Low-burning-loss abrasive coating material and application thereof

A technology of coating materials and wear, applied in the direction of coating, metal material coating process, molten spraying, etc., can solve the problems of inability to exert superior characteristics, low deposition rate of thermal spraying, poor adhesion, etc., to reduce loss, Effect of increasing component content and easy deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Select lamellar hBN with a graphitization index of 1.4, a purity of 99.6%, and a primary particle size of 3-20 μm as the raw material, and its microscopic appearance is as follows: figure 1 shown;

[0034] Step 2: Prepare the powder mixture of Ni-15Cr-10Fe (particle size 45-105 μm), Al (particle size 0.1-3 μm) and hBN according to the mass ratio of 9:1:1, and stir evenly;

[0035] Step 3: adding polyvinyl alcohol (number average molecular weight 77,000) accounting for 3% of the total weight of the materials in step 2 as a binder, and adopting a mechanical coating process to prepare nickel-based boron nitride composite powder.

Embodiment 2

[0039] Step 1: Select lamellar hBN with a graphitization index of 1.8, a purity of 99.6%, and a primary particle size of 6-30 μm as a raw material;

[0040] Step 2: Prepare the powder mixture of Al-12Si (particle size 3-45 μm) and hBN according to the mass ratio of 4:1, and stir evenly;

[0041] Step 3: Add polyvinyl alcohol (number average molecular weight 77,000) accounting for 5% of the total weight of the materials in step 2 as a binder, and prepare aluminum-silicon-boron nitride composite powder by using a mechanical coating process.

Embodiment 3

[0045] Step 1: select lamellar hBN with a graphitization index of 2.0, a purity of 99.5%, and a primary particle size of 3-20 μm as a raw material;

[0046] Step 2: Prepare a powder mixture of Ni-5Si (particle size 1-45 μm), hBN and graphite (particle size 5-38 μm) according to the mass ratio of 5:1:1, and stir evenly;

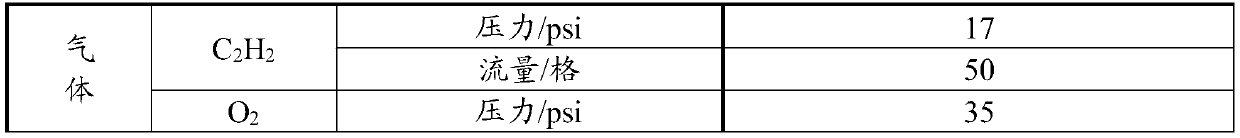

[0047] Step 3: Add water glass (modulus 2.4, density 1.3g / cm2) that accounts for 8% of step 2 material gross weight 3 ) as a binder, a nickel-silicon-boron nitride composite sprayed rod is prepared by adopting a cold-bonding extrusion process, the diameter of the rod is 4.75mm, and the length is 400-600mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com