Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Improve abradability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

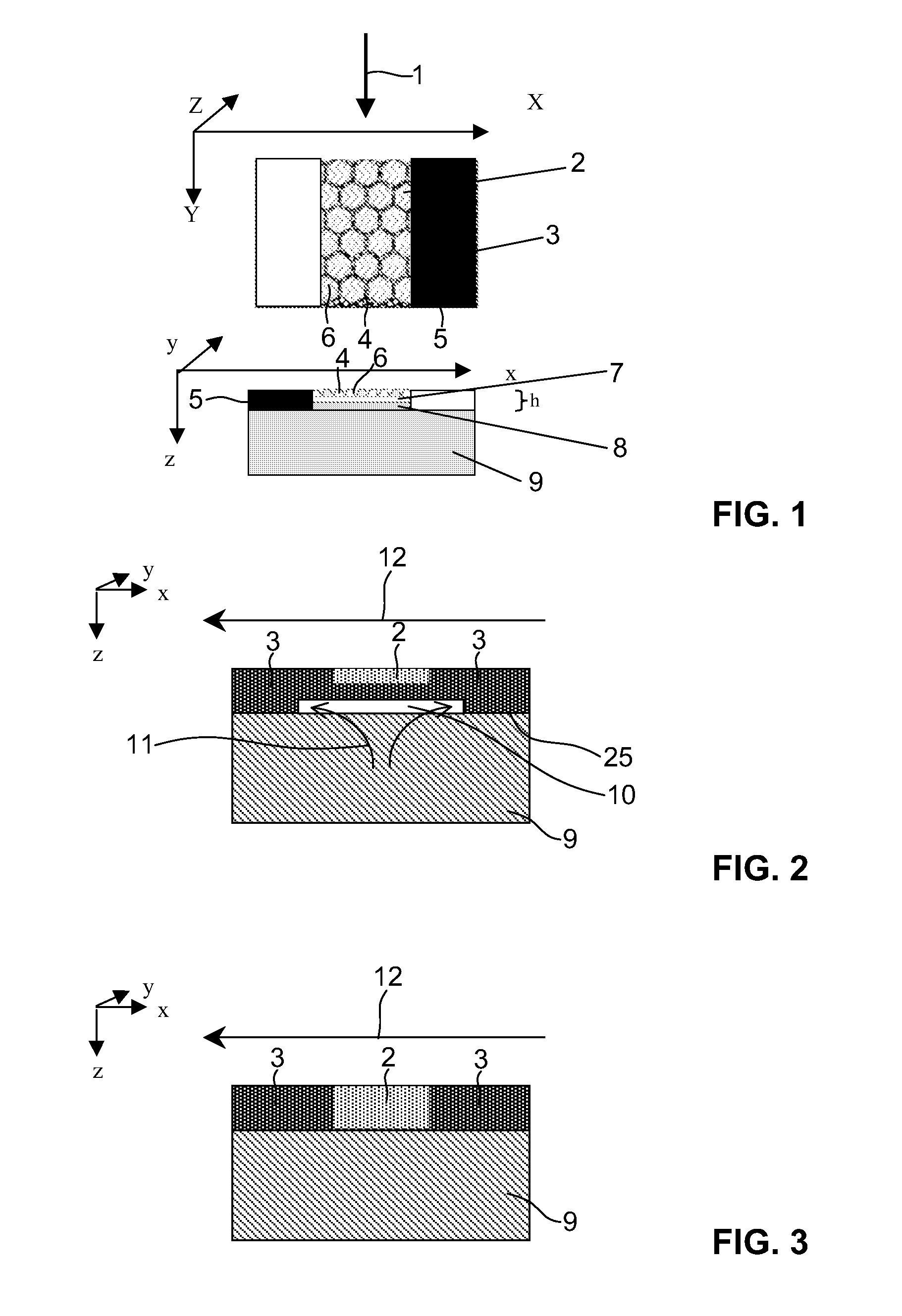

High temperature insulation with enhanced abradability

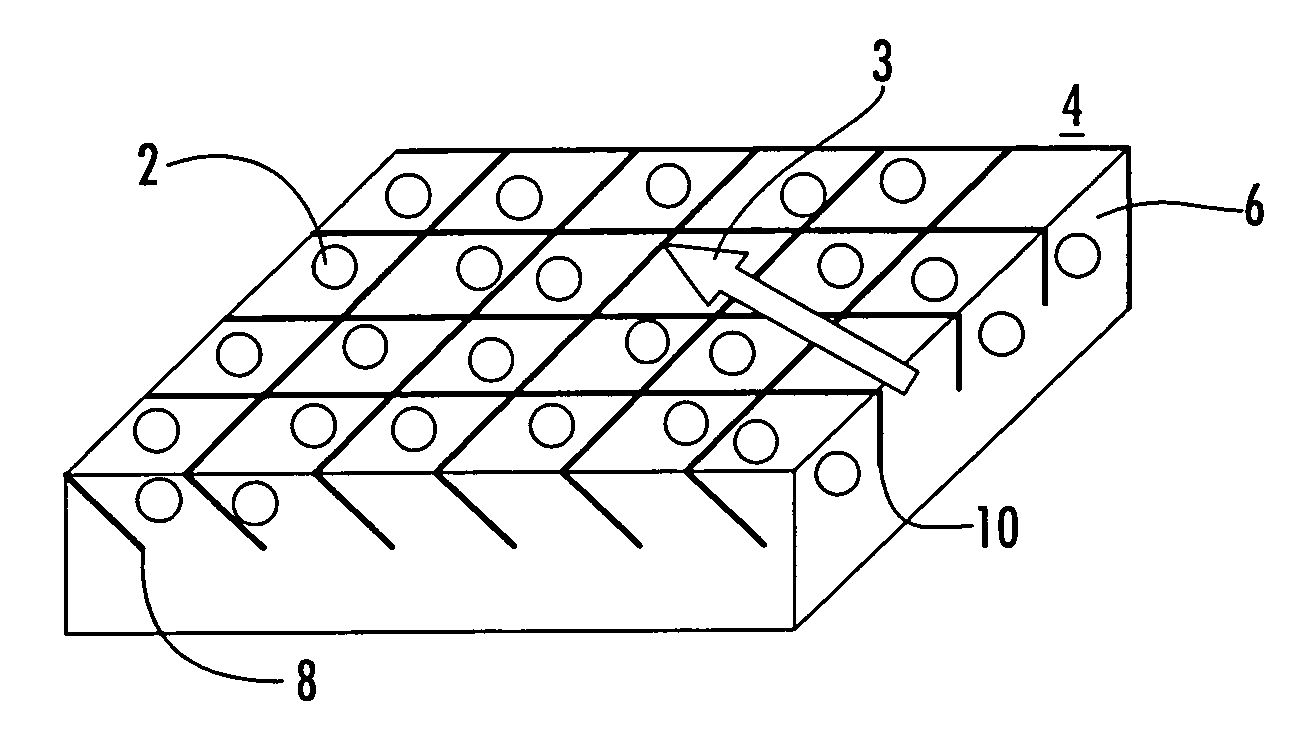

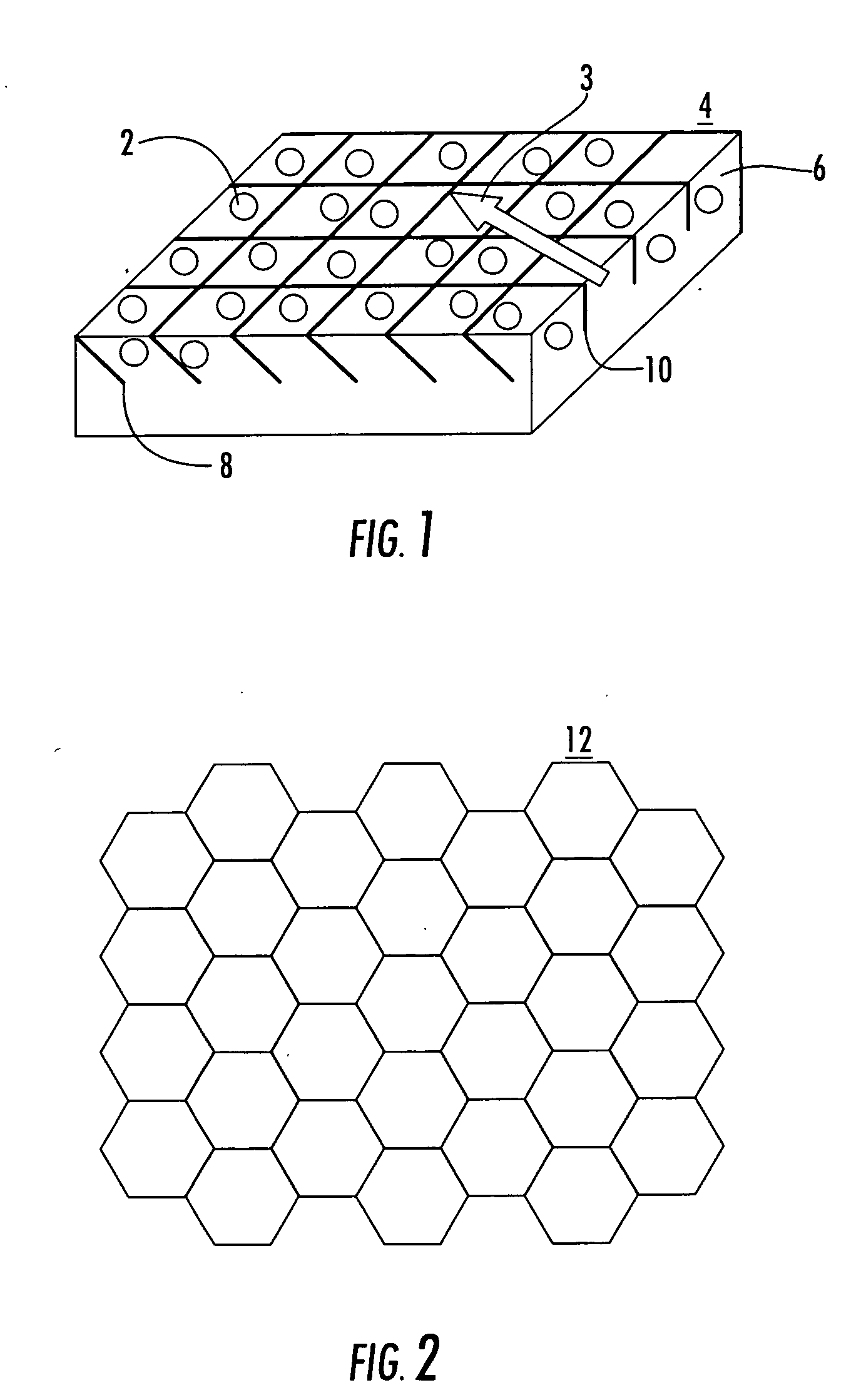

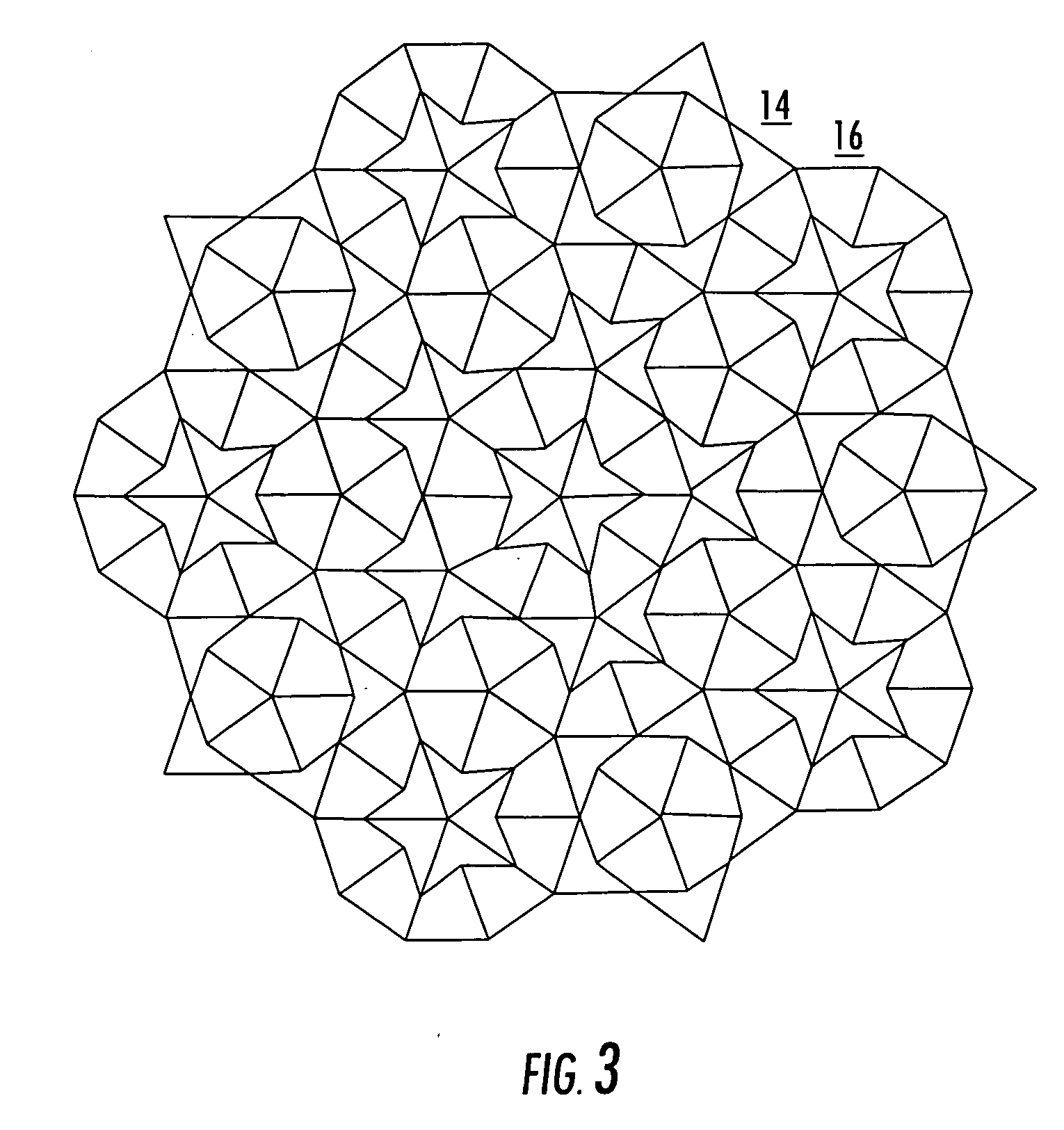

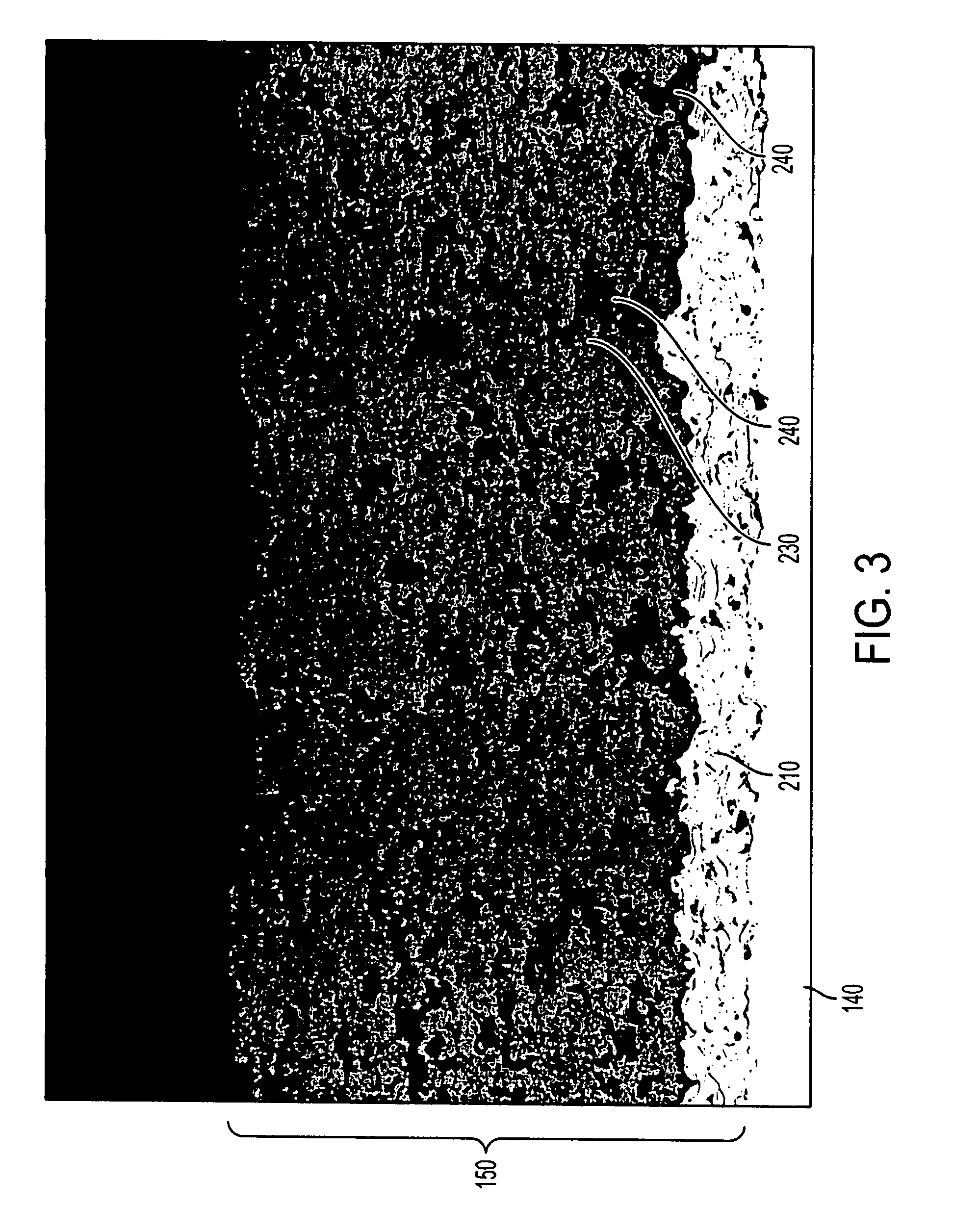

InactiveUS20080274336A1Improve abradabilityMolten spray coatingElectric discharge heatingAcute angleLaser patterning

A enhanced abradable friable graded insulator FGI results from the laser patterning of a coating where a series of top surfaces reside on a series of columns such that the walls of the columns are not significantly densified relative to the interior of