Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117 results about "Zirconia coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

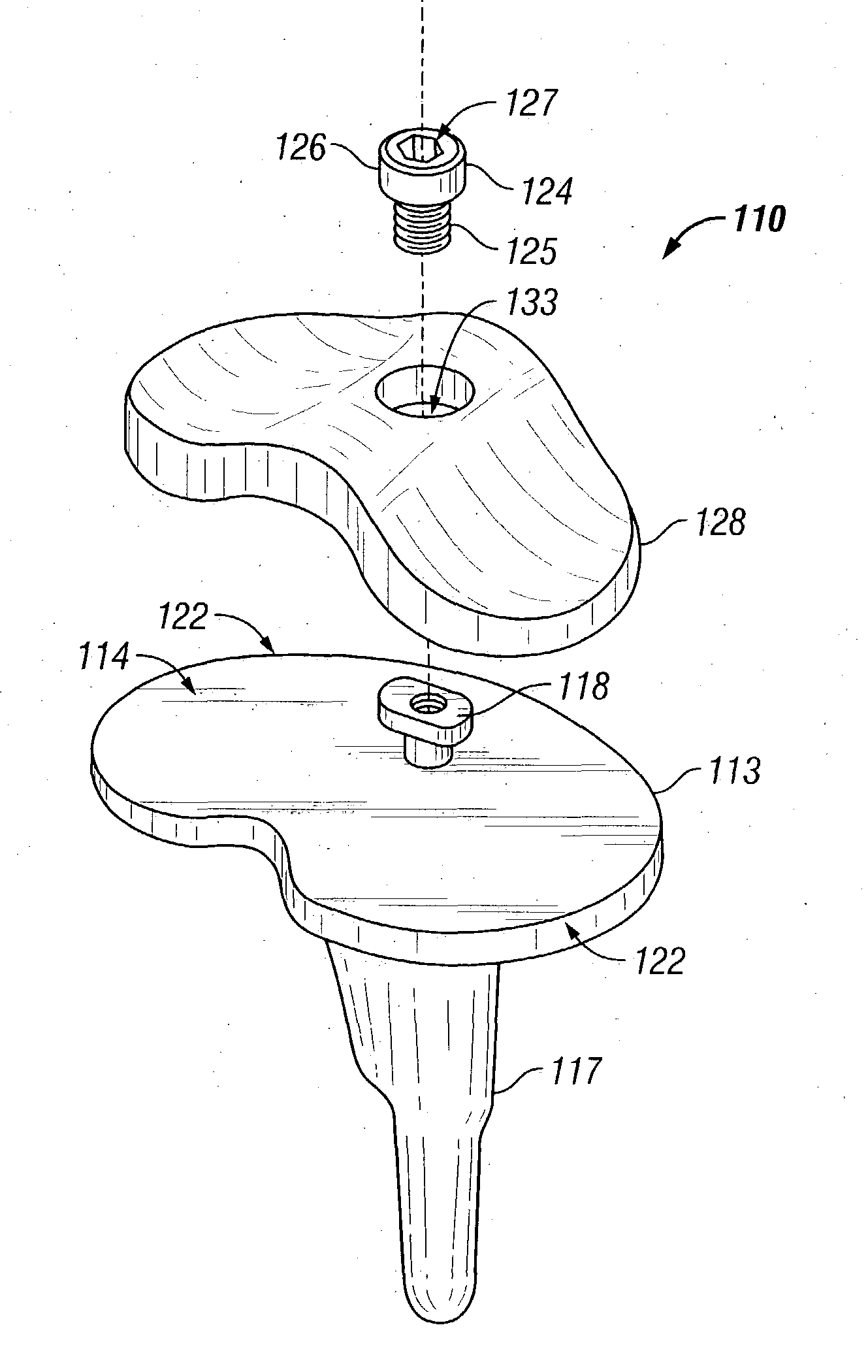

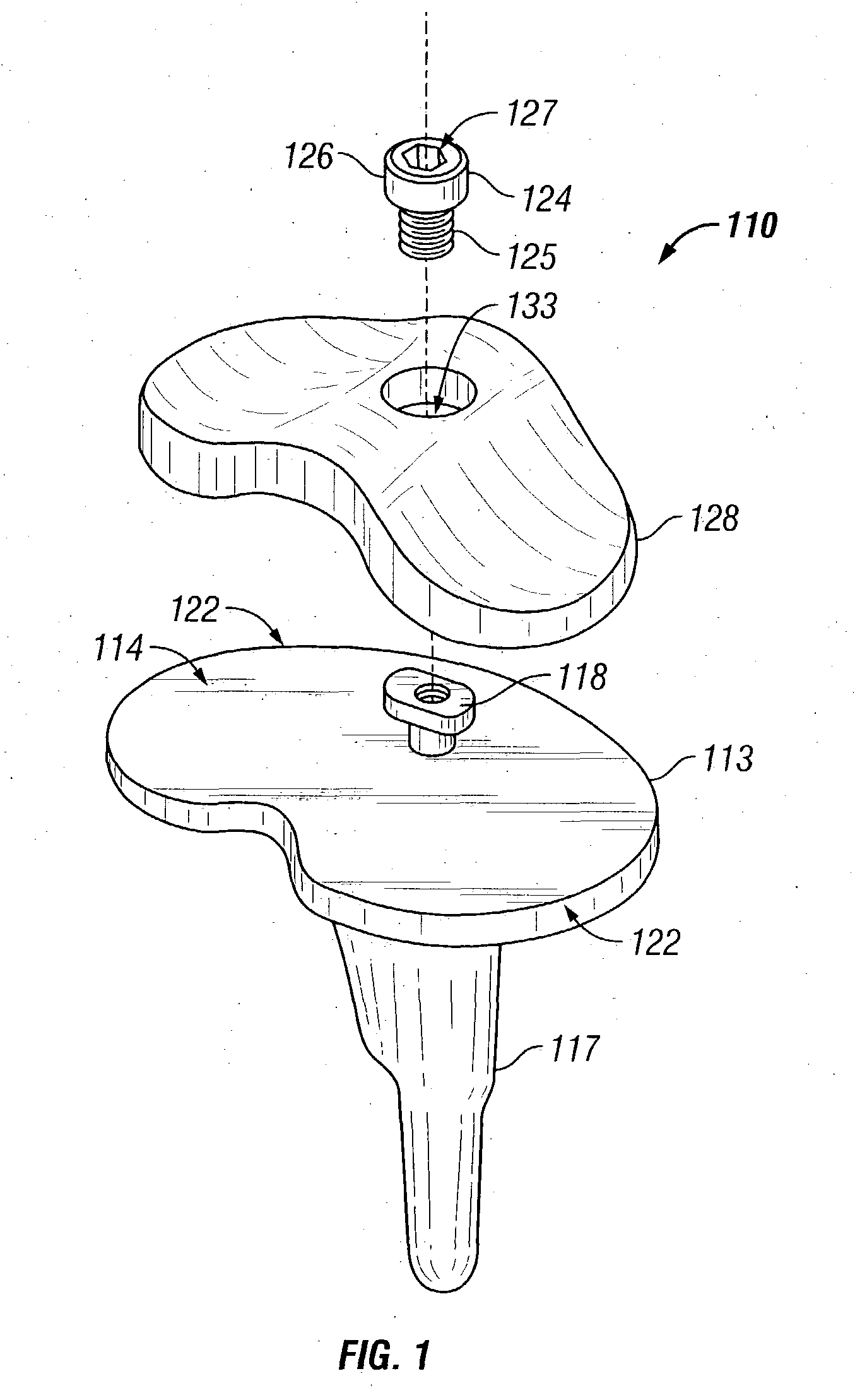

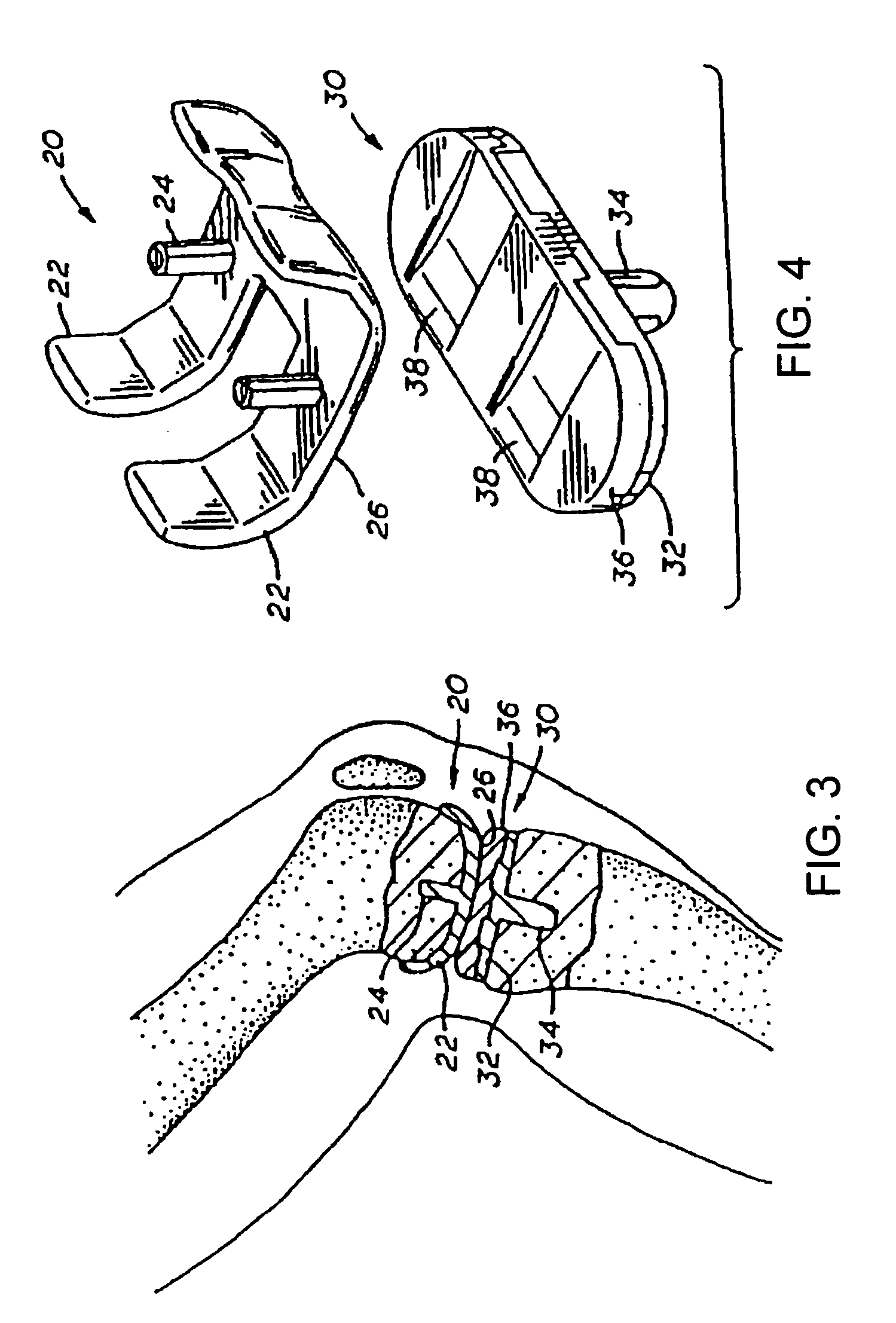

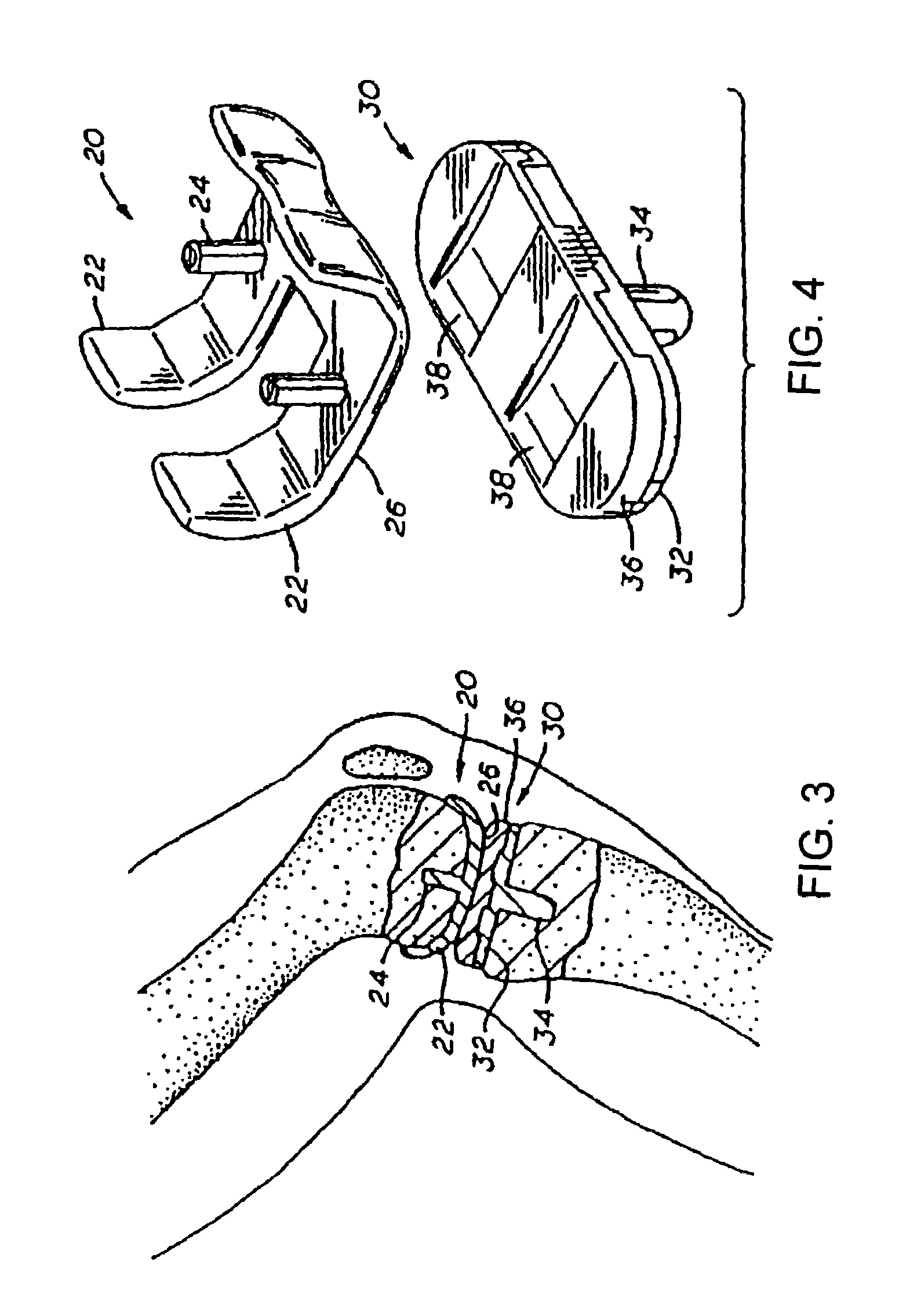

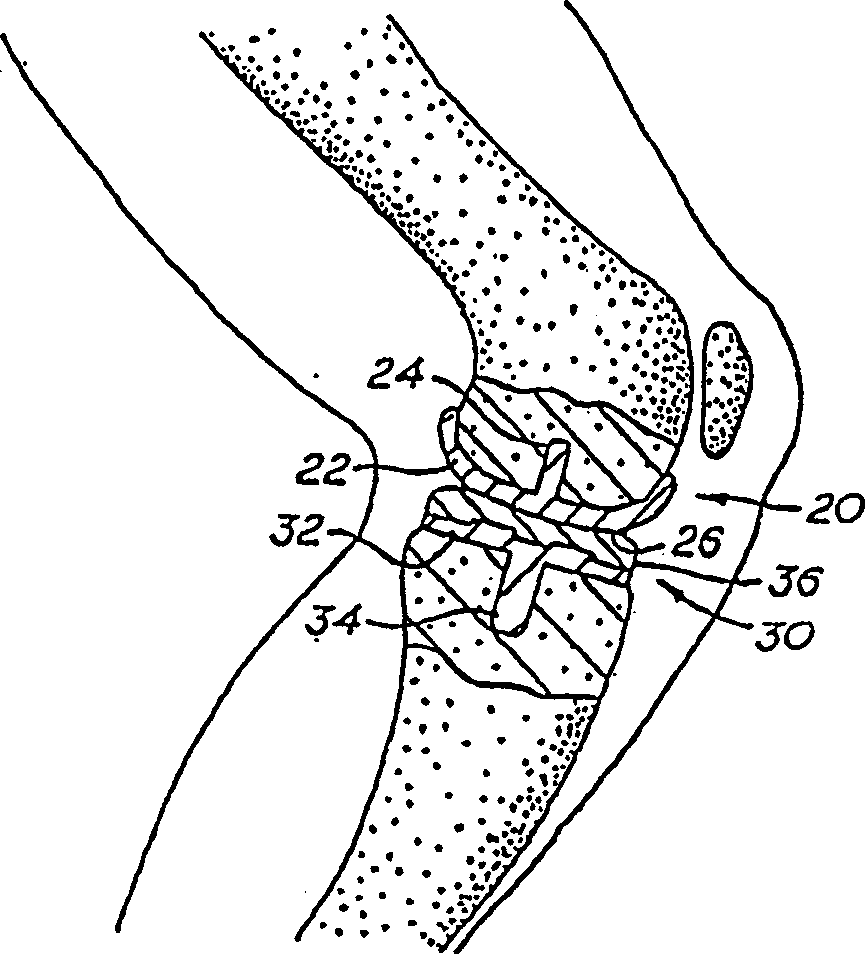

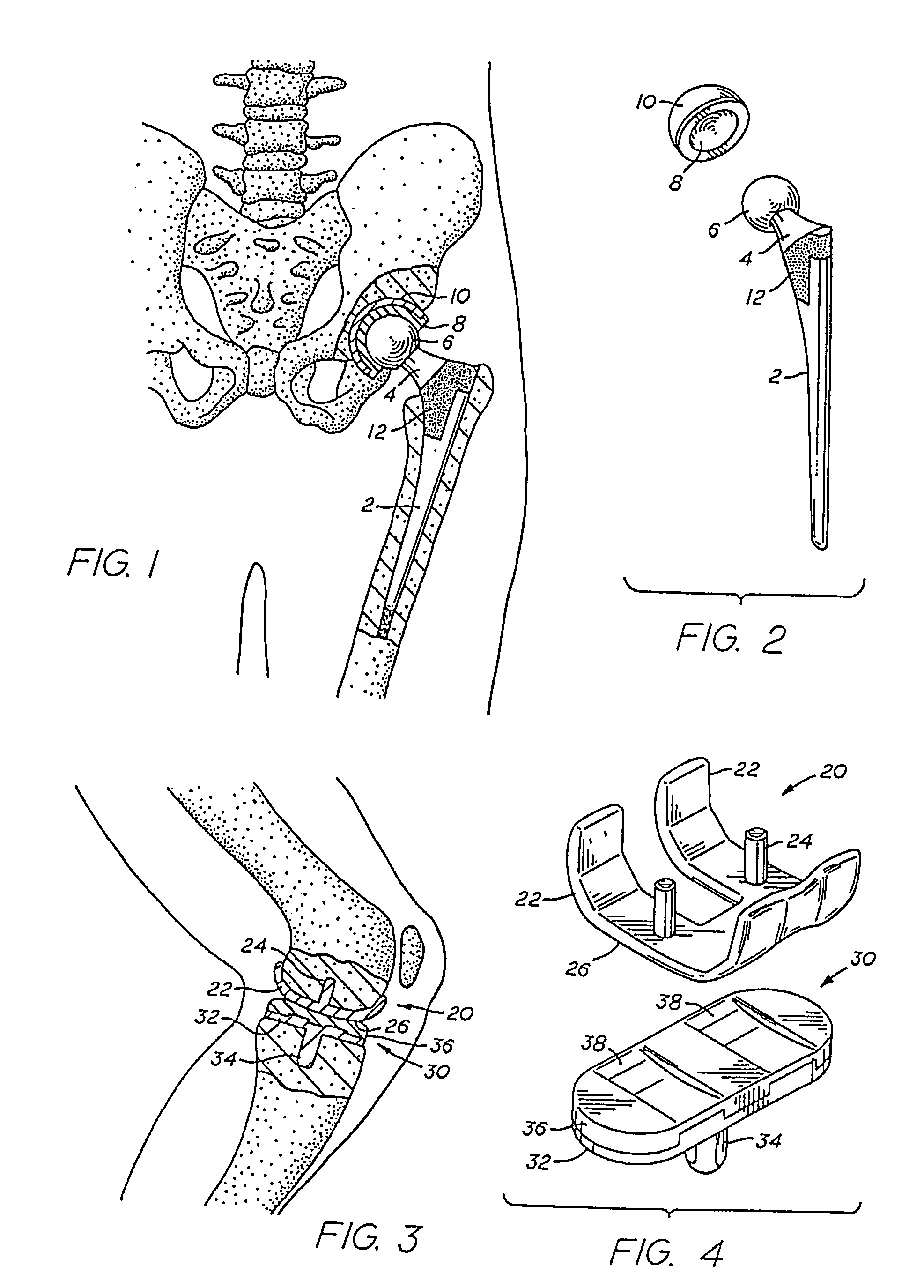

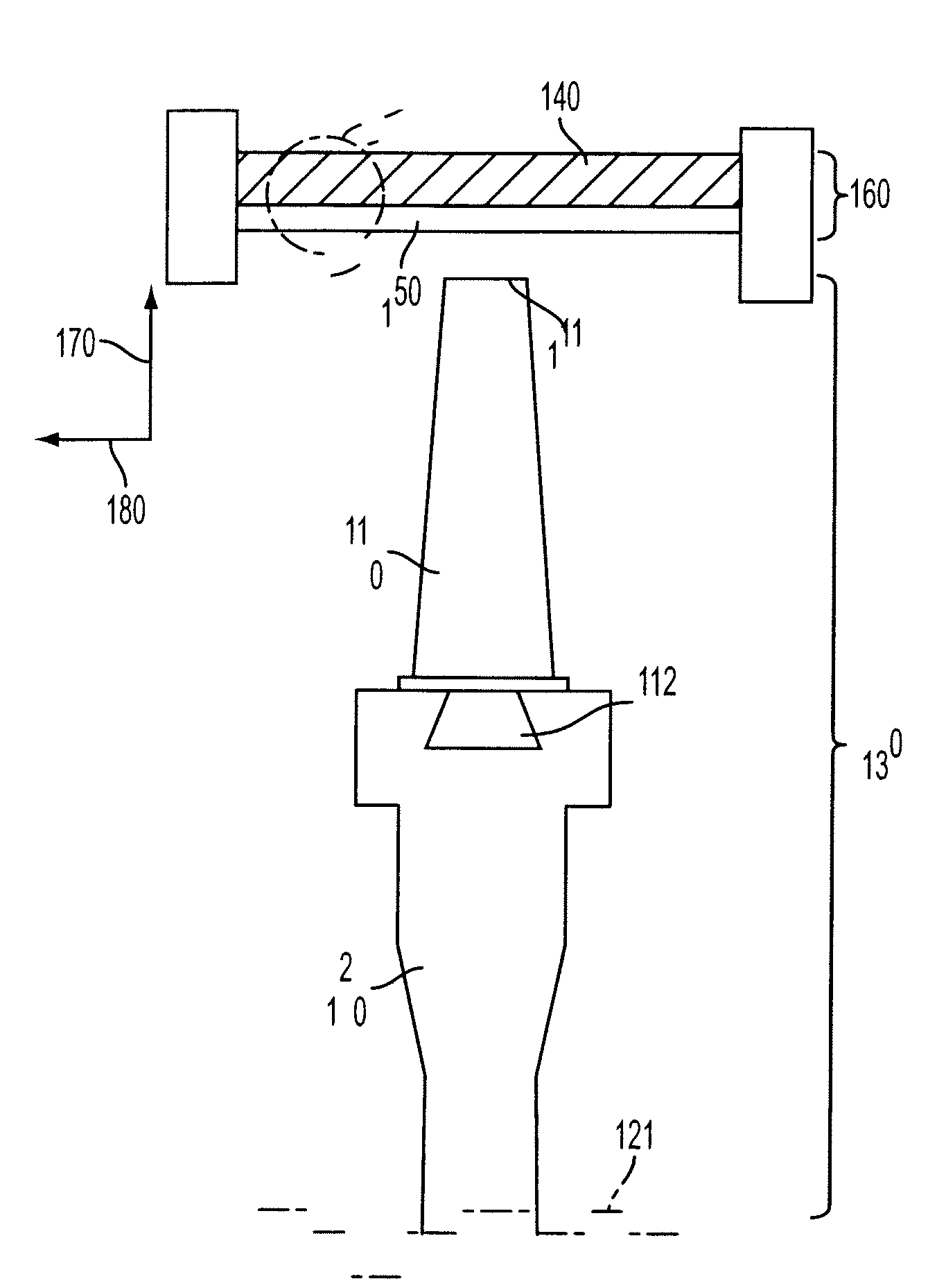

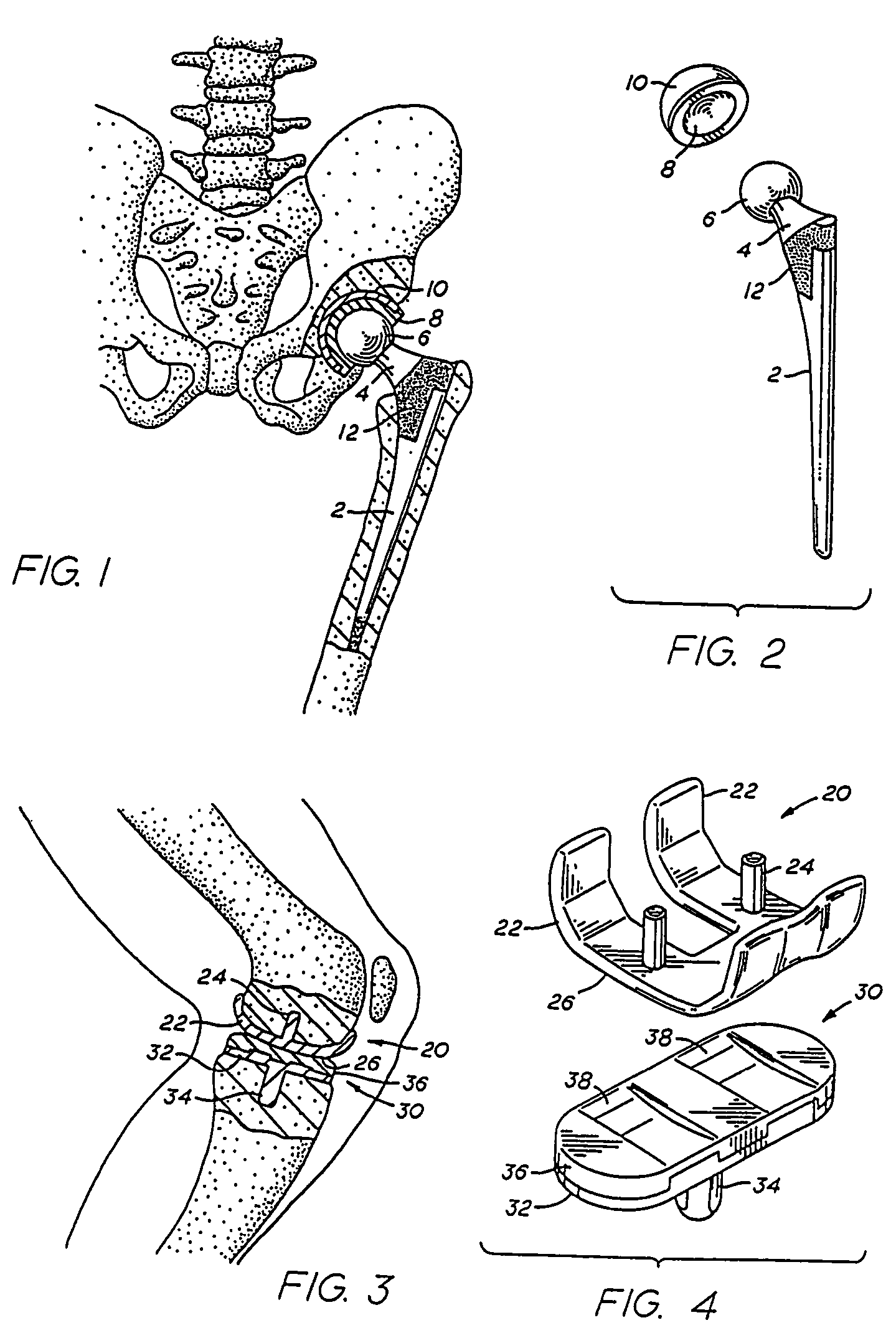

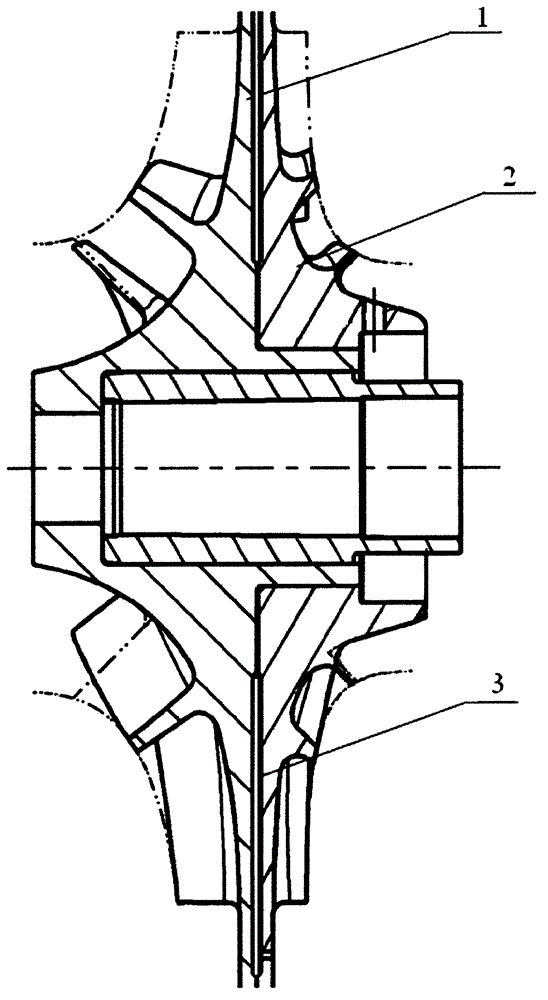

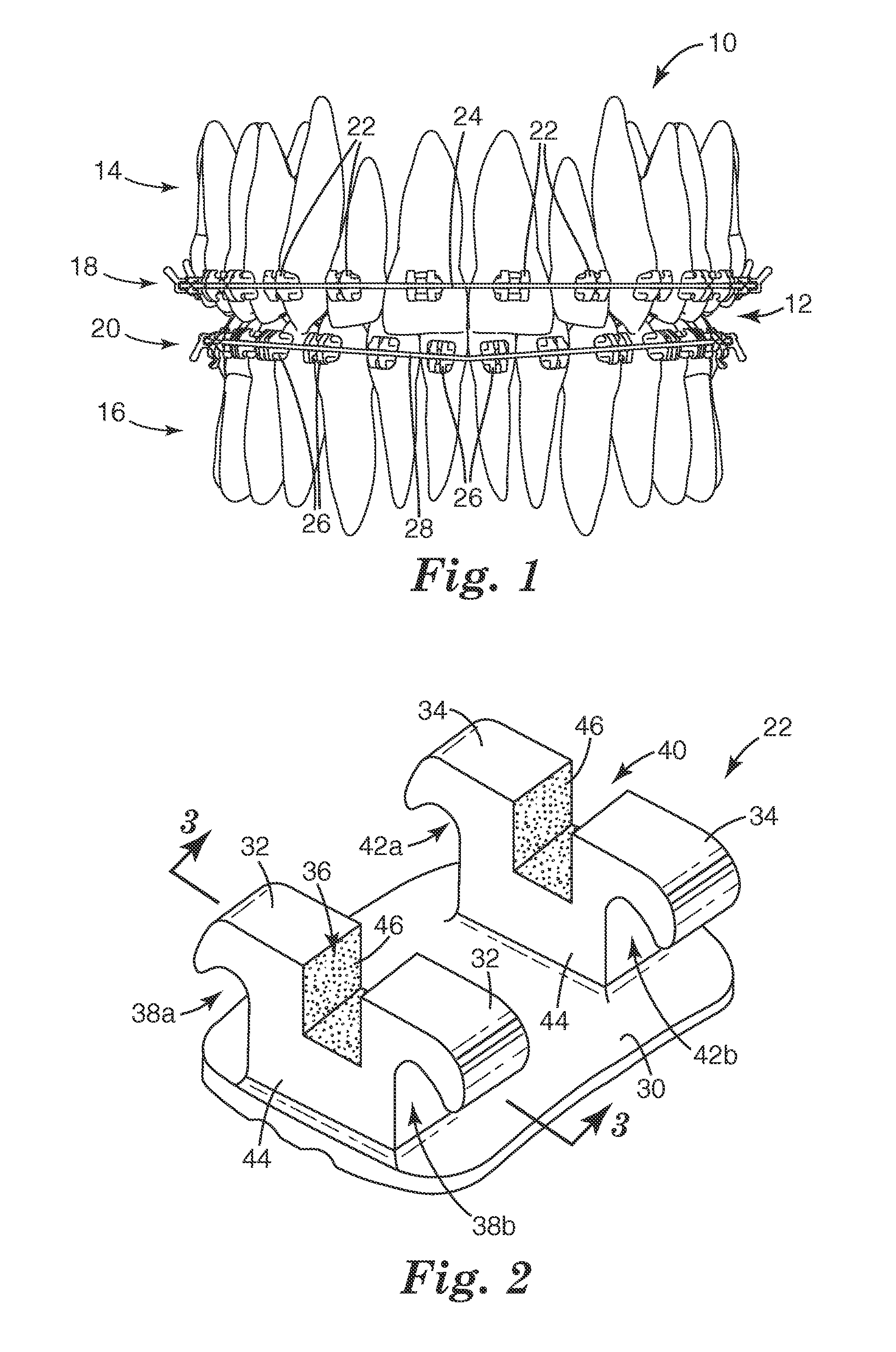

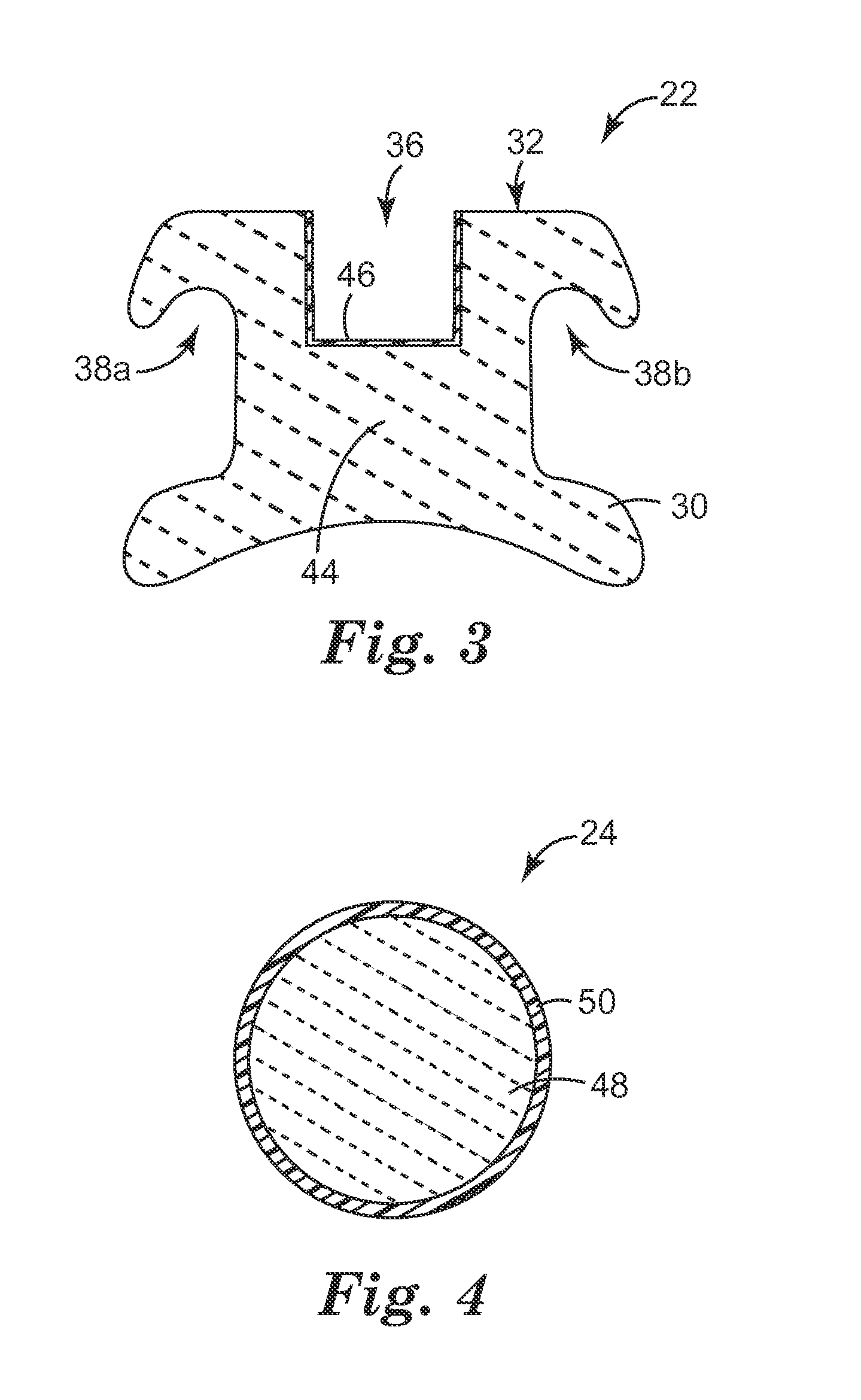

Mobile bearing tibial base prosthetic devices employing oxidized zirconium surfaces

An orthopedic implant with a diffusion-hardened surface on non-load bearing areas of the implant for interaction with non-load bearing surfaces of a polymeric bio-compatible material, such as UHMWPE (ultra-high molecular weight polyethylene). The orthopedic implant is a mobile-bearing knee prosthetic and system where a coating of oxidized zirconium is formed on the post of the tibial tray of the prosthetic for interaction with an opening of a polymeric tibial insert. The diffusion-hardened surface of the orthopedic implant provides a strengthened post and reduction in wear in the opening of the polymeric insert.

