Polyamide resin and application thereof as well as polyamide composition consisting of same

A technology of polyamide composition and polyamide resin, which is applied in the field of polyamide composition and can solve the problems of affecting the health of users and consuming large energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

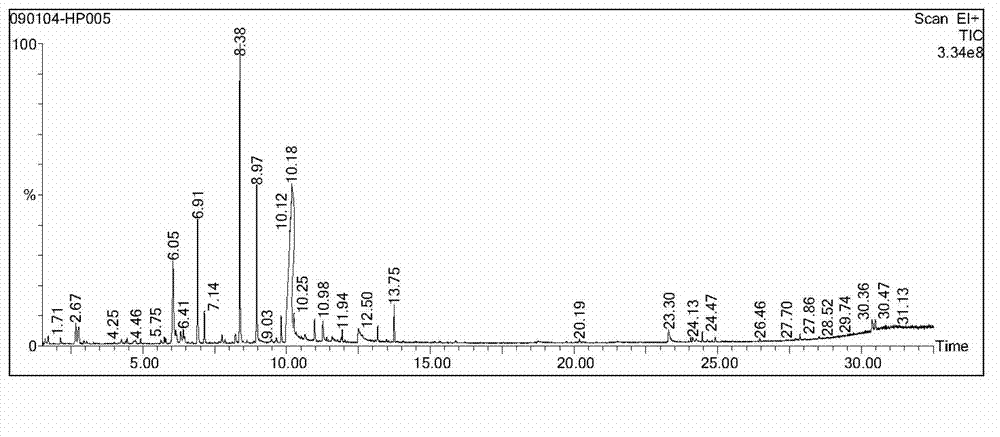

Image

Examples

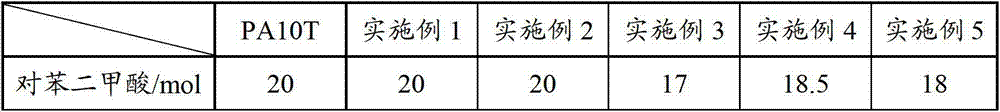

Embodiment 1~16 and comparative example 1~10

[0092] In the autoclave equipped with magnetic coupling stirring, condenser, gas phase port, feeding port, and pressure explosion-proof port, add the reaction raw materials according to the ratio in the table. Then add benzoic acid, sodium hypophosphite and deionized water. The amount of benzoic acid substance is 2.5% of the amount of diamine, nylon salt, lactam and amino acid total substance, sodium hypophosphite weight is 0.1% of other feeding weight except deionized water, and deionized water weight is 30% of total feeding weight %. Vacuumize and fill high-purity nitrogen as a protective gas, heat up to 220°C within 2 hours with stirring, stir the reaction mixture at 220°C for 1 hour, then raise the temperature of the reactant to 230°C with stirring. The reaction was continued at a constant temperature of 230°C and a constant pressure of 2.2MPa for 2 hours, and the pressure was kept constant by removing the formed water. After the reaction was completed, the material was d...

Embodiment 17~22

[0105] Embodiment 17~22 and comparative example 11~12

[0106] Mix the polyamide resin, flame retardant and other additives uniformly in the high mixer according to the formula in Table 6~7, then feed them into the twin-screw extruder through the main feeding port, and the reinforcing filler passes through the side feeding scale side feeding, extrusion, water cooling, granulation and drying to obtain the polyamide composition. Wherein, extrusion temperature is 330 ℃.

[0107] Formulations in the following table of table 6 are parts by weight

[0108]

[0109]

[0110] Among them, ⊙ means no foaming; Indicates foaming.

[0111] Table 7

[0112]

[0113]

[0114] Among them, ⊙ means no foaming; Indicates foaming.

[0115] It can be seen from Table 6 and Table 7 that the polyamide composition prepared from the polyamide resin prepared in the examples of the present application has a lower gas volatile content and better reflow soldering surface performance, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com