Process for preparing zirconia coating

A preparation process, zirconia technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve problems that have not been seen in reports, and achieve uniform and dense structure, uniform and dense structure, and high ionization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is to deposit ZrO on the 1Cr18Ni9Ti stainless steel substrate 2 Coating, sample size is 15×10×2mm 3 . The substrate is ground, cleaned and polished with metallographic sandpaper. Depositing ZrO on Domestic MIP-8-800 Arc Ion Plating Equipment 2 coating, the cathode target material is metal zirconium (99%, wt.%), and the vacuum degree of the vacuum chamber is evacuated to 7×10 -3 After Pa, Ar gas was introduced to raise the pressure in the furnace to about 2×10 -1 Pa, apply a high bias voltage of -800 ~ -1000V, and clean the surface of the sample by arc light bombardment for 2 ~ 5 minutes, and then pass O 2 deposited ZrO 2 For coating, the target base distance is about 240mm; the substrate temperature is about 300-400°C; the pulse bias voltage is -100-300V, the duty cycle is 20-40%; the arc voltage is 20-40V, and the arc current is 60-70A.

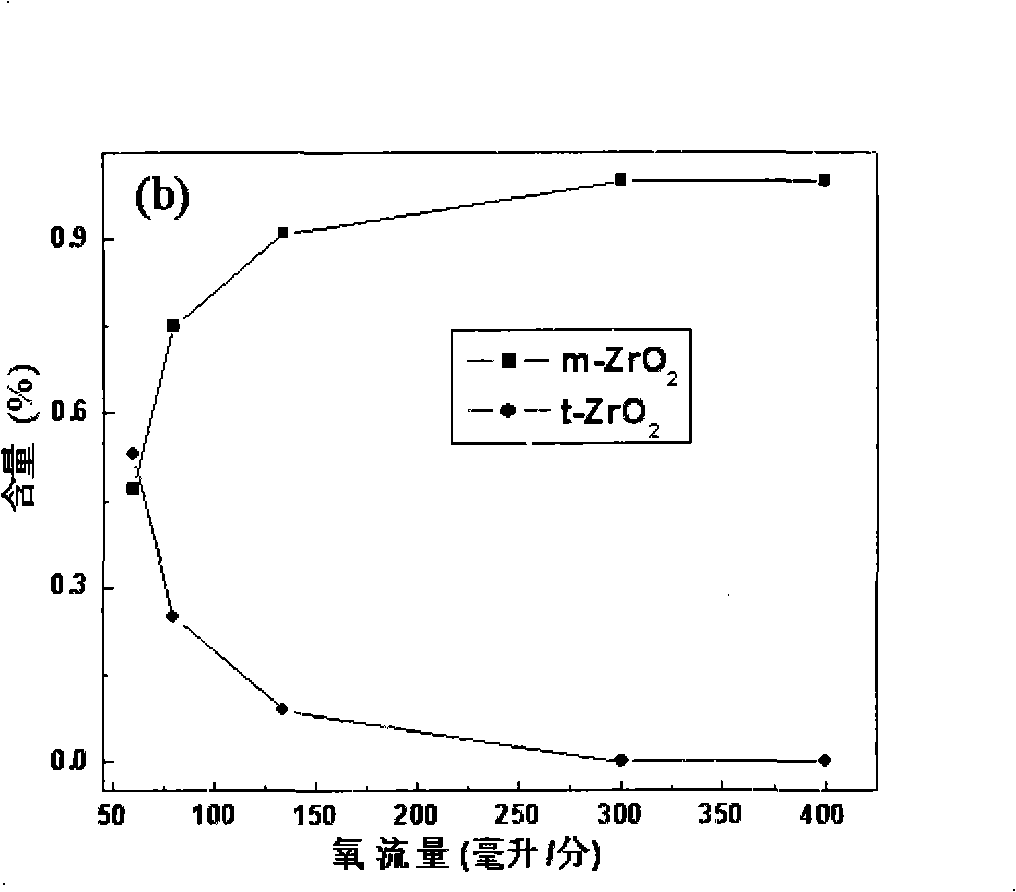

[0024] Change the oxygen flow in the range of 60-400sccm to prepare ZrO with different components and differen...

