Seawater-resistant anticorrosive paint and preparation method of seawater-resistant anticorrosive paint

A technology of anti-corrosion paint and seawater resistance, which is applied in the field of coatings to achieve the effect of excellent seawater resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

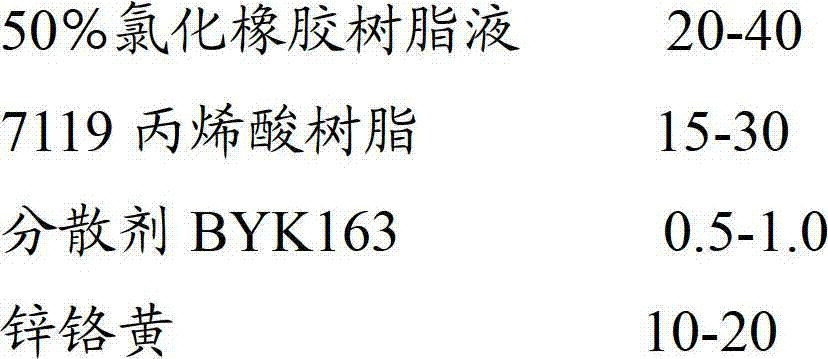

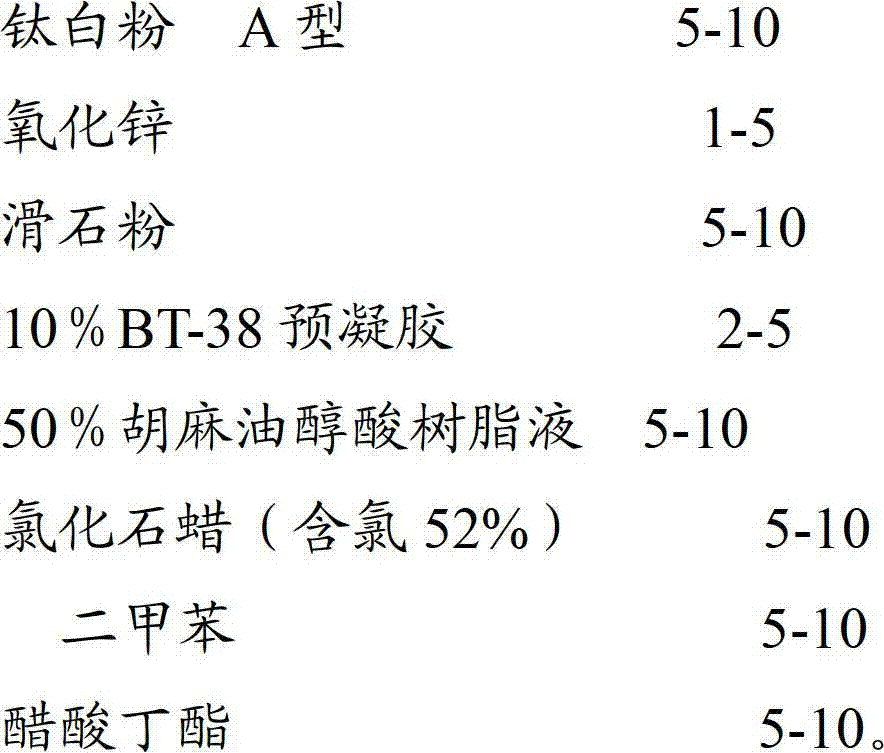

Image

Examples

Embodiment 1

[0027] The self-made 50% flax oil alkyd resin liquid consists of the following components, by weight (g),

[0028] Flax oil 25 Glycerin 5 Huang Dan 0.005

[0029] Phthalic anhydride 15 Silicone oil 0.0001 Xylene 50.

Embodiment 2

[0031] The self-made 50% flax oil alkyd resin liquid consists of the following components, by weight (g),

[0032] Flax oil 35 Glycerin 10 Huang Dan 0.02

[0033] Phthalic anhydride 25 Silicone oil 0.0003 Xylene 56.

Embodiment 3

[0035] The self-made 50% flax oil alkyd resin liquid consists of the following components, by weight (g),

[0036] Flax oil 30 Glycerin 8 Huang Dan 0.01

[0037] Phthalic anhydride 20 Silicone oil 0.0002 Xylene 55.

[0038] The preparation method of above-mentioned 50% flax oil alkyd resin liquid, carries out according to the following steps,

[0039] ⑴Put flax oil and glycerin into the reaction kettle according to the formula amount, stir gradually to heat up, and pass in CO 2 gas;

[0040] ⑵Raise the temperature to 120°C, add Huangdan, and continue to heat up to 220±2°C;

[0041] (3) Maintain alcoholysis at 220±2°C for 1 hour, take samples to measure the degree of alcoholysis, and cool down to below 180°C after passing the alcoholysis;

[0042] (4) Add silicone oil, then add phthalic anhydride and reflux xylene with 6% of the total formula, heat up to 200±2°C in 1.5 hours, and stop CO when there is reflux in the condenser sight glass 2 Gas, keep the low temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com