the columns. Patterns can be generated where the columns are oriented independently normal to or at an acute angle to the top surfaces. The cross sections of the top surfaces are formed to conform to the average dimensions of the spheres of the FGI coating. The cross sections of the top surfaces can be more than 1.5 times the diameter of the spheres. Various patterns of top surfaces can be used including regular, random, quasiperiodic patterns. A gradient of abradability can be imposed on the coating.

Owner:SIEMENS ENERGY INC

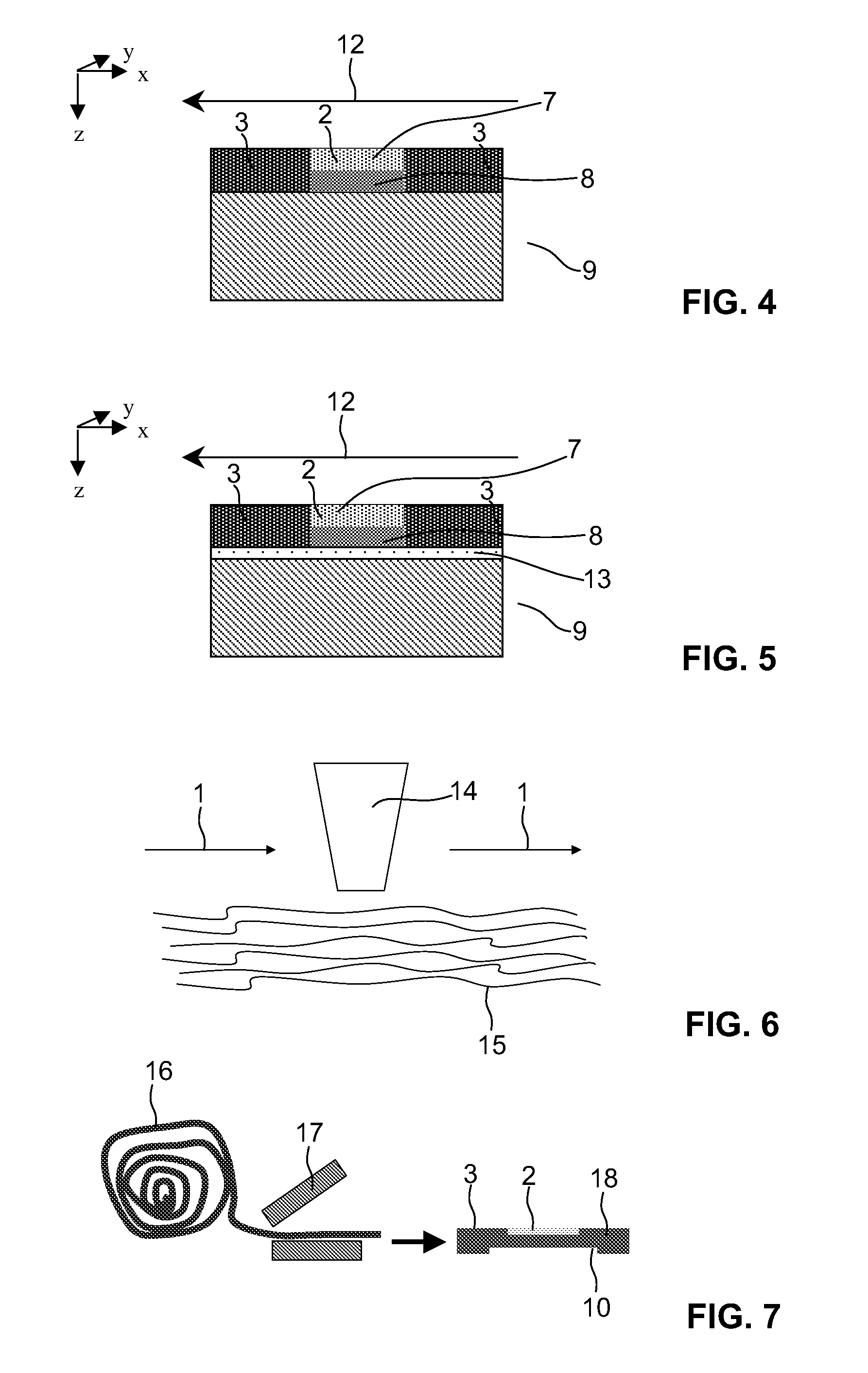

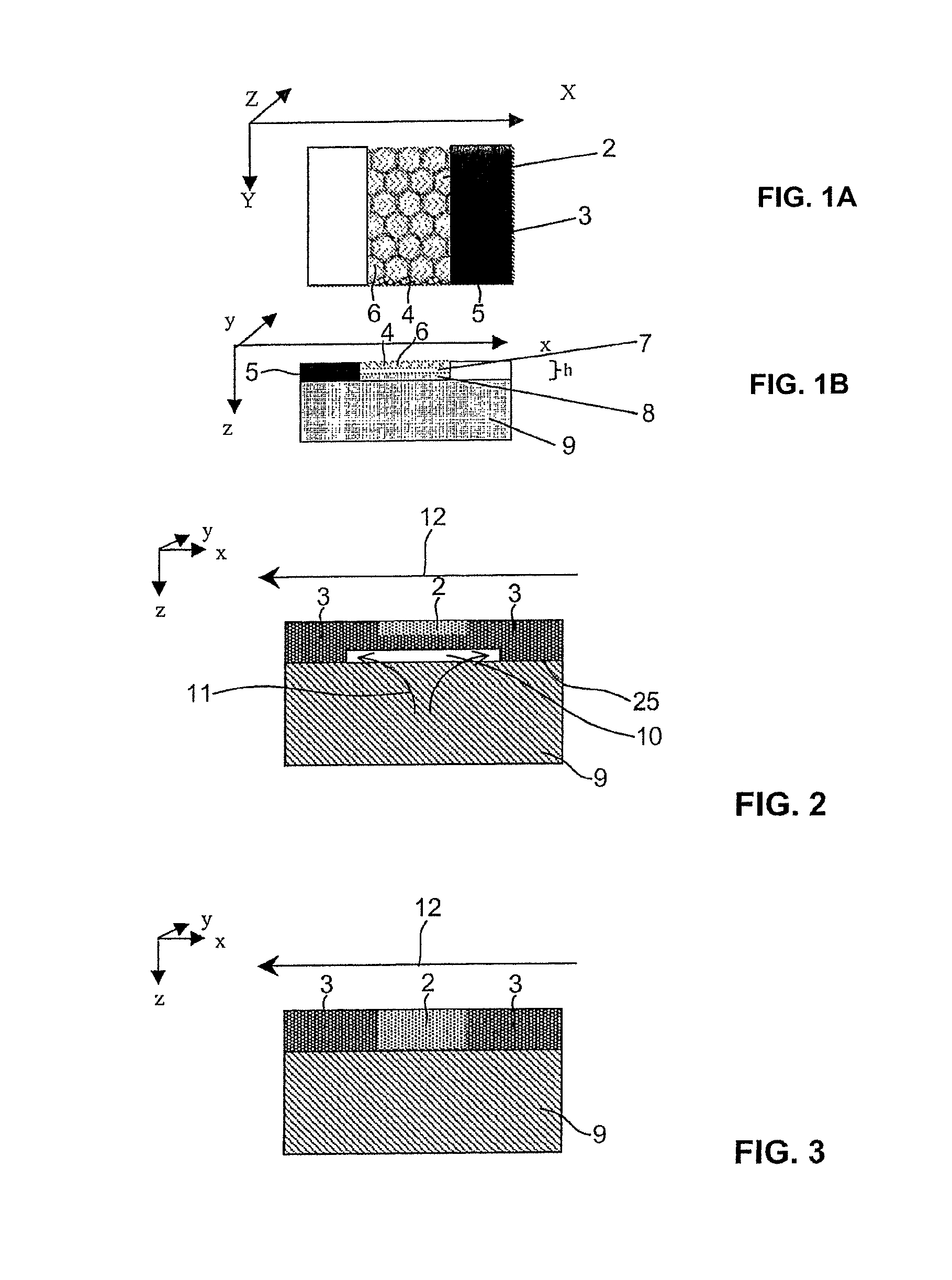

Abradable coating system

ActiveUS20110103940A1Process stabilityReduces air lossPump componentsSynthetic resin layered productsCoating systemTurbine

