Contact pin terminal for press-fit connection

A pin terminal and butt end technology, applied in the field of pin terminals, can solve the problems of low processing cost, insufficient current carrying capacity and strength, etc., and achieve the effects of simple structure and assembly, great flexibility and breadth, and large contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

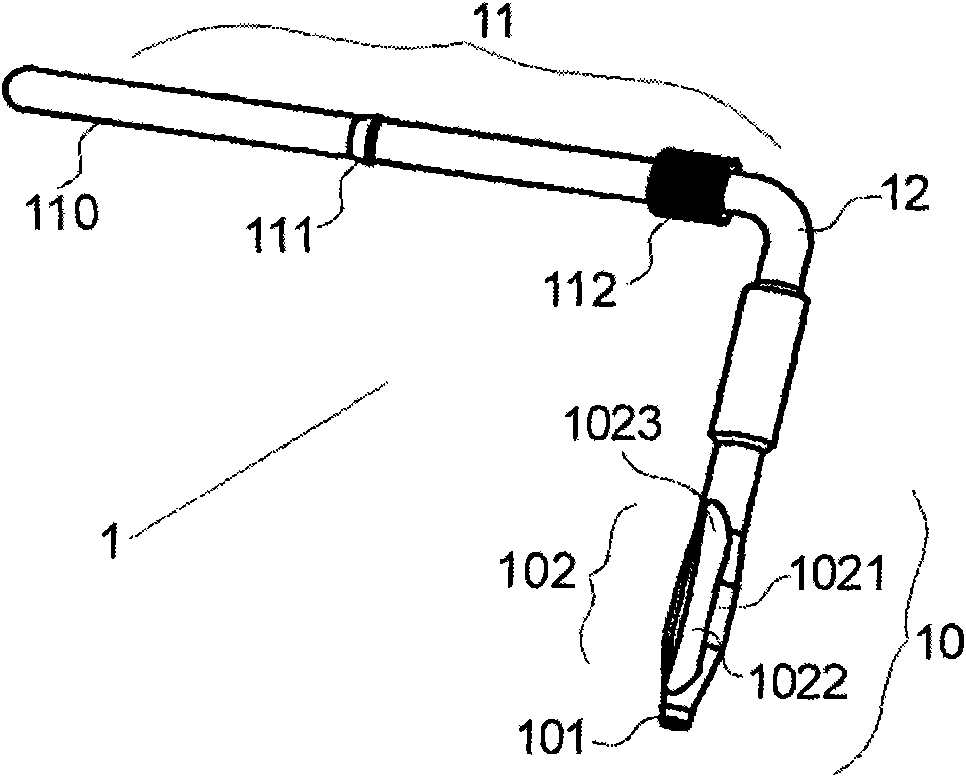

[0023] Example: such as figure 1 As shown, a pin terminal for press-fit connection, which includes a mounting butt joint part 11, a bent connection part 12 and a press-fit part 10 whose tail end is press-fit connected with the circuit board opening 3.

[0024] The installation docking part 11 is provided with a docking end 110 for docking, a barb 111 for fixing the pin terminal 1 in the base, and an anti-rotation structure straight line 112. The tail end press-fitting part 10 includes: a guide part 101, The holding part 102 matched with the hole 3 of the circuit board. The guide part 101 ensures that the holding part 102 can be smoothly pressed into the opening 3 of the circuit board.

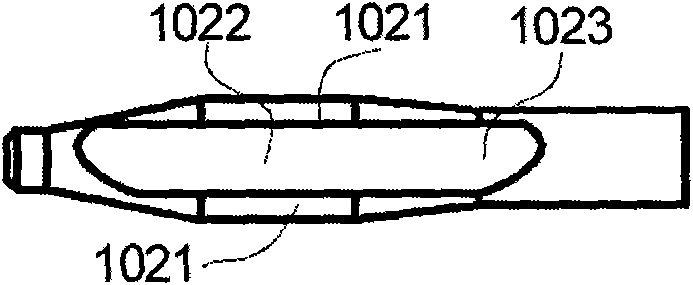

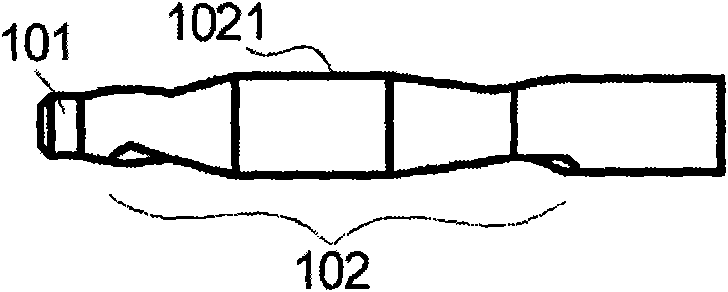

[0025] Such as figure 2 , image 3 , Figure 5 As shown, the holding part 102 includes two grooves 1023 and four sidewalls 1021 extending from the root to the distal end. Between the two grooves is a section of thin wall with a slope, that is, the middle inclined beam 1022 . The middle sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com