Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Strong color fixing ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

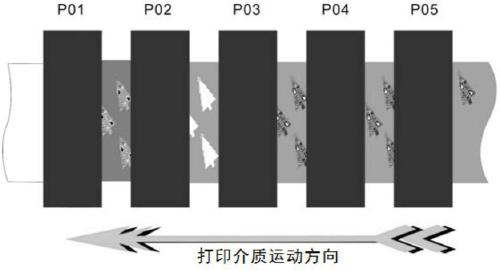

Functional ink and printing method thereof

ActiveCN109627848AImprove permeabilityStrong color fixing abilityInksDyeing processChemistrySurface-active agents

The invention discloses functional ink. The functional ink is prepared from, by weight, 5-40% of a wetting agent for printing inks, 0.1-5% of a viscosity modifier, 0.1-10% of a surface active agent, 0.1-5% of a pH regulator, 0.1-5% of a complexing agent, 0.1-2% of bactericide, 0.1-30% of functional auxiliaries and the balance water. The functional auxiliaries are one or more of a rapid color developing agent, a fastness promoting agent, a penetrant, a softening agent, an antistatic agent, an anti-stiff finishing agent, an antibacterial finishing agent and a waterproof finishing agent. In addition, the invention discloses a printing method of the functional ink. The method comprises the steps that 1, before ink jet ink is used for jetting ink, the functional ink is used for performing pre-printing on a printing medium; 2, after the jet ink is used for performing ink printing on a printing medium, the functional ink is used for performing post-printing on the printing medium; 3, the functional ink and the jet ink are used for simultaneously performing at least one printing on the printing medium.

