coating

ActiveCN110819175ANo need to worry about pollutionNo need to worry about hazardsClimate change adaptationCellulose coatingsFiberPlastic mulch

The invention discloses a preparation method and application of a degradable mulching film coating. The preparation method comprises the following steps: uniformly mixing chitosan with an acetic acidsolution, adding nanocellulose and glycerol, carrying out mixing, performing dispersing, then adding carboxylic butadiene-styrene latex, and carrying out uniform dispersing to obtain a degradable mulching film coating solution. The degradable mulching film coating is wide in raw material source, biodegradable and non-toxic. When applied as a surface coating for a biomass-based mulching film, the coating is harmless to soil and crops, can effectively seal a large number of inter-fiber pores in the surface of a base mulching film, forms a compact network structure on the surface of the mulchingfilm, allows the toughness and the gas barrier property of the mulching film to be greatly improved, prolongs the degradation period of the mulching film, and effectively inhibits the post-growth of weeds in the growth process of rice.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES +1

Automotive tire antiskid device and mounting method thereof

ActiveCN109747352AIncrease production costReduce manufacturing costNon-skid devicesDamping functionHook plate

The invention discloses an automotive tire antiskid device and a mounting method thereof. The automotive tire antiskid device comprises a plurality of rivet unit assemblies and two fixed steel cable assemblies, the rivet unit assemblies are connected end to end to form circles fitting the circumferences of automotive tires, the fixed steel cable assemblies are arranged on the front and rear sidesof the rivet unit assemblies, and are separately hang and fixed to the rivet unit assemblies in a tightening mode; the rivet unit assemblies comprise middle inserted rods, adjusting sleeving rods, left hinged seats, right hinged seats, jointed connecting rods, side hinged seats, hook connecting rods, fixed hook plates and anti-skid rivets; and the fixed steel cable assemblies comprise steel cablebodies, binding blocks, fixed blocks, jacking screws and limiting blocks. The automotive tire antiskid device and the mounting method thereof can be applied to a plurality of types of tires, originalbuffering and damping functions of the tires are not interfered, the operation is simpler and more efficient, accidental snap and falling off can be prevented, and road safety is ensured.