Owner:SMITH & NEPHEW INC

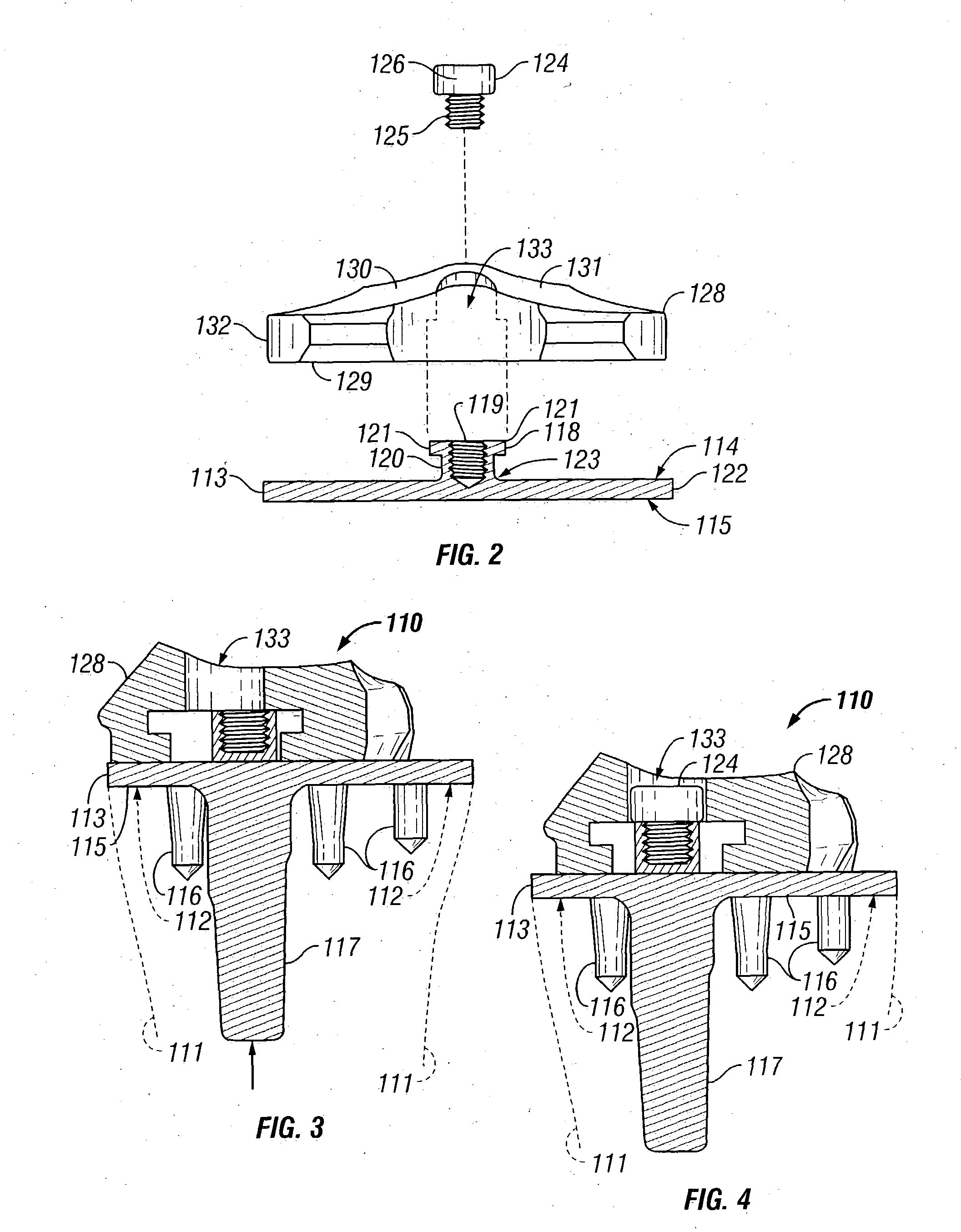

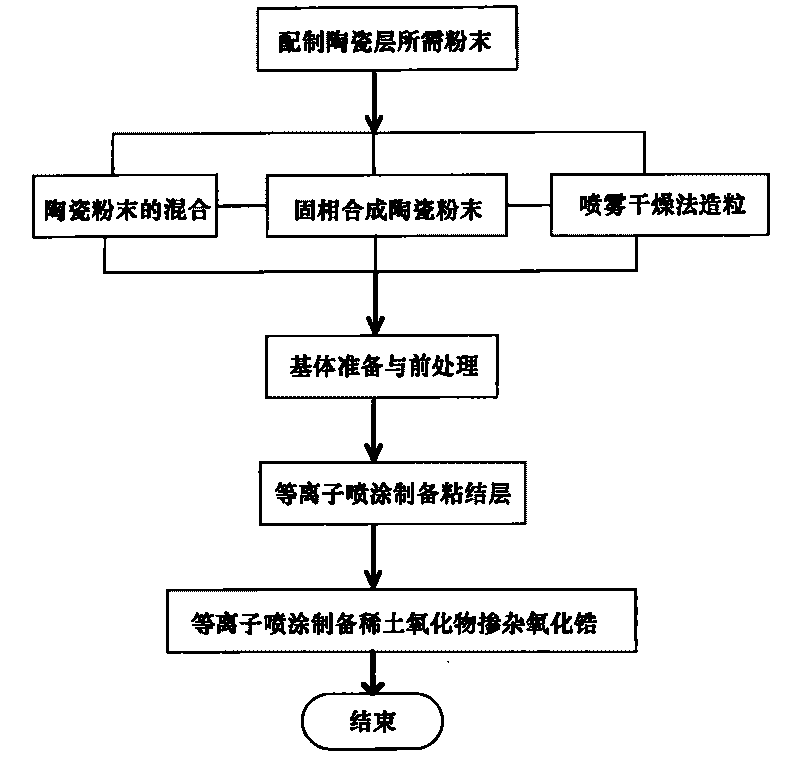

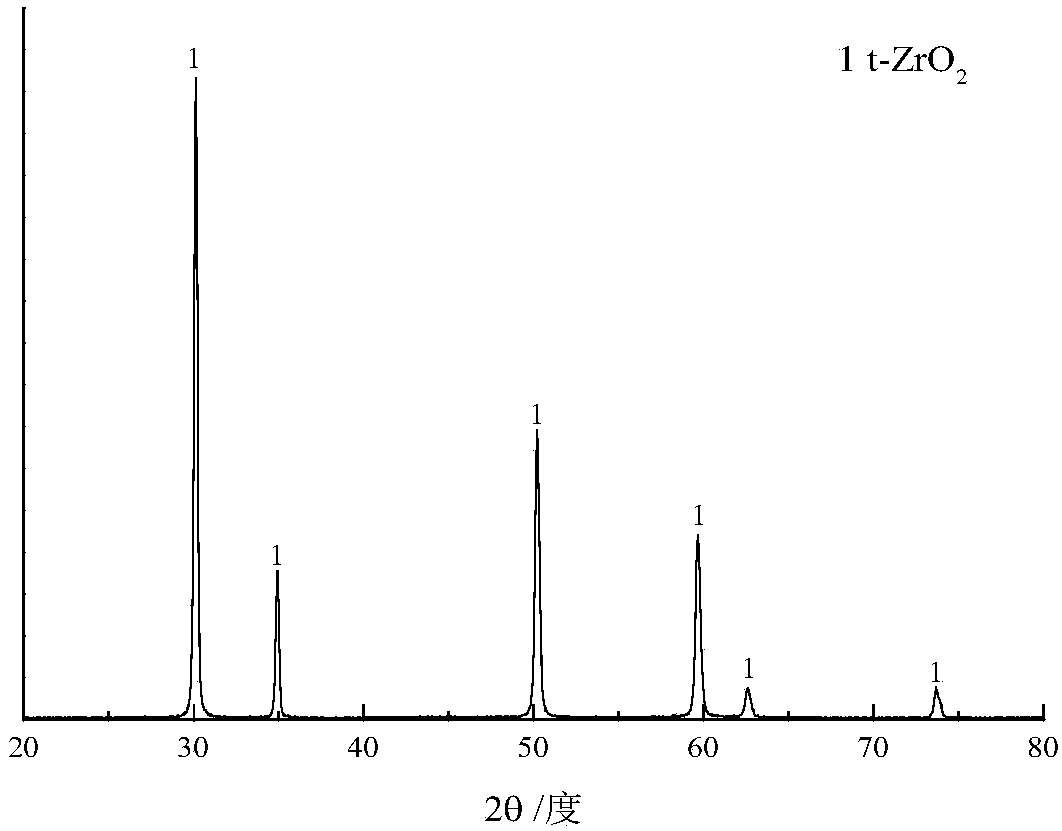

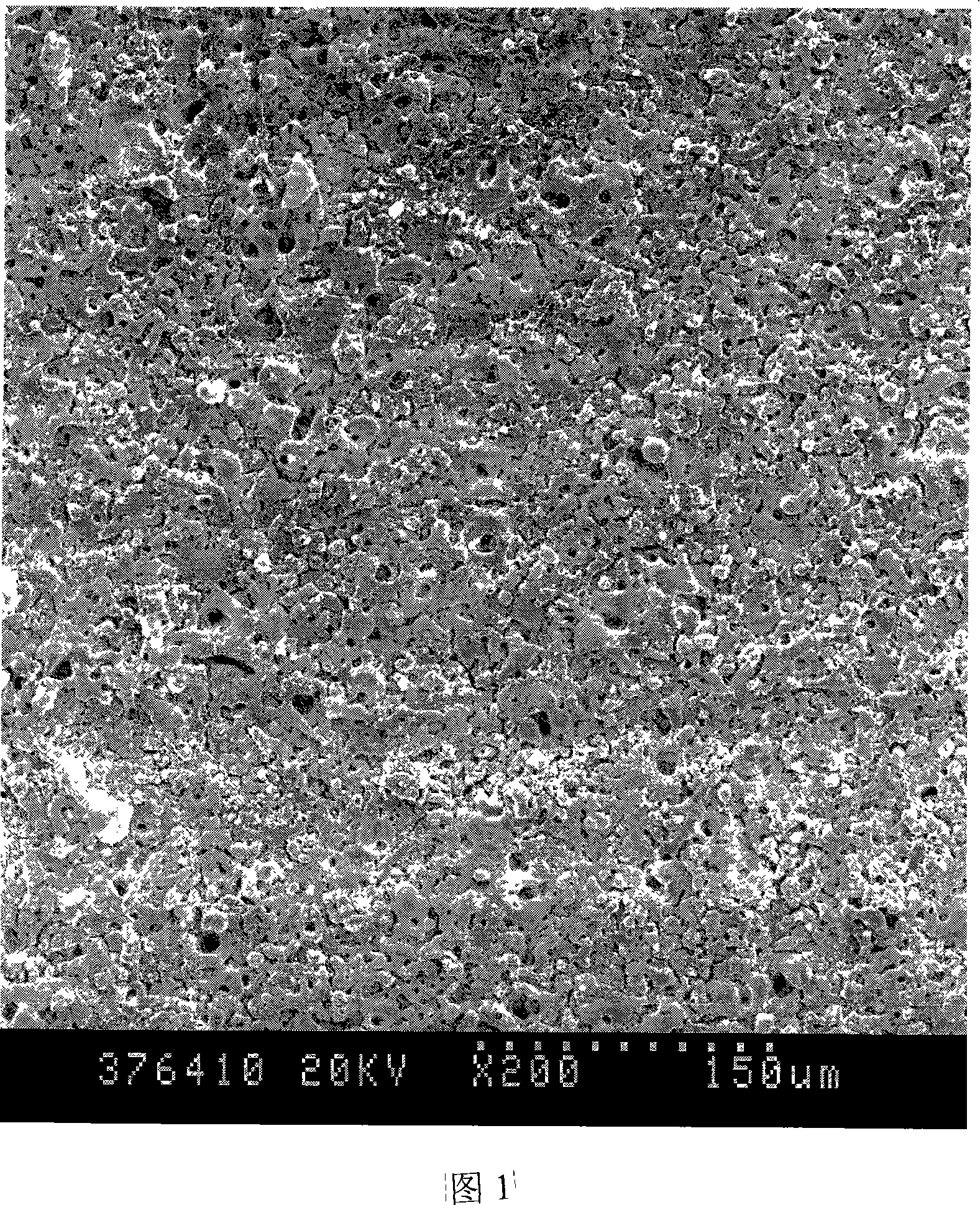

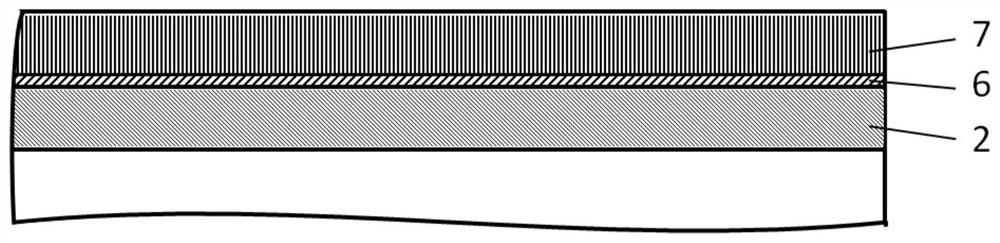

Multielement rare earth oxide doped zirconia thermal barrier coating with craze crack structure and preparing method thereof

InactiveCN101723667AGood phase stability at high temperatureLow temperature for long-term useMolten spray coatingEfficient propulsion technologiesThermal insulationRare earth

The invention discloses a method for preparing a rare earth oxide doped zirconia thermal barrier coating with a craze crack structure, which solves the problems of low thermal shock resistance property, difficult further thermal conductivity reduction and the like of the thermal coating prepared by conventional plasma spraying. Under the condition of the plasma spraying technology, the preheating temperature of a base body, the moving speed of a plasma spraying gun and a powder delivery rate are adjusted, then a rare earth oxide doped zirconia thermal barrier coating (BH-TBCO1) with a craze crack structure and stable thermodynamics is prepared. The rare earth oxide doped zirconia thermal barrier coating with a craze crack structure has good high-temperature phase stability at the temperature below 1300 DEG C; the thermal insulation property of the thermal barrier coating is further enhanced, and the thermal insulation temperature achieves more than 150 DEG C and is enhanced by more than 50% when compared with the coating prepared by the conventional plasma spraying; the thermal shock life of the coating exceeds 4000 cycles and is enhanced by more than 1 time when compared with the coating prepared by the conventional plasma spraying.

Owner:BEIHANG UNIV

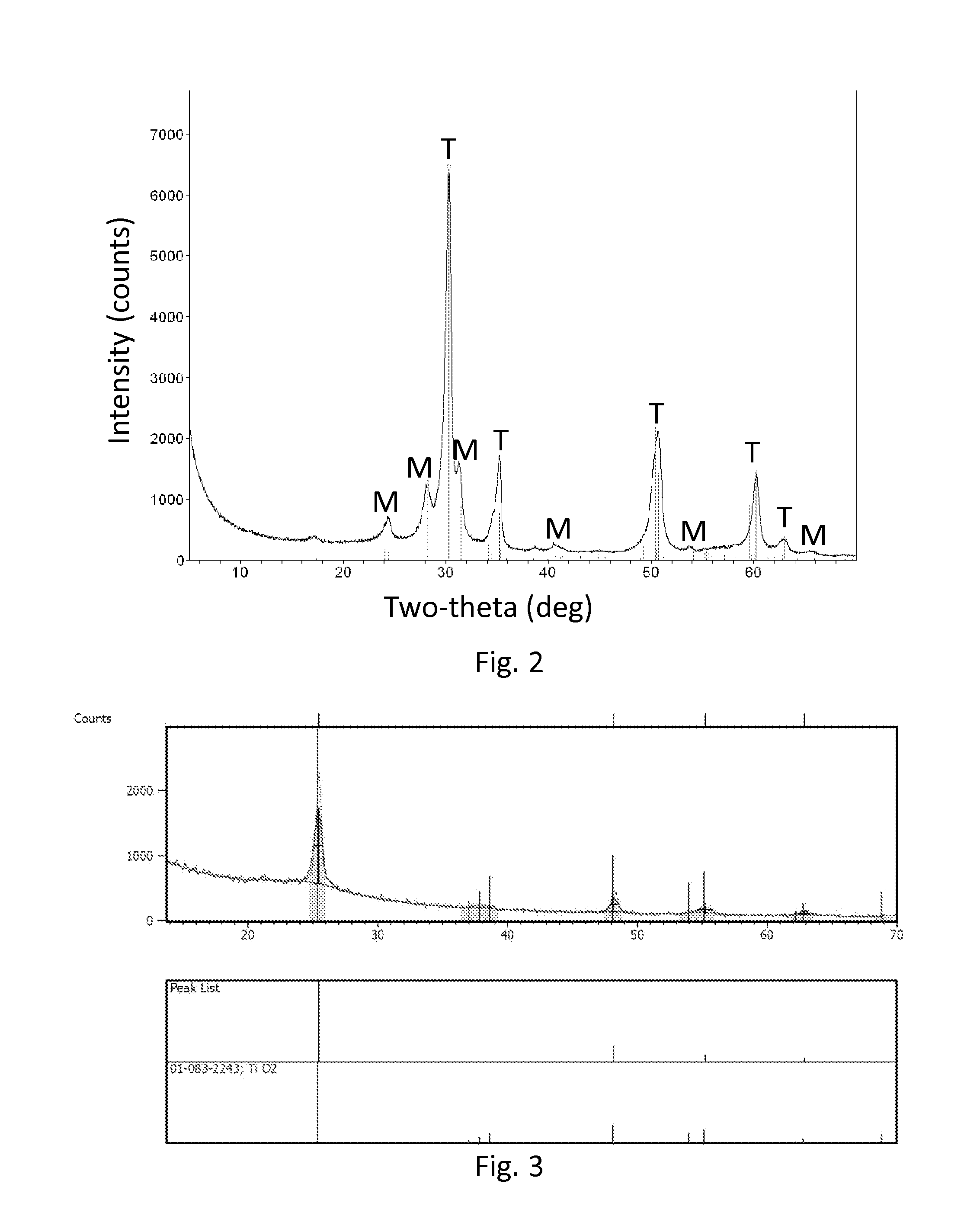

Thermal spray coatings for semiconductor applications

InactiveUS20100272982A1Erosion is goodImproved corrosion resistant coatingLiquid surface applicatorsMolten spray coatingThermal sprayingIntegrated circuit manufacturing

This invention relates to thermal spray coatings on a metal or non-metal substrate. The thermal spray coating comprises a partially or fully stabilized ceramic coating, e.g., yttria stabilized zirconia coating, and has sufficiently high thermodynamic phase stability to provide corrosion and / or erosion resistance to the substrate. This invention also relates to methods of protecting metal and non-metal substrates by applying the thermal spray coatings. The coatings are useful, for example, in the protection of integrated circuit manufacturing equipment, internal chamber components, and electrostatic chuck manufacture.

Owner:PRAXAIR ST TECH INC

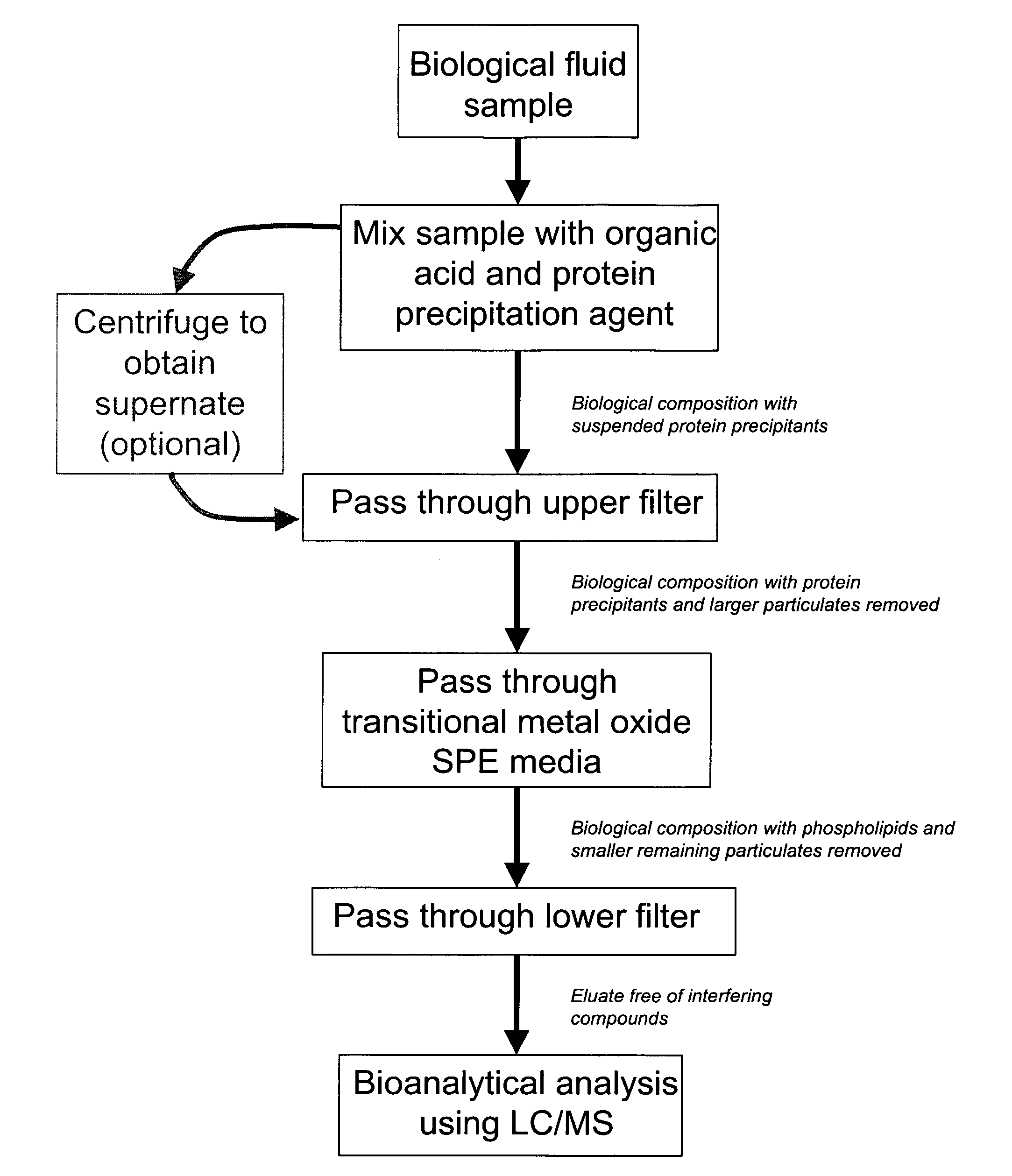

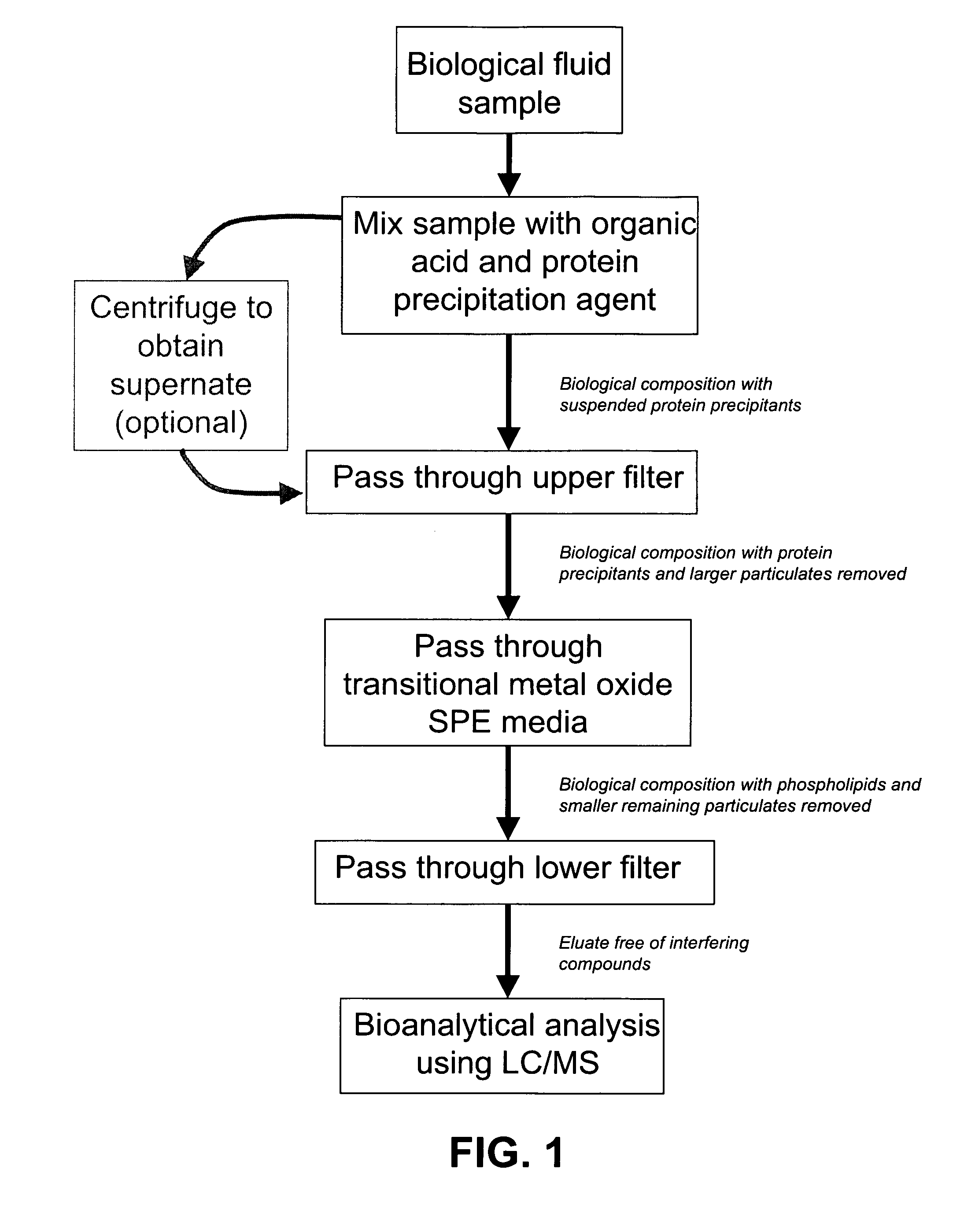

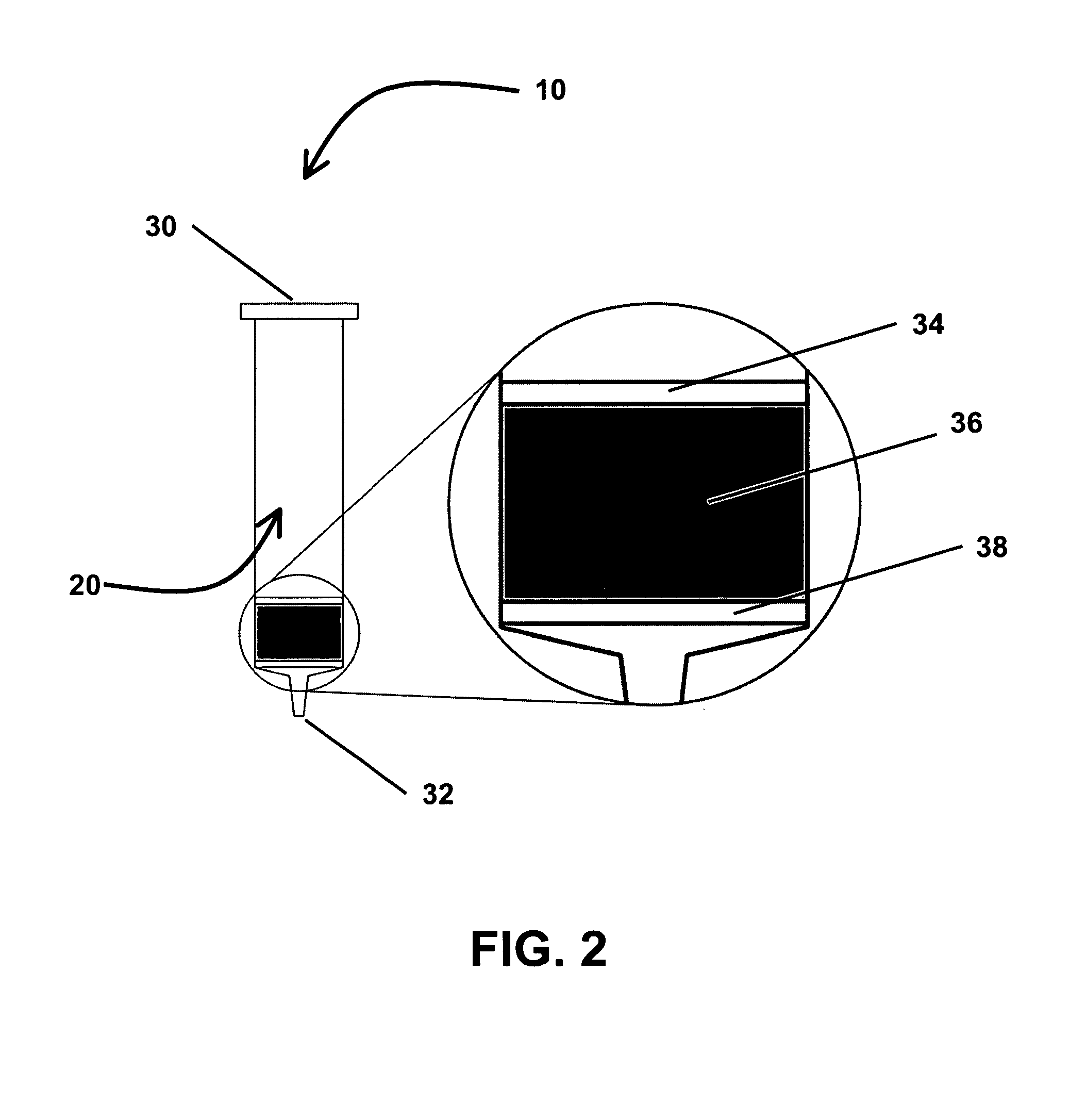

Compositions and methods for combining protein precipitation and solid phase extraction

ActiveUS20080213906A1Large specific surface areaEliminate later ion-suppressionComponent separationBiological testingProtein insertionPhosphate

A composition, method and device for the preparation of biological samples for subsequent LC-MS analysis using a combined and concurrent protein precipitation and solid phase extraction (SPE) process is described. Through an integrated combination of protein precipitation, filtration, and SPE using a novel zirconia-coated chromatographic media, interfering compounds, such as proteins and phosphate-containing compounds, are eliminated from the biological samples, affording a higher degree of analyte response during LC-MS analysis.

