Biphase alloy steel tank container seal head and preparation technology thereof

A technology for alloy steel and tank containers, which is applied in the field of dual-phase alloy steel tank container heads and its preparation process, which can solve the problems of low strength and achieve low hot cracking tendency, good chloride stress corrosion resistance, and weldability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

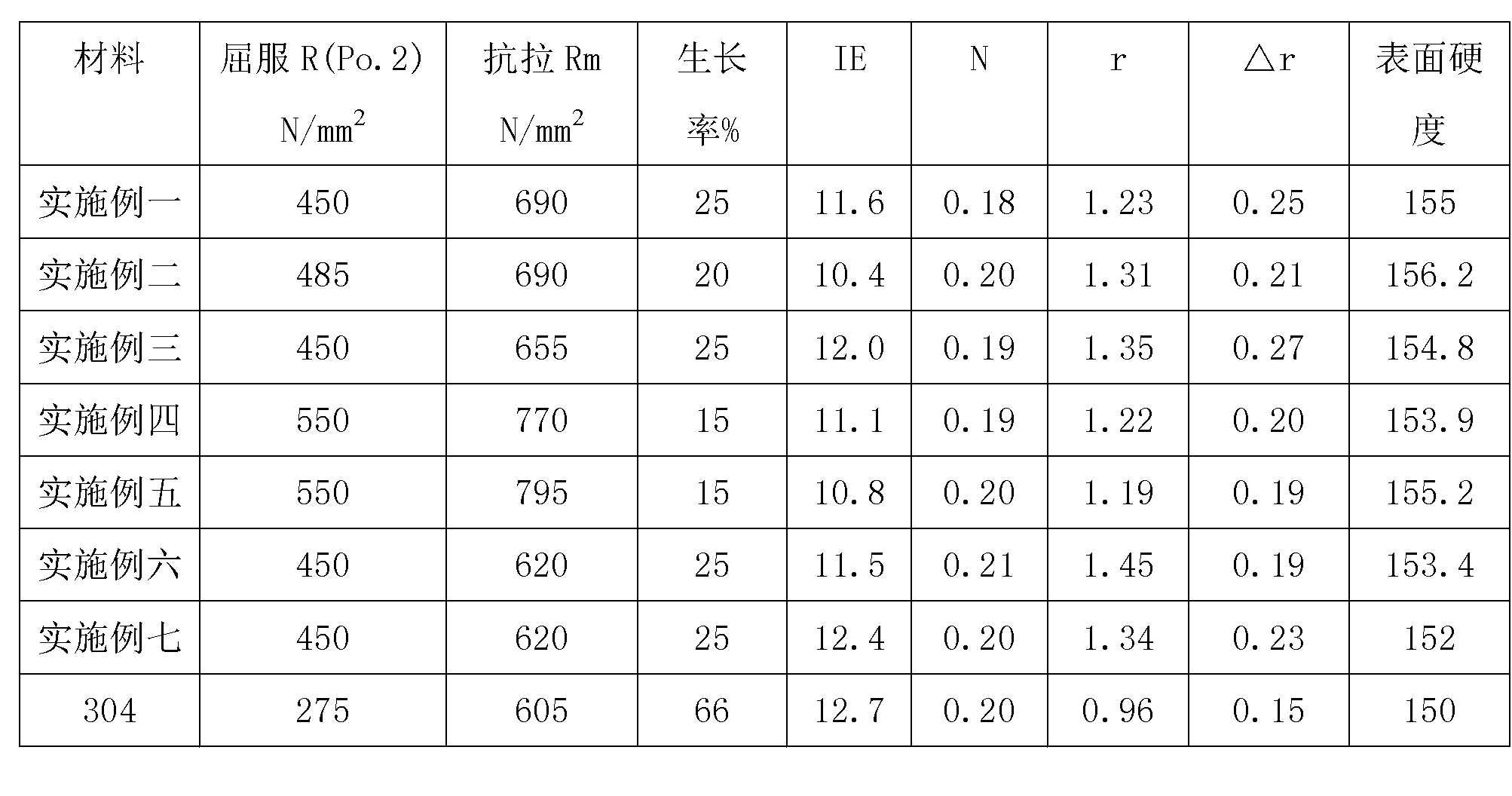

Examples

Embodiment 1

[0032] The dual-phase alloy steel plate of this embodiment has a thickness of 6mm and a width of 1800mm, and its chemical composition mass percentage is: C:

[0033] 0.027%, Si: 0.87%, Mn: 1.90%, Cr: 21%, Ni: 6.00%, N: 0.16%, Mo: 3.20%, P: 0.025%, S: 0.015%, the rest is Fe and not Avoid impurities.

[0034] A process for preparing a dual-phase alloy steel tank head, comprising the steps of:

[0035] (1) Circle cutting: Draw on the steel plate according to the shape of the drawing, adjust the knife distance, use plasma cutting, and transfer after confirming that there are no sundries;

[0036] (2) Welding: Place the wafer on the working platform of the plasma welding machine, spot-fix the weld, and then perform welding. The weld is formed on one side and double-sided, and the weld must not be lower than the base material; the surface must not have cracks, pores, Defects such as arc craters, undercuts and slag inclusions, and no slag and spatter. The welds are ground on both ...

Embodiment 2

[0053] The dual-phase alloy steel plate in this example has a thickness of 6mm and a width of 1600mm, and its chemical composition mass percentages are: C: 0.009%, Si: 0.70%, Mn: 1.50%, Cr: 22.00%, Ni: 5.00%, N: 0.18%, Mo: 3.00%, P: 0.022%, S: 0.011%, and the rest are Fe and unavoidable impurities.

[0054] The preparation method of this embodiment is as described in Example 1.

Embodiment 3

[0056] The dual-phase alloy steel plate in this example has a thickness of 10mm and a width of 1800mm, and its chemical composition mass percentages are: C: 0.022%, Si: 0.56%, Mn: 0.45%, Cr: 22.5%, Ni: 4.67%, N: 0.14%, Mo: 3.30%, P: 0.008%, S: 0.014%, and the rest are Fe and unavoidable impurities.

[0057] The preparation method of this embodiment is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com