Owner:HONGSAM DIGITAL SCI & TECH

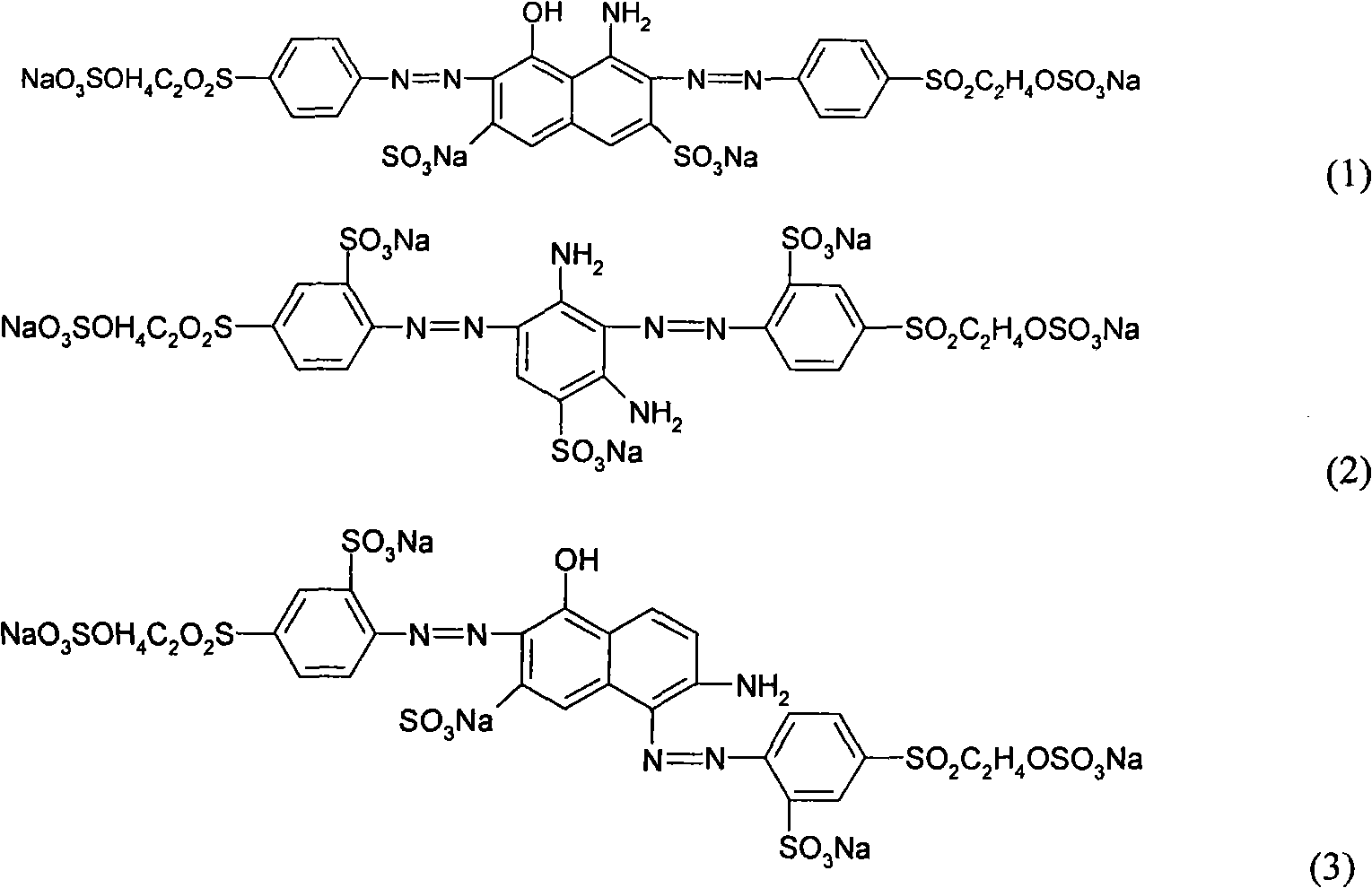

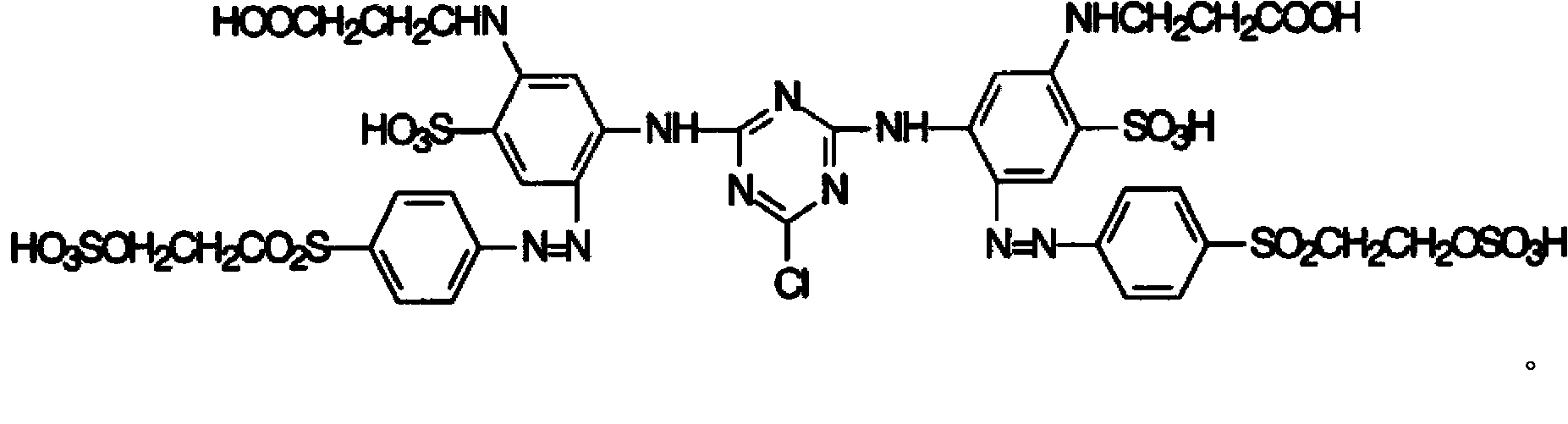

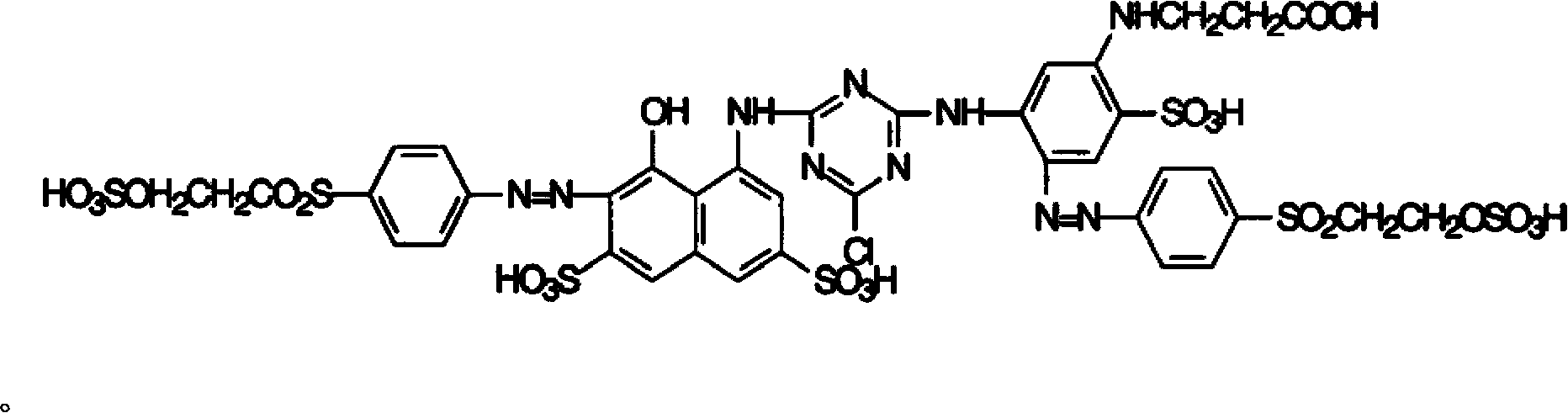

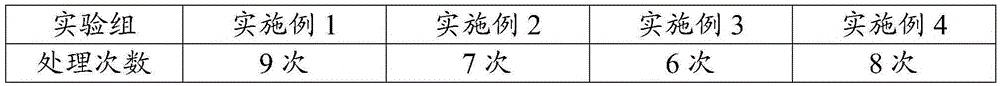

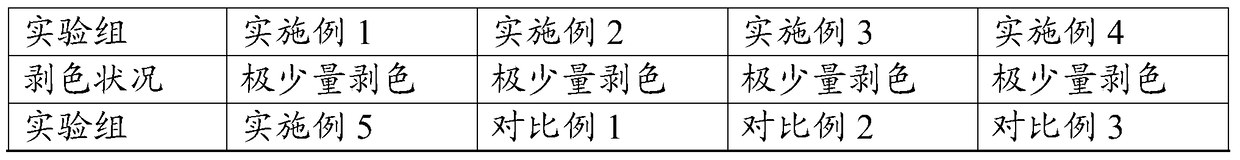

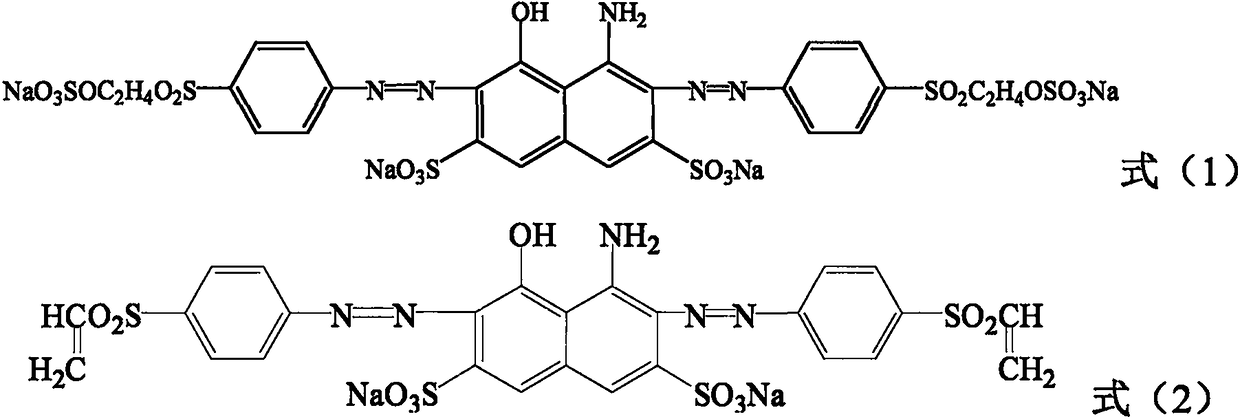

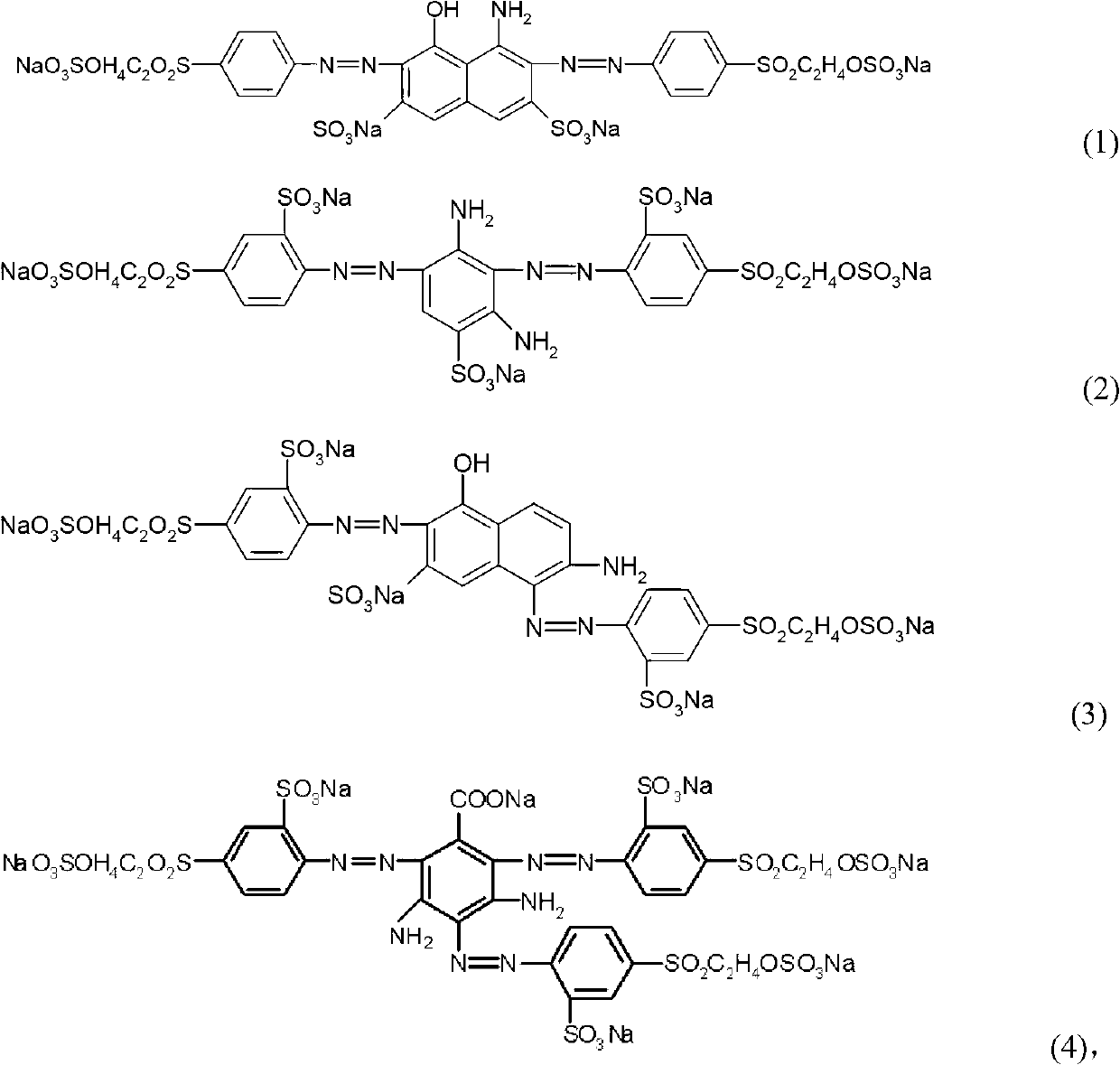

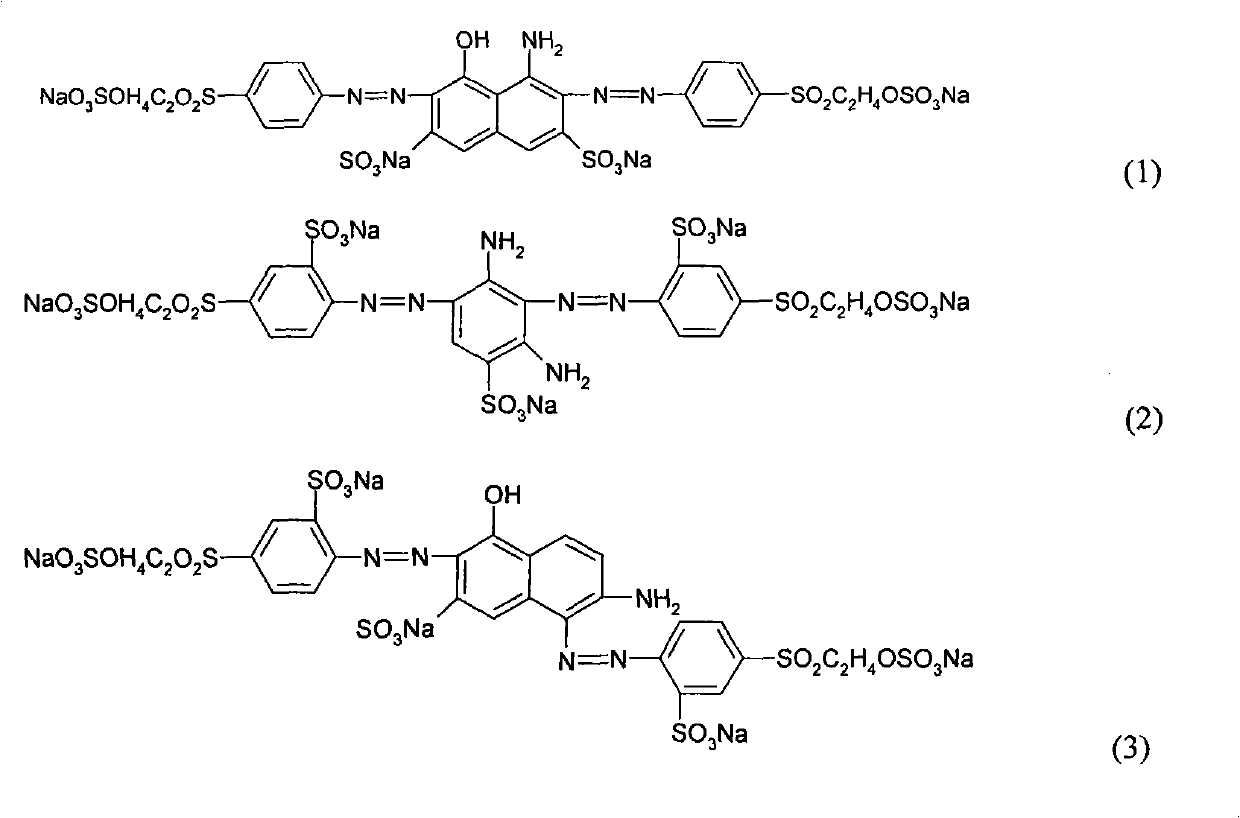

Composite active black dye

ActiveCN101580649AStrong color fixing abilityExcellent color depthOrganic dyesDyeing processDyeingFiber

The invention relates to a composite active black dye, which is characterized in that the dye is compounded by four dyes shown in formula (1), formula (2), formula (3) and formula (4) according to parts by weight of 80-84, 6-10, 1-3 and 6-10, has high responsiveness, good color fixing capability and excellent deep dyeing property, and is suitable for dyeing cotton fiber.

Owner:HUBEI HUALI DYESTUFF INDAL

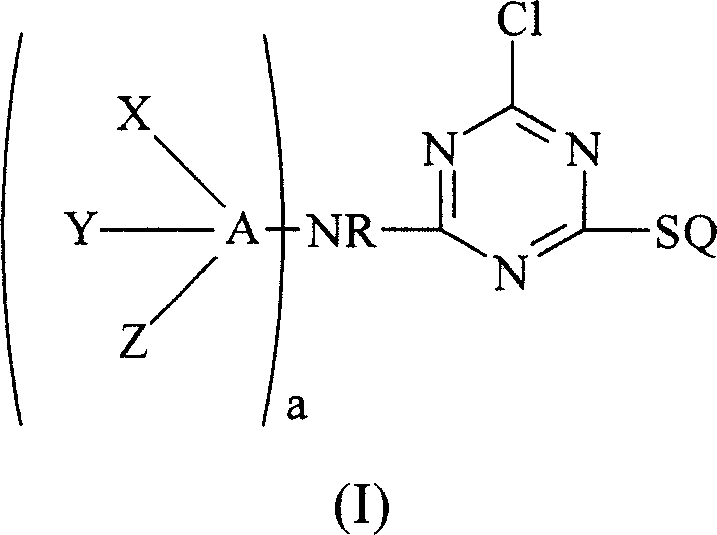

Chemically-reactive dyes with thioalkyl-s-triazine reactive group

InactiveCN101121827AImprove cleanlinessImprove dyeing propertiesReactive dyesDyeing processFiberSulfur

The present invention is a reactive dye of the following formula (I) with the sulfur alkyl-s-triazoxide base; therein, the definitions of A, X, Y, Z, R, Q, as well as (a) are as shown in the patent specification. The reactive dye of the present invention can be used in the medium-temperature dip-dye, cool dye and continuous dye of the fiber containing the hydroxyand nitrogen.

Owner:ETHICAL INT WAREHOUSING TRADING SHANGHAI

Formaldehyde-free color-fixing agent and preparation method of color-fixing agent

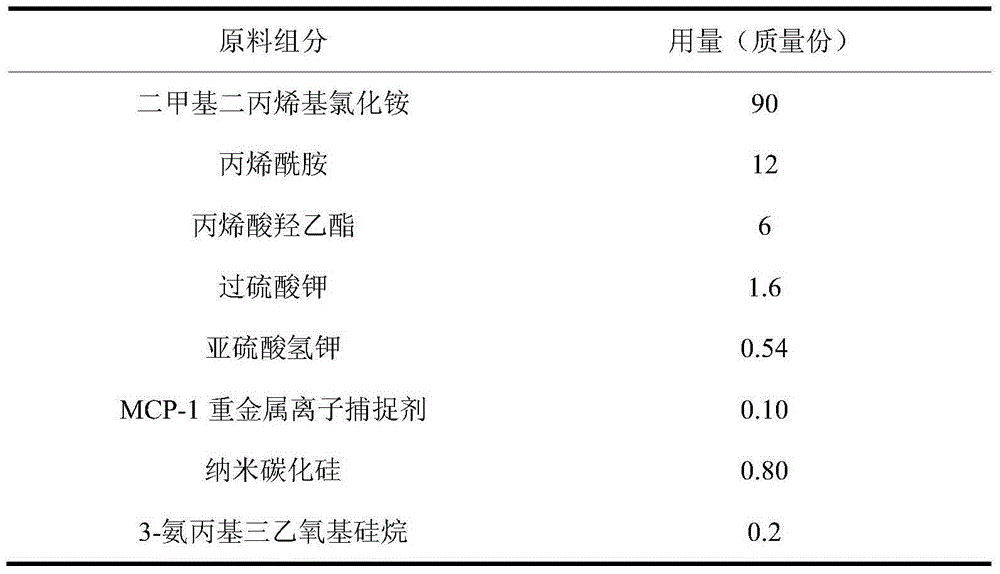

InactiveCN104452366AImprove wear resistanceImprove mechanical propertiesDyeing processEnvironmental resistancePersulfate