Owner:SIGMA ALDRICH CO LLC

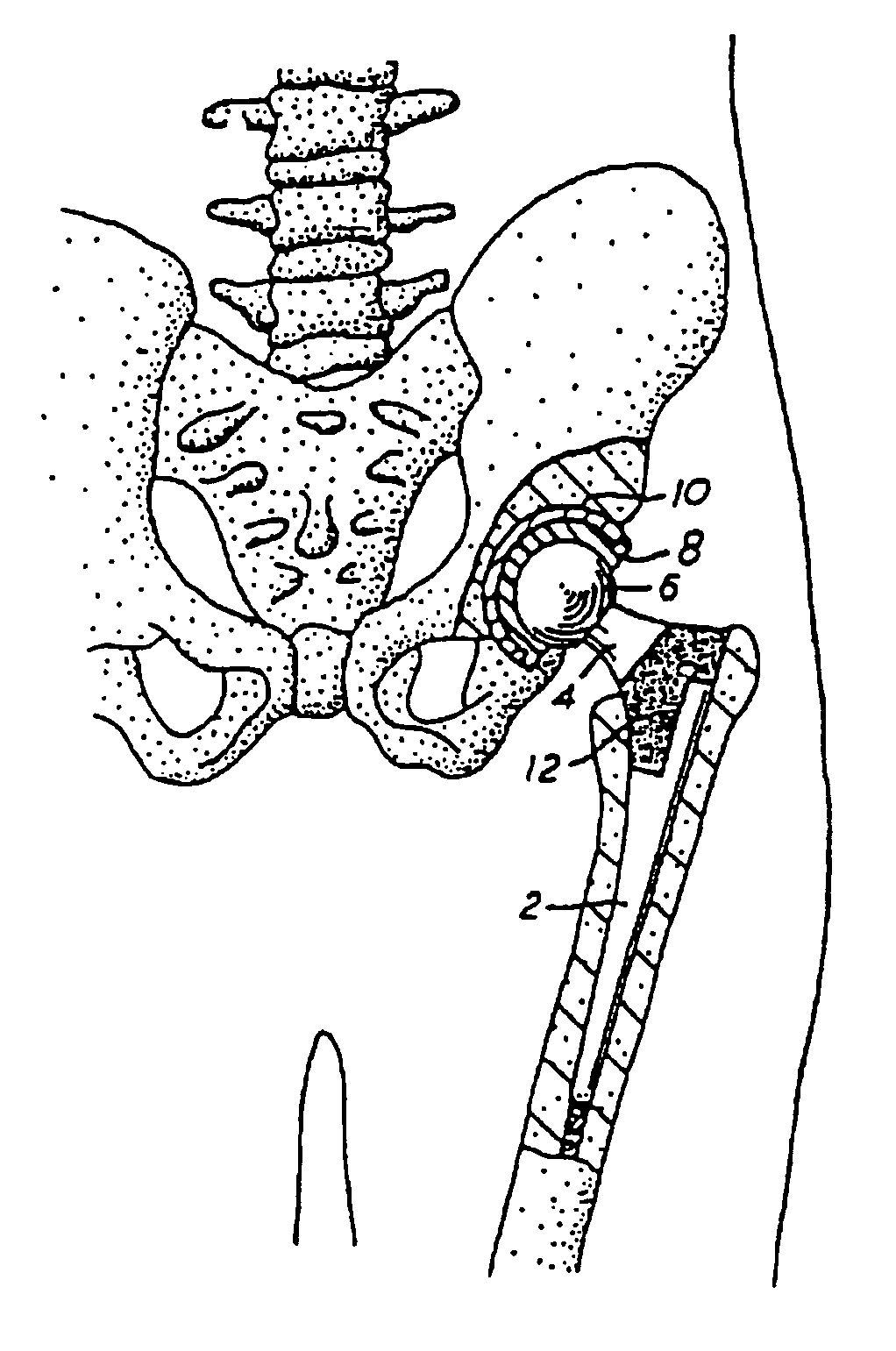

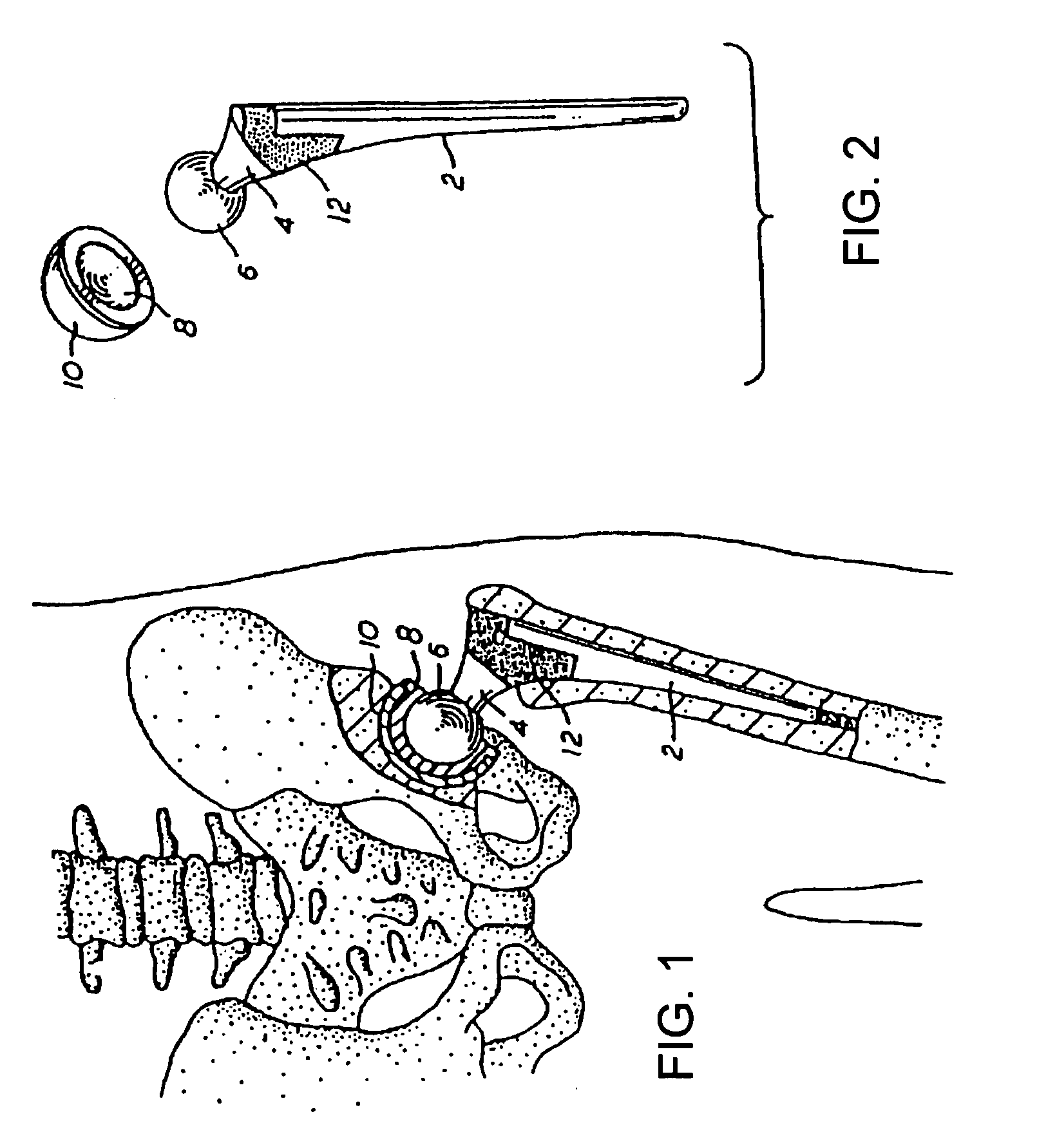

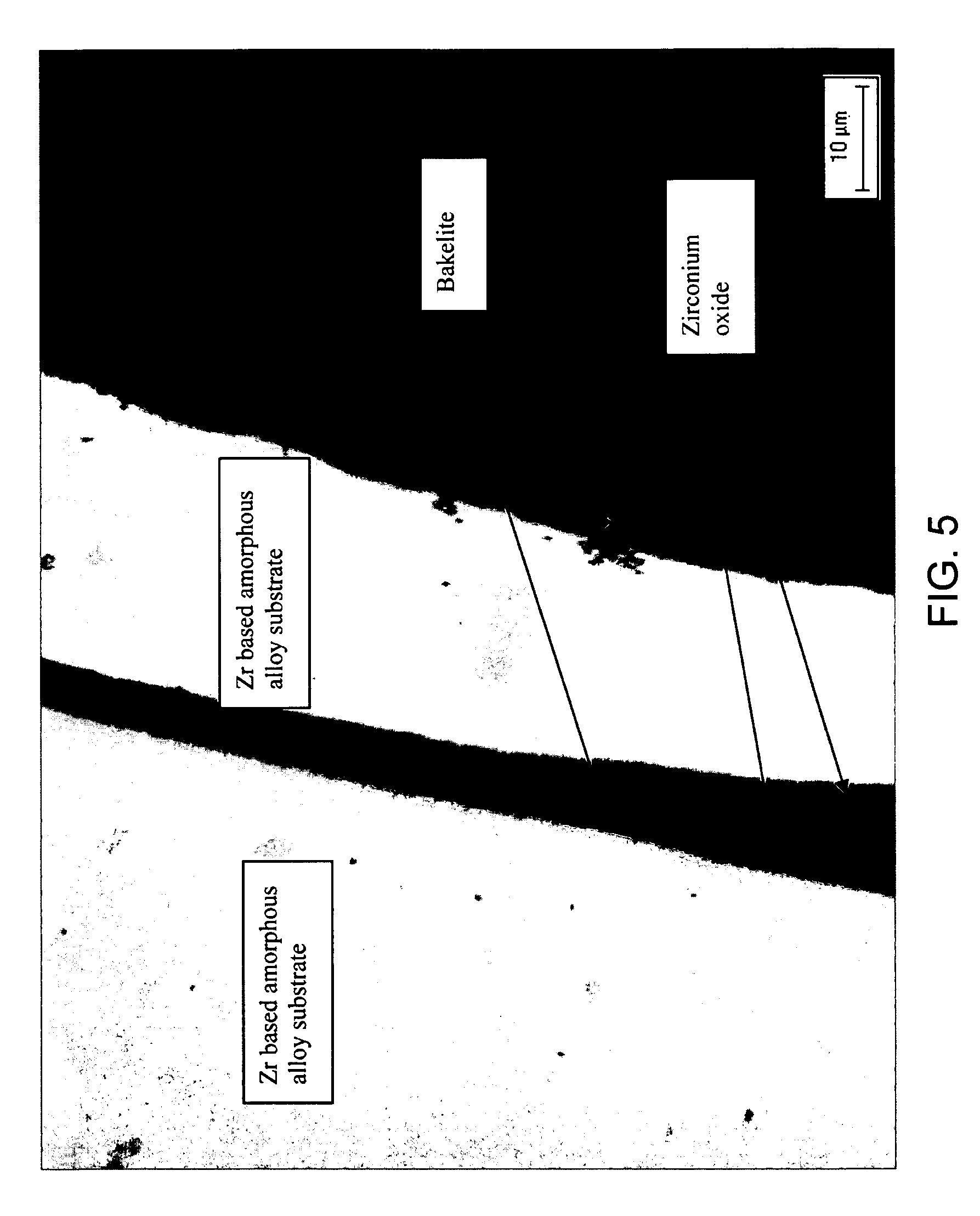

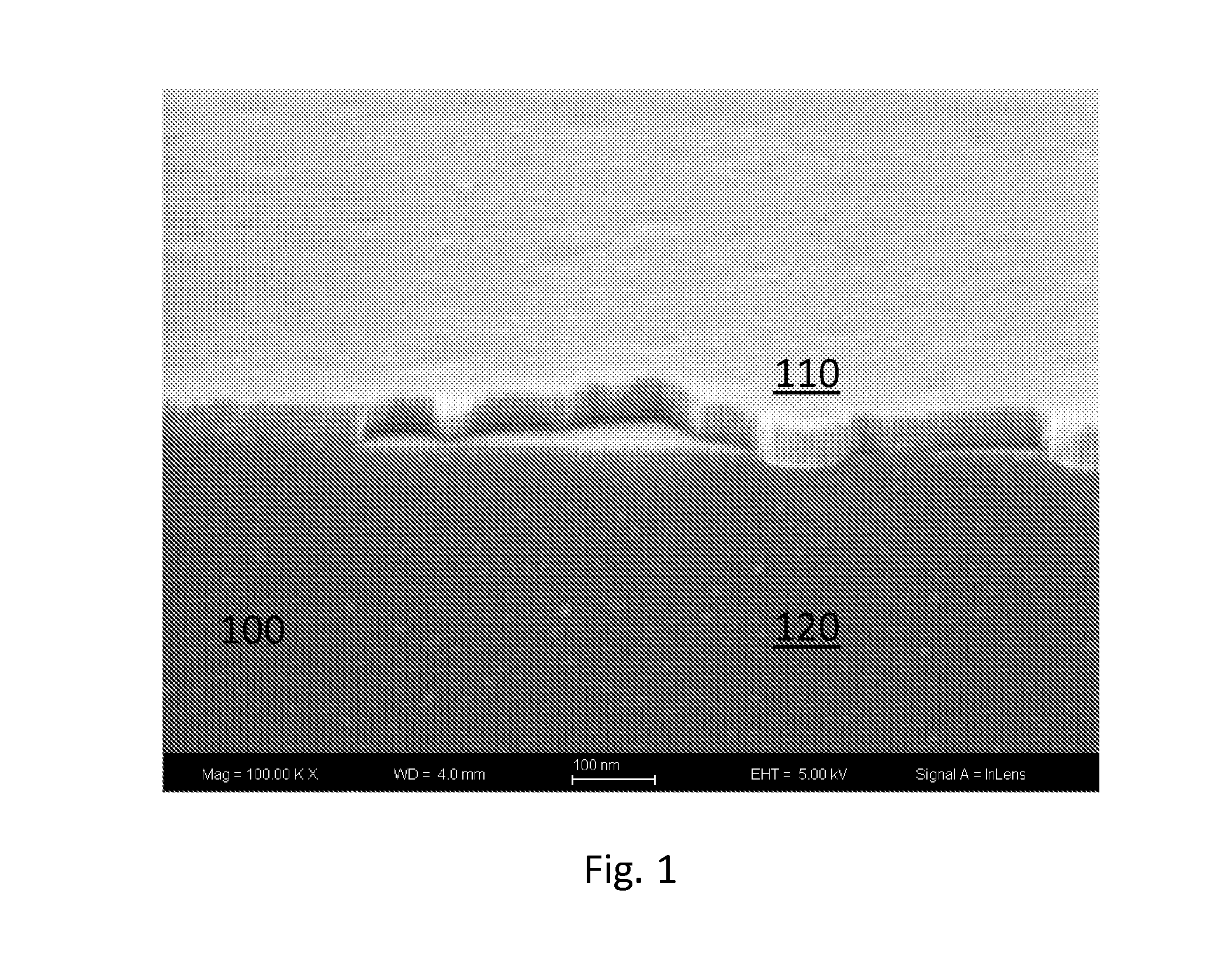

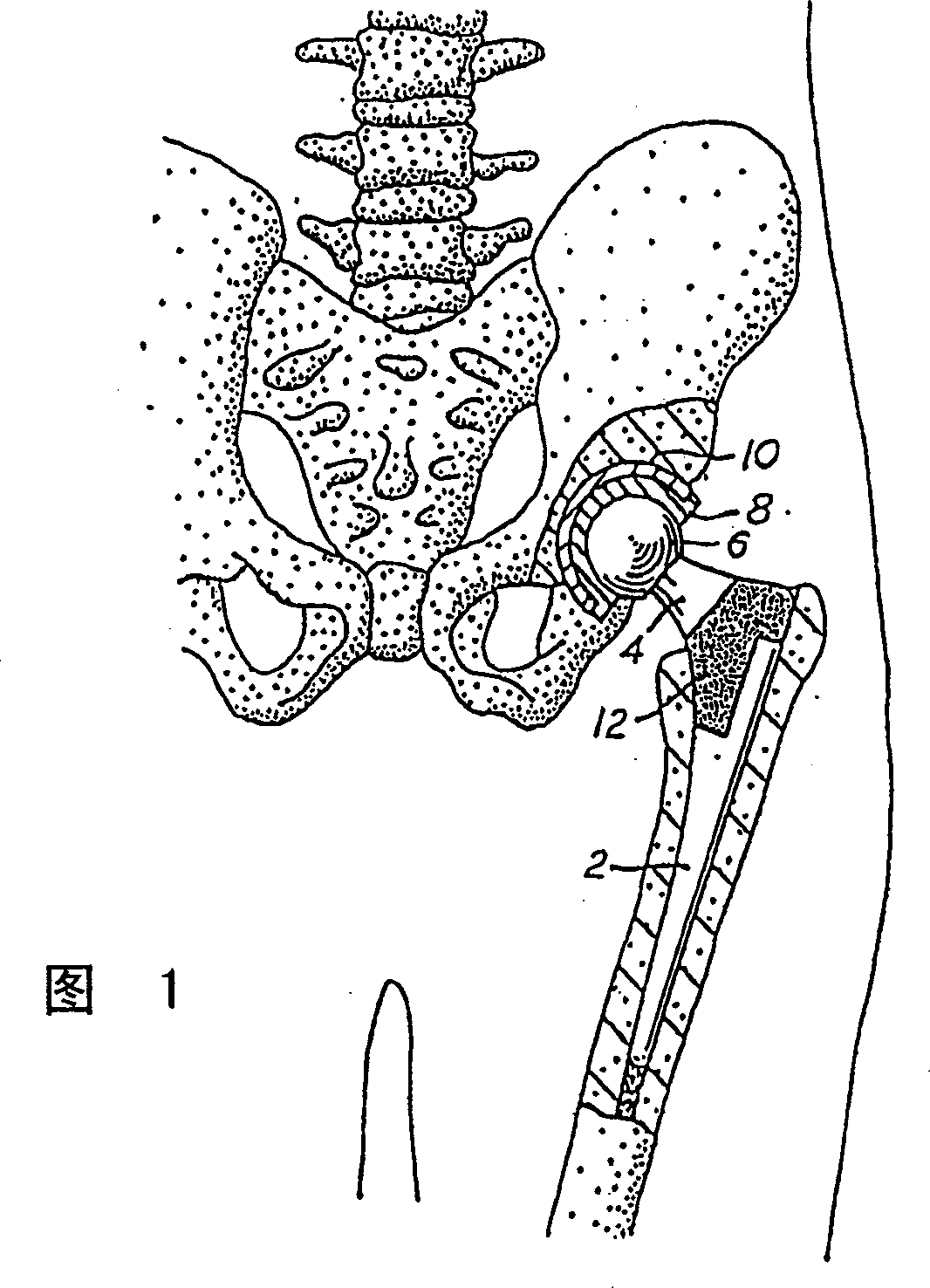

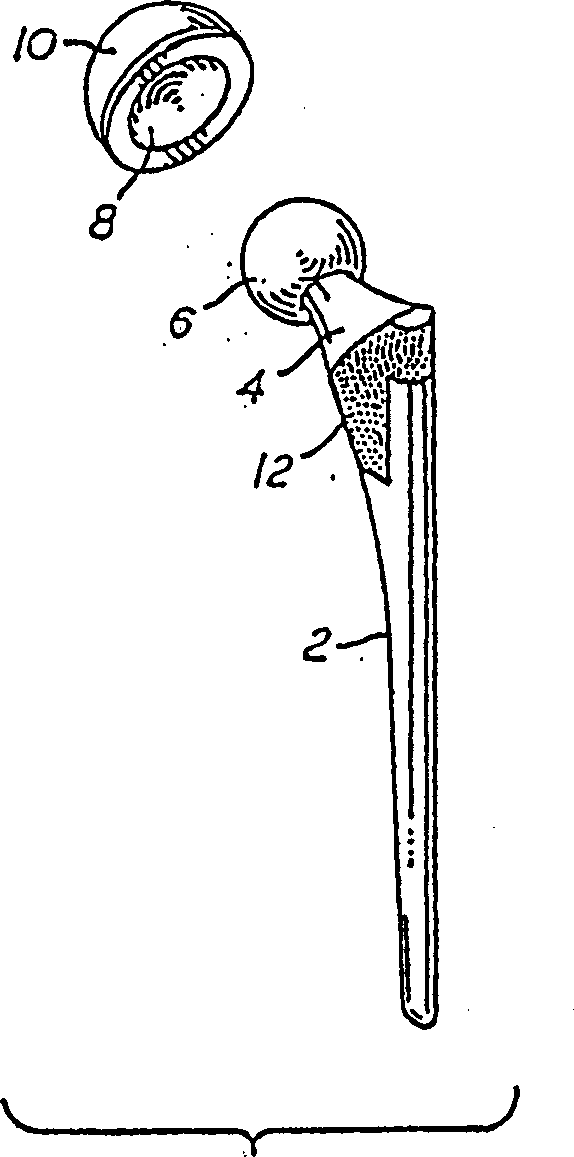

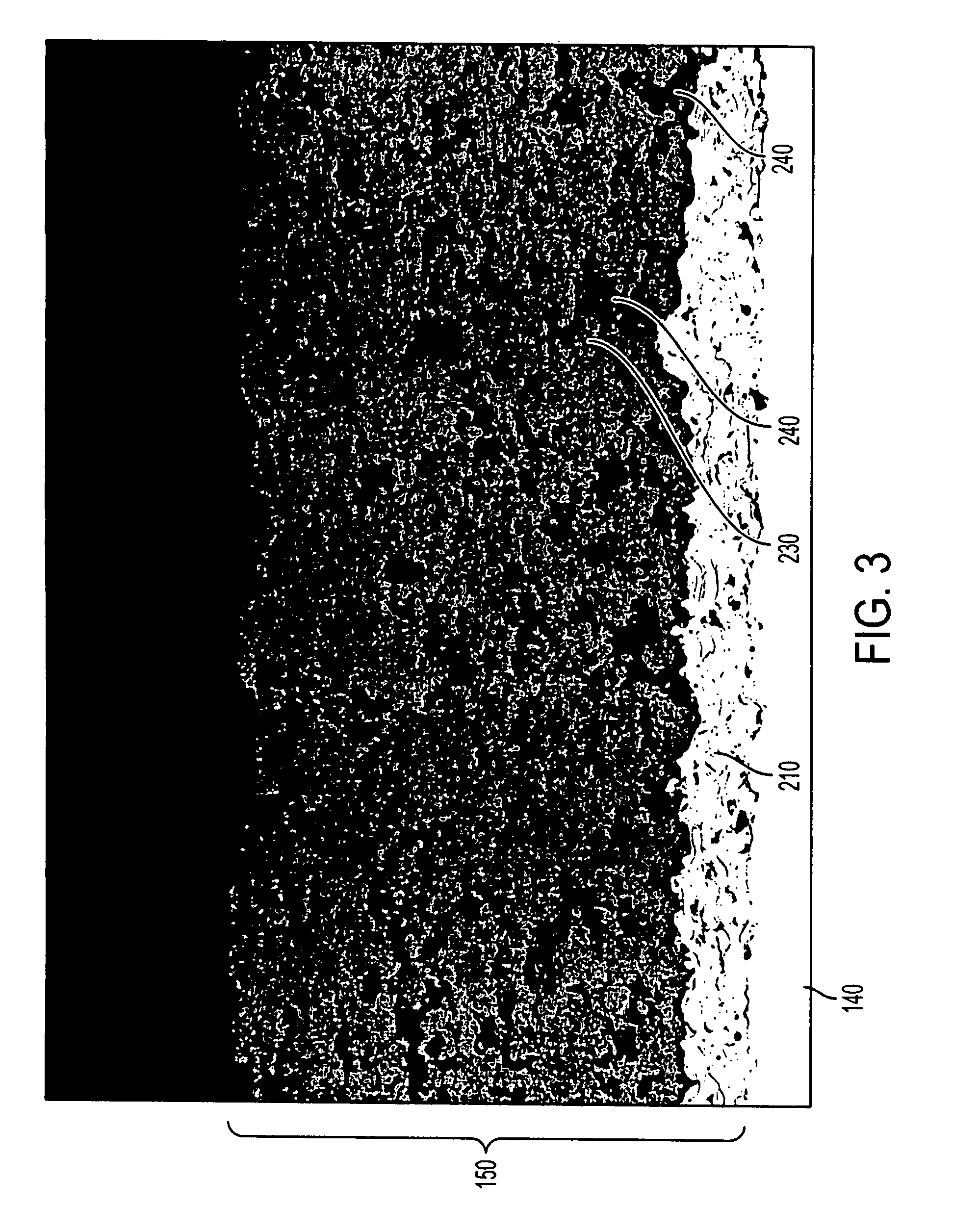

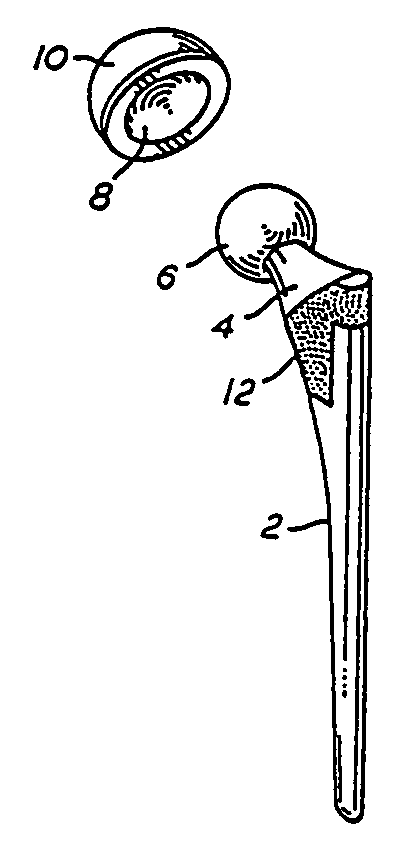

Method of surface oxidizing zirconium and zirconium alloys and resulting product

ActiveUS20060058888A1Bone implantSurface reaction electrolytic coatingWear resistantSurface oxidation

