Method for improving strength of glass

A glass and strength technology, applied in the field of improving the strength of glass, can solve the problems of difficult industrialized production and the inability to reliably increase the strength of glass, and achieve the effects of improving the surface condition, increasing the strength and improving the surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

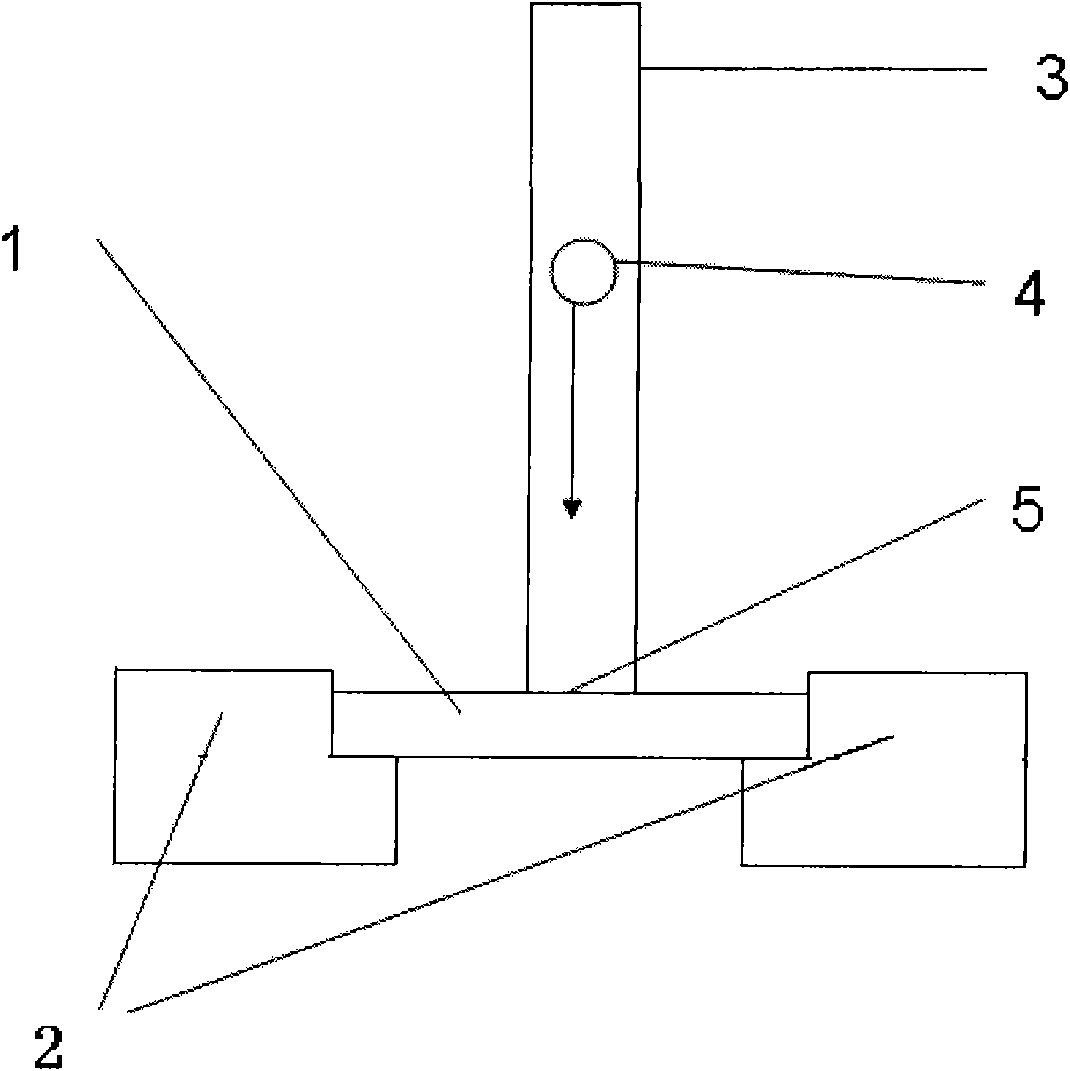

Image

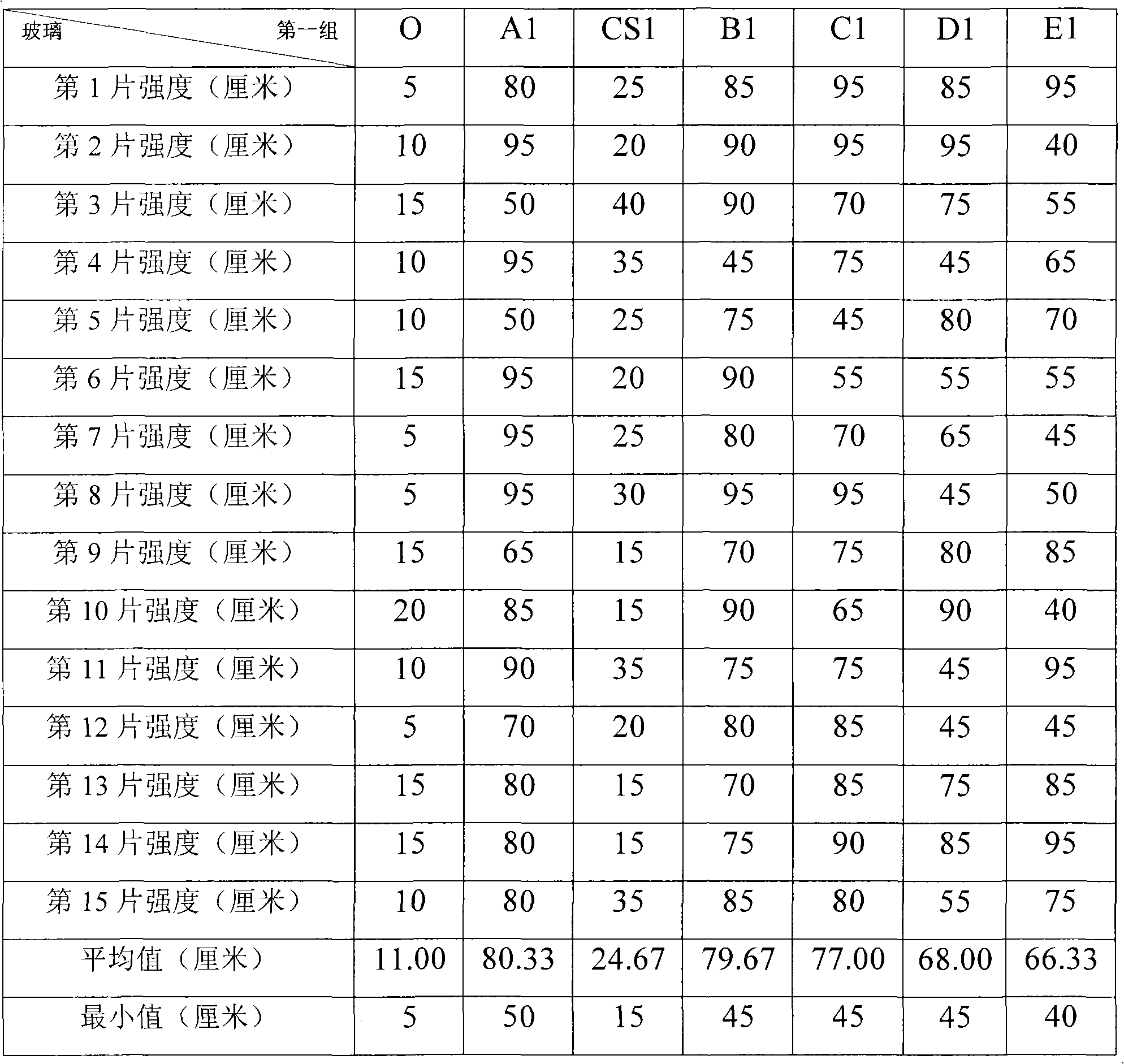

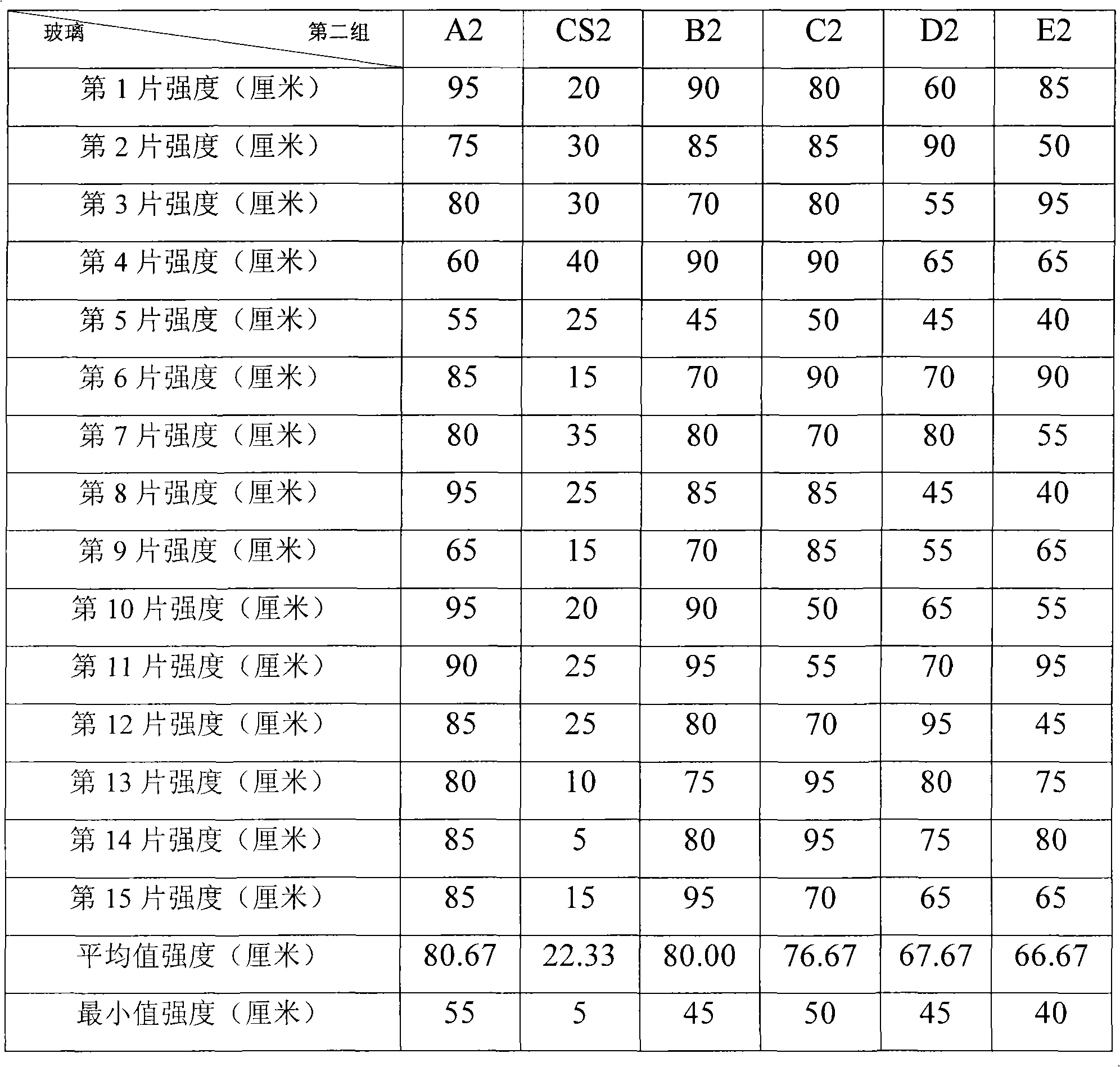

Examples

reference example 1

[0026] The ASAHI (Asahi Glass Blue) glass of 940 mm (length) × 510 mm (width) × 1.3 mm (thickness) was cut by the automatic glass cutting machine model WGA-500 produced by Guangzhou Huanyu Glass Machinery Factory, and used The desktop edging forming machine model F-80 produced by Jiangxi Zhonghang Optical Equipment Co., Ltd. and