An abradable coating system (2-8) for a turbine or a compressor is proposed has at least one layer of woven or non-woven tissue (15) or foam made of: ceramic, glass, glass-ceramic, ceramic-metal composite and combinations thereof. A free-standing preformed element (18) has at least one layer of such a woven or non-woven tissue or foam is filled with fillers and / or binder. A method prepares such a system. Finally, a method for the repair of an abradable coating portion of a turbine or the compressor component (9) includes in a first optional step that the damaged portion is at least partly removed and / or cleaned and / or surface treated, and in a second step at least one free-standing preformed abradable coating element (18) or a complete abradable coating system is attached to the component (9), preferably by using a matrix, wherein for example only a center part (2) or a fraction of a center part (2) is replaced.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Abradable seal having improved durability

InactiveUS6899339B2Improved acceptable durabilityImprove abradabilityEngine sealsPump componentsEngineeringGas turbines

An air seal for use in a gas turbine engine provides improved durability, particularly at higher temperatures. The seal includes a seal substrate and an abradable seal layer on the substrate. The abradable seal layer is composed of a densified polyimide foam, preferably a thermomechanically densified foam. The seal is bonded to a stationary engine component such as a stator box or a case.

Owner:RAYTHEON TECH CORP

Dysprosia stabilized zirconia abradable

ActiveUS20080124548A1Improve thermal shock resistanceImprove abradabilityMolten spray coatingMachines/enginesPorosityThermal spraying

Ceramic abradable materials, in particular thermally sprayable ceramic abradable powder materials, and abradable seals formed by thermally spraying the materials include dysprosia (Dy2O3) and zirconia (ZrO2). Coatings are porous whereby the porosity, in part, is induced by plastic or fugitive phases. Abradable seal coatings comprising dysprosia and zirconia exhibit improved thermal shock and sintering resistance and can be worn into tolerance by untreated, bare turbine blades, at least in certain regimes of relative blade speed and coating porosity. Ceramic abradable seal coatings comprising dysprosia and zirconia can be used up to 1200° C.

Owner:SULZER METCO (US) INC

Dysprosia stabilized zirconia abradable

ActiveUS7981530B2Improve thermal shock resistanceImprove abradabilityPropellersMolten spray coatingPorosityThermal spraying

Ceramic abradable materials, in particular thermally sprayable ceramic abradable powder materials, and abradable seals formed by thermally spraying the materials include dysprosia (Dy2O3) and zirconia (ZrO2). Coatings are porous whereby the porosity, in part, is induced by plastic or fugitive phases. Abradable seal coatings comprising dysprosia and zirconia exhibit improved thermal shock and sintering resistance and can be worn into tolerance by untreated, bare turbine blades, at least in certain regimes of relative blade speed and coating porosity. Ceramic abradable seal coatings comprising dysprosia and zirconia can be used up to 1200° C.

Owner:SULZER METCO (US) INC

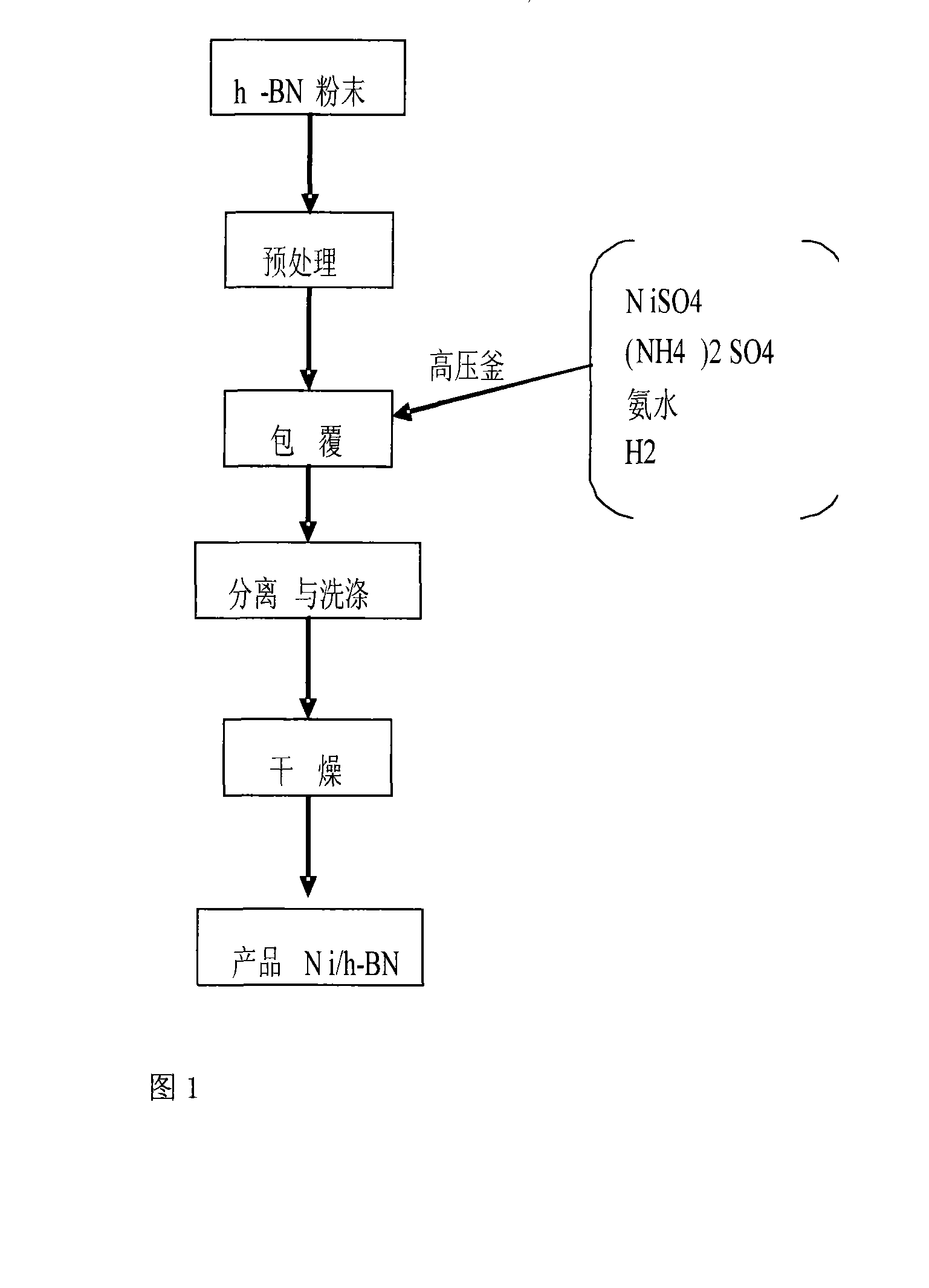

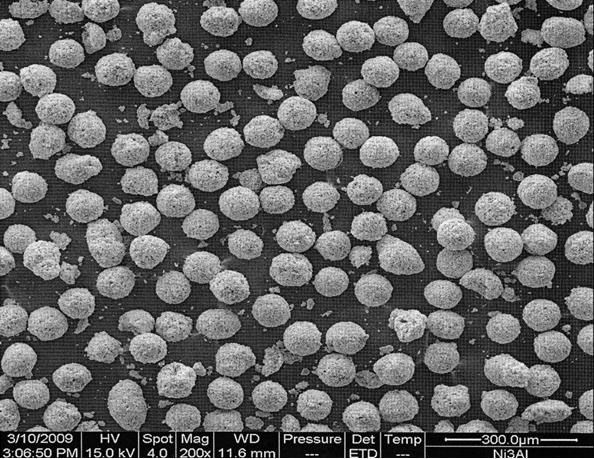

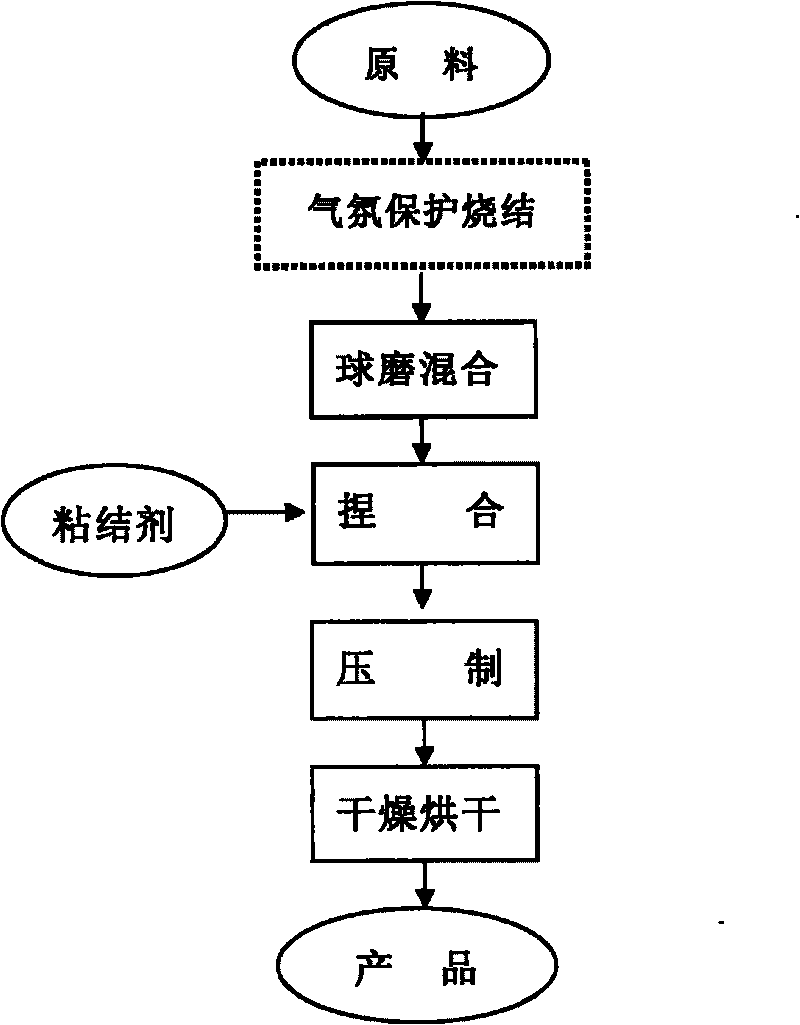

Method for preparing metal ceramic composite powder body suitable for hot spraying

The invention relates to a method for preparing nickel-coated kubonit cermet compound powder body with complete subsphaeroidal topography suitable for plasma spraying, supersonic speed flame spraying and hot spraying. The technical scheme includes the following steps: preparing NaOH liquor, sensitizing liquor and active liquor with a consistency of 1 to 20 percent; (2) carrying through preliminary treatment on hexagonal boron nitride ceramics powder, weighing the hexagonal boron nitride with a certain proportion and using the liquor prepared by step (1) to carry through the preliminary treatment; (3) preparing a reaction liquor;(4) simultaneously adding the hexagonal boron nitride after treated in step (2) and the reaction liquor prepared by step (3) into a high pressure reaction kettle to react, cooling, opening the kettle and discharging after the reaction is finished; (5) carrying through washing, filtering and drying after washing on the acquired powder body to get the nickel-coated kubonit powder body.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Turbine shroud with abradable layer having dimpled forward zone

ActiveUS20170370241A1Improve corrosion resistanceImprove abradabilityMolten spray coatingEngine manufactureControl mannerHot working

Turbine and compressor casing abradable components for turbine engines include abradable surfaces with a zonal system of forward (zone A) and rear or aft sections (zone B) surface features. The zone A surface profile comprises an array pattern of non-directional depression dimples, or upwardly projecting dimples, or both, in the abradable surface. The dimpled forward zone A surface features reduce surface solidity in a controlled manner, to help increase abradability during blade tip rubbing incidents, yet they provide sufficient material to resist incoming hot working fluid erosion of the abradable surface. In addition, the dimples provide generic forward section aerodynamic profiling to the abradable surface, compatible with different blade airfoil-camber profiles. The aft zone B surface features comprise an array pattern of ridges and grooves.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