The invention discloses a formaldehyde-free color-fixing agent and a preparation method of the color-fixing agent. The formaldehyde-free color-fixing agent comprises the following raw materials in parts by weight: 90-110 parts of dimethyl diallyl ammonium chloride, 12-20 parts of acrylamide, 6-10 parts of 2-hydroxyethyl acrylate, 1.6-2.3 parts of peroxysulphate, 0.45-0.85 part of hydrosulphite, 0.10-0.18 parts of a heavy metal ion capture agent, 0.8-3 parts of nano silicon carbide, 0.2-1 part of a siloxane coupling agent and the balance of water. A siloxane coupling agent is used for carrying out surface modification on the nano silicon carbide to obtain the modified nano disilicon; the abrasion resistance and the mechanical property of the color-fixing agent can be remarkably improved; dimethyl diallyl ammonium chloride is used as a main monomer and is used for carrying out solution copolymerization together with water-soluble acrylamide and 2-hydroxyethyl acrylate to prepare a cationic quaternary ammonium salt polymer, so that the prepared color-fixing agent is environmentally friendly, safe and strong in color-fixing effect.

Owner:TAICANG YUNTONG BIOCHEM ENG

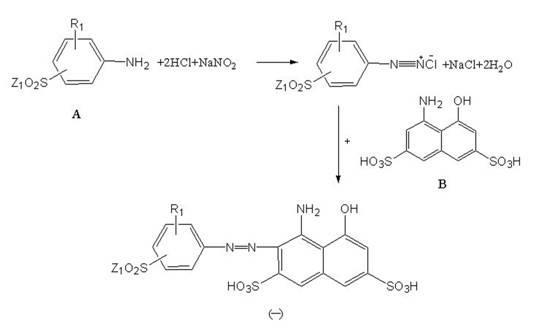

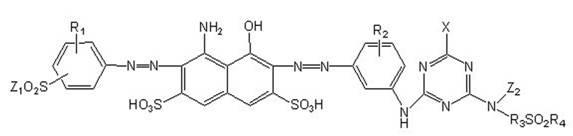

Reactive dark blue bisazo dye and preparation method thereof

ActiveCN102504582AImprove responseStrong color fixing abilityReactive dyesDyeing processFiberPhenyl group

The invention relates to a reactive dark blue bisazo dye having a structural formula shown in the formula (1), wherein R1 and R2 are selected from -H, CH3 (CH2)n-, CH3(CH2)n-O-, -COOH or -SO3H and n is between 0 and 3; R3 is can be -CH2CH2- or -CH2CH2CH2-; R4 can be -CH2CH3 or -CH2CH2-W and W is an acid radical or halogen element; X is a halogen element; Z1 is -CH2-CH2-U and U is an acid radical or halogen element; and Z2 can be phenyl, tolyl, naphthyl or naphthyl sulfonyl. The dye provided by the invention has high reactivity, excellent color fixation and excellent deep dyeing property and good stability of combination with fiber fabric, and the fabric dyed with the reactive dark blue bisazo dye has excellent light fastness, humidity resistance and acid-base-resistance fastness; in addition, the invention relates to a preparation method of the dye and the application of the dye in fabrics such as cotton.