Embodiment 2

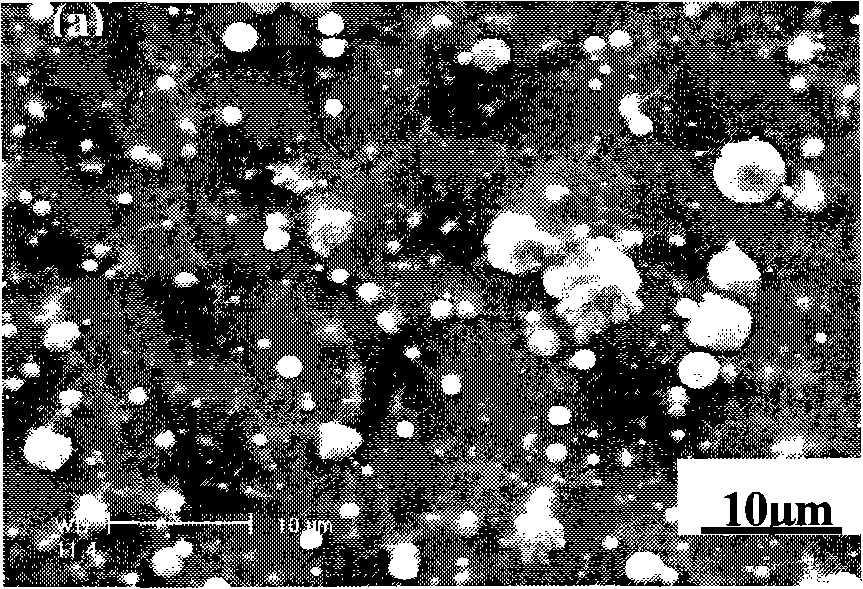

[0026] This embodiment is to deposit ZrO on the DZ125 superalloy with Ni32Co20Cr8Al0.5Y (wt.%) coating on the surface 2Coating, sample size is 15×10×2mm 3 . The substrate is ground with metallographic sandpaper, cleaned and water blasted (220 mesh hollow glass pellets). The deposition parameters are the same as in Example 1. Same as Example 1, the oxygen flow rate can be prepared in the range of 134~400sccm close to ZrO 2 Stoichiometric coating with monoclinic ZrO 2 phase-based. Figure 3(a)-(c) shows the typical ZrO deposited on the DSM11 superalloy with NiCoCrAlY coating deposited on the surface 2 The surface, polished section and fracture morphology of the coating, it can be seen that ZrO 2 The columnar growth of the coating along the growth direction is more obvious, and the ZrO 2 The coating is grown on the basis of the arc ion plating MCrAlY coating, which determines that it has a similar MCrAlY coating surface on the surface, showing an obvious ridge-like morpholo...

Embodiment 3

[0028] This embodiment is to deposit Zr(Y)O on the DZ125 superalloy with Ni32Co20Cr8Al0.5Y (wt.%) coating on the surface 2 Coating, sample size is 15×10×2mm 3 . The substrate is ground with metallographic sandpaper, cleaned and water blasted (220 mesh hollow glass pellets). Deposition of Zr(Y)O in Domestic MIP-8-800 Arc Ion Plating Equipment 2 Coating, the cathode target material is ZrY (containing 8wt% Y) alloy target material, the target base distance is about 240mm, and the vacuum degree of the vacuum chamber is evacuated to 7×10 -3 After Pa, Ar gas was introduced to raise the pressure in the furnace to about 2×10 -1 Pa, apply a high bias voltage of -800 ~ -1000V, and clean the surface of the sample by arc light bombardment for 2 ~ 5 minutes, and then pass O 2 Deposit Zr(Y)O 2 For coating, the oxygen flow rate is controlled within the range of 134-400sccm; the substrate temperature is about 300-400°C; the pulse bias voltage is -100-300V, the duty cycle is 20-40%; the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com