High temperature sealing coating and making method thereof

ActiveCN104404514AHigh bonding strengthImprove bindingMolten spray coatingSuperimposed coating processBraze alloyHigh pressure

The invention provides a high temperature sealing coating and a making method thereof. The high temperature sealing coating comprises a sealing coating bottom layer and a sealing coating surface layer; the material of the sealing coating bottom layer is NiCoCrWMoSiB high temperature brazing alloy or NiCrCoSiB high temperature brazing alloy; and the material of the sealing coating surface layer comprises 5-12wt% of polyphenyl ester, 5-10wt% BaF2 / CaF2, and the balance of NiCrAlYSi alloy or NiCrAlY alloy or NiCoCrAlTaY alloy or CoCrAlY alloy. The making method of the high temperature sealing coating comprises the following steps: making the sealing coating bottom layer on a substrate through cold gas dynamic spraying; making the sealing coating surface layer through plasma spraying; carrying out heat insulation on the substrate sprayed with the high temperature sealing coating at 500DEG C to obtain a pre-product; and carrying out vacuum diffusion treatment on the pre-product at 1150-1250DEG C for 15-30min to complete the production of the high temperature sealing coating. The high temperature sealing coating has the characteristics of low hardness, self lubrication, low friction coefficient and long life, can work at a temperature of 1150DEG C, and can be used for sealing gas paths of aeroengines and ground gas turbine high pressure turbines.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

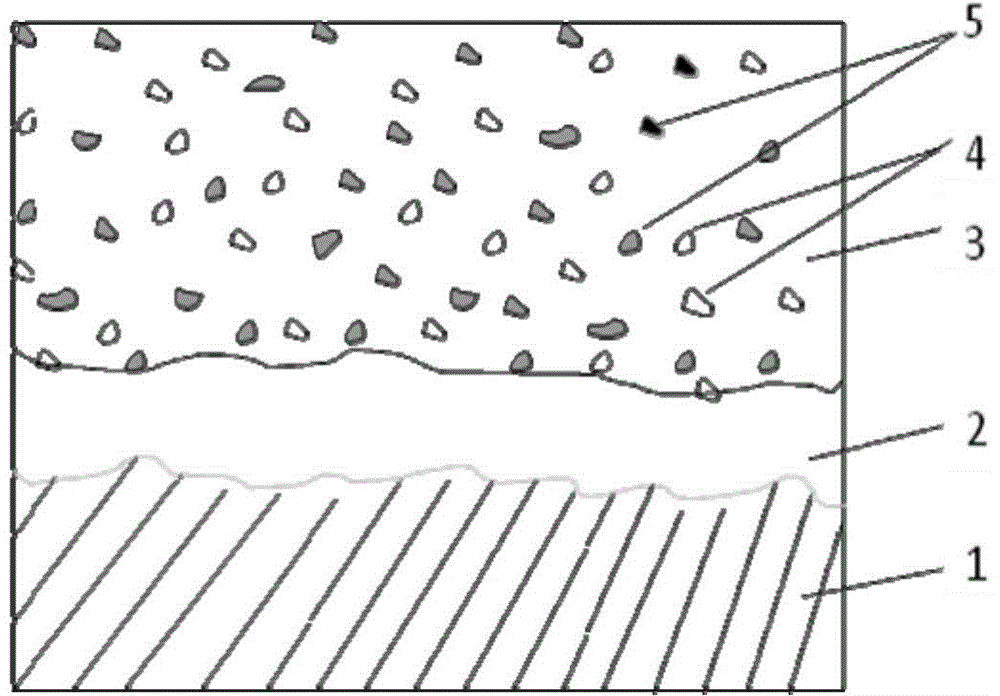

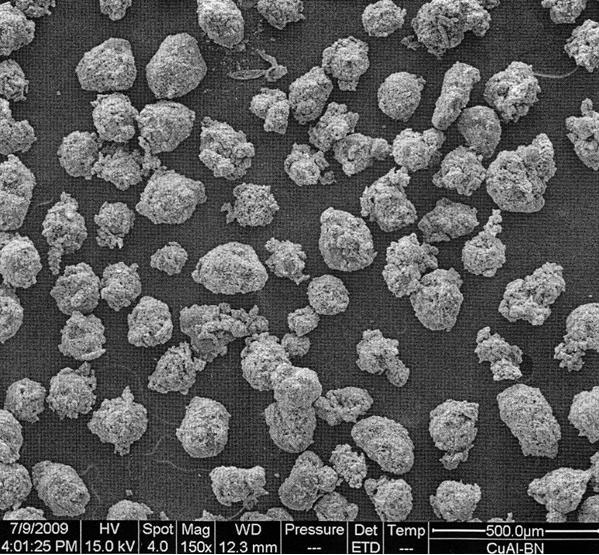

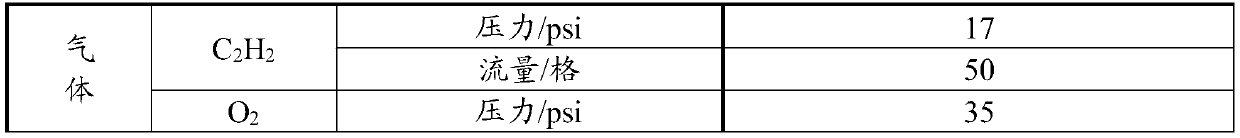

Preparation method of wearable seal coating with titanium fire preventing function

InactiveCN102560322AScour resistantImprove abradabilityMolten spray coatingEfficient propulsion technologiesSurface layerPower flow

The invention aims at providing a preparation method of a wearable seal coating with a titanium fire preventing function. The preparation method is characterized in that the wearable seal coating is a three-layer coating system, wherein a bottom layer is an Ni3Al coating, a middle layer is a ZrO2.Y2O3 heat insulation coating, and a surface layer is a CuAl / BN wearable seal coating. The wearable seal coating is prepared by adopting a plasma spraying method, process parameters are as follows: the bottom layer has a process current of 500-520A and a spraying distance of 120-140mm as well as a spraying power of 30-36kW, the middle layer has a process current of 600-620A and a spraying distance of 80-110mm as well as a spraying power of 42-46kW, and the surface layer has a process current of 360-420A and a spraying distance of 110-130mm as well as a spraying power of 20-25kW. The three-layer coating system has better heat insulation performance, a certain scouring resistance, better wearability and low friction coefficient, and can be used as a titanium fire preventing coating of a titanium alloy casing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Multi-component hot spraying flexible wire and preparation method thereof

ActiveCN101177771AHigh bonding strengthImprove abradabilityMolten spray coatingAlloyMechanical equipment

The invention relates to a multi-components hot spray flexible wire and a preparation method thereof. A flexible wire which is good in spraying technology adaptability is prepared through a method of mechanical milling, rubber mixing and squeezing by a slow vernier hydraulic press. The wire comprises Ni, Al, Cr, W, Co, Mo, Ti, Cu, C, BN and Si oxide or salts thereof, wherein the raw materials can be simple substance powder or alloy or compound, while the oxides can be one or more or the combination of a few materials. The binder can be inorganic materials, and the combination of some additives and addition agents is also included. The coating prepared by the wire has the advantages that the coating combines well with a matrix, the wearable performance is good, and the thermal shock resistance and salt-fog resistance are excellent. The wire has a wide application range, which can be applied in the surface modification and the reproduction of mechanical equipment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

High-temperature abradable seal coating and preparation method thereof

InactiveCN108179371ASimple structureEase of mass productionMolten spray coatingWorking temperatureHardness

The invention provides a high-temperature abradable seal coating and a preparation method thereof. The MCrALY alloy powder is sprayed to the surface of a base body through a supersonic flame sprayingdevice to prepare a coating, multiple times of spraying are carried out on the surface of the base body, and the deposition thickness of the single spraying is smaller than or equal to 0.01mm; stressrelief and diffusion treatment are carried out on the sprayed coating with the thickness of 0.5-1.0mm by adopting vacuum heat treatment; and finally spraying is carried out to obtain a sealing coatingwith the thickness larger than or equal to 1.5mm. The sealing coating prepared by the preparation method has the advantages of oxidation resistance, high-temperature low hardness, abrasion resistance, high temperature stability, thermal shock resistance and high bonding strength, the working temperature can reach 1100 DEG C, the abrasion of a turbine rotor blade can be obviously reduced, the abrasion resistance and the reliability of the coating are improved, the service life of the coating is prolonged, the service life of the turbine rotor blade is obviously prolonged, the maintenance costof the engine is remarkably reduced, and the reliability of the engine is improved.

Owner:AECC AVIATION POWER CO LTD

Multi-component rod for hot spraying wearable sealing coating and preparation method thereof

ActiveCN101177770ASimple processing conditionsHigh strengthMolten spray coatingSurface modificationThermal spraying

The invention relates to a multi-components bar applied to a hot spray wearable sealing coating and a preparation method thereof. A bar which is good in spraying technology adaptability is prepared through a method of mechanical milling, bonding at room temperature and squeezing. The bar comprises Ni, Si, Cu, Al, Cd, BN, C and oxides, binders and other materials. The raw materials can be simple substance powder or alloy or compound, and the oxides can be one kind or more or the combination of a few materials. The binder can be inorganic materials and can also be organic substances, and the combination of some additives and addition agents is also included. The coating prepared by the bar has the advantages that: the coating combines well with a matrix, the wearable performance is excellent, and the thermal shock resistance and salt-fog resistance are excellent. The bar has wide application range and can be applied to the surface modification and the reproduction of mechanical equipments.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Abradable coating system

ActiveUS8821116B2Efficient removalImprove abradabilityPump componentsBlade accessoriesCoating systemCeramic metal