Owner:吴江桃源染料有限公司

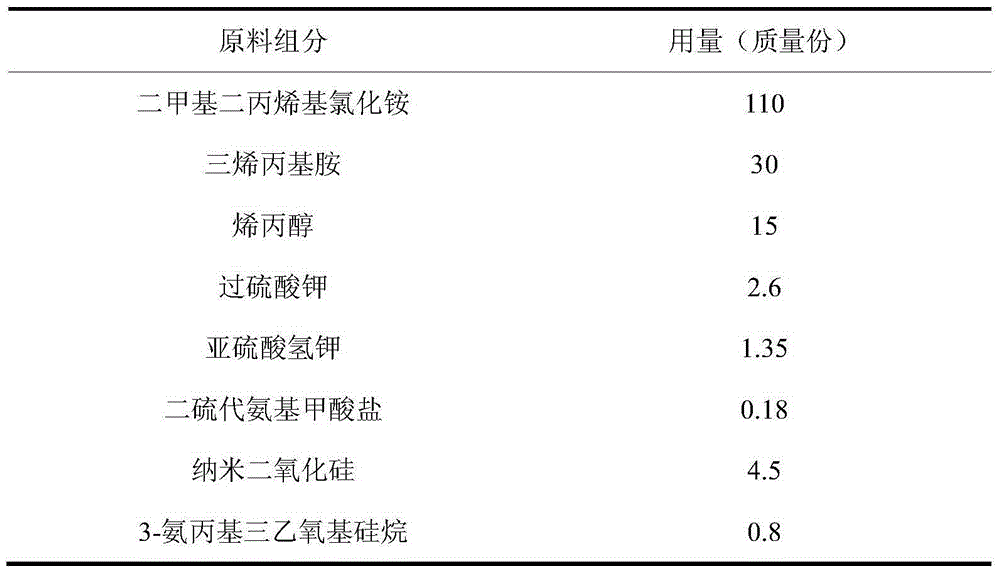

Color fixing agent and preparation method thereof

InactiveCN104389209AImprove wear resistanceImprove mechanical propertiesDyeing processEnvironmental resistancePersulfate

The invention discloses a color fixing agent and a preparation method thereof. The color fixing agent is prepared from the following raw materials in parts by mass: 90-110 parts of dimethyl diallyl ammonium chloride, 20-30 parts of triallylamine, 8-16 parts of allyl alcohol, 2-2.6 parts of persulfate, 0.95-1.35 parts of hydrosulphite, 0.16-0.2 part of dithiocarbamate, 1.2-4.5 parts of nano-silicon dioxide, 0.15-0.8 part of a silane coupling agent and the balance being water. The silane coupling agent is adopted for modifying the surface of the nano-silicon dioxide, and the obtained modified nano-silicon dioxide is capable of obviously improving the wear resistance and the mechanical properties of the color fixing agent; the dimethyl diallyl ammonium chloride is selected as a main monomer and subjected to solution copolymerization with the water-soluble triallylamine and the allyl alcohol to obtain a cationic quaternary ammonium salt polymer; as a result, the obtained color fixing agent is environmentally-friendly, safe, and high in color fixation effect.

Owner:TAICANG YUNTONG BIOCHEM ENG

Cationic binder emulsion for pigment dyeing as well as preparation method and application thereof

The invention discloses a cationic binder emulsion for pigment dyeing as well as a preparation method and application thereof. The binder emulsion is generated by carrying out reaction on the following components: a soft monomer, a hard monomer, a cross-linking monomer, a cationic monomer, a comonomer, a composite emulsifier of a cationic surfactant and a nonionic emulsifier and an initiator. Thepreparation method comprises the following steps of adding a mixture of the soft monomer, the hard monomer and the cross-linking monomer and an initiator aqueous solution into the emulsifier and distilled water for reaction, carrying out rapid heating, rapidly adding the comonomer, carrying out rapid cooling, adjusting the pH value, carrying out cooling, carrying out heat preservation reaction, and carrying out filtering so as to obtain the cationic binder emulsion. According to the cationic binder emulsion as well as the preparation method and application thereof, water-based latex not only is simple and convenient in preparation method, but also can be used for pigment dyeing for textiles.

Owner:XINGTAI POLYTECHNIC COLLEGE

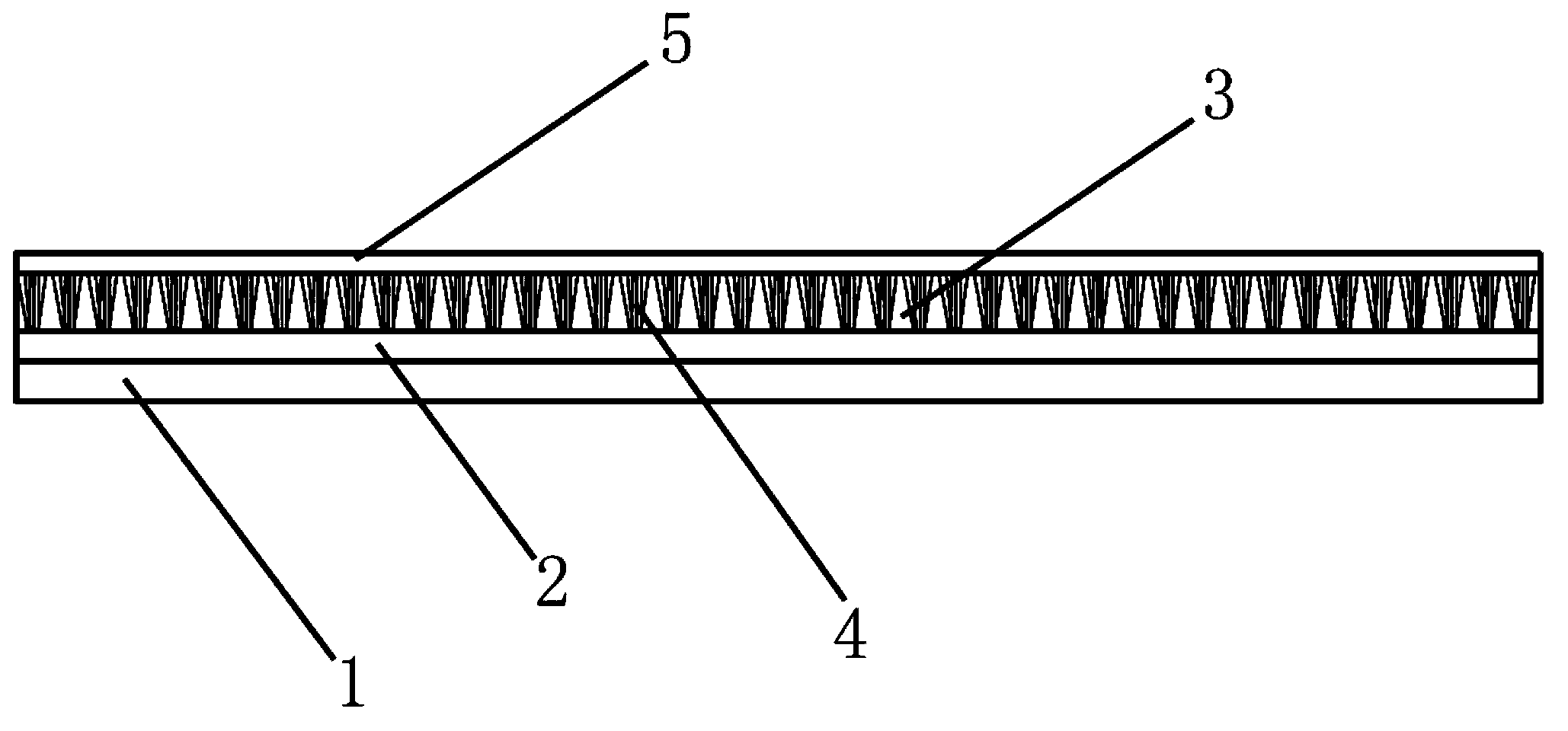

Colorfast carpet

The invention belongs to the field of textile, and particularly relates to a piece of colorfast carpet, which comprises a base cloth layer, a bonding agent layer and a carpet surface layer, wherein the carpet surface layer is fixedly arranged on the base cloth layer through the bonding agent layer. The colorfast carpet is characterized in that the carpet surface layer is formed by nanometer fiber cotton strands, and a PTFE (polytetrafluoroethylene) microporous film layer covers the upper part of the carpet surface layer. The colorfast carpet provided by the invention has the advantages that the structure is simple, and the practicability is high.