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the oxidative treatment of an amorphous zirconium or zirconium alloy substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

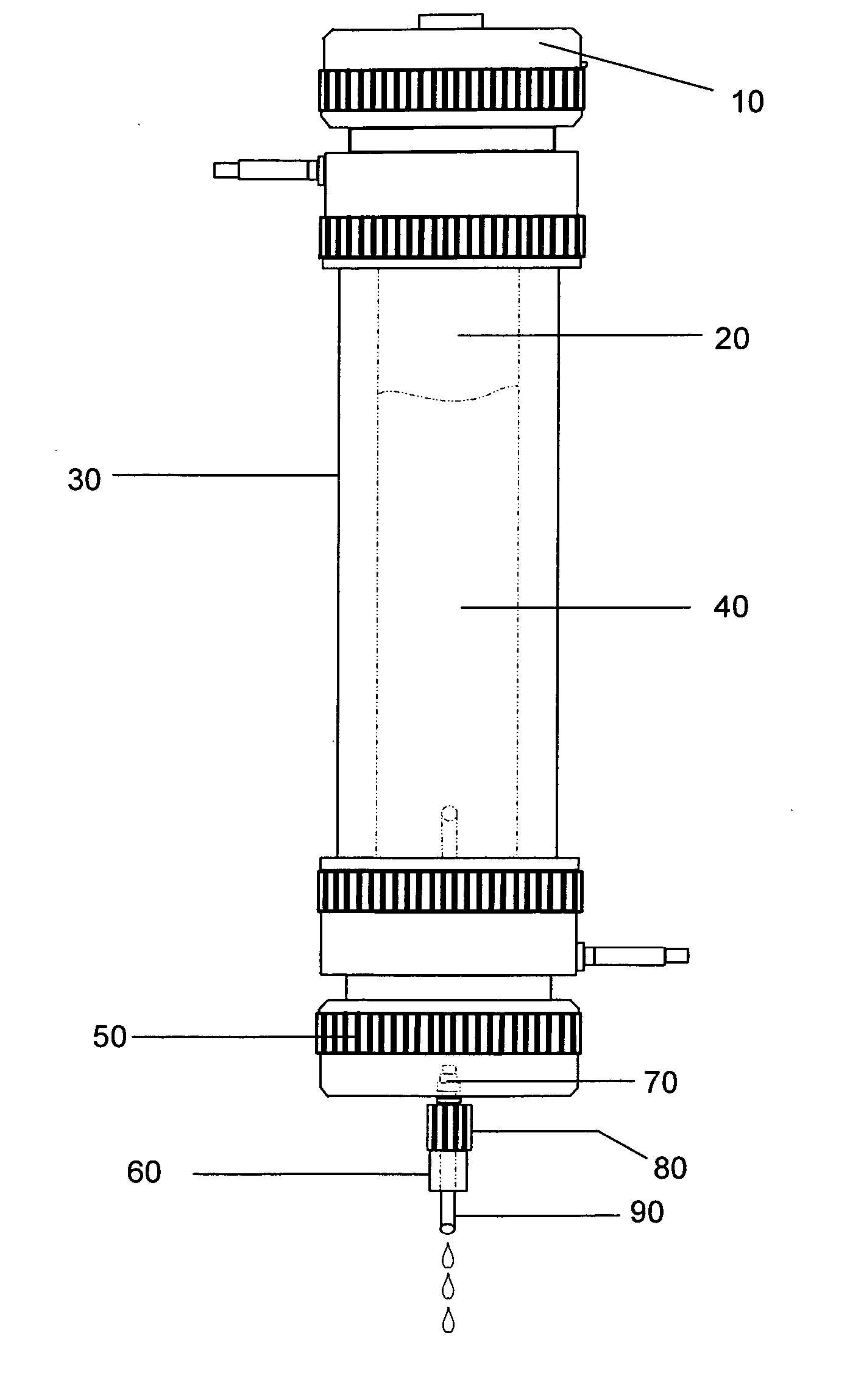

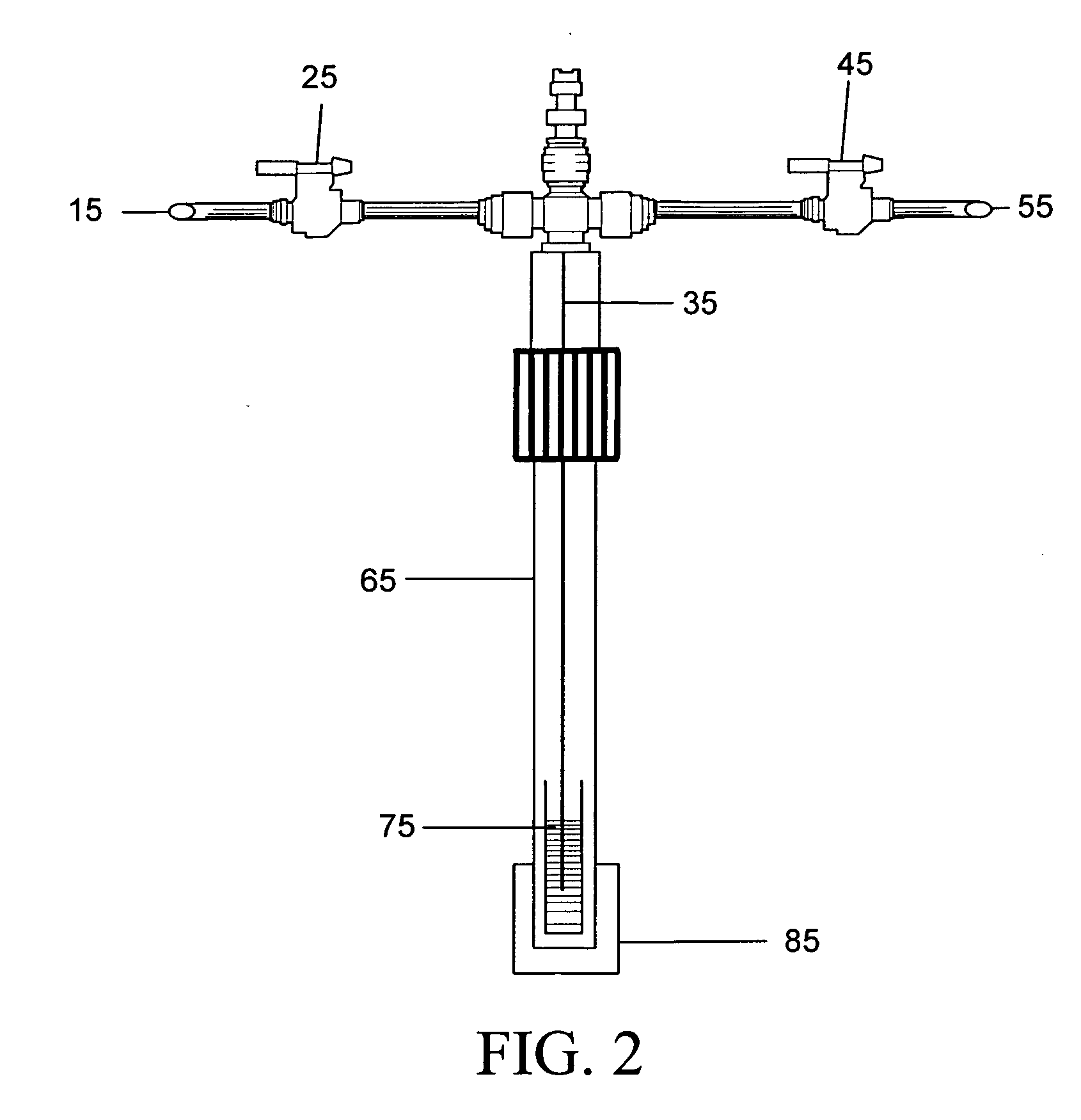

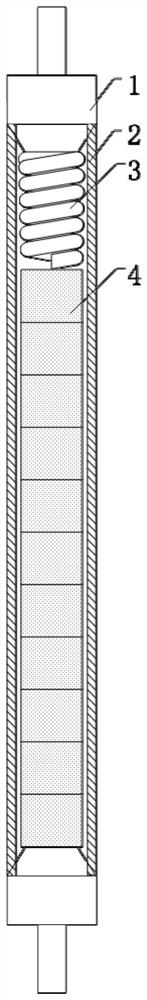

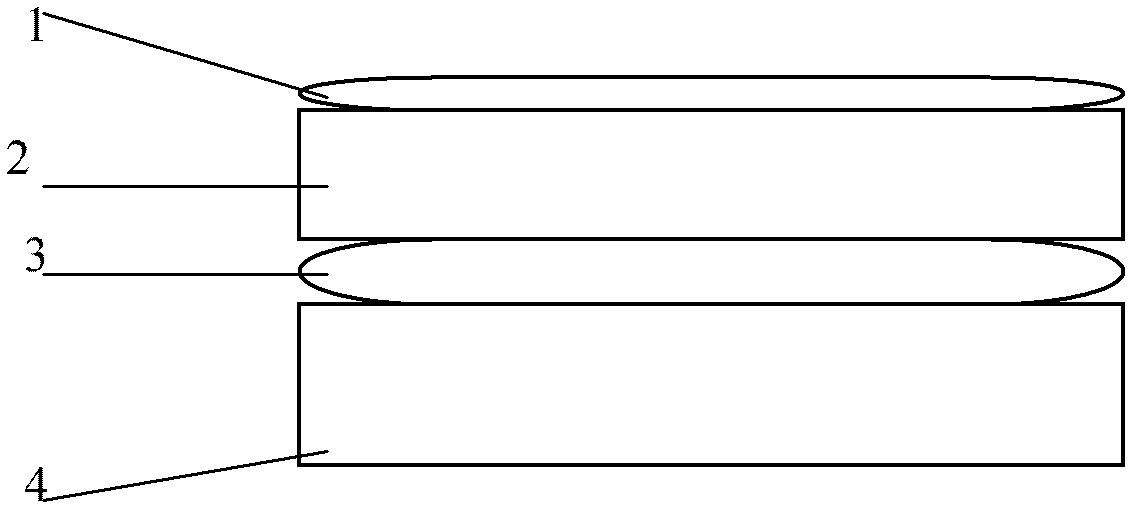

Tube structure with sol-gel zirconia coating

InactiveUS20070095736A1Improve stabilityUnique surface chemistryIon-exchange process apparatusOther chemical processesKetoneHYDROSOL

The subject invention concerns zirconia-based hybrid organic-inorganic sol-gel coating for optional use as a stationary phase in capillary microextraction (CME), gas chromatographic (GC), high performance liquid chromatography (HPLC), capillary electrophoresis (CE), capillary electrochromatography (CEC) and related analytical techniques. Sol-gel chemistry is employed to chemically bind a hydroxy-terminated silicone polymer (polydimethyldiphenylsiloxane, PDMDPS) to a sol-gel zirconia network. In one embodiment, a fused silica capillary is filled with a properly designed sol solution to allow for the sol-gel reactions to take place within the capillary. In the course of this process, a layer of the evolving hybrid organic-inorganic sol-gel polymer becomes chemically bonded to the silanol groups on the inner capillary walls. The unbonded part of the sol solution is expelled from the capillary under helium pressure, leaving behind a chemically bonded sol-gel zirconia —PDMDPS coating on the inner walls of the capillary. Polycyclic aromatic hydrocarbons, ketones, and aldehydes are efficiently extracted and preconcentrated from dilute aqueous samples followed by GC separation of the extracted analytes.

Owner:MALIK ABDUL +1

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the oxidative treatment of an amorphous zirconium or zirconium alloy substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

Scratch-resistant liquid based coatings for glass

ActiveUS20150132563A1High hardnessIncreased durabilityPretreated surfacesLiquid/solution decomposition chemical coatingMetallurgyZirconia coating

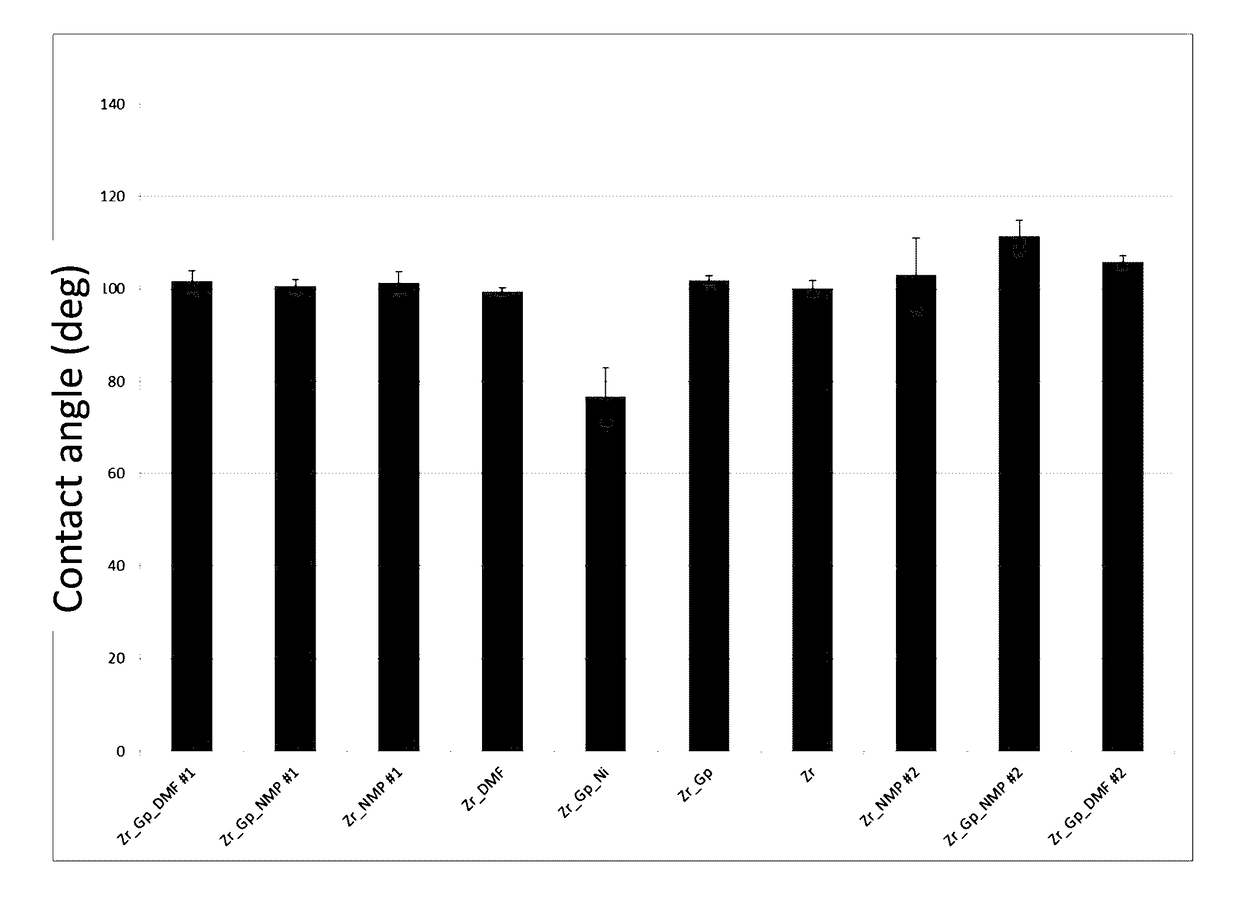

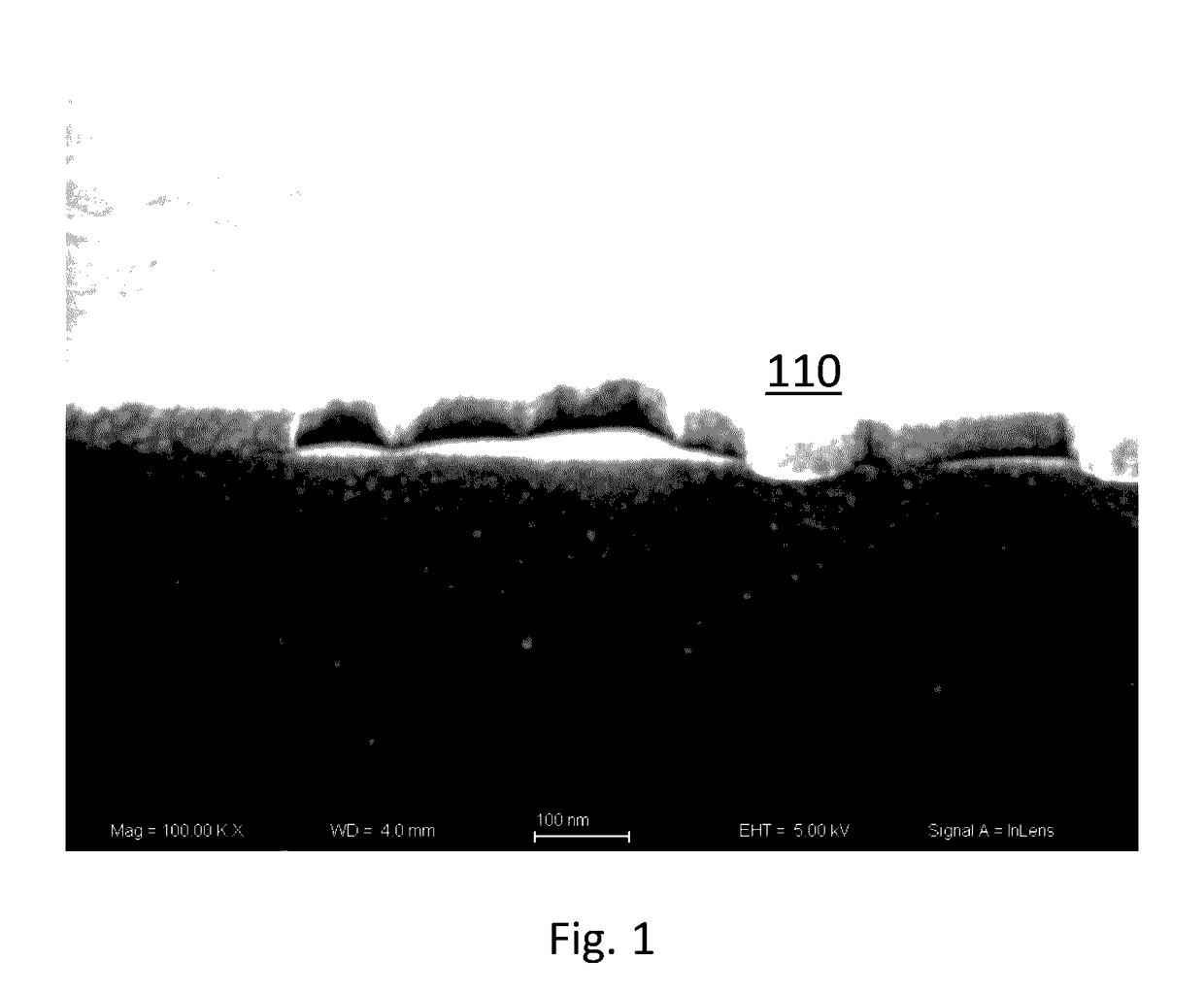

A sol-gel method for forming durable, scratch-resistant coatings on glass substrates. Zirconia coatings, for example, are formed from a solution of zirconium oxychloride octahydrate in an organic, polar, aprotic solvent such as dimethylformamide. Annealed coatings, which optionally include an additive such as graphene, have a low coefficient of friction and can exhibit high hardness and hydrophobicity.