Owner:ANSALDO ENERGIA SWITZERLAND AG

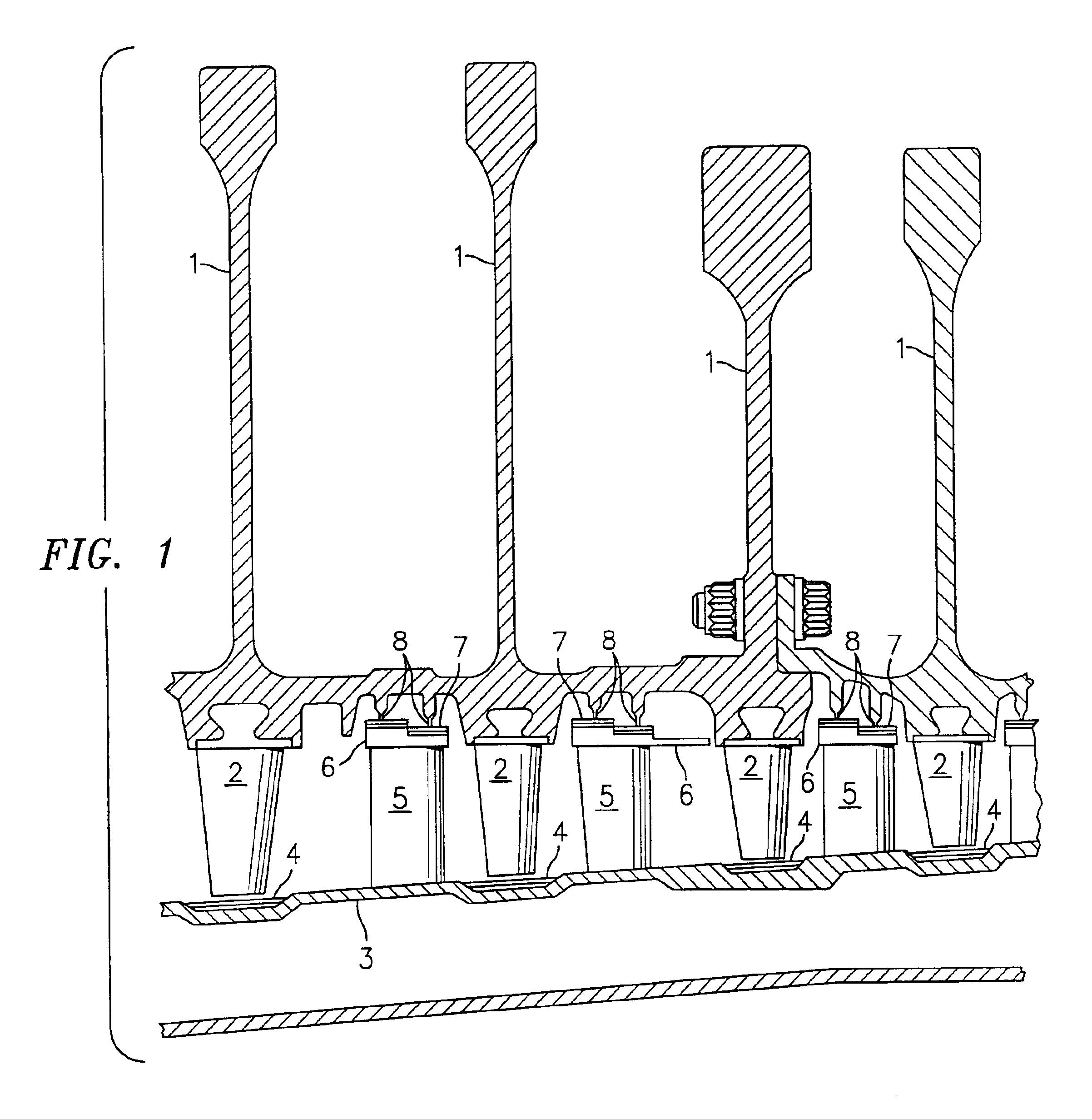

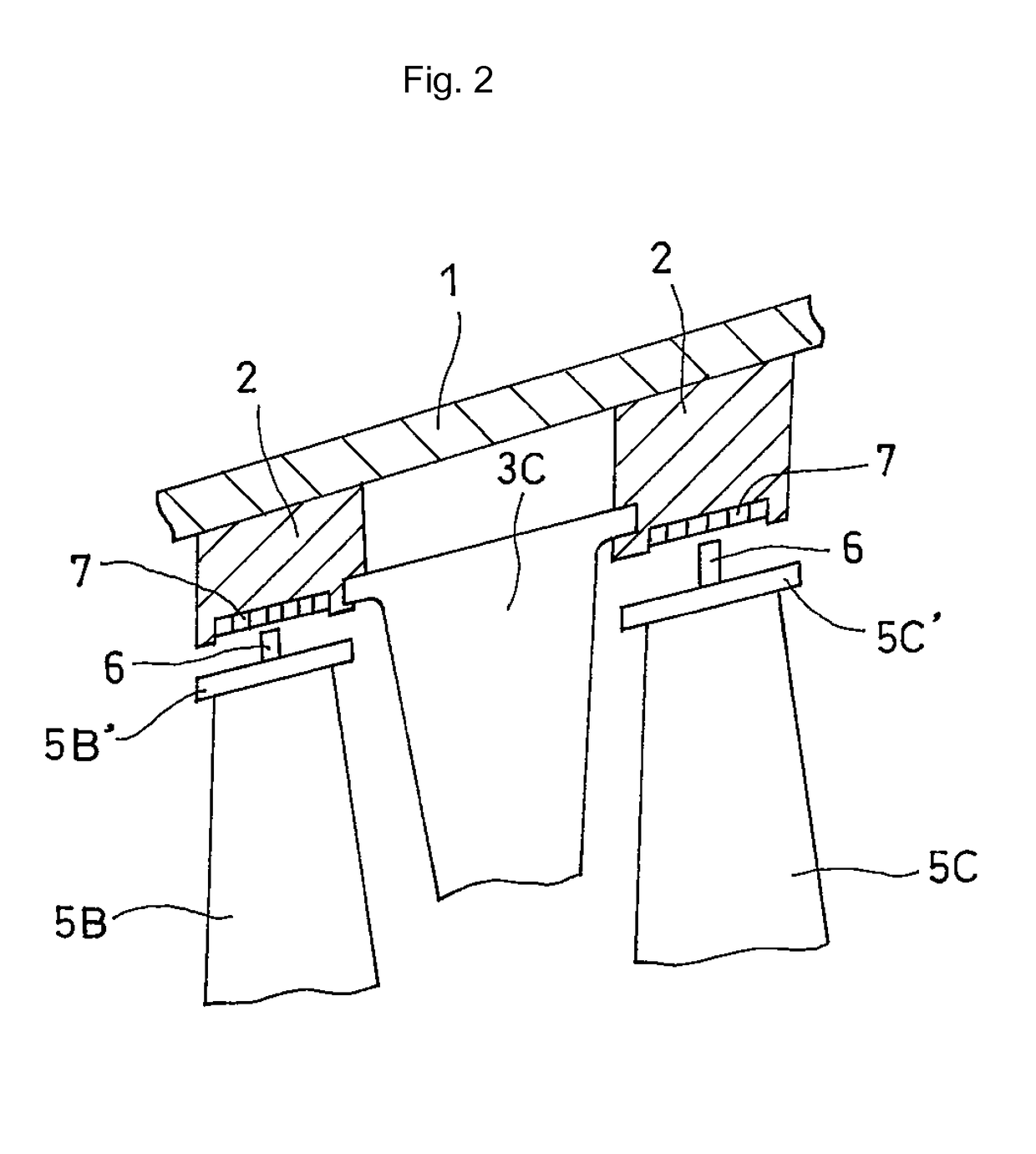

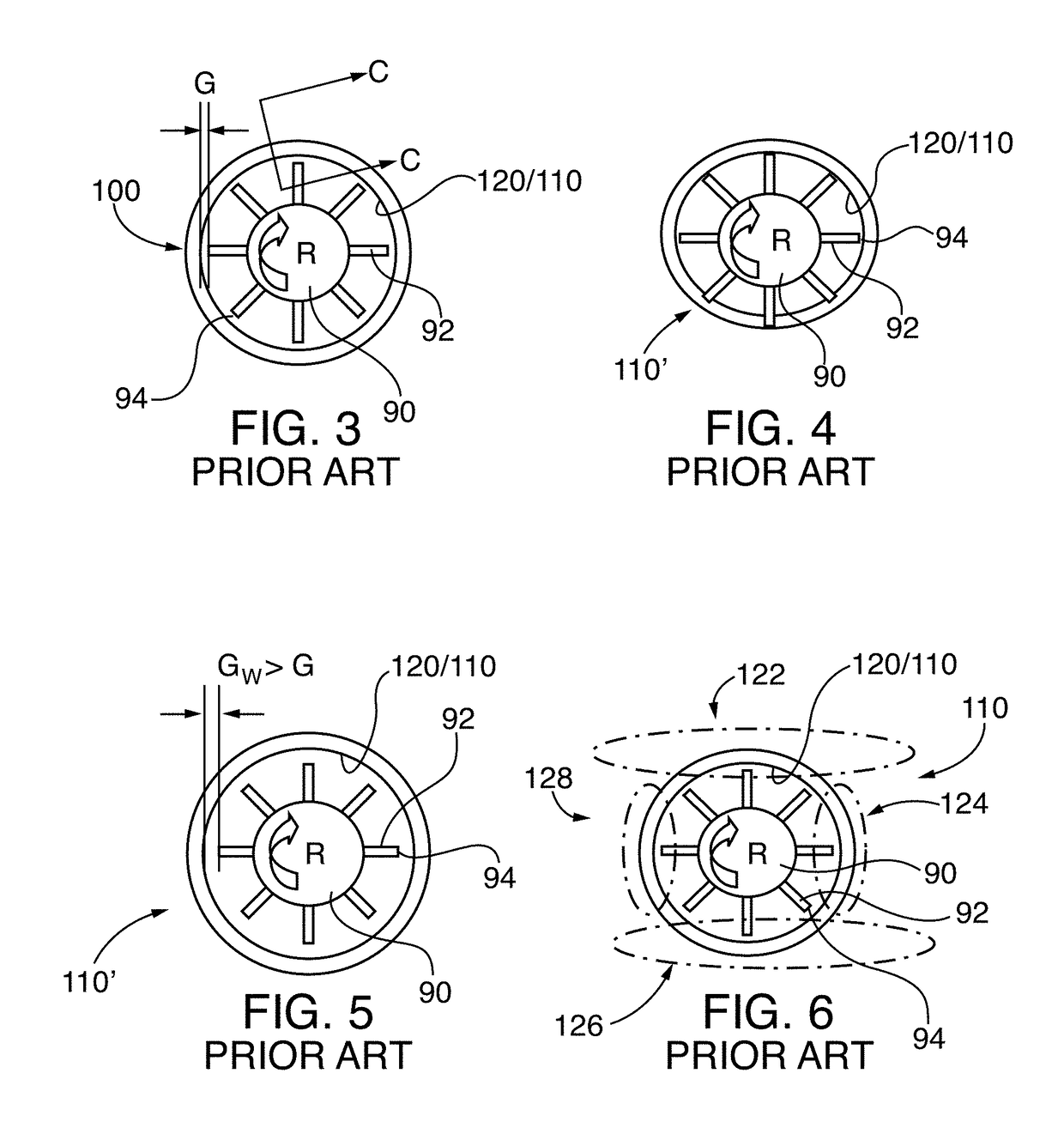

Gas turbine with honeycomb seal

ActiveUS9822659B2Improve abradabilityImprove sealingEngine manufactureLeakage preventionCombustorTurbine blade

A gas turbine includes a compressor, a combustor, and a turbine. The turbine includes a honeycomb seal disposed so as to be secured to a casing side in a clearance between the casing and turbine blades rotating around a rotating shaft and a seal fin that is provided on an end face of each of the turbine blades facing the honeycomb seal. The seal fin extends in a direction perpendicular to the rotating shaft. The honeycomb seal is formed by a plurality of corrugated sheet metals overlapped with each other at walls of nodes thereof and the walls of the nodes are blazed with each other. Each of the corrugated sheet metals has trapezoids formed in alternating fashion. A longer direction of each wall of the nodes of the honeycomb seal is angled with respect to the rotational direction of the turbine blades.

Owner:MITSUBISHI POWER LTD

Low-burning-loss abrasive coating material and application thereof

ActiveCN110872677AIncrease deposition rateReduce burning lossMolten spray coatingAviationThermal spraying

The invention belongs to the technical field of coating materials, and particularly relates to a low-burning-loss abrasive coating material and an application thereof. The low-burning-loss abrasive coating material provided by the invention comprises an abrasive component and a framework component, wherein the abrasive component comprises hexagonal boron nitride, the graphitization index of the hexagonal boron nitride is 0.7-2.0, and the pattern of the hexagonal boron nitride is lamellar. The hexagonal boron nitride having specific graphitization indexes and specific pattern is selected as theabrasive component, so that the loss of a boron nitride system abrasive coating material in the hot spraying process can be effectively reduced, the content of boron nitride components in the coatingcan be increased, the abradability of the coating can be improved, and the low-burning-loss abrasive coating material has great application prospects in aircraft engines and combustion turbines.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Marine-corrosion-resisting and wear-resisting material, coating and preparation method thereof

ActiveCN110512166AReduce the effectGood effectMolten spray coatingTransportation and packagingCorrosion resistantSingle phase

The invention discloses a marine-corrosion-resisting and wear-resisting material, a coating and a preparation method thereof and belongs to the technical field of fuel gas turbines. Single-phase CuAlwith excellent marine-corrosion-resisting and wear-resisting properties is adopted as a wear-resisting face layer skeleton component, insulating polyester or boron nitride and the like are adopted asa wear-resisting component, CuAl with chemical compositions completely consistent with those of the wear-resisting face layer skeleton component is adopted as a bottom layer material, and the coatingis prepared through a thermal spraying method. According to the material, the coating and the preparation method, the problems that a traditional wear-resisting coating skeleton component does not resist to corrosion, galvanic corrosion is generated between the compositions and between a face layer and a bottom layer due to the potential difference, and coating corrosion is caused by easy seepageof corrosion media to the coating and a base body interface are solved, and the material is widely applied to marine gas turbines serving in marine environment, aircraft engines, ground fuel gas turbines and the like.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Cyclic silicon resin seal coating

InactiveCN102051118AGuaranteed working temperatureMeet the requirements of complex working conditionsPump componentsPolyether coatingsHexagonal boron nitrideFilling materials

The invention relates to a wearable seal coating material, in particular to a cyclic silicon resin seal coating used for an industrial centrifugal compressor. The cyclic silicon resin seal coating comprises the following components in percentage by weight: 65-80% of cyclic silicon resin, 15-25% of filling material A and 5-10% of filling material B, wherein the filling material A is one or more than two of polyether ether ketone, polybenzoate and polytetrafluoroethylene, and the granularity is 50-100 microns; when more than two of polyether ether ketone, polybenzoate and polytetrafluoroethylene are mixed, the mixing ratio can be an any ratio; the filling material B is one or more than two of hexagonal boron nitride, graphite and bentonite, and the granularity is 20-50 microns; and when more than two of hexagonal boron nitride, graphite and bentonite are mixed, the mixing ratio can an any ratio. The invention effectively increases the scraping property of the coating, can control and regulate the hardness of the coating and has self lubricating property so that the hardness of the coating can reach the range applicable to scraping, the abrasion of vanes is reduced, the wearable property of the coating is increased, and the invention can ensure that contact wearing can not endanger a rotor.