Owner:天津立秋工艺品有限公司

Golden dye

InactiveCN103788702AImprove suction capacityImprove dyeing propertiesReactive dyesDyeing processHigh absorptionCellulose fiber

The invention discloses a golden dye which is a reactive dye with industrial value for cellulose fibers. The golden dye has the advantages of excellent color fixation capacity, excellent deep dyeing property and high absorption cleaning capacity, and is suitable for dyeing within a wide temperature range.

Owner:WUXI VISION PRO

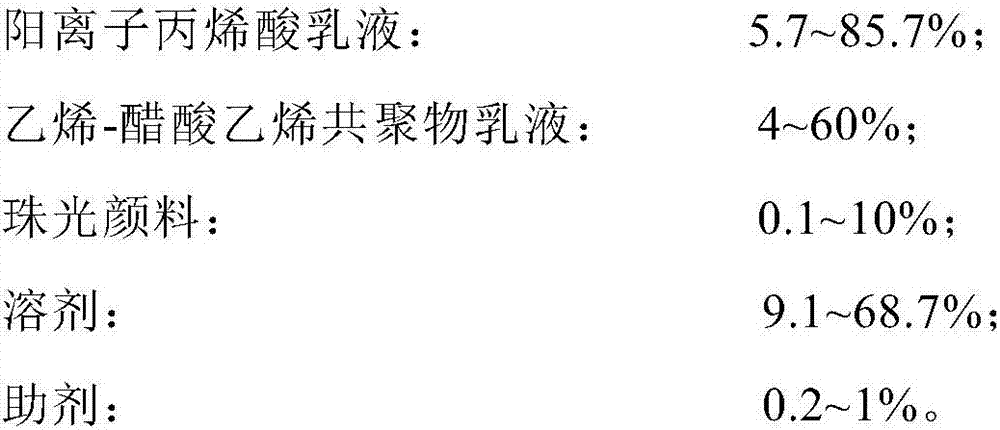

Electronic ink printing coating compound with pearl effect and preparation method of compound

InactiveCN107418309AStrong adhesionEffective combinationCoatingsPolyethylene terephthalate glycolEmulsion

The invention provides an electronic ink printing coating compound with a pearl effect and a preparation method of the compound. The compound comprises cation acrylic emulsion, ethylene-vinyl acetate copolymer emulsion, pearl pigments, solvents and auxiliaries. The preparation method includes the steps: uniformly mixing the cation acrylic emulsion with the ethylene-vinyl acetate copolymer emulsion and then adding the solvents; uniformly mixing the emulsion with the solvents, adding the auxiliaries, uniformly mixing the emulsion, the solvents and the auxiliaries and then adding the pearl pigments to obtain the electronic ink printing coating compound with the pearl effect. Compared with the prior art, the compound has the advantages that the compound is a waterborne coating, conforms to the trend of environmental protection and adapts to various substrates such as paper, aluminum foils, aluminum-plating paper, PET (polyethylene terephthalate) films and OPP (oriented polypropylene) films, the production process of pearl printing paper is simplified, and the problem of poor fastness of electronic ink varnish and pearl varnish layers is solved.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Method for dyeing down feather

The invention discloses a method for dyeing down feather. The method for dyeing the down feather comprises the following steps: separating the raw material feather into waste feather, feather slices and down clusters by using a feather separator; removing dust of the separated feather slices and the down clusters, adding the feather slices and the down clusters subjected to dust removal into a scouring machine for souring, subsequently dyeing the soured down feather, simultaneously dyeing and adding a levelling agent, dye and a color curing agent, and enabling the down feather to have different colors through the dyeing process. Through the method for dyeing the down feather, the conventional view that the down feather only has white color and gray color is broken, so that the genuine down feather is obtained; the theoretical basis is provided for the market innovation of the down feather industry.

Owner:东隆家纺股份有限公司

Pink dye

InactiveCN103788700AImprove suction capacityImprove dyeing propertiesReactive dyesDyeing processHigh absorptionCellulose fiber

The invention discloses a pink dye which is a reactive dye with industrial value for cellulose fibers. The pink dye has the advantages of excellent color fixation capacity, excellent deep dyeing property and high absorption cleaning capacity, and is suitable for dyeing within a wide temperature range.

Owner:WUXI VISION PRO

Preparation method of ceramic white salix integra strips

ActiveCN108789700ALow costImprove textureWood treatment detailsReed/straw treatmentWater contentSalix integra

The invention discloses a preparation method of ceramic white salix integra strips. The preparation method includes the following operation steps that (1) salix integra is subjected to natural dryingtreatment for 5-7 days after being harvested in autumn, then salix integra strips are put into a soaking solution, after the soaking solution is boiled, soft-fire boiling is continued for 30-40 min, and then the salix integra strips are taken out and peeled; (2) when dried till the water content is 7-9%, the peeled salix integra strips are put into a color changing solution, soaked for 3-4 h, thentaken out, and put into a drying oven to be dried till the water content is 12-16%; and (3) a color fixing solution is evenly sprayed on the surfaces of the salix integra strips treated in the step (2), and after 3-4 h, the salix integra strips are put into the drying oven to be dried, so that the ceramic white salix integra strips are obtained. The prepared salix integra strips have the color ofceramic white, so that the texture of manufactured wicker products is effectively improved, and the ornamental value of the products is increased; and meanwhile, the color fixing performance of the ceramic white is high, and a color fading phenomenon is not prone to occurring in the using process.

Owner:阜南县大喜柳编工艺品有限公司

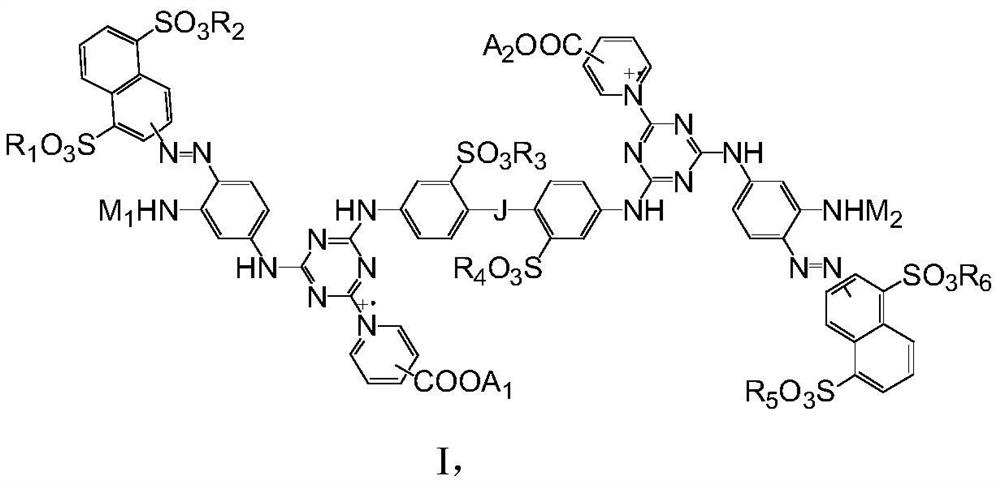

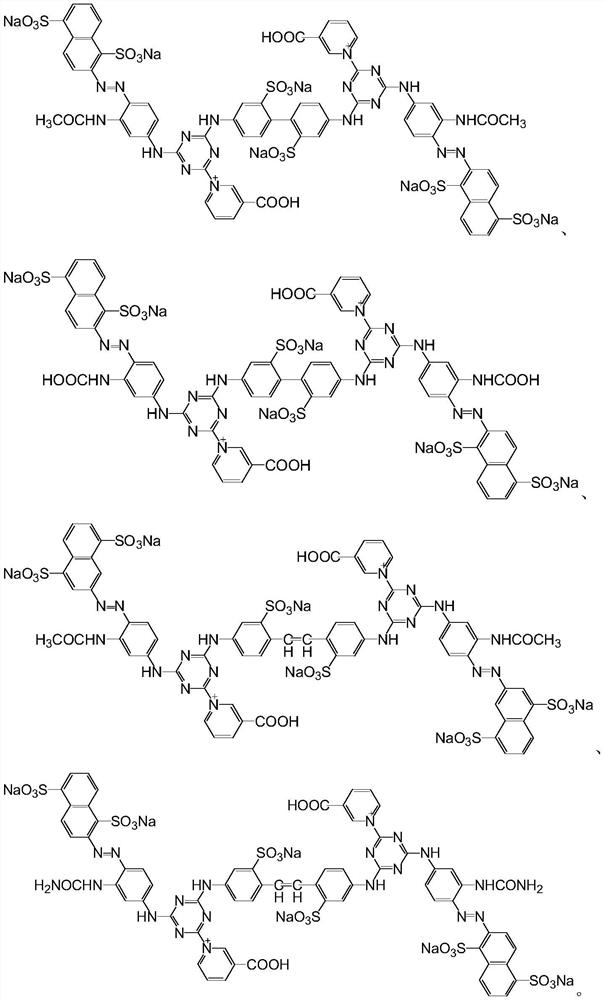

Reactive dye red as well as preparation method and application thereof

ActiveCN112480708AImprove responseStrong color fixing abilityOrganic chemistryReactive dyesDisperse dyeEngineering

The invention relates to reactive dye red as well as a preparation method and application thereof, and the compound structure of the reactive dye red is shown as a general formula (I). The reactive dye provided by the invention has relatively high reactivity, good color fixing capability and good dyeing capability, and during dyeing, soda ash does not need to be added for color fixing, so that theuse of soda ash is avoided. Meanwhile, the reactive dye also has high-temperature resistance, can be matched with a disperse dye for use, and can be used for simultaneously dyeing T / R or T / C blendedfabric products at the temperature higher than 100 DEG C, so that a one-bath dyeing process is realized, the dyeing process is simplified, the dyeing time is shortened, the discharge capacity is greatly reduced, and the labor cost and the energy consumption are reduced.