the double-sided grinding and thinning machine model YJ2M9S-5L produced by Hunan Yujing Machinery Industry Co., Ltd. process the glass into 66.3 (length) Glass in mm x 42.8 mm (width) x 0.88 mm (thick) dimensions. 300 pieces of the above glass were produced.

Embodiment 1

[0028] The present invention is used to illustrate the method for increasing the strength of glass provided by the present invention.

[0029] (1) Polishing: The glass from the above reference example 1 was polished using a YJ2M9S-5L Yujing polishing machine. The polishing includes 10 rpm polishing under the condition of 0.03 MPa light pressure and 20 rpm, and then the machine pressure is increased to 0.1 MPa medium pressure and 2400 rpm polishing under the condition of 45 rpm. Described polishing liquid is the aqueous solution that buys from Zhicheng 620 polishing powder, and the weight of described water is 100 grams, and the weight of described polishing powder is 35 grams, and described polishing powder contains powdery red iron oxide, tin dioxide, Aluminum oxide, barium carbonate, chalk, clay, diatomaceous earth and cerium oxide, the particle diameter of the cerium oxide is 2-8 nanometers, and the amount of the cerium oxide is 70% by weight of the polishing powder. After...

Embodiment 2

[0035]The present invention serves to illustrate the method of obtaining glass with increased strength according to the invention.

[0036] The glass from Reference Example 1 above was strengthened according to the method of Example 1, except that,

[0037] In step (3), the polishing includes polishing at a medium pressure of 0.1 MPa and a rotational speed of 45 rpm for 60 rpm, and the obtained glass has a size of 66.3 mm (length) × 42.8 mm (width) × 0.7992 mm (thick).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com