Owner:SHENYANG BLOWER WORKS GROUP CORP

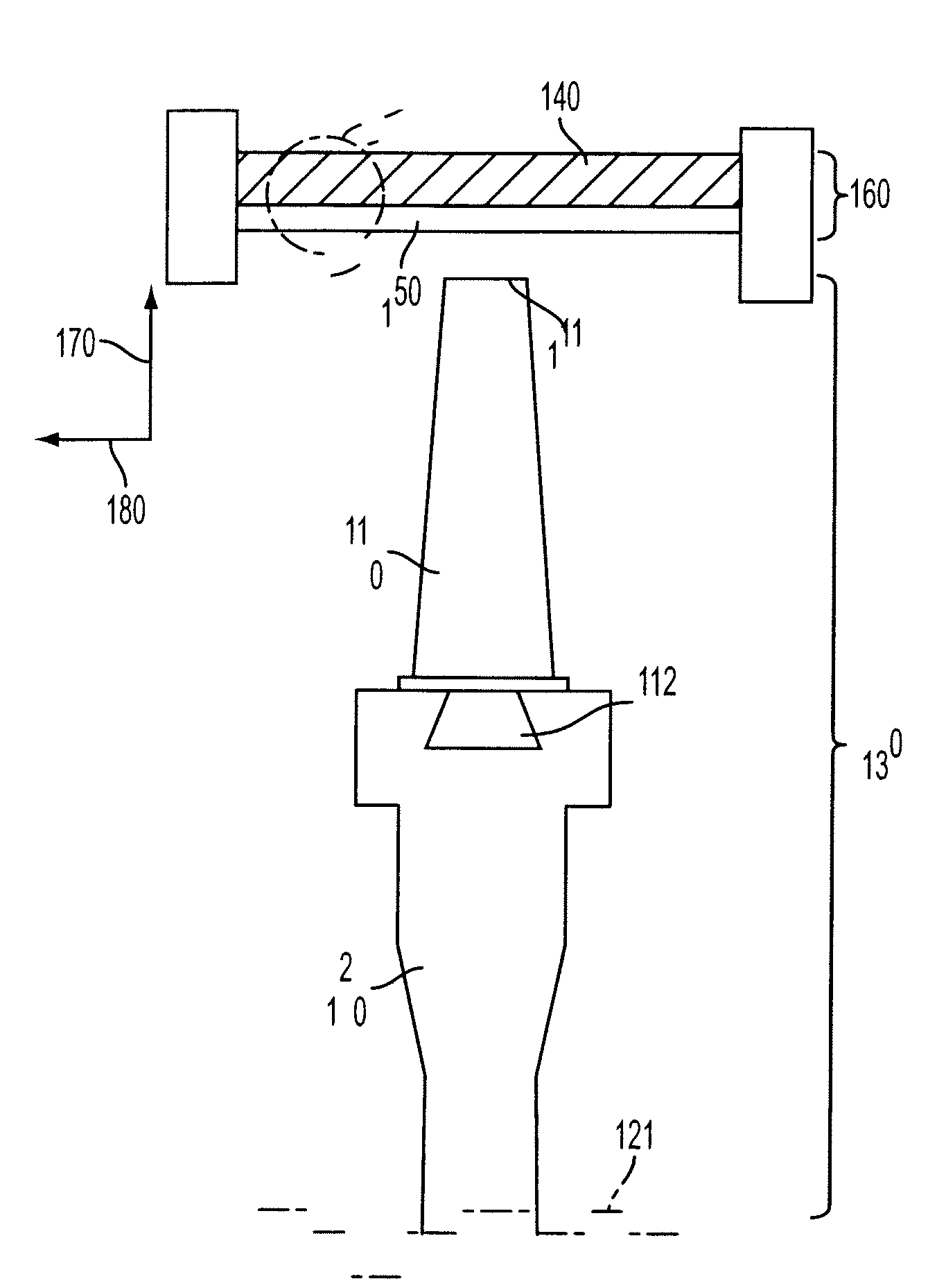

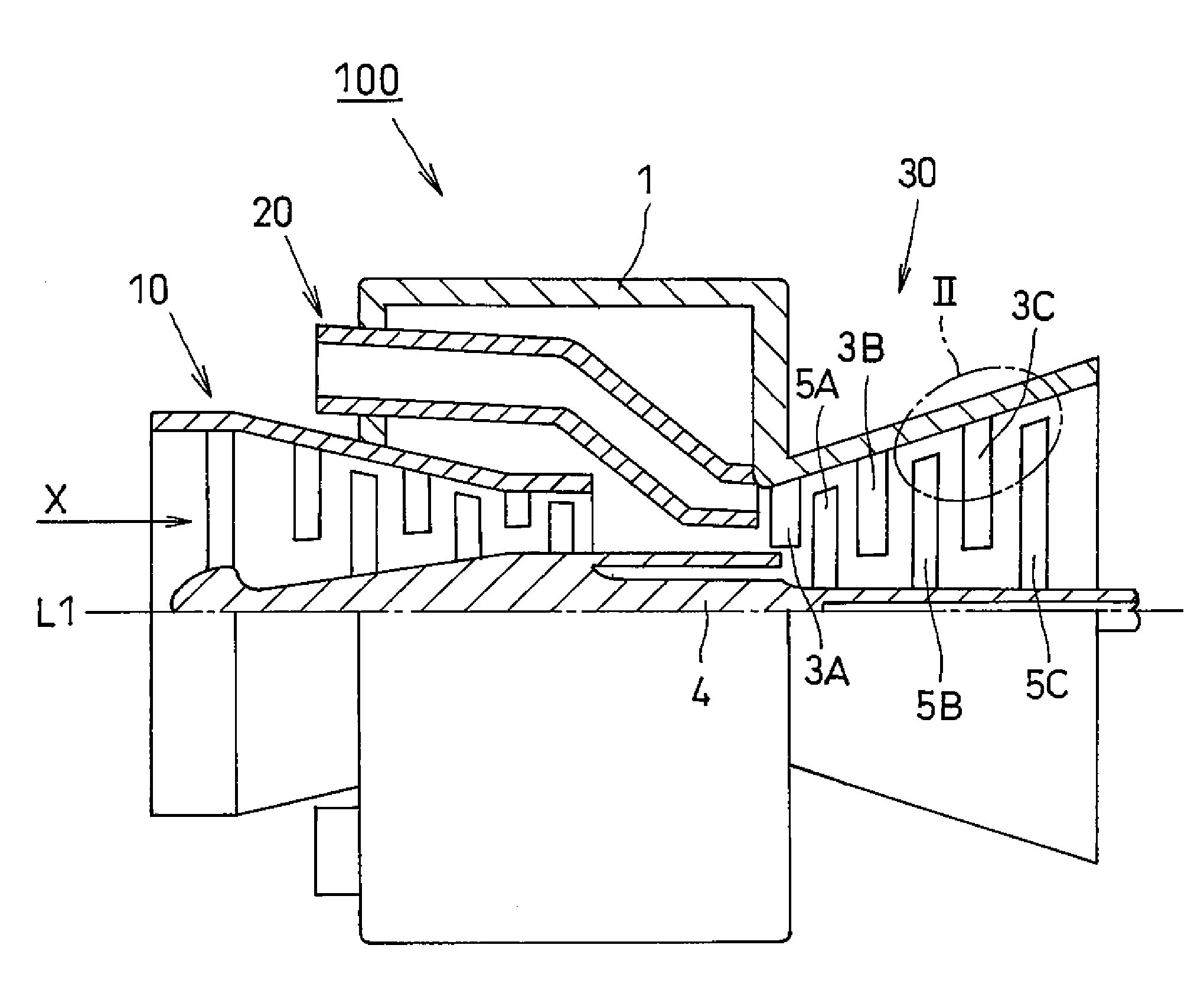

Gas Turbine with Honeycomb Seal

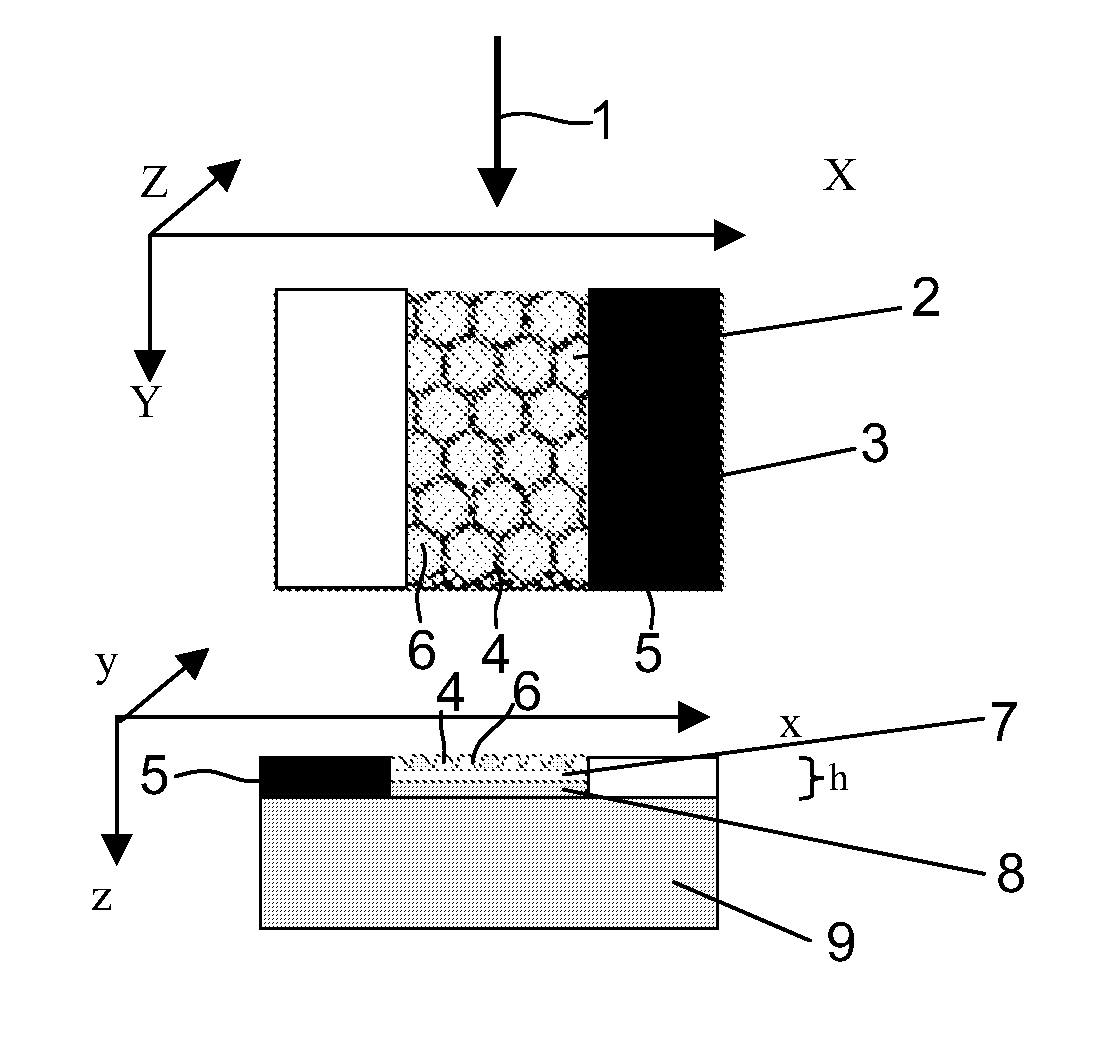

ActiveUS20140356142A1Improve wear resistanceImprove abradabilityEngine manufacturePump componentsCombustorTurbine blade

Provided is a gas turbine that can solve a problem in which a seal fin of a turbine blade is abraded by a brazed place of a honeycomb seal.A gas turbine 100 includes a compressor 10, a combustor 20, and a turbine 30. The turbine 30 includes: a honeycomb seal 7 disposed so as to be secured to a casing side in a clearance between the casing 1 and turbine blades 5A-5C rotating around a rotating shaft 4 extending in a longitudinal direction of the casing 1 and a seal fin 6 provided on an end face of each of the turbine blades 5A-5C facing the honeycomb seal 7, the seal fin 6 extending in a direction perpendicular to the rotating shaft 4. The honeycomb seal 7 is formed by a plurality of corrugated thin sheet metals 71 overlapped with each other at walls of node 71a thereof and the walls of node 71 blazed with each other, each of the corrugated thin sheet metals 71 having trapezoids alternately continued. A longer direction (Y1 direction) of the wall of node 71a of the honeycomb seal 7 is tilted with respect to the rotational direction (Z direction) of the turbine blades 5A-5C.

Owner:MITSUBISHI POWER LTD

Room-temperature curing coating with abradable sealing function and preparation method thereof

ActiveCN110982388AExcellent wearabilityExcellent air erosion resistanceEpoxy resin coatingsFirming agentPolymer chemistry

The intention discloses a room-temperature curing coating with an abradable sealing function. The room-temperature curing coating is a putty-like material formed by mixing a component A and a component B, wherein the component A consists of liquid rubber, liquid epoxy resin and talcum powder; and the component B is an amine curing agent. During use, the component A and the component B are fully mixed according to the mass ratio of 100: 8-100: 15, the mixture is applied to the surface of a component through a blade coating method, and the abradable seal coating is obtained after full curing atthe room temperature. The material has good adhesive force to metal and composite material base materials, has excellent abradability and airflow erosion resistance, is used for an aero-engine fan / supercharging level part, when a coating layer rubs with a running part, the coating layer can be ground, the part is not abraded. Meanwhile, the gap between a rotating part and a non-rotating part can be controlled, the effects of air sealing and oil sealing are achieved, loss of compressed air flow and leakage of lubricating oil are reduced, the efficiency of an engine is improved, and oil consumption of the engine is reduced.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Nano zirconium oxide based wearable sealing composite coating material and preparation method thereof

The invention discloses a nanometer zirconia abrasion sealing composite paint material, which comprises the following parts: base-phase material, filling material A, filling material B, adhesive and water, wherein the base-phase material is 70-75% in the base-phase material, filling material A and filling material B; the filling material A is 14-20% in the base-phase material, filling material A and filling material B; the filling material B is 9-15% in the base-phase material, filling material A and filling material B; the adhesive is 2-5.5% in the base-phase material, filling material A and filling material B; the water is 70-78% in the base-phase material, filling material A, filling material B and adhesive.