Owner:苏州澳缘盛新材料科技有限公司

Preparation technology of azo active dye

InactiveCN1261505CHigh reactivityStrong color fixing abilityMonoazo dyesReactive dyesCelluloseAniline

The invention relates to an azo active material preparing process, where 2-amino-1.5-naphthalene disulfonic acid reacts with the added hydrochloric acid and sodium nitrite to form a diazo salt component; tricyanogen chloride, water and disodium hydrogen phosphate are fully mixed on condition of adding lubricant to form a suspension, dripping 4-(beta-hydroxyvinyl sulfone sulfate) aniline solution in the suspension, then adding sodium hydroxide solution to the suspension to make pH value of the suspension maintained between 3.5 and 4, and maintaining the reaction to the terminal; raising the temperature to 20-25 deg.C, adding in sodium hydroxide solution to regulate the pH value to 5-5.5, dripping in 2-amino-5-naphthol-7-sulfonic acid, and maintaining the pH value at 3-7 and the temperature at 25-40 deg.C, reaction, obtain a coupled component solution; adding the above diazo salt to the coupled component solution for making coupled reaction at the temperature of 0-60 deg.C and the pH value regulated to 3-7, reacting, eliminating the salts through ionic film and obtaining the azo active material. The advantages are high reacting activity, good color fixing ability and excellent improving performance.

Owner:吴江桃源染料有限公司

Technology for printing and dyeing animal skin through mulberry juice

The invention relates to a technology for printing and dyeing animal skin through mulberry juice. The technology includes the following steps that a, mulberry dye is prepared; b, the dye is compounded; c, the animal skin is treated; d, dyeing is conducted; e, hot steaming is carried out; f, after treatment is performed. By the adoption of the printing and dyeing technology, the adhesive force of plant dye on leather can be increased, and the printed and dyed leather is not prone to fading and losing colors.

Owner:GUANGZHOU PANYU POLYTECHNIC

Natural dye used for spinning

InactiveCN108708187AReasonable configurationImprove dyeing effectDyeing processCrocus sativusNatural dye

The invention relates to the technical field of spinning, in particular to natural dye used for spinning. The natural dye used for spinning is prepared from the following components in parts by mass:1-5 parts of brich liquid, 1-2 parts of crocus sativus powder, 5-10 parts of lavender flowers, 3-5 parts of lavender seeds, 1-3 parts of a softening agent, 1-3 parts of a neutralizing agent, 1-3 partsof a blender, 1-2 parts of mill base and the balance of water. The natural dye used for spinning is reasonable in preparation, non-toxic, harmless, high in fixation capability and soft in touch and has a good dyeing effect and fresh fragrance, thus the quality of clothes can be greatly improved, and the service life of the clothes can be greatly prolonged.

Owner:湖州林品服饰有限公司

A kind of reactive dye yellow and its preparation method and application

ActiveCN112480707BImprove responseStrong color fixing abilityOrganic chemistryReactive dyesDisperse dyeSewage

The invention relates to a reactive dye yellow and its preparation method and application. The compound structure of the reactive dye yellow is shown in the general formula (I): the reactive dye of the present invention has high reactivity, good color fixing ability and good Excellent dyeing ability, and the reactive dye of the present invention does not need to add soda ash to fix the color when dyeing, avoiding the use of soda ash. At the same time, the reactive dyes of the present invention also have high temperature resistance, and can be used in conjunction with disperse dyes to simultaneously dye T / R or T / C blended fabric products at a temperature higher than 100°C, realizing a one-bath dyeing process, which not only simplifies the dyeing process , Shorten the dyeing time, greatly reduce the amount of sewage, reduce labor costs and energy consumption.

Owner:苏州澳缘盛新材料科技有限公司

A kind of down dyeing method

The invention discloses a method for dyeing down feather. The method for dyeing the down feather comprises the following steps: separating the raw material feather into waste feather, feather slices and down clusters by using a feather separator; removing dust of the separated feather slices and the down clusters, adding the feather slices and the down clusters subjected to dust removal into a scouring machine for souring, subsequently dyeing the soured down feather, simultaneously dyeing and adding a levelling agent, dye and a color curing agent, and enabling the down feather to have different colors through the dyeing process. Through the method for dyeing the down feather, the conventional view that the down feather only has white color and gray color is broken, so that the genuine down feather is obtained; the theoretical basis is provided for the market innovation of the down feather industry.

Owner:DONGLONG HOME TEXTILE CO LTD

A process for printing and dyeing artificial leather with mustard juice

The invention relates to a process for printing and dyeing artificial leather by using leaf mustard juice, comprising the following steps: a, preparing a leaf mustard dye; b, preparing a dye; c, treating the artificial leather; d, dyeing; e, heating for evaporation; f, performing afterfinish. The printing and dyeing process can improve the attachment of the vegetable dye on the artificial leather, so that the printed and dyed artificial leather is not easy to fade.

Owner:GUANGZHOU PANYU POLYTECHNIC

A process for printing and dyeing artificial leather with mangosteen peel juice

The invention relates to a process for printing and dyeing artificial leather by using mangosteen bark juice, comprising the following steps: a, preparing a mangosteen bark dye: taking mangosteen bark, performing superfine grinding to obtain the mangosteen bark juice, then adding ethyl alcohol with the concentration of 80 percent, dipping for 12-24h, filtering with a sieve of 80-100 meshes, and collecting filter liquor, wherein a ratio of the volume of the ethyl alcohol to the mass of the mangosteen bark is (5 to 10) : 1; dipping filter residues by adopting the same ethyl alcohol for 12-24h, filtering with a sieve of 80-100 meshes, and collecting filter liquor; combining filter liquor obtained by two times of collecting, concentrating, and vacuum-drying to obtain the solid, i.e., the mangosteen bark dye; b, preparing a dye; c, treating the artificial leather; d, dyeing; e, heating for evaporation; f, performing afterfinish. The printing and dyeing process can improve the attachment of the vegetable dye on leather, so that the printed and dyed leather is not easy to fade.

Owner:GUANGZHOU PANYU POLYTECHNIC

A kind of preparation method of reactive dye ruby

The invention relates to a preparation method of reactive dye carnelian, comprising: performing a condensation reaction with a condensate to obtain a condensed product; performing a secondary condensation reaction with a condensed product to obtain a condensed product; making the condensed product in Carry out diazo reaction under the action of nitrous acid to obtain the first intermediate; make the first intermediate react with acid couple to obtain the second intermediate; make diazo reaction under the action of nitrous acid to obtain the third intermediate ; Make the second intermediate and the third intermediate carry out alkali coupling reaction to obtain the fourth intermediate; make the fourth intermediate and carry out three condensation reactions to obtain the reactive dye carnelian. The reactive dye prepared by the invention has high reactivity, good color fixation and dyeing ability, and does not need to add soda ash during dyeing, thus avoiding the use of soda ash. At the same time, the reactive dye also has high temperature resistance, and can be used in conjunction with disperse dyes to simultaneously dye T / R or T / C blended fabric products at a temperature higher than 100°C to achieve a one-bath dyeing process.

Owner:苏州澳缘盛新材料科技有限公司

A process for printing and dyeing artificial leather using kiwi fruit juice

The invention relates to a technology for printing and dyeing artificial leather by using a kiwi fruit juice. The technology comprises the following steps: 1, preparing a kiwi fruit dye; 2, preparing a dye; 3, processing artificial leather; 4, dyeing the artificial leather; 5, carrying out heating evaporation on the artificial leather; and 6, after-finishing the artificial leather. The printing and dyeing technology can improve the adhesion of plant dyes on leather, and makes the color of the printed and dyed leather difficultly fade.