Owner:CORNING INC

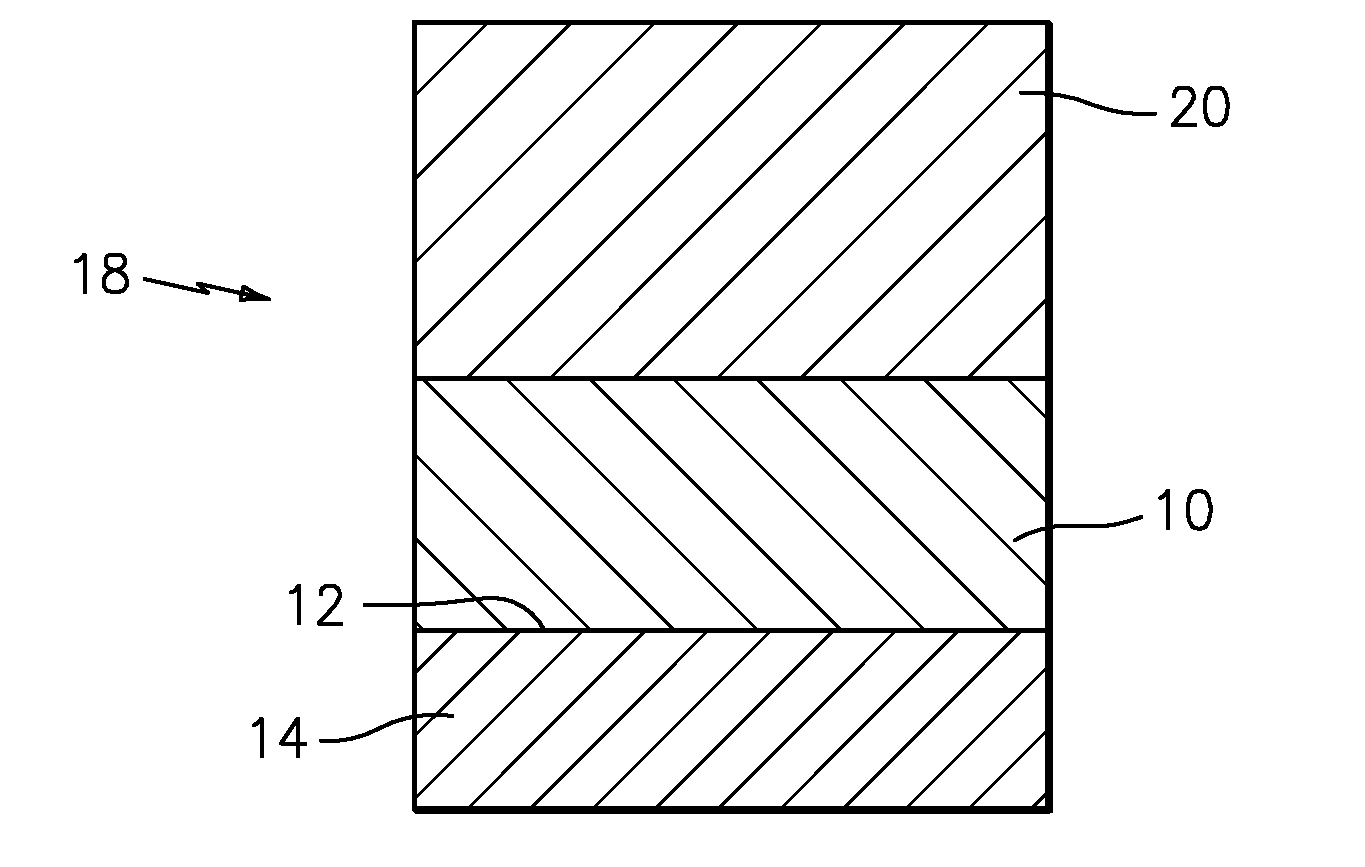

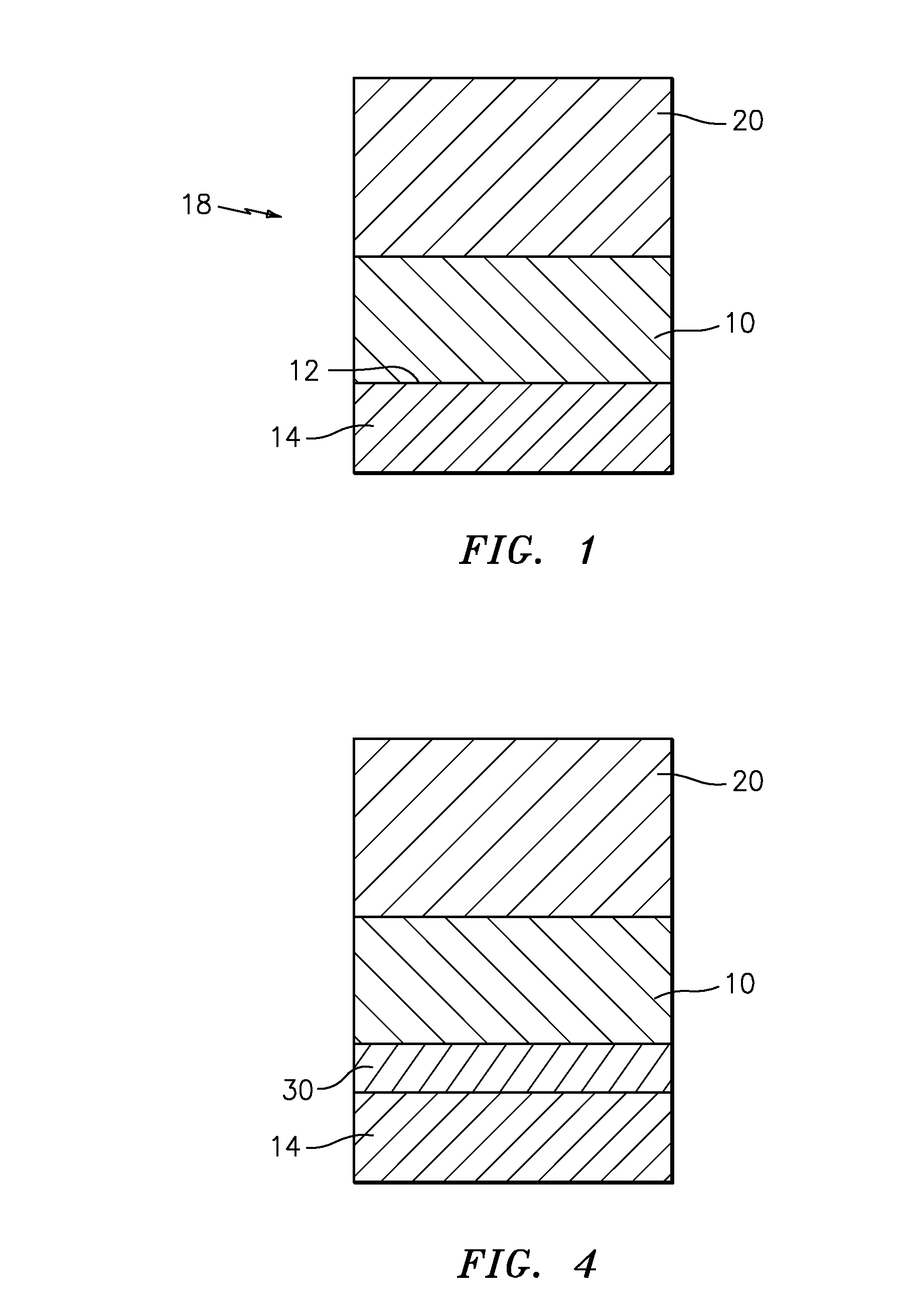

CMAS corrosion-resistance micronanometer composite thermal barrier coating layer and preparation method thereof

InactiveCN106086765ASuperhydrophobicCleanlinessMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionAlloy

The invention discloses a preparation method of a CMAS corrosion-resistance micronanometer composite thermal barrier coating layer. The thermal barrier coating layer includes a bonding layer prepared on an alloy basal body, a first ceramic layer and a second ceramic layer; the first ceramic layer is a yttrium oxide part stable zirconium oxide coating layer, can be prepared by atmosphere plasma spraying, an electronic beam physical vapor deposition method or a plasma evaporation deposition method, and has a thickness of 50-200 microns; and the second ceramic layer is a CMAS-resistance coating layer prepared by a plasma evaporation deposition system, and has a thickness of 1-100 microns. At high temperature, molten CMAS is not wet on the surface of the prepared second ceramic layer. The prepared multi-layer thermal barrier coating layer system including the bonding layer, the first ceramic layer and the CMAS-resistance second ceramic layer can effectively stop permeation of molten CMAS, and is excellent in molten CMAS corrosion resistance.

Owner:BEIHANG UNIV

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the use of a single phase crystalline material substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the use of a single phase crystalline material substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

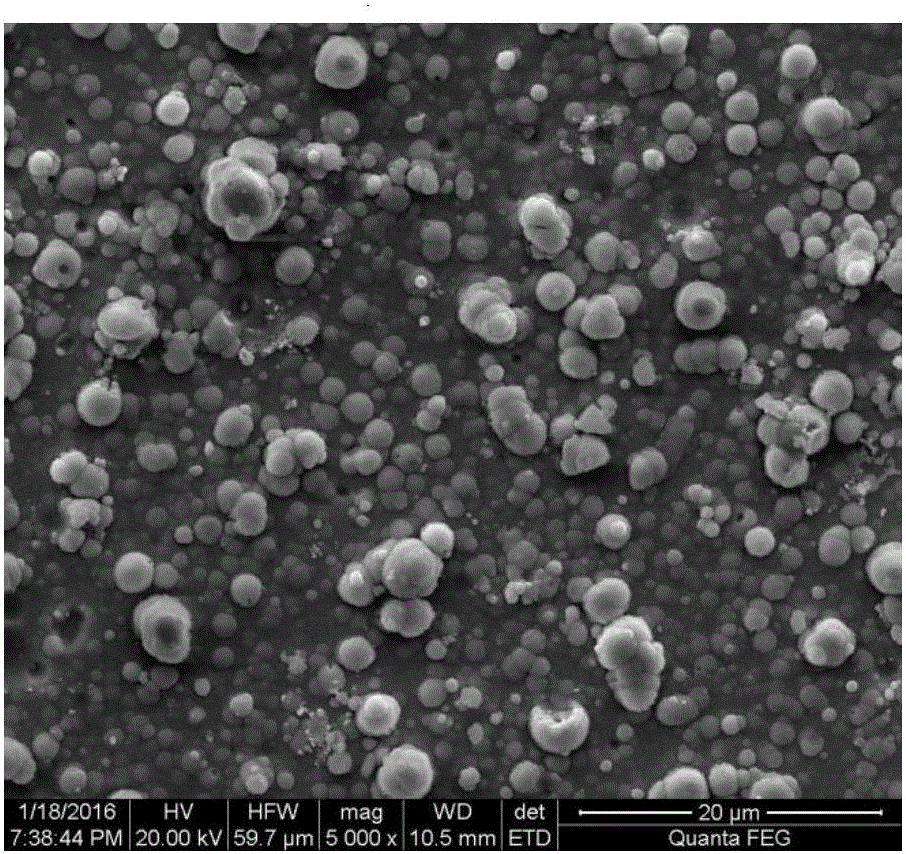

Dysprosia stabilized zirconia abradable

ActiveUS20080124548A1Improve thermal shock resistanceImprove abradabilityMolten spray coatingMachines/enginesPorosityThermal spraying

Ceramic abradable materials, in particular thermally sprayable ceramic abradable powder materials, and abradable seals formed by thermally spraying the materials include dysprosia (Dy2O3) and zirconia (ZrO2). Coatings are porous whereby the porosity, in part, is induced by plastic or fugitive phases. Abradable seal coatings comprising dysprosia and zirconia exhibit improved thermal shock and sintering resistance and can be worn into tolerance by untreated, bare turbine blades, at least in certain regimes of relative blade speed and coating porosity. Ceramic abradable seal coatings comprising dysprosia and zirconia can be used up to 1200° C.

Owner:SULZER METCO (US) INC

Preparation method for porous zirconium oxide thermal barrier coating

InactiveCN107699840AHighlight substantive featuresImprove insulation performanceMolten spray coatingPorosityElectron beam physical vapor deposition

The invention discloses a preparation method for a porous zirconium oxide thermal barrier coating, and relates to coating of metal materials by oxides. The method for preparing the porous zirconium oxide thermal barrier coating by combining a thermal spraying technology with thermal treatment comprises the following steps of: uniformly mixing nano zirconium oxide powder stabilized by 8% (in percentage by mass) of yttrium oxide and high-molecular polymer pore-forming agent powder to obtain a mixture, uniformly mixing a binder to prepare zirconium oxide based composite powder used for thermal spraying; pre-treating a metal matrix material; preparing a porous zirconium oxide coating through a thermal spraying method; and thermally treating the porous zirconium oxide coating, thereby preparingthe porous zirconium oxide thermal barrier coating on the surface of the metal matrix material. According to the preparation method disclosed by the invention, effective control on porosity can be realized by regulating components and adding amount of the pore-forming agent, so that porosity is obviously improved, and therefore, heat insulation of the coating is also improved. The preparation method overcomes various defects of electron beam physical vapor deposition in the prior art for preparing the porous zirconium oxide thermal barrier coating.

Owner:HEBEI UNIV OF TECH

Synthesis technique of high-grade self-sharpening polycrystalline diamond

InactiveCN103521132ALow oxygenGuaranteed synthetic yieldUltra-high pressure processesIn situ polymerizationPolycrystalline diamond

The invention relates to a synthesis technique of a high-grade self-sharpening polycrystalline diamond, which comprises the following steps: metering and mixing the raw materials for synthesizing the diamond according to percentage by mass, granulating, and pressing into a synthetic stick; putting the synthetic stick into a synthesis block, and drying in a vacuum drying oven at constant temperature for later use, wherein the synthesis block is synthesized at high temperature under superhigh pressure with a cubic press; and taking out the synthetic stick, carrying out after-treatment to obtain a self-sharpening polycrystalline diamond, carrying out in-situ polymerization by a sol-gel process, and applying a zirconia coating on the diamond surface to form the high-grade self-sharpening polycrystalline diamond. The product has the advantages of favorable impact toughness, favorable thermal stability and favorable comprehensive properties, can obviously enhance the holding force of the self-sharpening polycrystalline diamond in a grinding tool, can keep the self-sharpness in the grinding process, and finally, is beneficial to prolonging the service life of th grinding tool and enhancing the machining efficiency of the grinding tool.

Owner:ZHONGYUAN ENGINEERING COLLEGE +1

Thermal Spray Coatings for Semiconductor Applications

InactiveCN102272344AHigh thermodynamic phase stabilityLow thermal conductivityMolten spray coatingElectric discharge tubesIntegrated circuit manufacturingCeramic coating

Owner:PRAXAIR TECH INC

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the use of a single phase crystalline material substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

Scratch-resistant liquid based coatings for glass

ActiveUS9663400B2Improve durability and lifetimeHigh hardnessPretreated surfacesLiquid/solution decomposition chemical coatingHardnessZirconia coating

A sol-gel method for forming durable, scratch-resistant coatings on glass substrates. Zirconia coatings, for example, are formed from a solution of zirconium oxychloride octahydrate in an organic, polar, aprotic solvent such as dimethylformamide. Annealed coatings, which optionally include an additive such as graphene, have a low coefficient of friction and can exhibit high hardness and hydrophobicity.

Owner:CORNING INC

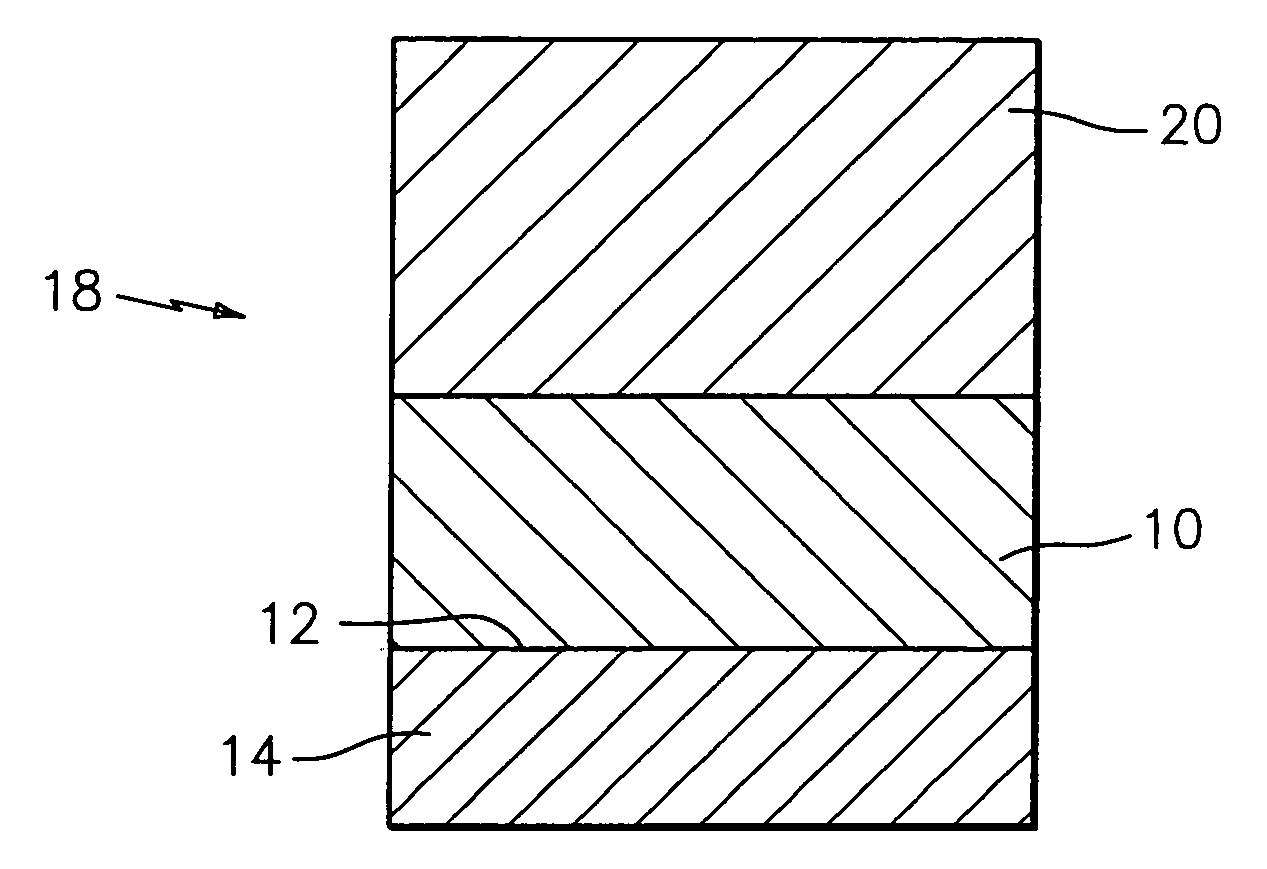

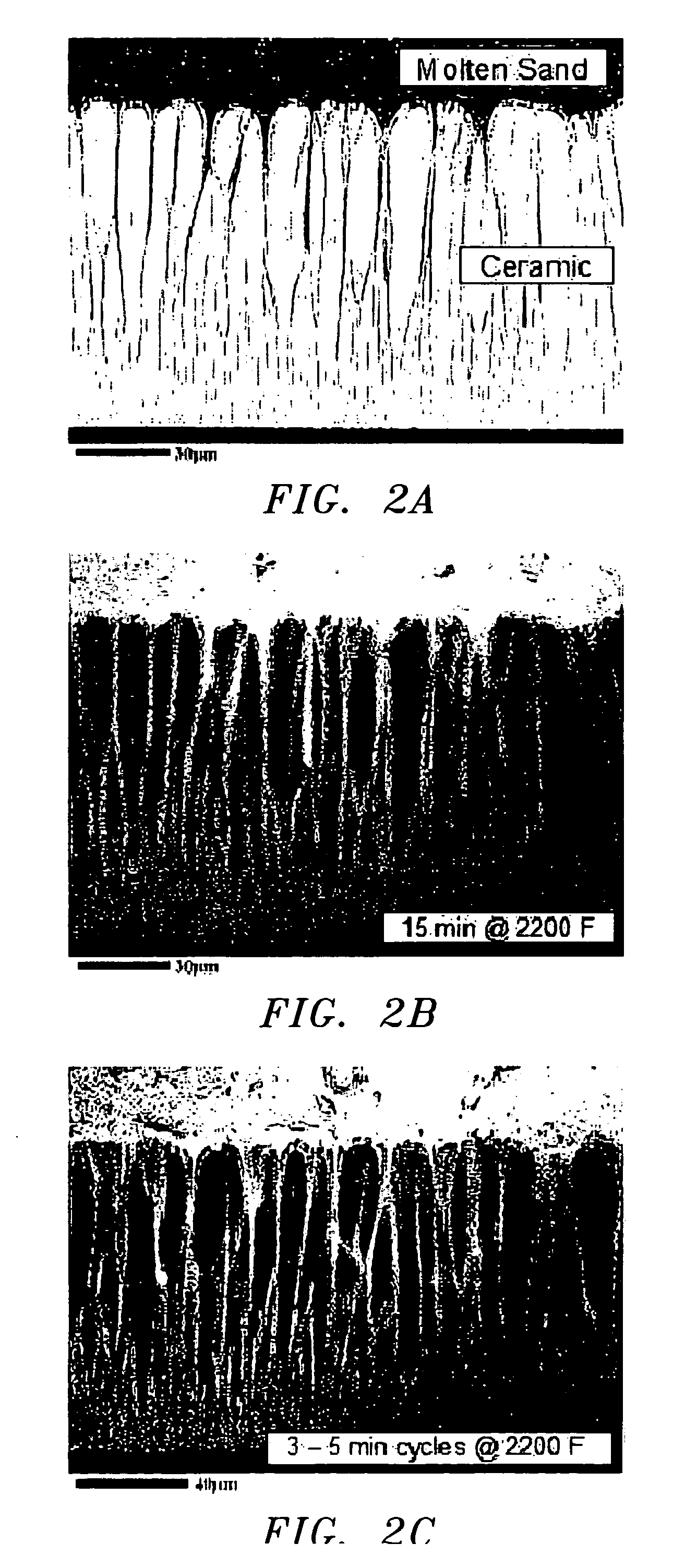

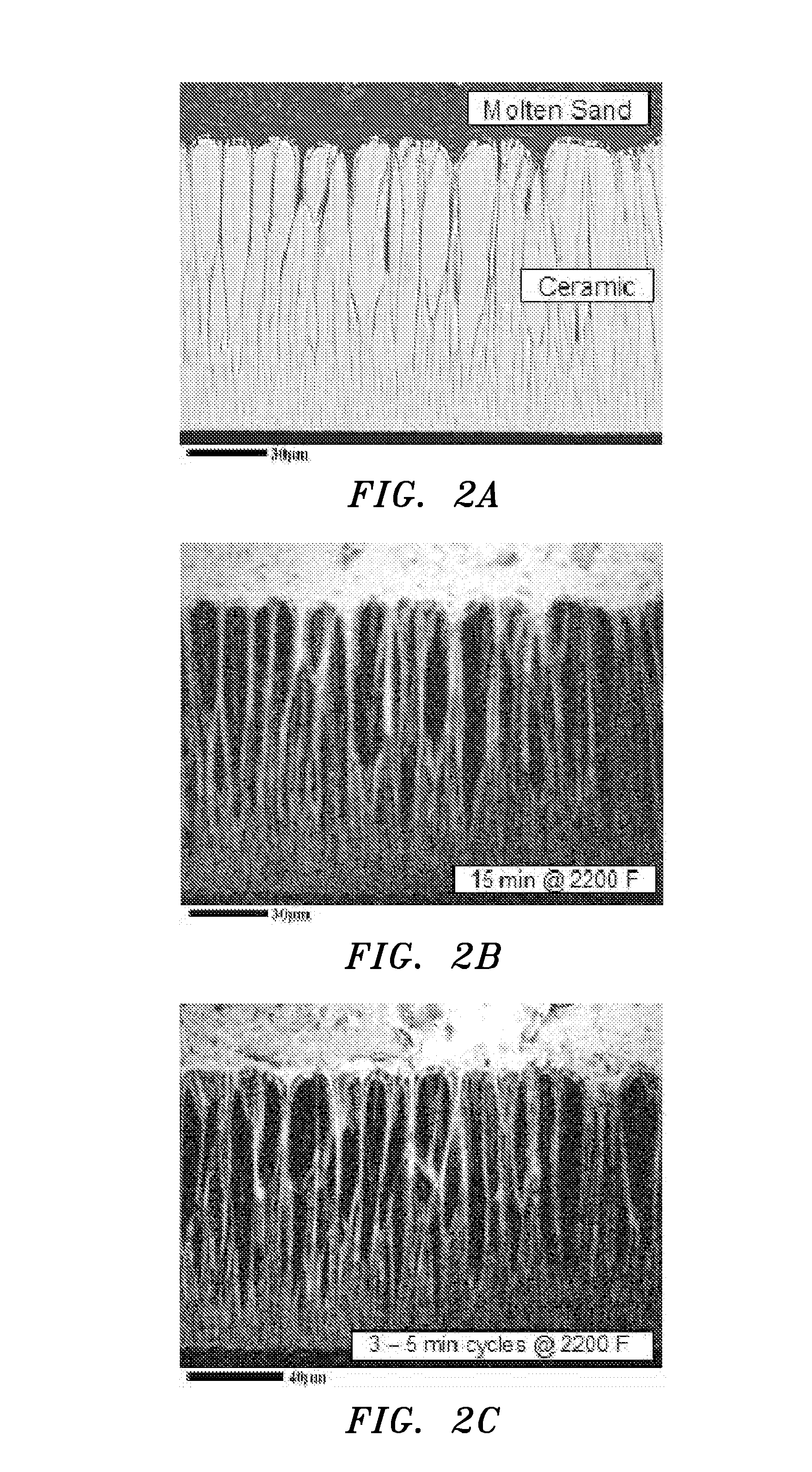

Yttria-stabilized zirconia coating with a molten silicate resistant outer layer

ActiveUS20080176097A1Reduces sand related distressVacuum evaporation coatingPretreated surfacesMetallurgyCoating system

A turbine engine component is provided which has a substrate, a yttria-stabilized zirconia coating applied over the substrate, and a molten silicate resistant outer layer. The molten silicate resistant outer layer is formed from gadolinia or gadolinia-stabilized zirconia. A method for forming the coating system of the present invention is described.

