Manufacturing method and process device of reactivated cleaning agent for regeneration of honeycomb SCR (selective catalytic reduction) denitration catalyst

A denitrification catalyst and manufacturing method technology, applied in the engineering field of power plant denitrification catalyst regeneration, can solve problems such as potential safety hazards, processing time, secondary pollution, etc., and achieve the effects of saving replacement costs, efficient regeneration, and accelerating cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

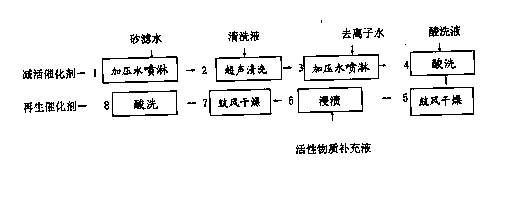

Image

Examples

Embodiment 1

[0034] Take a piece of honeycomb-type integral block catalyst that has been running for more than 15000 hours. The volume is 122.5cm3. The main components of the catalyst are vanadium, titanium, and tungsten. The cross-sectional size of the catalyst is 150mmx150mm. Cut a piece of 40mmx40mmx40mm. Water spray for 10min. Then put it in a constant temperature water bath ultrasonic cleaner, at a cleaning frequency of 32kHz, 10kW / m 2 sound intensity, wash at 40°C for 10 minutes. Then put it into a blast drying oven to dry for 30 minutes, and put the dried catalyst into the cleaning solution. Preparation of cleaning solution: cleaning solution is composed of (NH4) 2SO4 (0.1~10mol / l), EDTA (0.01~0.2wt%), OP~10, (0.1~5wt%), penetrant JFC (0.1~5wt%), flat Add 0 (0.1-5wt%), oxalic acid (0.03-0.1%wt%), pure water as solvent; regeneration replenishment liquid preparation: regeneration replenishment liquid and oxalic acid as solvent, add ammonium metavanadate (0.5-10wt%) , ammonium parat...

Embodiment 2

[0043] Take a piece of honeycomb-type integral block catalyst that has been running for more than 30,000 hours, with a volume of 122.5cm3 and a volume of 122.5cm3. The main components of the catalyst are vanadium, titanium, and tungsten. The cross-sectional size of the catalyst is 150mmx150mm. Cut a piece of 40mmx40mmx40mm. Spray with pressurized sand filter water for 10 minutes. Then put it in a constant temperature water bath ultrasonic cleaner, at a cleaning frequency of 32kHz, 10kW / m 2 sound intensity, wash at 40°C for 10 minutes. Then put it into a blast drying oven to dry for 30 minutes, and put the dried catalyst into the cleaning solution. Preparation of cleaning solution: cleaning solution is composed of (NH4)2SO4 (0.1~10mol / l), EDTA (0.01~0.2wt%), OP~10 (0.1~5wt%), penetrant JFC (0.1~5wt%), and add Add O (0.1-5wt%), oxalic acid (0.03-0.1%wt%), citric acid (0.05-1%wt%), pure water as solvent; regeneration replenishment liquid preparation: regeneration replenishment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com