Owner:GUANGZHOU PANYU POLYTECHNIC

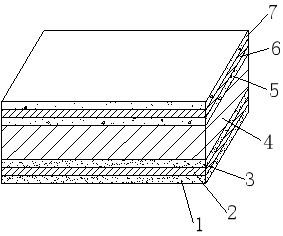

One-way moisture guiding polylactic acid woven fabric and preparation method thereof

InactiveCN113022042ABright colorStrong color fixing abilitySynthetic resin layered productsClothingsPolyesterPolymer science

The invention discloses a one-way moisture guiding polylactic acid woven fabric and a preparation method thereof. The one-way moisture guiding polylactic acid woven fabric comprises a first polylactic acid fiber layer, an antibacterial layer, a second polylactic acid fiber layer, a hydrophilic polyester fiber layer, a first cotton fiber layer, an anti-ultraviolet layer, a second cotton fiber layer and a wormwood fiber filling layer. The fabric is reasonable in structural design; through the first polylactic acid fiber layer, the antibacterial layer, the second polylactic acid fiber layer, the hydrophilic polyester fiber layer, the first cotton fiber layer, the anti-ultraviolet layer, the second cotton fiber layer and the wormwood fiber filling layer which are arranged layer by layer, the one-way moisture guiding fabric can be formed, and the fabric has the antibacterial, insect-repelling and anti-ultraviolet performance at the same time; and the prepared fabric is bright in color, high in color fixation and not prone to deformation and shrinkage.

Owner:苏州盟红新材料科技有限公司

Method for preparing colored recombined tobacco leaf cigarette paper by microencapsulation of coating solution

ActiveCN103451999BStrong color fixing abilityImprove stabilityNon-fibrous pulp additionPaper coatingFlavorCombustion

The invention relates to a method for preparing colorful recombined tobacco leaf paper by microencapsulation of coating liquid. According to the method, substances such as pigments, a combustion improver and spices in the coating liquid are wrapped by a microencapsulation technology to prepare a core material, ethyl cellulose, hydroxypropyl cellulose and the like are adopted as wall materials, a complex coacervation method is adopted for preparing coating liquid microcapsules, and the coating liquid microcapsules are applied to recombined tobacco leaf paper in an airblade coating way to prepare the colorful recombined tobacco leaf paper. The colorful recombined tobacco leaf paper is good in color-fixing capability and free from fading, has slow-releasing and fragrance-keeping effects, and can be effectively improved in appearance quality and smoking quality.

Owner:HUBEI CHINA TOBACCO IND +1

Golden yellow dye

InactiveCN103788699AStrong color fixing abilityGood dyeing depthReactive dyesDyeing processReactive dyeHigh absorption

The invention discloses a golden yellow dye which is a reactive dye with industrial value for cellulose fibers. The golden yellow dye has the advantages of excellent color fixation capacity, excellent deep dyeing property and high absorption cleaning capacity, and is suitable for dyeing within a wide temperature range.