Owner:RTX CORP

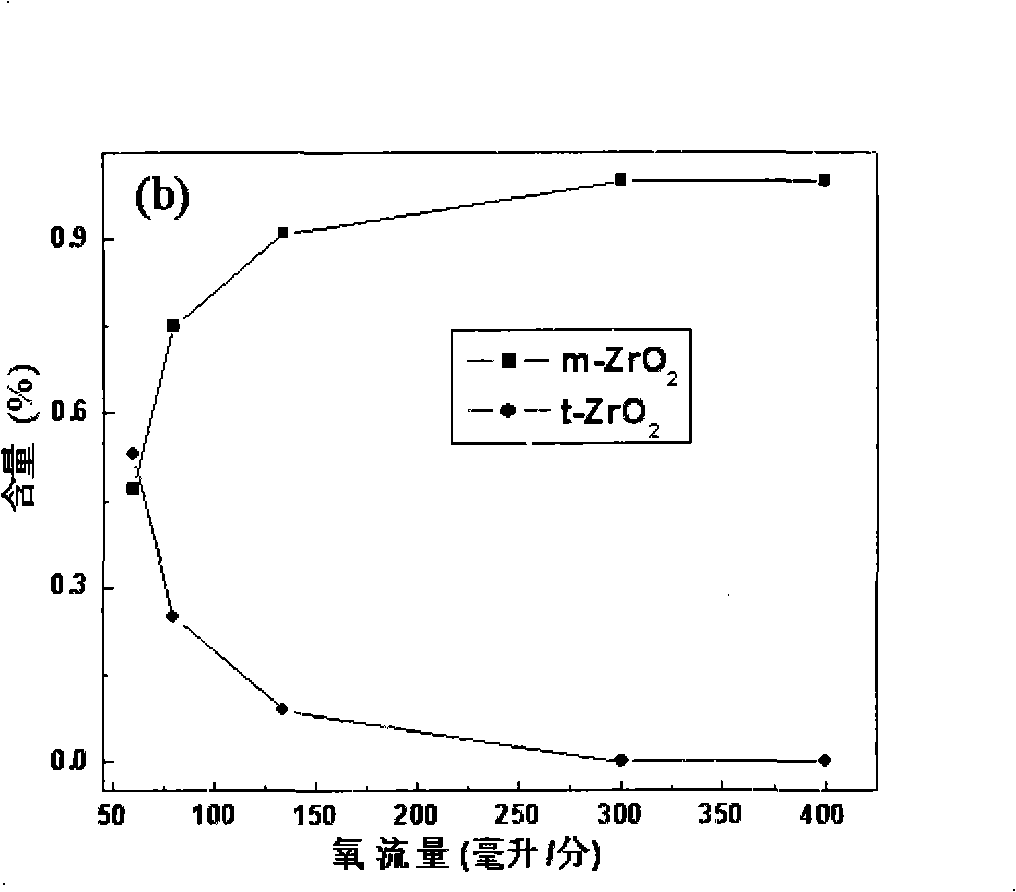

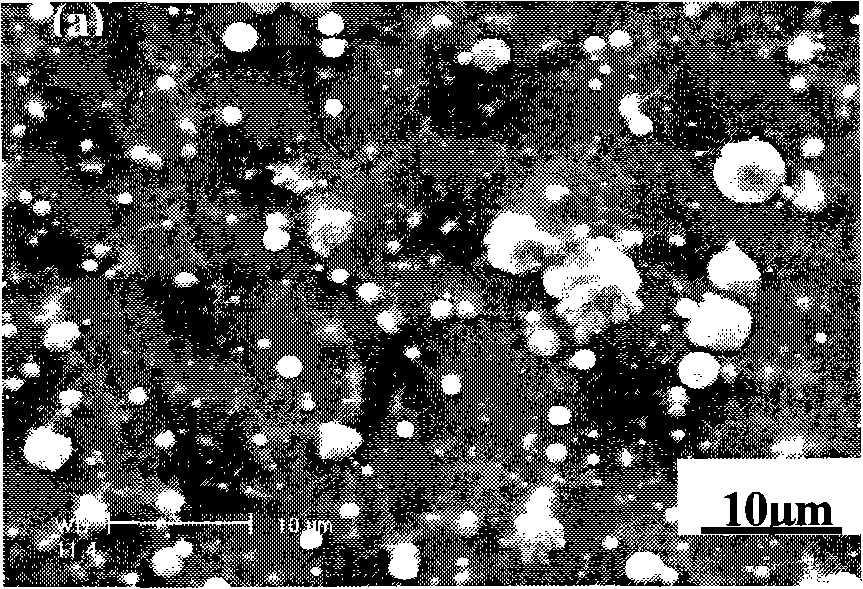

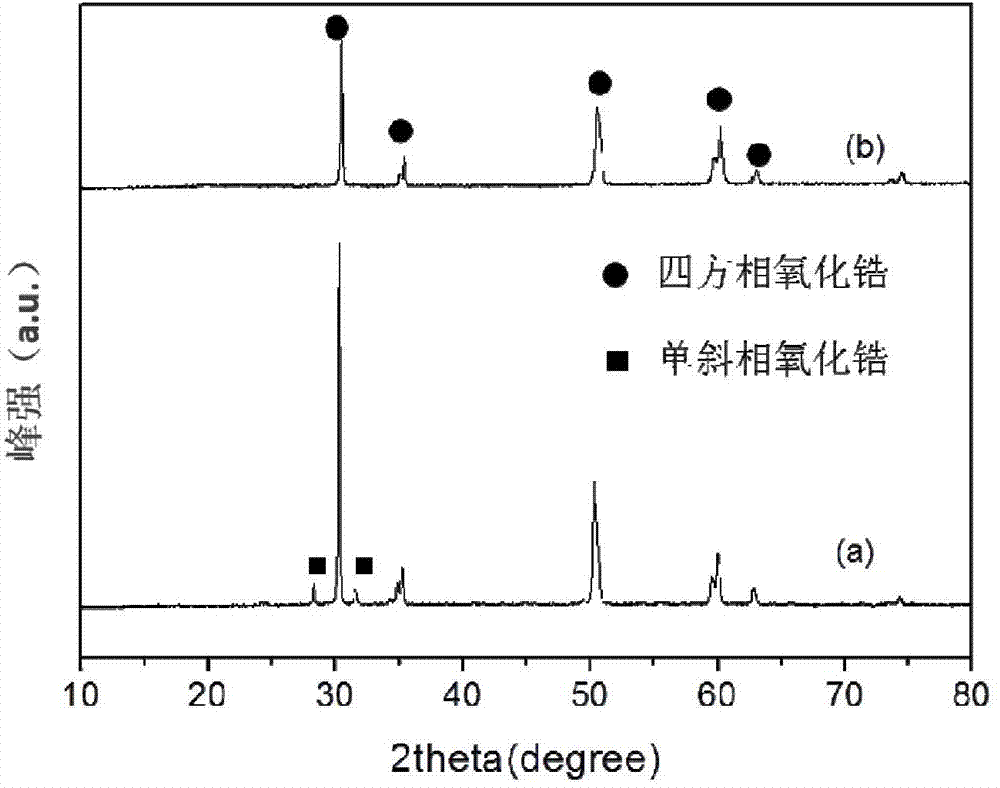

Process for preparing zirconia coating

InactiveCN101307424AGood process repeatabilityLarge adjustment rangeVacuum evaporation coatingSputtering coatingAlloy substrateCrystal structure

The invention relates to a coating preparation technology, in particular to a technique for preparing a zirconia coating, which is to adopt the arc ion plating technology and utilize pure Zr or ZrY alloy target materials for deposition reaction of a ZrO2 coating or a Zr(Y)O2 coating on an alloy substrate or an arc ion plating MCrAlY coating in O2 atmosphere. The technique for preparing the zirconia coating has the advantages of good technical repeatability, easy realization of industrial production and so on; the ZrO2 coating or the Zr(Y)O2 coating prepared has uniform and compact texture, is a cylindrical crystal structure, and has good bonding strength; and the Zr(Y)O2 coating has good thermal shock resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

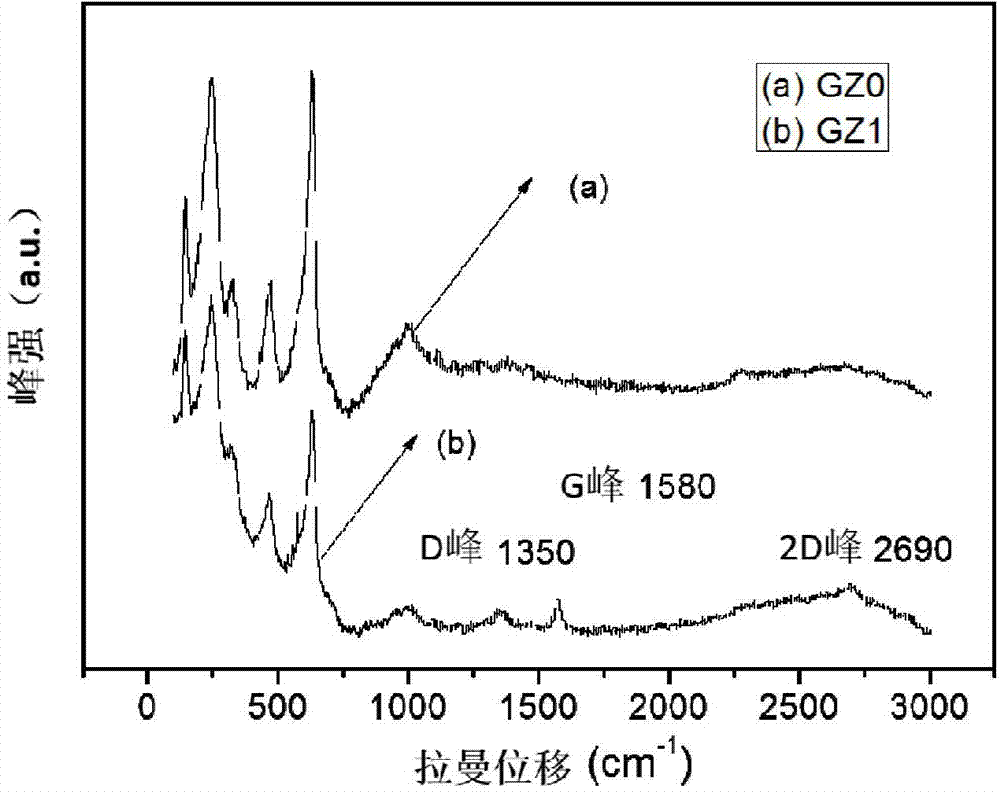

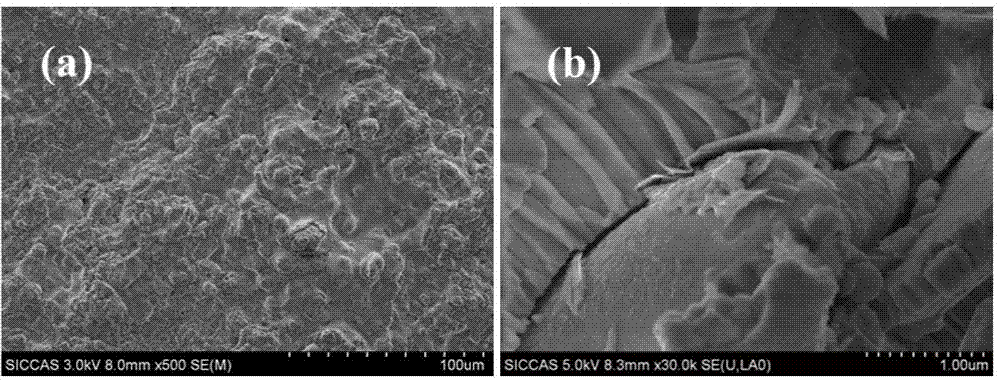

Composite powder composition for ceramic coating and ceramic coating, and preparation method thereof

InactiveCN104725038AInhibition of germinationInhibition of expansionMolten spray coatingEffective solutionCeramic coating

The invention discloses a composite powder composition for a ceramic coating and a ceramic coating, and a preparation method thereof. The composite powder composition comprises an yttria stable zirconia powder and graphene nanosheets. The ceramic coating, which is obtained by spraying the composite powder composition on a metal substrate, has obviously higher wear resistance than the pure-phase yttria stable zirconia coating, can obviously reduce abrasive dust generated by friction under high-load conditions, and obviously lowers the friction factor and average abrasion rate. The invention provides a feasible solution for enhancing wear resistance of the ceramic coating. Besides, the method has the advantages of high efficiency, favorable repeatability and the like, and is simple to operate and suitable for large-scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

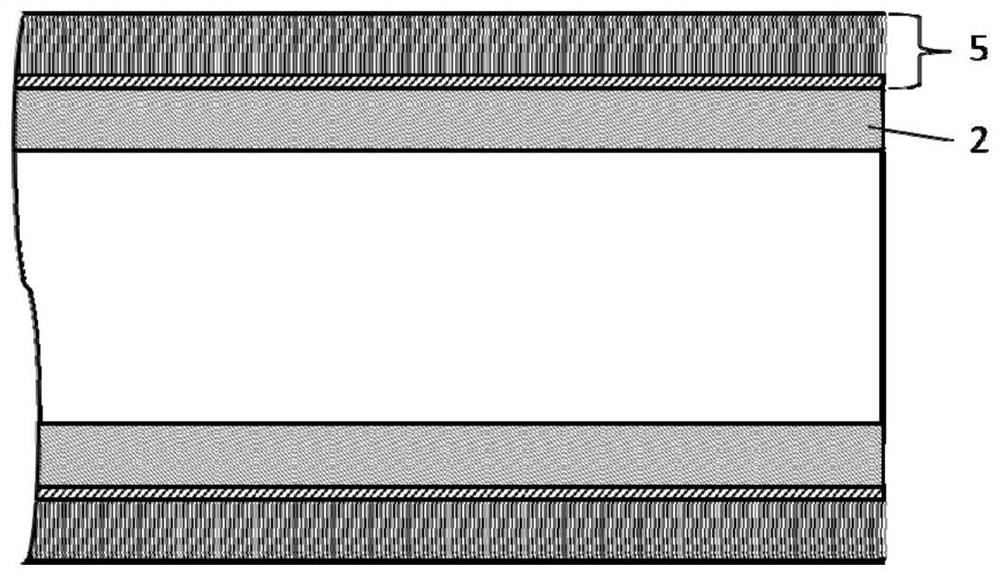

Metal composite ceramic thermal barrier coating preparation method

ActiveCN104775087AReduce porosityHigh bonding strengthMolten spray coatingComposite ceramicSuperalloy

The invention discloses a metal composite ceramic thermal barrier coating preparation method, belongs to the technical field of thermal spraying, and mainly aims to solve the problem of low structural strength and poor toughness of zirconia coating which is stabilized by yttrium oxide. The metal composite ceramic thermal barrier coating preparation method is mainly characterized in that: 1, cleaning high temperature alloy matrix surface, 2, sand-blasting roughening the cleaned high temperature alloy matrix surface, 3, spraying the sand-blasting roughened matrix surface with nickel chromium aluminum cobalt yttrium powder by plasma to use as a bottom layer, and 4, spraying the nickel chromium aluminum cobalt yttrium bottom layer with a plasma spraying material to obtain a metal composite ceramic thermal barrier coating, wherein the plasma spraying material comprises 25%-27% of Ni, 5-7% of Cr, 0.5%-2% of Al and 64%-66% ofZrO2.Y2O3. The metal composite ceramic thermal barrier coating prepared by the method has the characteristics of being high in combination strength, good in toughness, and capability of working in hot and cold alternating environment of 950 DEG C to room temperature for 1500h, and the method is mainly used for the preparation of metal composite ceramic thermal barrier coatings with good toughness and high strength of combination with the matrix.

Owner:襄阳航泰动力机器厂

Yttria-Stabilized Zirconia Coating with a Molten Silicate Resistant Outer Layer

ActiveUS20100196605A1Reduces sand related distressBlade accessoriesVacuum evaporation coatingMetallurgyCoating system

A turbine engine component is provided which has a substrate, a yttria-stabilized zirconia coating applied over the substrate, and a molten silicate resistant outer layer. The molten silicate resistant outer layer is formed from gadolinia or gadolinia-stabilized zirconia. A method for forming the coating system of the present invention is described.

Owner:RTX CORP

Pure titanium seamless pipe cross rolling piercing method

ActiveCN104889163AEliminate stickingSolve the sticking problemMetal rolling arrangementsMicrometerSurface roughness

The invention discloses a pure titanium seamless pipe cross rolling piercing method which includes the steps: hot spraying a zirconium oxide coating with the thickness of 0.2-0.4mm on a working surface of a guide plate of a cross rolling piercing machine by the aid of plasma; grinding the zirconium oxide coating with surface roughness of 0.9-1.5 micrometers; smearing boron nitride lubricants on a working surface of a front guide plate of the cross rolling piercing machine; setting the ellipticity of a pure titanium seamless pipe cross rolling piercing hole pattern to be 1.09-1.2. By the method, piercing and sizing can be performed on a hot rolling mill comprising the cross rolling piercing machine, so that a high-precision pure titanium seamless pipe is directly produced on a production process line, and the problems of easiness in adhesion and low yield of guide plates of a cross rolling piercing machine in the prior art are solved.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Method for preparing zirconium oxide coating on magnesium alloy surface

InactiveCN101139731AImprove corrosion and wear resistanceImprove fracture toughnessAnodisationElectrolytic inorganic material coatingMicro arc oxidationCelsius Degree

A method to prepare zirconia coating on magnesium alloy surface relates to a coating preparation coating method. The invention resolves the following problems in prior zirconia coating preparation on magnesium alloy surface: Complex equipment, high cost, thermal influences on the basic body and no firm binding with the basic body and etc. The invented process steps are as follows: 1. Preparing electrolyte; 2. Grinding magnesium alloy smooth before water scrubbing; 3. Putting magnesium alloy from Step 2 process into the electrolyte to gain a anode, and select stainless steel plate as a cathode; electrolyte temperature is 10 to 40 celsius degrees; power is supplied with a microarc oxidation power source, so that maintain the charged reaction for 5 to 60 minutes in constant current or constant voltage; 4. Take out the magnesium alloy through Step 3 to perform water scrubbing, and dry it in room temperature condition or in 60 to 90 celsius degrees. The invented method lowers the cost but improves product performances, for which adapts to industrialized prdocution. The invented method can receive a coating with perfect binding force with the basic body, as well as smooth surface, small pore diameter, perfect corrosion resistance and ceramic appearances.