Owner:WUHAN UNIV OF TECH

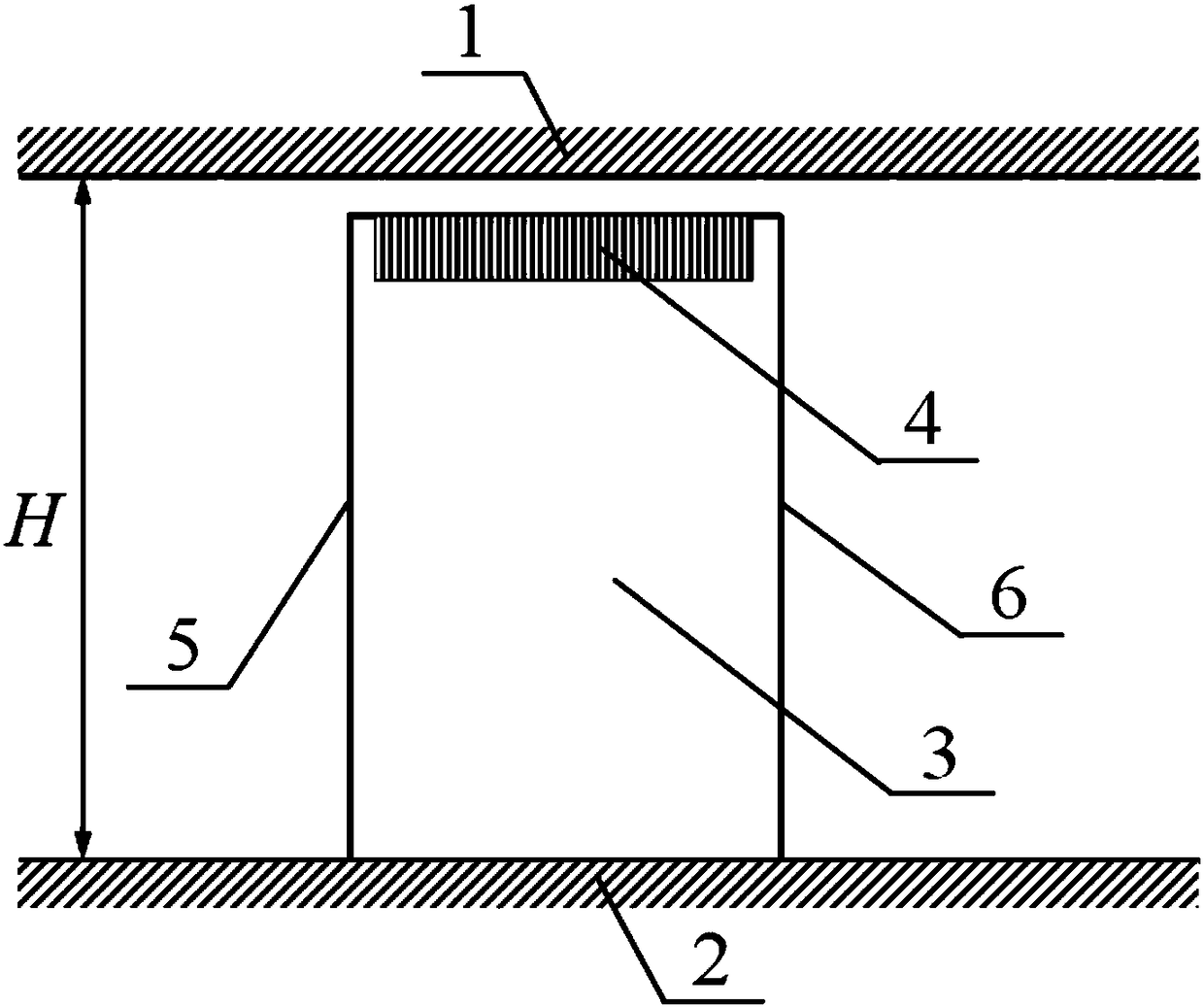

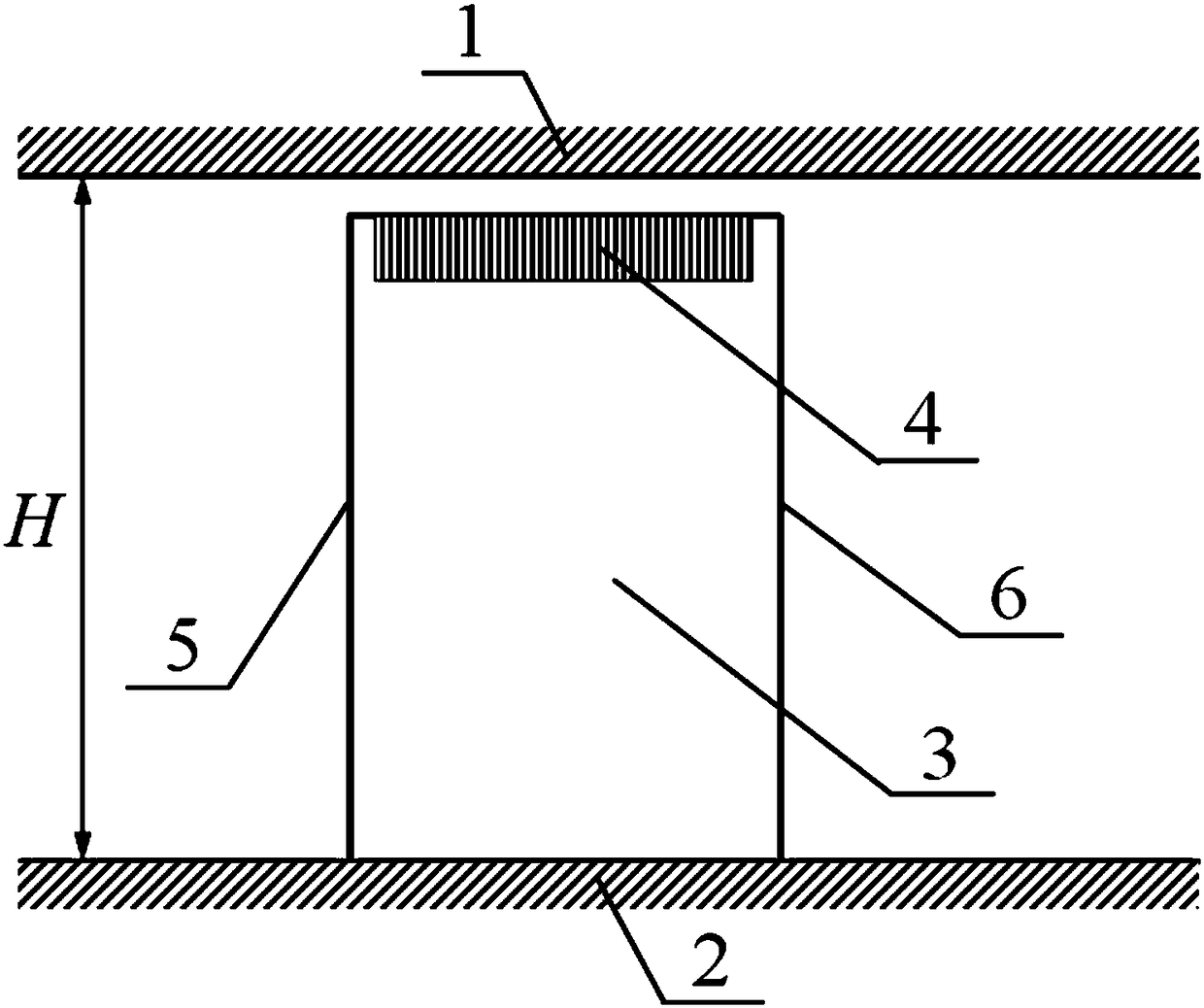

Prismatic cavity blade tip for controlling leakage flow of movable blade tip of turbine

InactiveCN108412556AShorten speedIncrease flow resistanceBlade accessoriesMachines/enginesTurbine bladeFront edge

The invention provides a prismatic cavity blade tip for controlling leakage flow of a movable blade tip of a turbine. At the blade tip of a movable blade of the turbine, a plurality of prismatic cavities are formed from the front edge to the tail edge of the movable blade of the turbine; and the ratio of the maximal depth h of the prismatic cavities to the height H of the movable blade of the turbine is 0.5%-4%. According to the prismatic cavity blade tip for controlling the leakage flow of the movable blade tip of the turbine provided by the invention, a part of leaking fluid which enters a clearance enters the prismatic cavities to form vortex in a rolling way; at one hand, the dynamic energy of the fluid in the clearance is dissipated; on the other hand, a jet flow stop effect is achieved on the fluid in the clearance above the cavities; and thus the aim of controlling the leakage flow of the blade tip of the turbine is realized; the leakage amount of the blade tip of the turbine isreduced; the size and strength of leakage vortex of the blade tip are reduced; leakage related loss of the turbine is reduced; the efficiency of the turbine is improved; and furthermore the prismaticcavity structure can reduce the weight of the blade of the turbine.

Owner:HARBIN INST OF TECH

Steam passage sealing method for steam turbine through-flow portion

InactiveCN107503804AImprove high temperature resistanceImprove corrosion resistanceMolten spray coatingLeakage preventionEngineeringHigh pressure

The invention discloses a steam passage sealing method for a steam turbine through-flow portion and relates to the technical field of steam passage sealing of the steam turbine through-flow portion. In order to solve the problems that in existing steam passage sealing methods, height loss happens to steam sealing teeth in the scraping process, the through-flow clearance is larger, and the unit efficiency is decreased, the steam passage sealing method for the steam turbine through-flow portion is provided. The steam passage sealing method for the steam turbine through-flow portion includes the steps that an abradable sealing coating is applied to a stator portion sleeve of the high-pressure, medium-pressure and low-pressure through-flow portion of a steam turbine, and the steam sealing teeth are disposed between two stages of adjacent movable vanes of the steam turbine and in the end steam sealing position. The steam passage sealing method for the steam turbine through-flow portion is suitable for the field of steam passage sealing of the steam turbine through-flow portion.

Owner:HARBIN TURBINE

Turbine shroud with abradable layer having ridges with holes

ActiveUS10190435B2Reduce leakageEasy to controlEngine manufactureLeakage preventionPorosityEngineering

Turbine and compressor casing abradable component embodiments for turbine engines vary localized porosity or abradability through use of holes or dimple depressions of desired polygonal profiles that are formed into the surface of otherwise monolithic abradable surfaces or rib structures. Abradable porosity within a rib is varied locally by changing any one or more of hole / depression depth, diameter, array pitch density, and / or volume. In various embodiments, localized porosity increases and corresponding abradability increases axially from the upstream or forward axial end of the abradable surface to the downstream or aft end of the surface. In this way, the forward axial end of the abradable surface has less porosity to counter hot working gas erosion of the surface, while the more aft portions of the abradable surface accommodate blade cutting and incursion with lower likelihood of blade tip wear.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Heat-curable resin composition for semiconductor encapsulation

ActiveUS20180186925A1Improve abradabilityIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesWaferingSemiconductor package

Provided is a versatile heat-curable resin composition for semiconductor encapsulation that has a favorable water resistance and abradability, and exhibits a superior fluidity and a small degree of warpage even when used to perform encapsulation on a large-size wafer.The heat-curable resin composition of the invention contains:(A) a cyanate ester compound having not less than two cyanato groups in one molecule;(B) a phenol curing agent containing a resorcinol-type phenolic resin;(C) a curing accelerator; and(D) a spherical inorganic filler.

Owner:SHIN ETSU CHEM IND CO LTD

Turbine moving blade with bevelled prism cavities formed in blade top

InactiveCN108361076AImprove abradabilitySimple structureBlade accessoriesMachines/enginesTurbine bladeBlock effect

The invention provides a turbine moving blade with bevelled prism cavities formed in a blade top. The turbine moving blade comprises a blade body, the multiple bevelled prism-shaped cavities are formed in the blade top of the blade body from the front edge to the tail edge, the bottom faces of the prism-shaped cavities adopt a bevelled mode, the ratio of the maximum height of the prism-shaped cavities to the height of the blade body is 0.5%-4%, and the beveled angles for beveling the bottom faces of the prism-shaped cavities are within the range of 30-60 degrees. According to the turbine moving blade with the bevelled prism cavities formed in the blade top, a part of leakage fluid entering a gap enters the prism-shaped cavities to be curled up to form vortexes, on the one hand, kinetic energy of the gap fluid is dissipated, on the other hand, the jet blocking effect on the gap fluid above the cavities is formed, then the purpose of controlling blade tip leakage flow of a turbine is achieved, the bottom faces of the prism cavities are beveled, the vortex intensity and development direction of the vortexes in the cavities are changed, the mixing effect of the fluid flowing into / flowing out of the cavities and the fluid in the gaps on the upper portion is enhanced, inhibiting turbine blade tip leakage flow is more advantageous, and the structure is simple.