Owner:合肥龙智机电科技有限公司

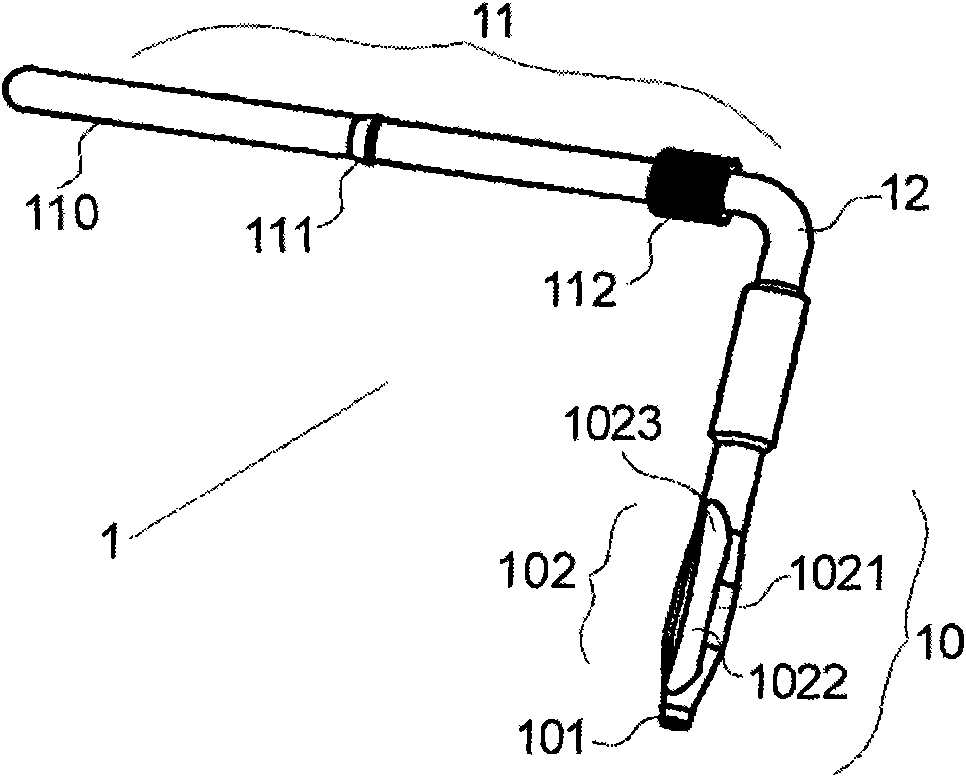

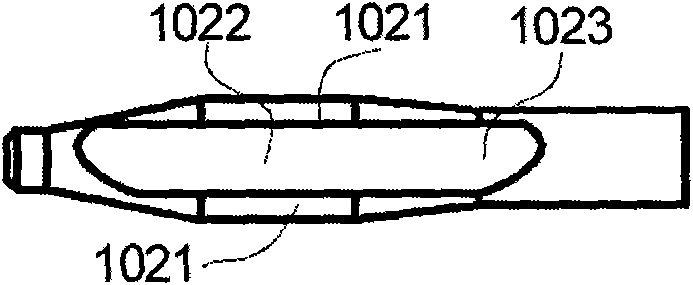

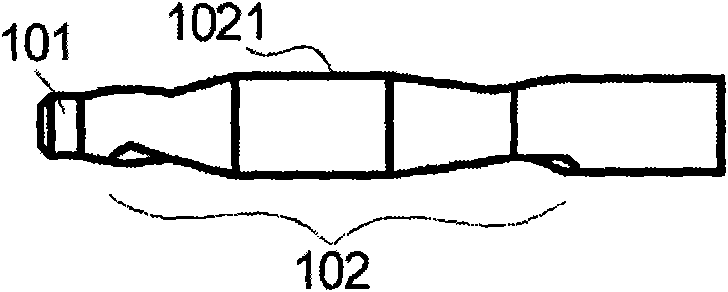

Contact pin terminal for press-fit connection

InactiveCN102055096ASimple structural assemblySimple press-fit actionCoupling contact membersButt jointMachining

The invention discloses a contact pin terminal for press-fit connection, comprising an installation butt-joint part (11) and a press-fit part (10), wherein the press-fit part (10) comprises a guiding part (101) and a holding part (102) matched with a circuit board open pore (3), two sides of the holding part (102) are respectively provided with a groove (1023) extending along the axial direction of the holding part (102), the bottoms of the grooves (1023) incline, a thin-wall type intermediate oblique beam (1022) with gradient is formed between the two grooves (1023) which are symmetrically distributed relative to the intermediate oblique beam (1022), and the two grooves (1023) form four side walls (1021), which can deform along the edge of the circuit board open pore (3) during press fit and are tightly appressed to the inner wall of the open pore (3). The contact pin terminal has a simple structure, is durable, reliable, resistant to shocks and impacts, and convenient and rapid for press fit; and in addition, the contact pin terminal is formed with a machining method and has the advantages of strong current bearing capacity, high mechanical strength, wide adaptation rang, and ideal press-fit force and holding power, and the materials can be selected flexibly.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

Fireproof fiber layer for high-temperature furnace roller

InactiveCN106396698AExcellent fire resistanceExcellent mechanical strengthFiber layerAqueous solution

The invention provides a fireproof fiber layer for a high-temperature furnace roller. The fireproof fiber layer comprises the following components in parts by mass: 55-65 parts of silicate fibers, 13-20 parts of silica aerogel, 4-7 parts of aluminum phosphate gel, 3-5 parts of an acidic aqueous solution of ethyl orthosilicate, and 10-17 parts of an admixture. The fireproof fiber layer has excellent fire resistance and mechanical strength, is suitable in cost and can be used for directly machining the surface of the furnace roller, the fire resistance of the furnace roller is improved, and the service effect and time of the furnace roller are improved.

Owner:江苏优泽科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com