Aqueous fire retardation antirust coating material

A kind of anti-rust coating, water-based technology, applied in the field of coatings, can solve problems such as the decline of bearing capacity and balance stability, endanger the health of users, damage the ecological environment, etc., achieve strong adhesion, wide application range, and overcome pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A water-based flame-retardant anti-rust coating, characterized in that it comprises the following raw materials in parts by weight: 100 parts of styrene-acrylic emulsion, 8 parts of epoxy resin, 15 parts of glass flakes, 0.1 part of zinc phosphate, dimethyl phosphonate 4 parts of ester, 2 parts of aluminum tripolyphosphate, 0.5 part of sorbitan monooleate, 0.2 part of nonylphenol polyoxyethylene ether, 0.1 part of triethylamine, 0.1 part of sodium hexametaphosphate, polyether modified Silicone oil 0.1 part, deionized water 10 parts.

[0015] The production method of the water-based flame-retardant and anti-rust coating of the present embodiment is obtained by mixing, stirring and removing impurities from the above-mentioned raw materials by physical methods.

Embodiment 2

[0017] A water-based flame-retardant anti-rust paint, characterized in that it includes the following raw materials in parts by weight: 120 parts of styrene-acrylic emulsion, 10 parts of epoxy resin, 25 parts of glass flakes, 0.3 parts of zinc phosphate, dimethyl phosphonate 10 parts of ester, 4 parts of aluminum tripolyphosphate, 2 parts of sorbitan monooleate, 0.3 part of nonylphenol polyoxyethylene ether, 0.2 part of triethylamine, 1 part of sodium hexametaphosphate, polyether modified 0.5 parts of silicone oil, 20 parts of deionized water.

[0018] The production method of the water-based flame-retardant and anti-rust coating of the present embodiment is obtained by mixing, stirring and removing impurities from the above-mentioned raw materials by physical methods.

[0019]

Embodiment 3

[0021] A water-based flame-retardant and anti-rust coating is characterized in that it includes the following raw materials in parts by weight: 110 parts of styrene-acrylic emulsion, 9 parts of epoxy resin, 20 parts of glass flakes, 0.2 part of zinc phosphate, dimethyl phosphonate 8 parts of ester, 3 parts of aluminum tripolyphosphate, 1.2 parts of sorbitan monooleate, 0.25 parts of nonylphenol polyoxyethylene ether, 0.14 parts of triethylamine, 0.7 parts of sodium hexametaphosphate, polyether modified 0.3 parts of silicone oil, 15 parts of deionized water.

[0022] The production method of the water-based flame-retardant and anti-rust coating of the present embodiment is obtained by mixing, stirring and removing impurities from the above-mentioned raw materials by physical methods.

[0023]

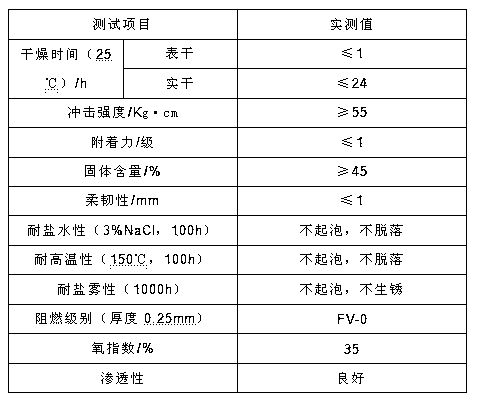

[0024] Product performance of the present invention is tested according to national standards, and its test results are as shown in Table 1.

[0025]

[0026] Table 1 Product performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com