Owner:HARBIN INST OF TECH

Titanium alloy surface inflaming retarding sealing integrated coating and preparing method an application thereof

ActiveCN110747428AReduce oxidation rateReduce porosityMolten spray coatingManufacturing cost reductionTitanium zirconium

The invention discloses a titanium alloy surface inflaming retarding sealing integrated coating and a preparing method an application thereof. The coating is composed of an inflaming retarding layer coating and a wearable sealing coating. The inflaming retarding layer coating is located between the titanium alloy surface and the wearable sealing coating. The preparing method comprises the following steps of firstly, surface treatment of a titanium alloy base material; secondly, preheating of the titanium alloy base material; thirdly, preparing of the inflaming retarding layer coating; and fourthly, preparing of the wearable sealing coating. An inflaming retarding layer of a titanium-zirconium amorphous alloy serves as a bonding layer to be used, an original bonding layer is omitted, NiCrAl-bentonite is adopted to serve as the wearable sealing face layer, blades and a case are protected, the porosity is reduced, the heat efficiency is improved, the manufacturing cost is reduced, and themaintaining cost is reduced.

Owner:INNER MONGOLIA UNIV OF TECH +1

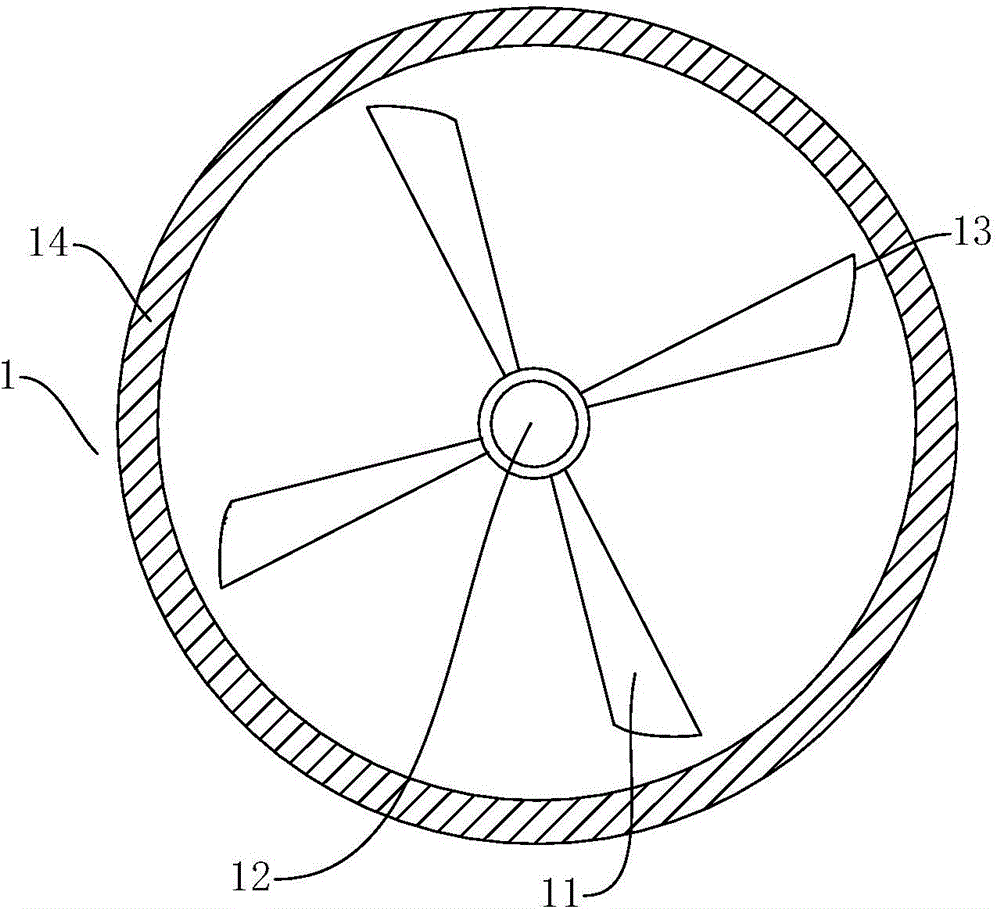

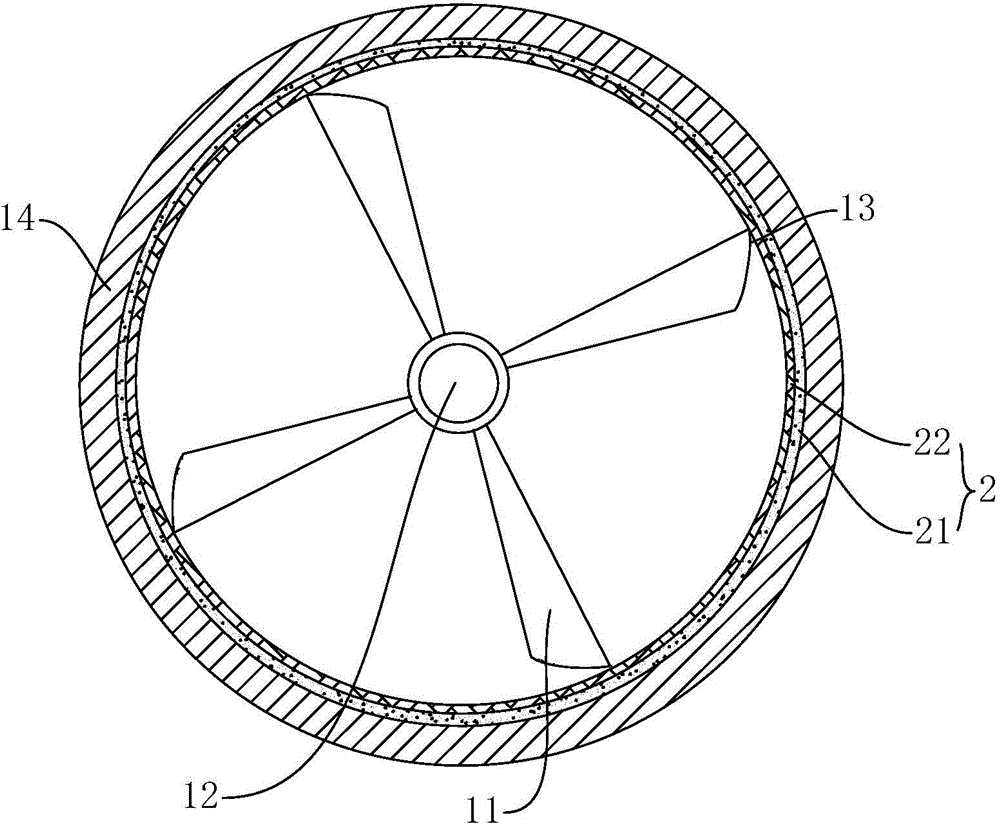

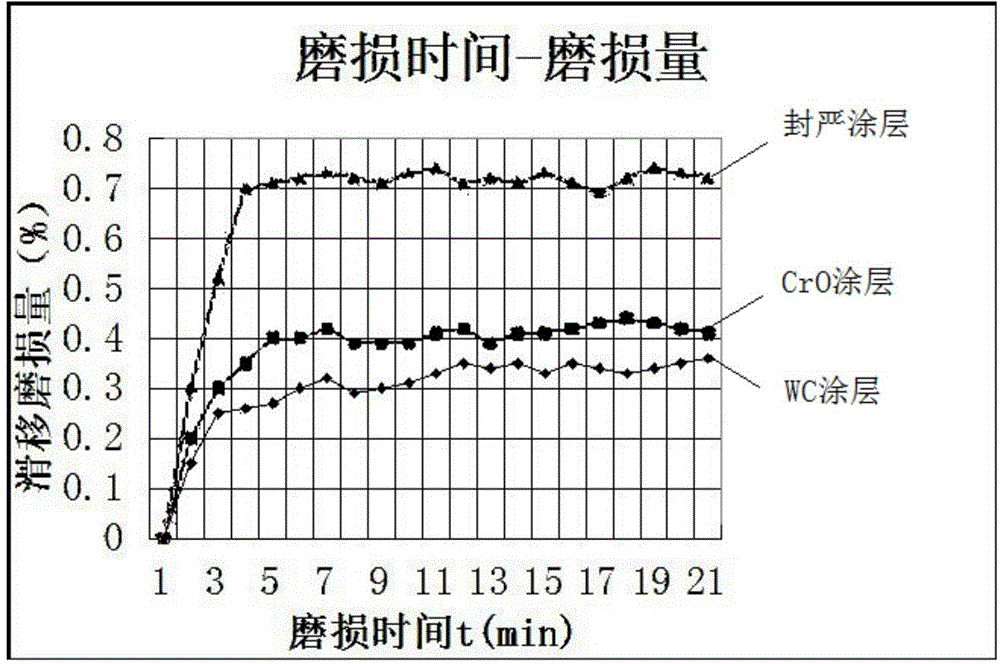

Turbine machinery

ActiveCN104975255ACorrosion resistanceAntioxidantMolten spray coatingPump componentsDifferential pressureAlloy

The invention discloses turbine machinery. The turbine machinery is characterized in that the turbine machinery is coated with a sealing coating; the sealing coating comprises at least two sub-coatings which are an alloy layer smeared on the surface of a base body and a metal ceramic layer smeared on the surface of the alloy layer respectively. A gap of the turbine machinery is coated with the sealing coating. In the working state, the tips of blades scrape the sealing coating to form ideal radial airflow gap, i.e., the maximum differential pressure is obtained with the minimum gap; the efficiency of the machinery is remarkably improved, energy consumption is reduced, and the service life is prolonged.

Owner:SHANGHAI JUSN SURFACE TECH ENG +1

Heat-curable resin composition for semiconductor encapsulation

InactiveUS20170009007A1Improve abradabilityImprove water resistanceSemiconductor/solid-state device detailsSolid-state devicesWaferingSemiconductor package

Provided is a versatile heat-curable resin composition for semiconductor encapsulation that has a favorable water resistance and abradability, and exhibits a superior fluidity and a small degree of warpage even when used to perform encapsulation on a large-size wafer.The heat-curable resin composition of the invention contains:(A) a cyanate ester compound having not less than two cyanato groups in one molecule;(B) a phenol curing agent containing a resorcinol-type phenolic resin;(C) a curing accelerator; and(D) a spherical inorganic filler.

Owner:SHIN ETSU CHEM IND CO LTD

Multi-component rod for hot spraying wearable sealing coating and preparation method thereof

ActiveCN101177770BGuaranteed StrengthGood adaptability to thermal spraying processMolten spray coatingThermal sprayingMechanical milling

The invention relates to a multi-components bar applied to a hot spray wearable sealing coating and a preparation method thereof. A bar which is good in spraying technology adaptability is prepared through a method of mechanical milling, bonding at room temperature and squeezing. The bar comprises Ni, Si, Cu, Al, Cd, BN, C and oxides, binders and other materials. The raw materials can be simple substance powder or alloy or compound, and the oxides can be one kind or more or the combination of a few materials. The binder can be inorganic materials and can also be organic substances, and the combination of some additives and addition agents is also included. The coating prepared by the bar has the advantages that: the coating combines well with a matrix, the wearable performance is excellent, and the thermal shock resistance and salt-fog resistance are excellent. The bar has wide application range and can be applied to the surface modification and the reproduction of mechanical equipments.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Coating for interstage sealing device of compressor

ActiveCN112646407AStable chemical propertiesStrong corrosion resistanceAnti-corrosive paintsMetallic material coating processesSilica fumeCorrosion resistant

The invention discloses a coating for an interstage sealing device of a compressor. The coating comprises the components in percentage by weight: not more than 35% but not zero of nickel powder with the granularity of less than or equal to 50 nm , 60-90% of graphite powder with the granularity of less than or equal to 50 nm, and not more than 5% but not zero of silicon powder with the granularity of less than or equal to 50 nm. The coating is based on the special performance requirements of the CCPP generator set gas compressor taking the byproduct gas as the fuel in domestic iron and steel enterprises on an interstage sealing coating layer; the coating enabling the gas compressor to have good erosion resistance, abrasion resistance, self-lubricating performance and corrosion resistance under the working condition of being rich in corrosive pollutants such as benzene, naphthalene, tar and sulfide is provided, and the high sealing performance of the compressor in the compression process can be guaranteed.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com