Owner:HARBIN INST OF TECH

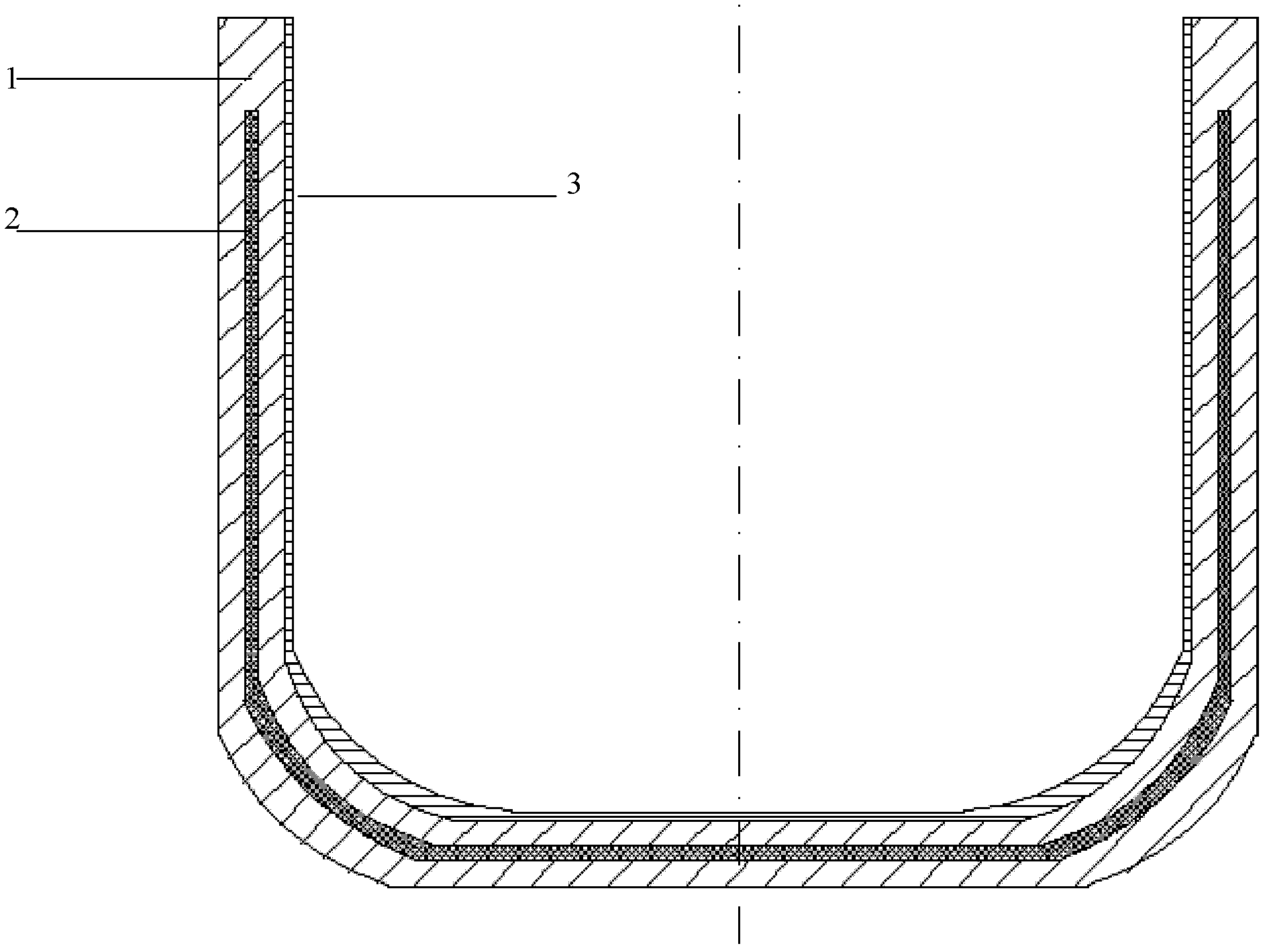

High-temperature steam corrosion resistant coating for zirconium alloy cladding tube

ActiveCN112164479APrevent infiltrationImprove economyOptical rangefindersFuel elementsBi layerZirconia coating

The invention discloses a high-temperature steam corrosion resistant coating for a zirconium alloy cladding tube. Two layers of the coating are arranged outside the zirconium alloy cladding tube, andthe first layer of the coating close to the zirconium alloy cladding tube is a metal transition layer or a ceramic transition layer; and the second layer of the coating is arranged on the metal transition layer, the second layer of the coating is a working layer, and the working layer is a zirconium coating or a zirconium oxide coating or a zirconium and zirconium oxide double-layer coating. By the adoption of the coating, the corrosion rate of the zirconium alloy cladding in 1000 DEG C steam can be reduced by 85% or above compared with that of an uncoated cladding, the turning acceleration phenomenon of oxidation is avoided, and the zirconium alloy cladding has more excellent LOCA accident resistance. Compared with a pure Cr coating, the coating remarkably improves the neutron economy ofthe cladding.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

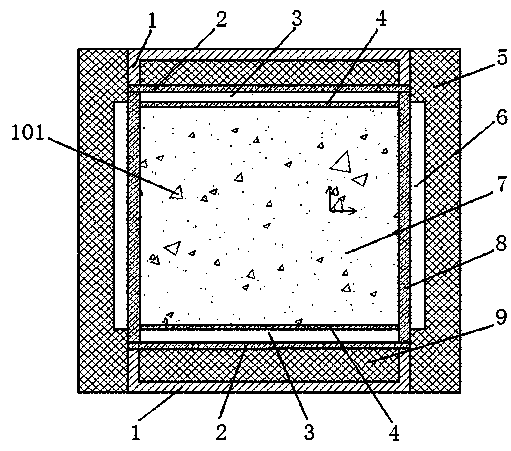

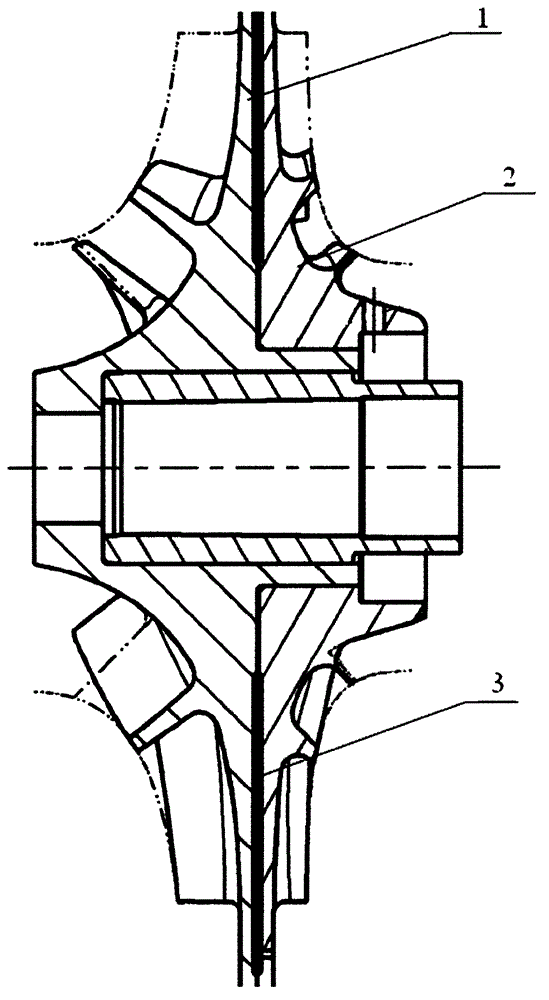

Split heat-insulation double-sided water pump impeller

InactiveCN103148014AReduce heat transferReduce interactionPump componentsPumpsInterference fitWorking temperature

The invention discloses a split heat-insulation double-sided impeller structure which comprises a large impeller 1 and a small impeller 2, wherein the large impeller 1 and the small impeller 2 are arranged axially in an interference fit manner, after being assembled, the large impeller 1 and the small impeller 2 form a heat-insulation structure 3 at the back of the impeller, and the heat-insulation structure is internally filled with a heat-insulation material or a coating with end surface coated with zirconium oxide. For a double-sided cooling water pump of a high-low-temperature double-loop cooling system meeting the application of a diesel engine, the working temperatures of cooling media at two sides of the impeller are commonly different, if the heat-insulation measure is not taken, the impeller is made of metals, so that strong heat transfer capability causes large influence on the heat dissipation at two sides during long-time working. The split heat-insulation impeller adopted can reduce the mutual temperature influence of two high-low-temperature sides, and meet the long-time working demand of high-low-temperature loops.

Owner:CHINA NORTH ENGINE INST TIANJIN

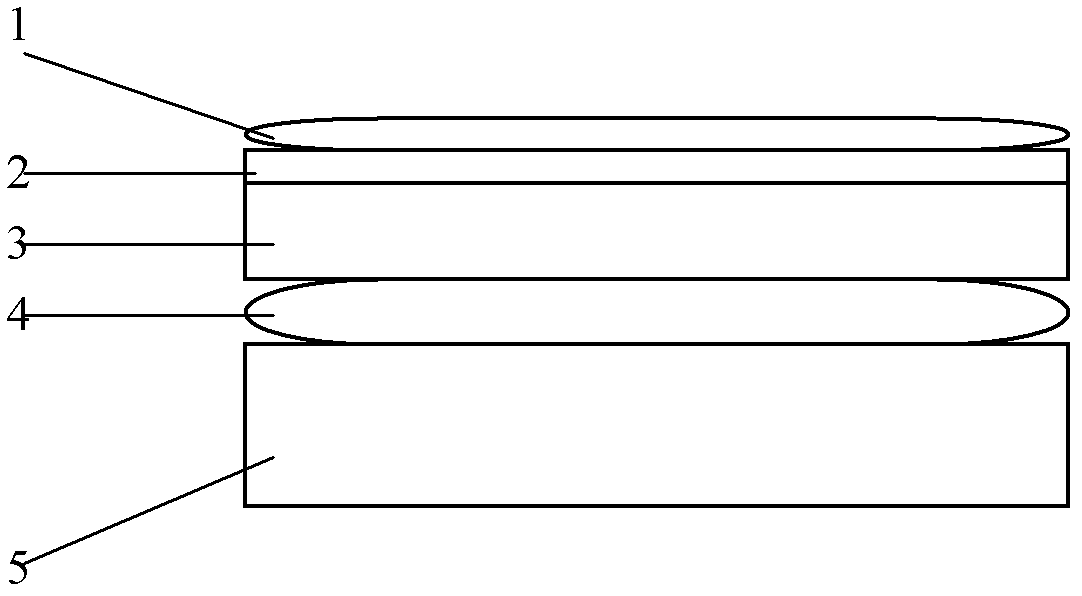

Silicon nitride crucible and manufacture method thereof

The invention discloses a silicon nitride crucible. The crucible comprises a silicon nitride outer wall layer, a rich silicon layer, a silicon nitride inner wall layer and a zirconia coating from outside to inside in sequence. The outer wall layer can replace a graphite crucible to play a role of supporting. The inner wall layer can resist a certain amount of heat shock. The rich silicon layer is in a softening state under high temperature and porosity is high. When heat shock transmits to the rich silicon layer, the heat shock is released through compression and certain deformation of pores, and heat impact resistance capacity of the silicon nitride crucible is greatly enhanced. An anti-bonding layer is formed by the zirconia coating. The problem of adhesion of silicon materials and the inner wall of the crucible when the silicon materials are solidified is effectively solved, and repeated use of the crucible is possible. Meanwhile, the invention further discloses a method for manufacturing the silicon nitride crucible with the characteristics.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

Preparation method of silicon carbide ceramic kiln furniture coated with yttria-stabilized zirconia coating

The invention discloses a preparation method of silicon carbide ceramic kiln furniture coated with an yttria-stabilized zirconia coating. The method comprises the following steps that 1, a silicon carbide ceramic kiln furniture blank is evenly coated with yttria-stabilized zirconia sol in a spraying mode, so that the coating is formed, and after natural drying is performed for 2-3 h, drying is performed at the temperature of 45-55 DEG C for 5-7 h, wherein the yttria-stabilized zirconia sol is the zirconium dioxide sol containing 3 mol% yttrium and is obtained through a sol-gel method; 2, the product obtained in the first step is fired at the temperature of 1450-1500 DEG C for 72-96 h, and the silicon carbide ceramic kiln furniture coated with the yttria-stabilized zirconia coating is obtained. By adopting the method, the oxidation resistance and high temperature resistance of the silicon carbide ceramic kiln furniture can be improved.

Owner:ANJI KELING MAGNETIC MATERIAL

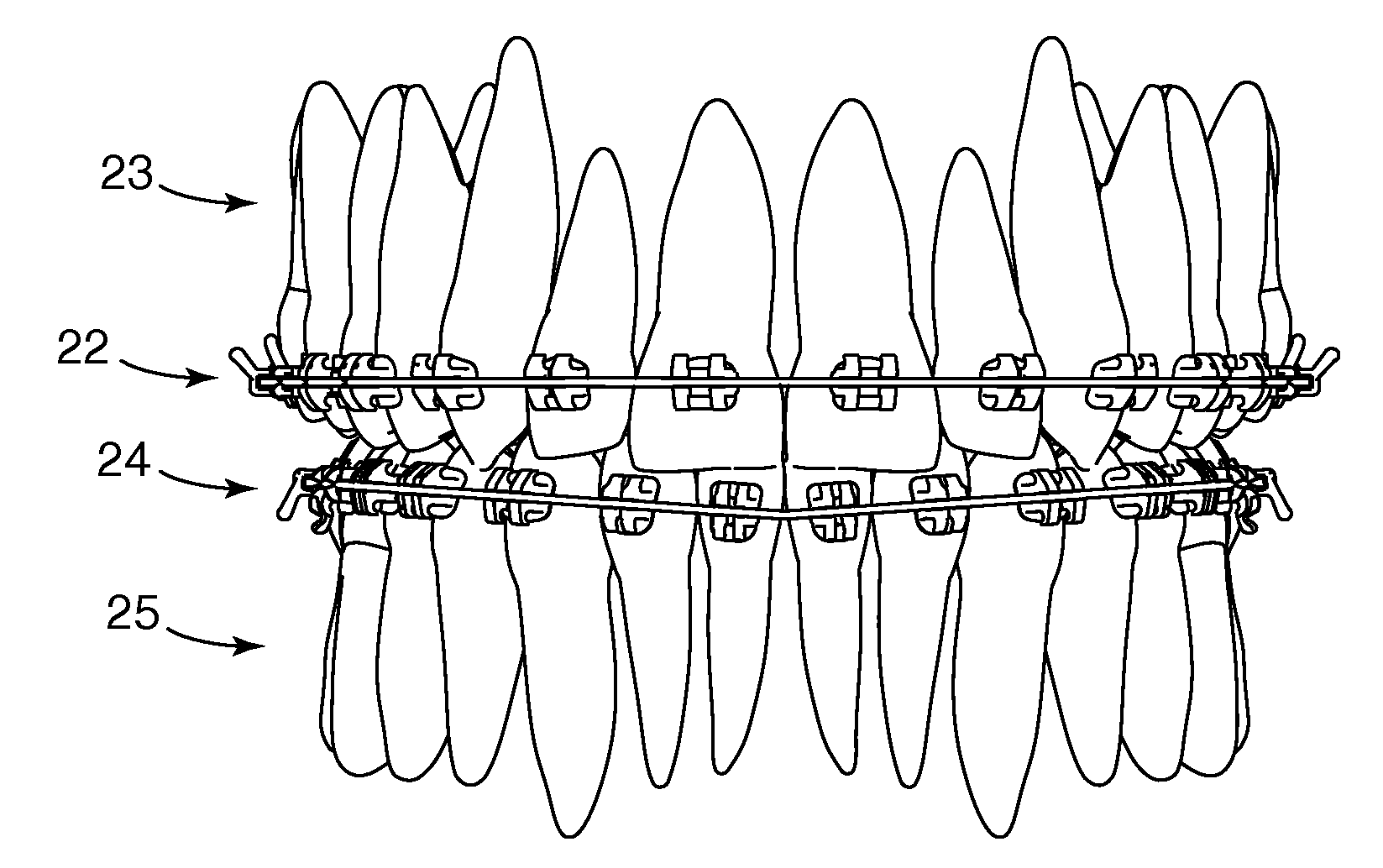

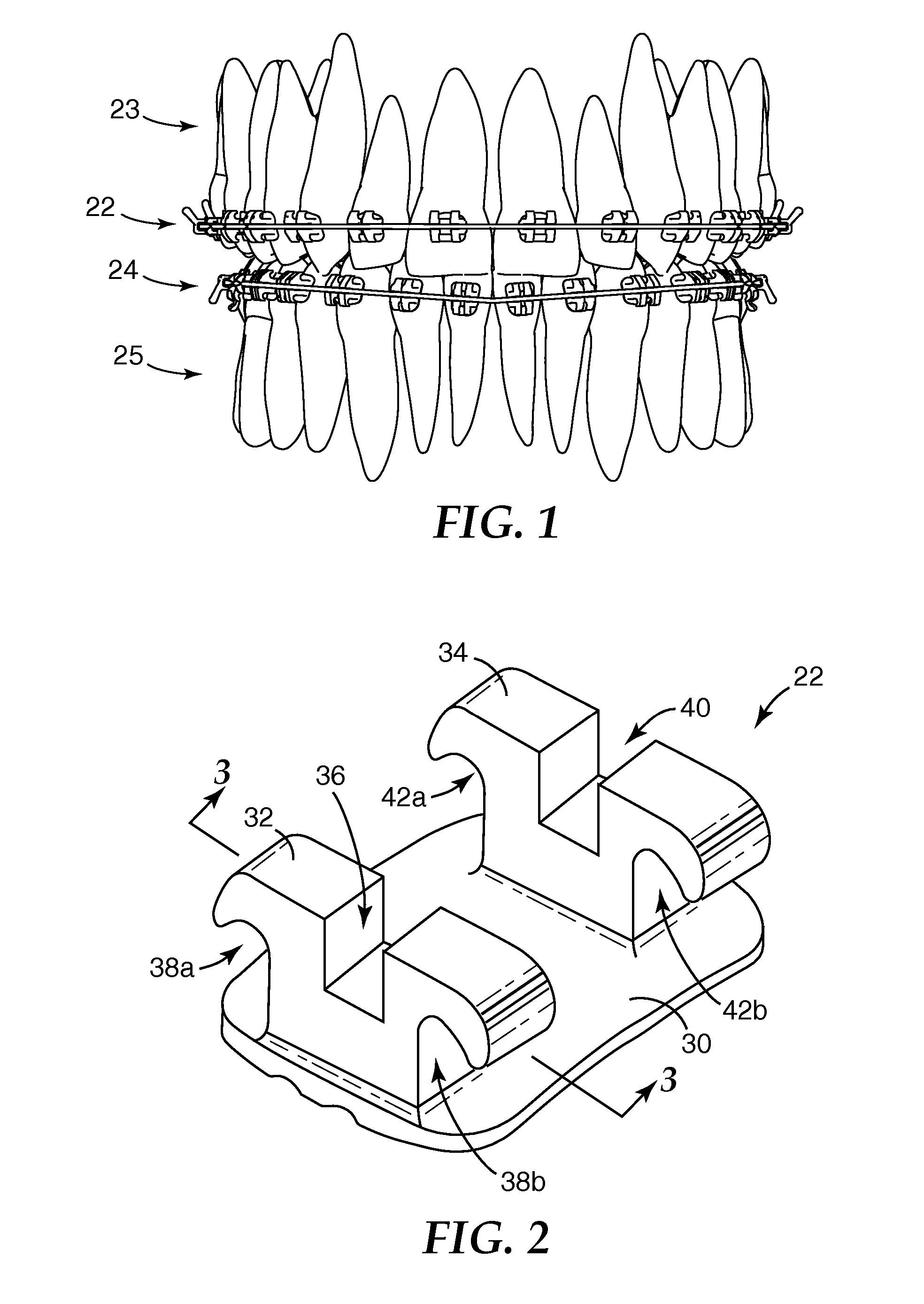

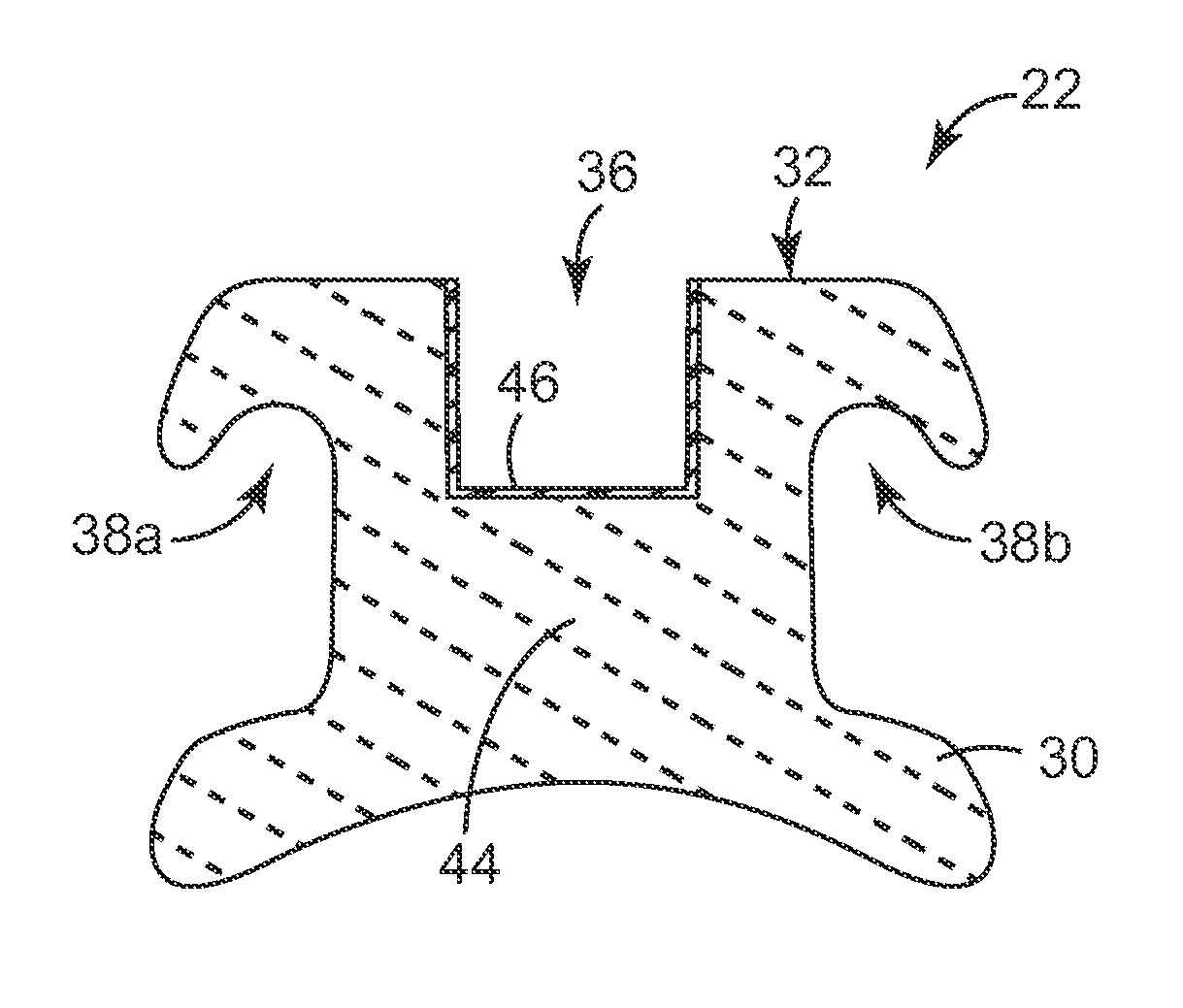

Coated Dental Articles and Related Methods of Manufacture

InactiveUS20130157225A1Excellent abrasion resistanceFacilitate archwire slidingArch wiresDental implantsZirconia coatingWear resistance

Provided are dental articles, and methods of making articles, having an aesthetic inorganic coating based on zirconia at least partially stabilized with yttrium oxide, calcium oxide, cerium oxide, or magnesium oxide. Stabilized zirconia coatings were found to provide a smooth, low friction surface having high abrasion resistance. These coatings are particularly applicable to orthodontic appliances. While virgin stabilized zirconia coatings can often have an undesirable color cast, it was discovered that this color cast can be substantially eliminated by heat treating the coated appliance in an oxygenated environment. The combination of depositing a stabilized zirconia coating and subsequently heat treating to decolorize the coating provides a surprisingly robust, stable, low-friction coating that is also aesthetic.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com