Owner:WUXI VISION PRO

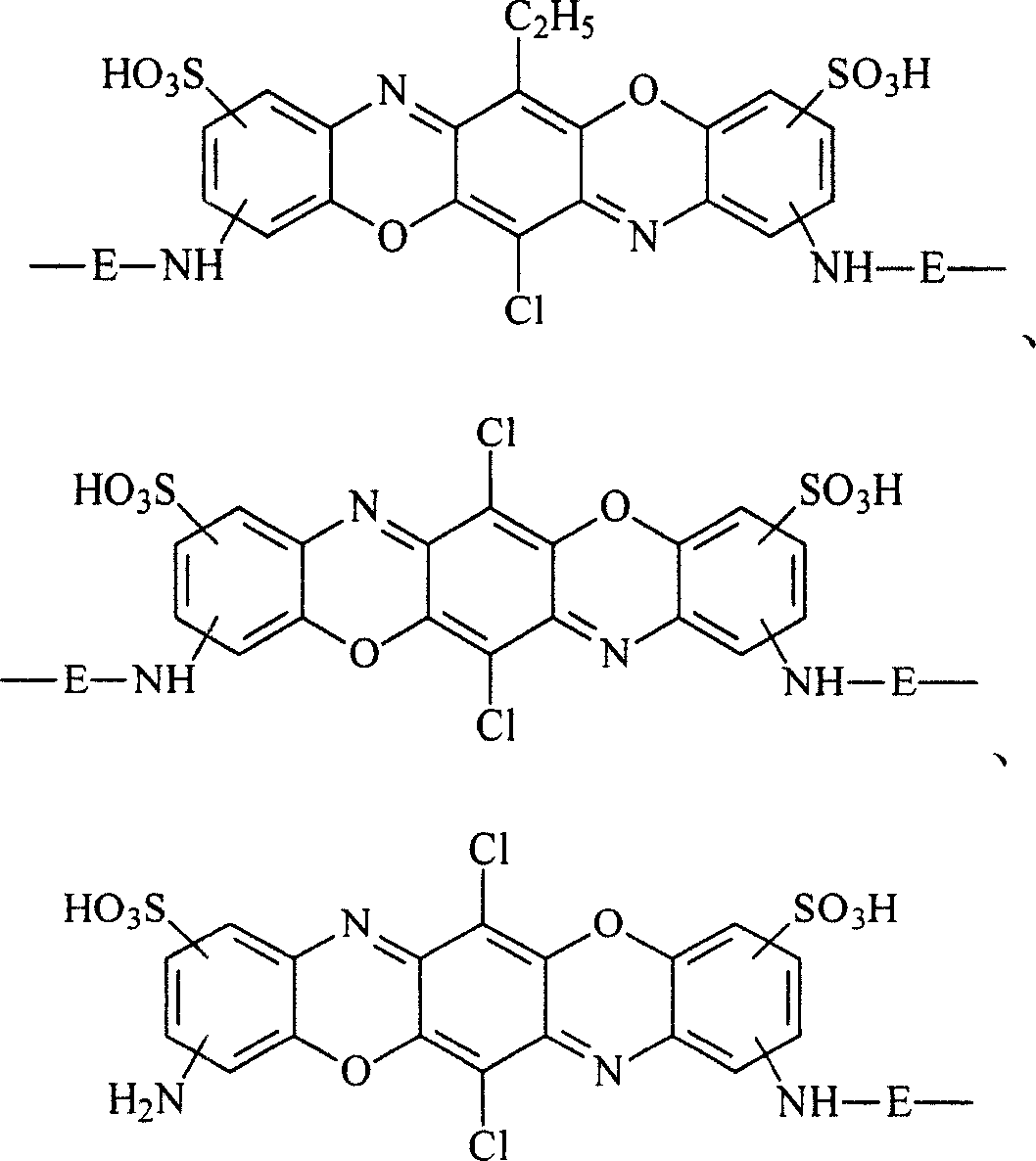

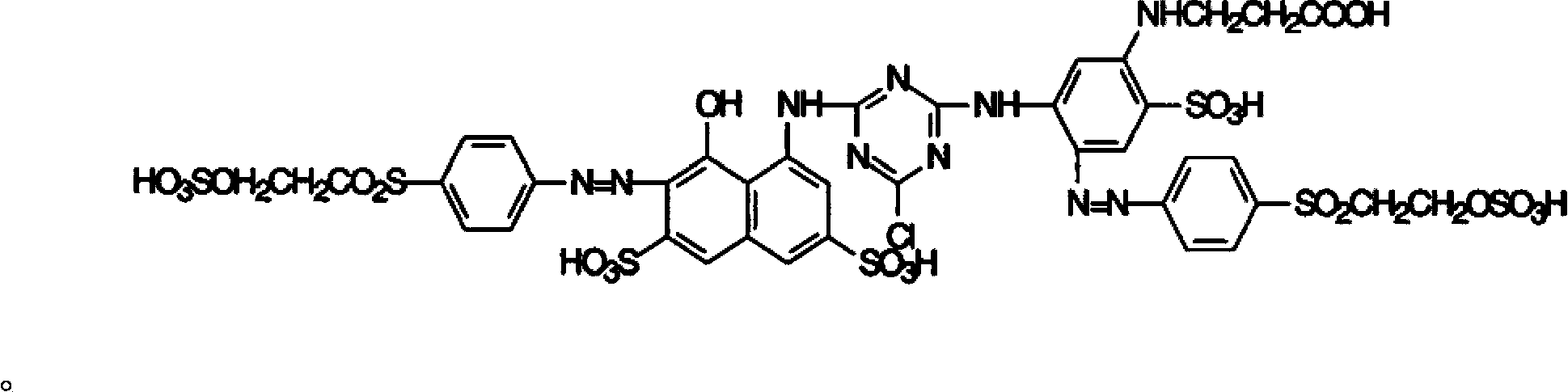

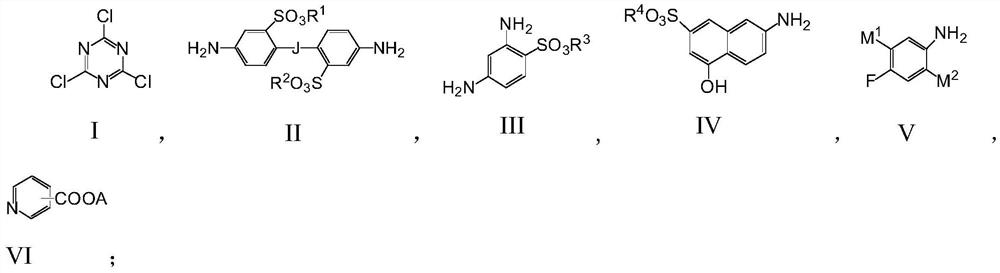

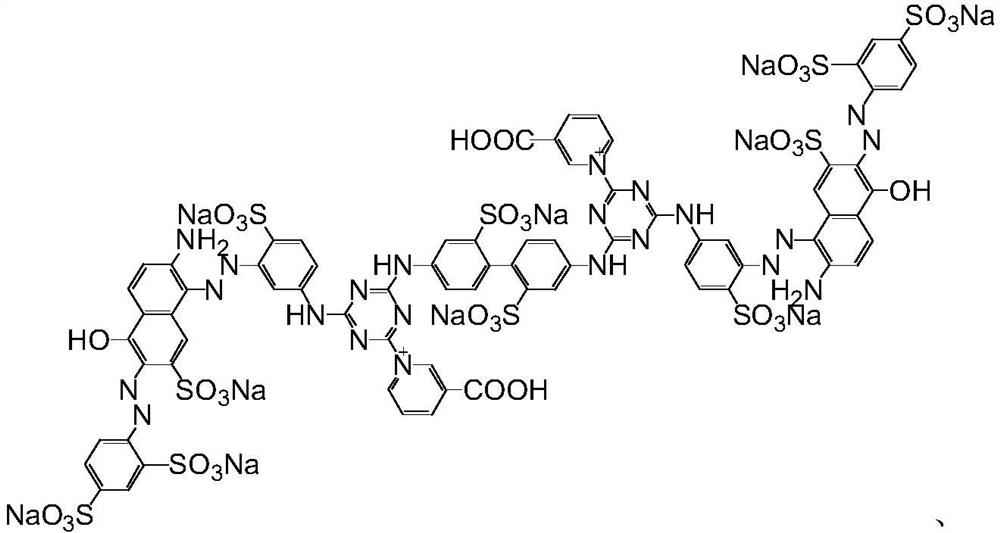

Preparation method of reactive dye blue

ActiveCN112111174AImprove dyeing effectHigh temperature resistanceReactive dyesDisperse dyeCombinatorial chemistry

The invention relates to a reactive dye blue preparation method, which comprises: carrying out a diazo reaction on a compound represented by a formula I under the action of nitrous acid to obtain a first intermediate; carrying out an acid coupling reaction on the first intermediate and a compound shown as a formula II to obtain a second intermediate; carrying out a primary condensation reaction onthe compound shown in the formula III and the compound shown in the formula IV to obtain a primary condensation product; carrying out a secondary condensation reaction on the primary condensation product and a compound shown as a formula V to obtain a secondary condensation product; carrying out a diazo reaction on the secondary condensation product under the action of nitrous acid to obtain a third intermediate; carrying out an alkali coupling reaction on the second intermediate and the third intermediate to obtain a fourth intermediate; carrying out a condensation reaction on the fourth intermediate and a compound shown in the formula VI three times to obtain the reactive dye blue, wherein the reactive dye blue has high reactivity and good color fixing and dyeing capacity, can be used in cooperation with disperse dyes, dyes polyester cotton products at the temperature higher than 100 DEG C at the same time, and achieves the one-bath dyeing process.

Owner:苏州澳缘盛新材料科技有限公司

an antirust paint

InactiveCN103483937BImprove rust resistanceStrong color fixing abilityAnti-corrosive paintsPolycarbonate coatingsPhosphoric acidTriphosphoric acid

The invention discloses an antirust paint. The components are calculated in parts by weight, including 75-80 parts of styrene-acrylic emulsion, 20-30 parts of iron red, 5-10 parts of polycarbonate, and 10-10 parts of cyclohexyl hexaphosphate. 15 parts, 1-3 parts of aluminum dihydrogen tripolyphosphate, 0.5-2 parts of iron-based phosphating agent, 0.02-1 part of silicon dioxide, and 100 parts of water. The antirust paint provided by the present invention has a better antirust effect than general water-based antirust paints, and has a strong color fixing effect, and will not lose its original color under the influence of long-term high temperature and harsh environment Bright color and low cost.

Owner:佛山市顺德区明邦化工实业有限公司

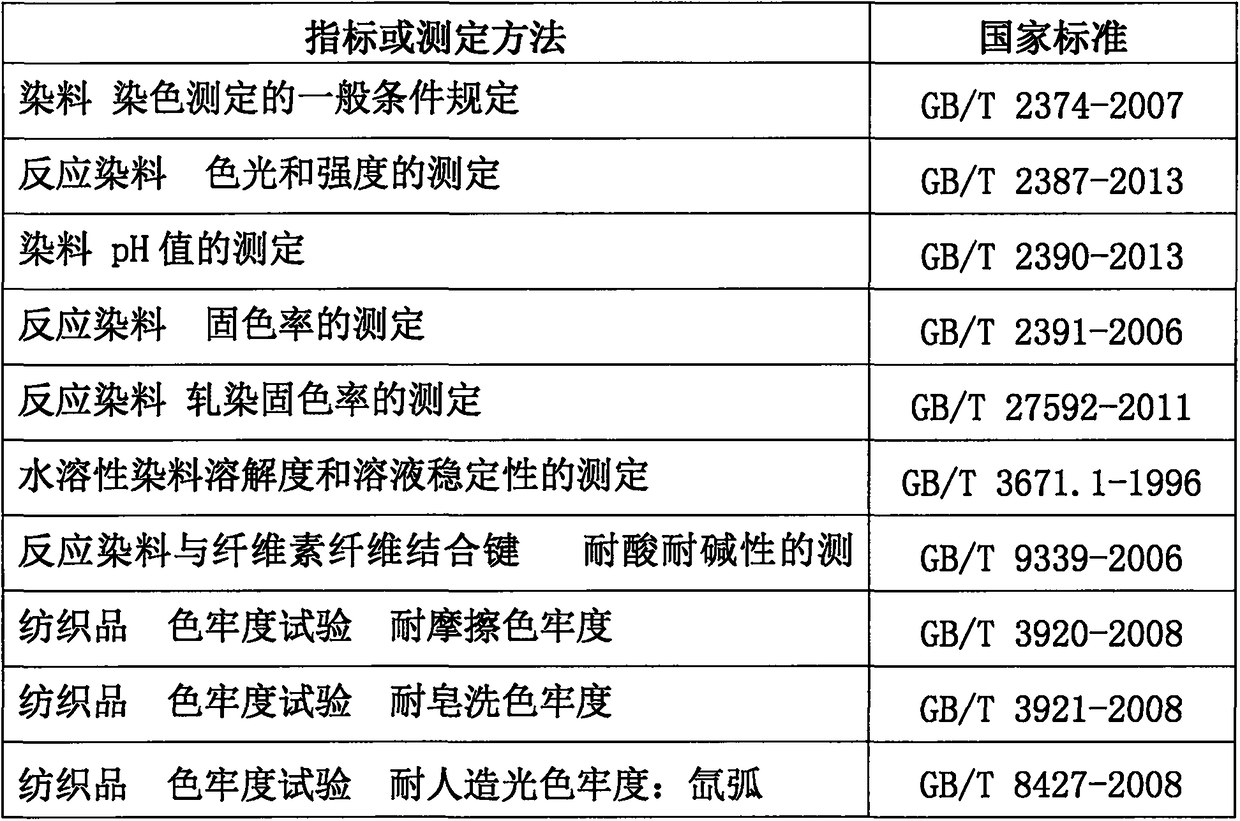

Composite ester-removing reactive black dye as well as preparation method and application thereof

ActiveCN108148447AImprove solubilityIncreased chance of reactionOrganic dyesDyeing processFiberChemical compound

The invention provides a composite ester-removing reactive black dye which is characterized by comprising at least two dye compounds in formula (1) or (2) as shown in the specification. The compositeester-removing reactive black dye is mainly prepared from C.I. reactive black 5 through partially degreasing or prepared via compounding 80-95 parts of a dye compound as shown in the formula (1) and 5-20 parts of a dye compound as shown in the formula (2), has relatively high reactivity, good fixation rate, excellent dyeing depth performance and relatively high pitch-black degree, and is suitablefor dyeing and printing of fiber of fur, brocade, cotton and the like.

Owner:TAIXING JINYUN DYESTUFF

Composite active black dye

ActiveCN101580649BImprove solubilityHigh color fixing rateOrganic dyesDyeing processFiberPhotochemistry

Owner:HUBEI HUALI DYESTUFF INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com